Device and method of utilizing blast furnace slag as heat carrier to prepare biomass oil

A biomass oil and blast furnace slag technology, applied in the treatment of hydrocarbon oil, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of high additional energy consumption, inability to recover slag heat, and large energy consumption. Realize the effect of waste heat and resource utilization and strong heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

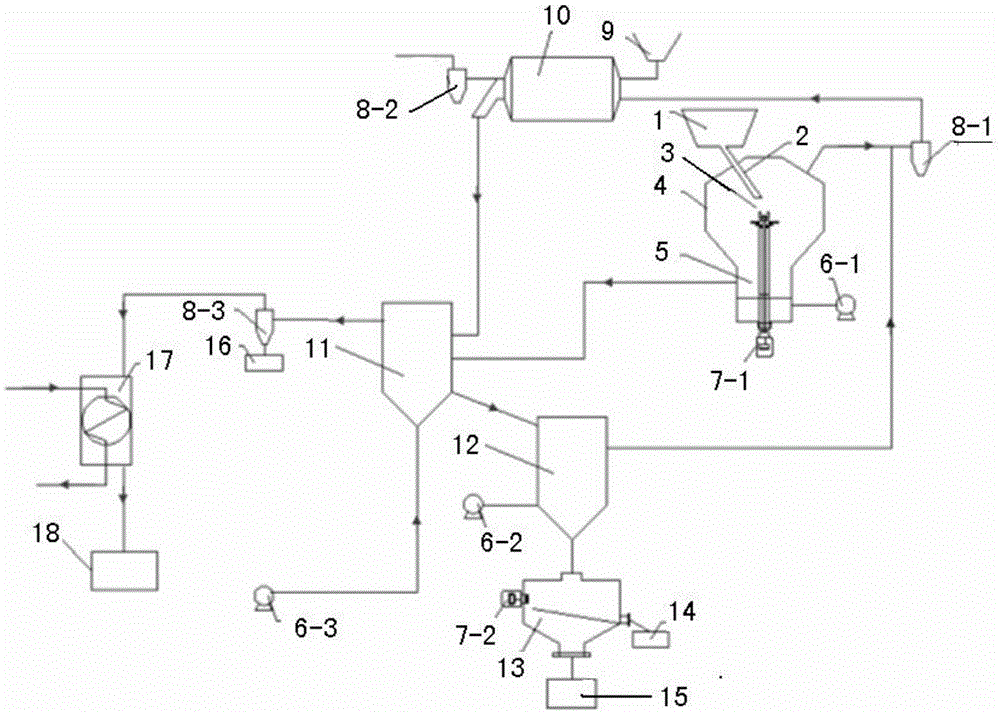

[0026] see figure 1 , a device for preparing biomass oil using blast furnace slag as a heat carrier, the device includes a granulation chamber 4, a dryer 10, a pyrolysis reactor 11, a countercurrent moving bed heat exchanger 12, a vibration separator 13 and a condensation separator 17 The granulation chamber 4 is provided with a granulator 3, and the granulator 3 is driven by the first motor 7-1 to rotate; the bottom of the granulation chamber 4 is provided with a blast furnace slag fluidization chamber 5; the blast furnace slag fluidization chamber 5 The cold air is provided by the first fan 6-1; the granulation chamber 4 communicates with the slag storage bin 1, and the blast furnace slag enters the granulation chamber 4 from the slag storage bin 1 through the slag feeding pipe 2; the upper part of the granulation chamber 4 is provided with There is an air outlet, and the air outlet of the granulation chamber 4 communicates with the air inlet of the dryer 10 through the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com