Compositions comprising quaternary material and sorel cements and methods of servicing a wellbore with the same

A cement composition and composition technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve problems such as difficulty in adding additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

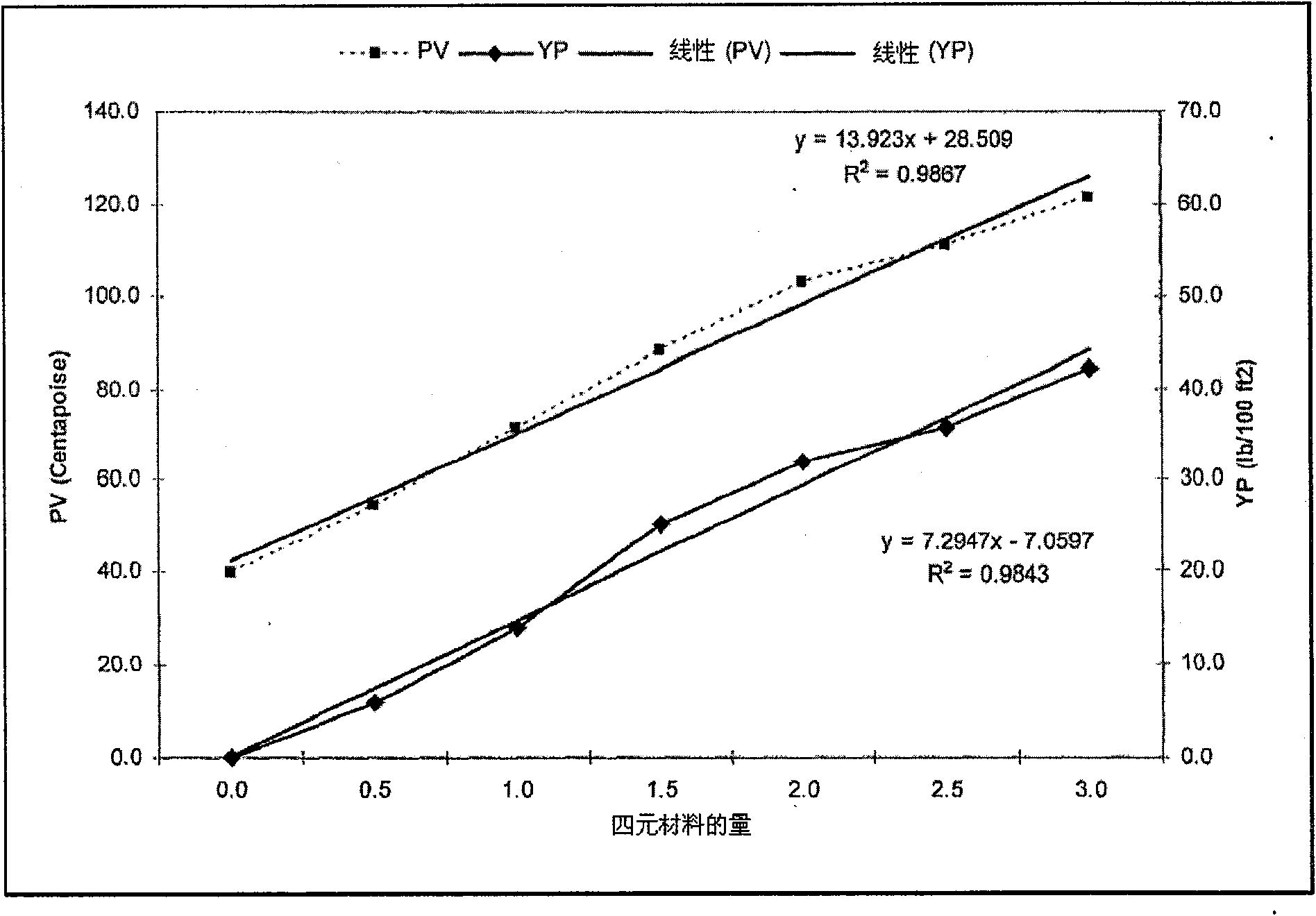

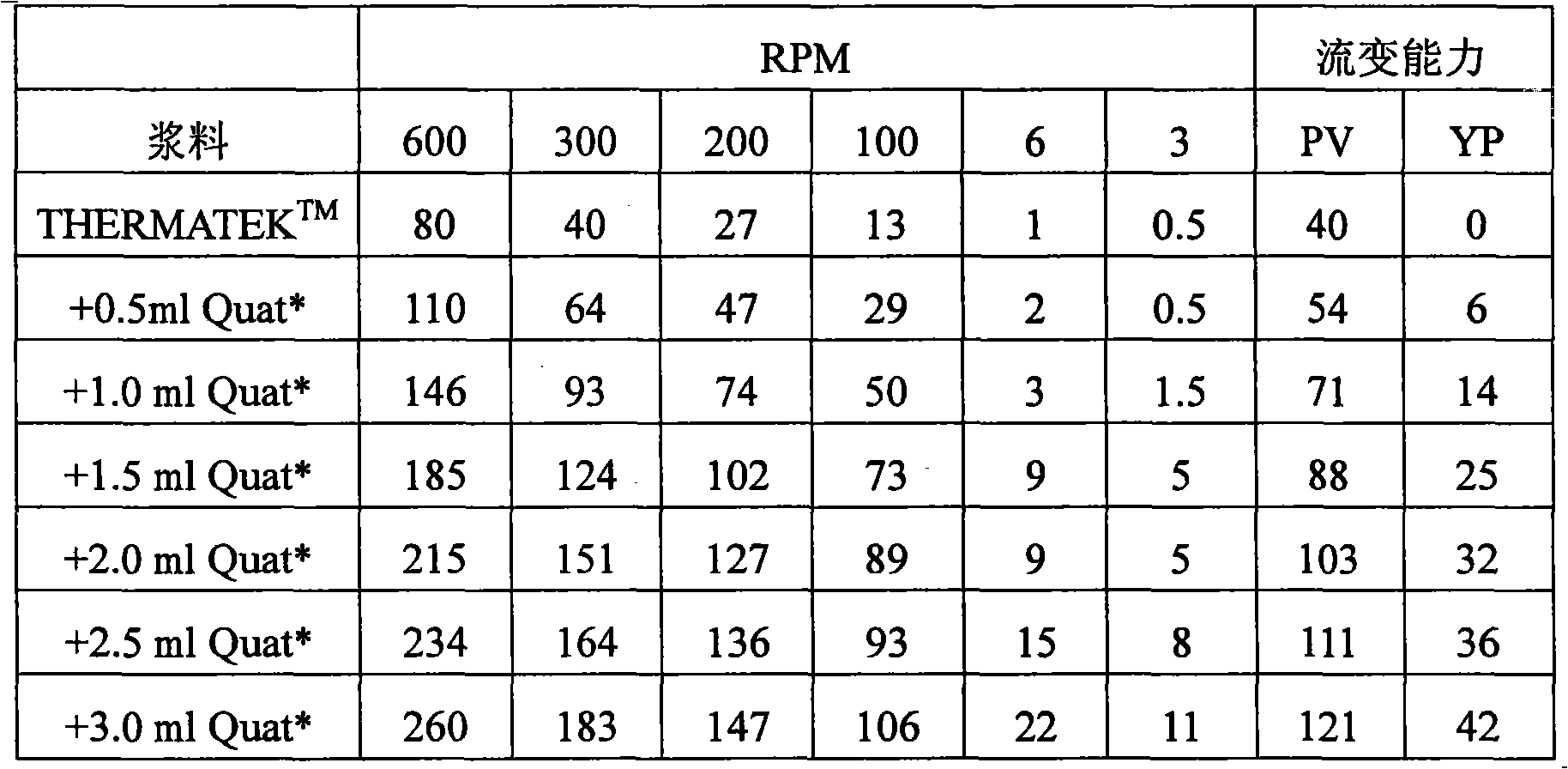

[0046] The effect of quaternary ammonium materials on the viscosity of Sorel cement was studied. Specifically, Sorel magnesia cement is THERMATEK TM Rigid setting fluid, which is MgO and MgCl purchased from Halliburton Energy Services 2 ·6H 2 O mixture. THERMATEK TM A hard setting fluid slurry was prepared as follows: 450 g of C-TEK was dissolved in 300 g of water in a Waring mixer; 450 g of THERMATEK was added to the C-TEK solution TM LT to prepare the slurry. Add AMMONXY SDBC stock solution to THERMATEK TM A specified amount of quaternary ammonium material was added to the hard solidified fluid slurry, and the AMMONXY SDBC stock solution was quaternary amidopropyl benzyl dimethyl ammonium chloride purchased from Stepan. The concentration of the stock solution is 60%. The rheological properties of the fluids were measured with a FANN 35 viscometer at 3, 6, 100, 200, 300 and 600 RPM at room temperature. Viscosity, plastic viscosity (centipoise) and yield point (lbs / 10...

