Stripping film, polarizing film with stripping film and two-sided bonding sheet without base material

A peeling sheet and base material technology, which is applied in the direction of polarizing elements, instruments, synthetic resin layered products, etc., can solve the problems that the peeling agent layer cannot be fully hardened and the peeling performance of the peeling agent layer is reduced, and achieve good peeling performance and hardening performance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

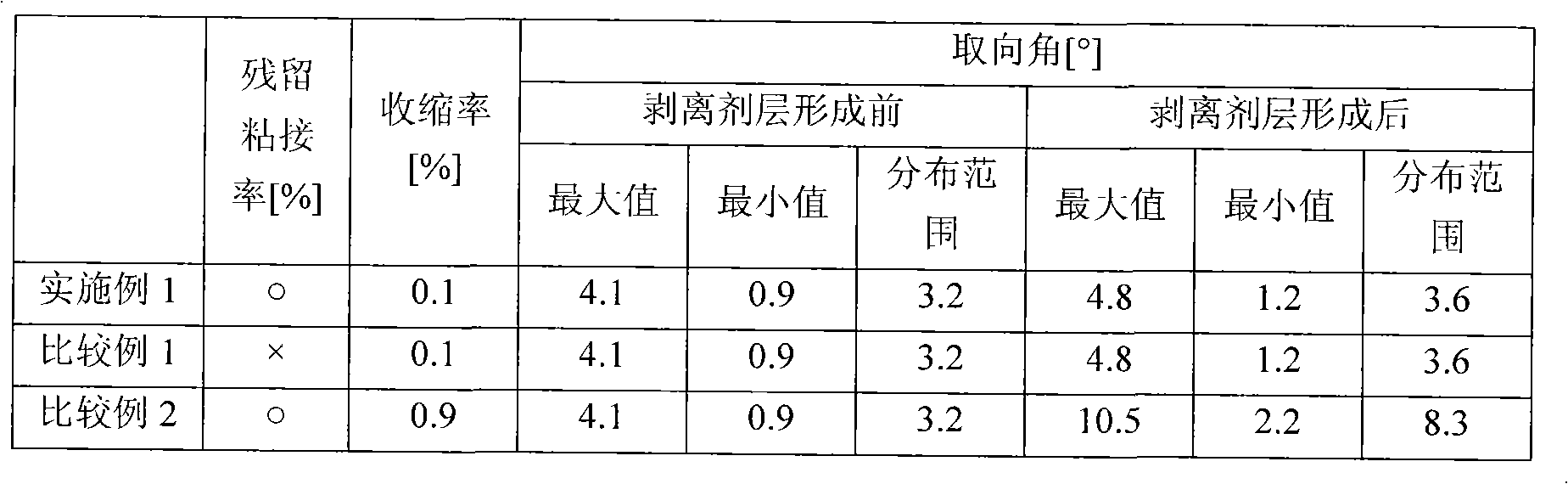

Examples

Embodiment 1

[0050] (manufacturing peel-off sheet)

[0051] A silicone resin solution containing 30 parts by weight of an organopolysiloxane having an alkenyl group and an organopolysiloxane having a hydrosilyl group (manufactured by Toray Dow Corning Silicone Co., Ltd., trade name " LTC-750A") and MQ resin (manufactured by Toray Dou Corning Silicone Co., Ltd., trade name "SD7292") having a vinyl group in terms of solid content of 30 parts by weight were diluted and mixed in toluene solvent, so that the solid content The concentration is 2.0% by weight. 3 parts by weight of a platinum-based catalyst (manufactured by Toray Dow Corning Silicone Co., Ltd., trade name "SRX-212") was added to this solution to obtain an addition reaction type silicone resin composition. This solution was coated on a transversely and longitudinally biaxially stretched polyethylene terephthalate film (manufactured by Toray Co., Ltd., trade name "Lumiror R64") with a thickness of 38 μm using a Mayer rod, and the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com