Embodiment 2

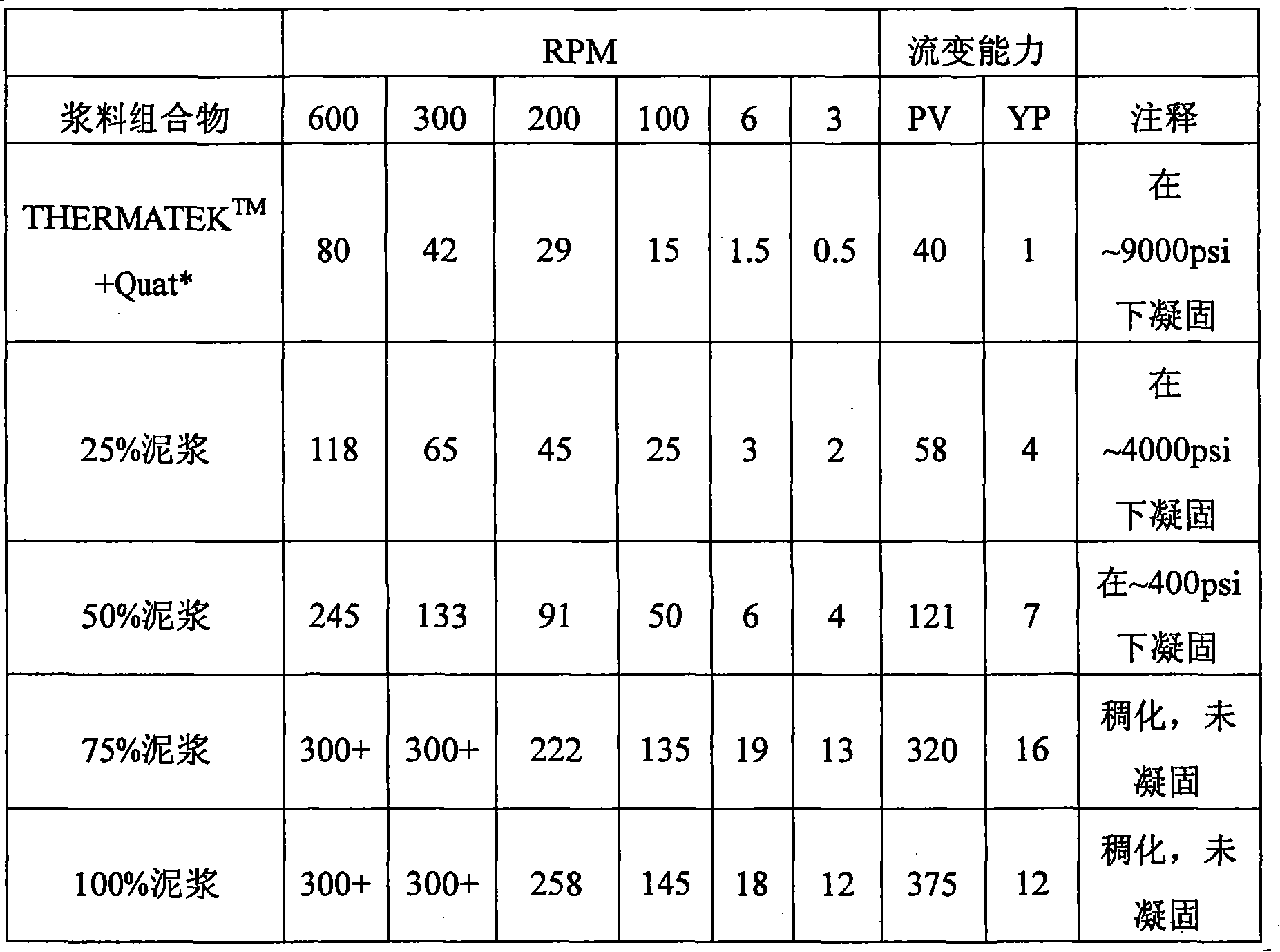

[0052] The addition of quaternary ammonium materials to THERMATEK TM Influence of Hard Setting Fluids and Compatibility of Oil-based Muds. THERMATEK TM A hard-setting fluid slurry was prepared as follows: In a Waring mixer, 450 g of C-TEK was dissolved in 300 g of water; to the C-TEK solution was added 450 g of THERMATEK TM LT to prepare the slurry. to THERMATEK TM To the hard setting fluid slurry was added 5 ml of an 83% solution of ARQUAD 83E, a quaternary amine available from Stepan. to THERMATEK TM To the mixture of hard setting fluid and quaternary ammonium material was added the indicated amount of PETROFREE LV, a synthetic slurry available from Halliburton Energy Services. At room temperature, the rheological properties of the fluid were measured with a FANN 35 viscometer at 3, 6, 100, 200, 300 and 600 RPM, and allowed to solidify at room temperature for 24 hours to determine the compressive strength of the coagulated composition. Viscosity, plastic viscosity (ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com