Patents

Literature

40 results about "Moving bed heat exchanger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

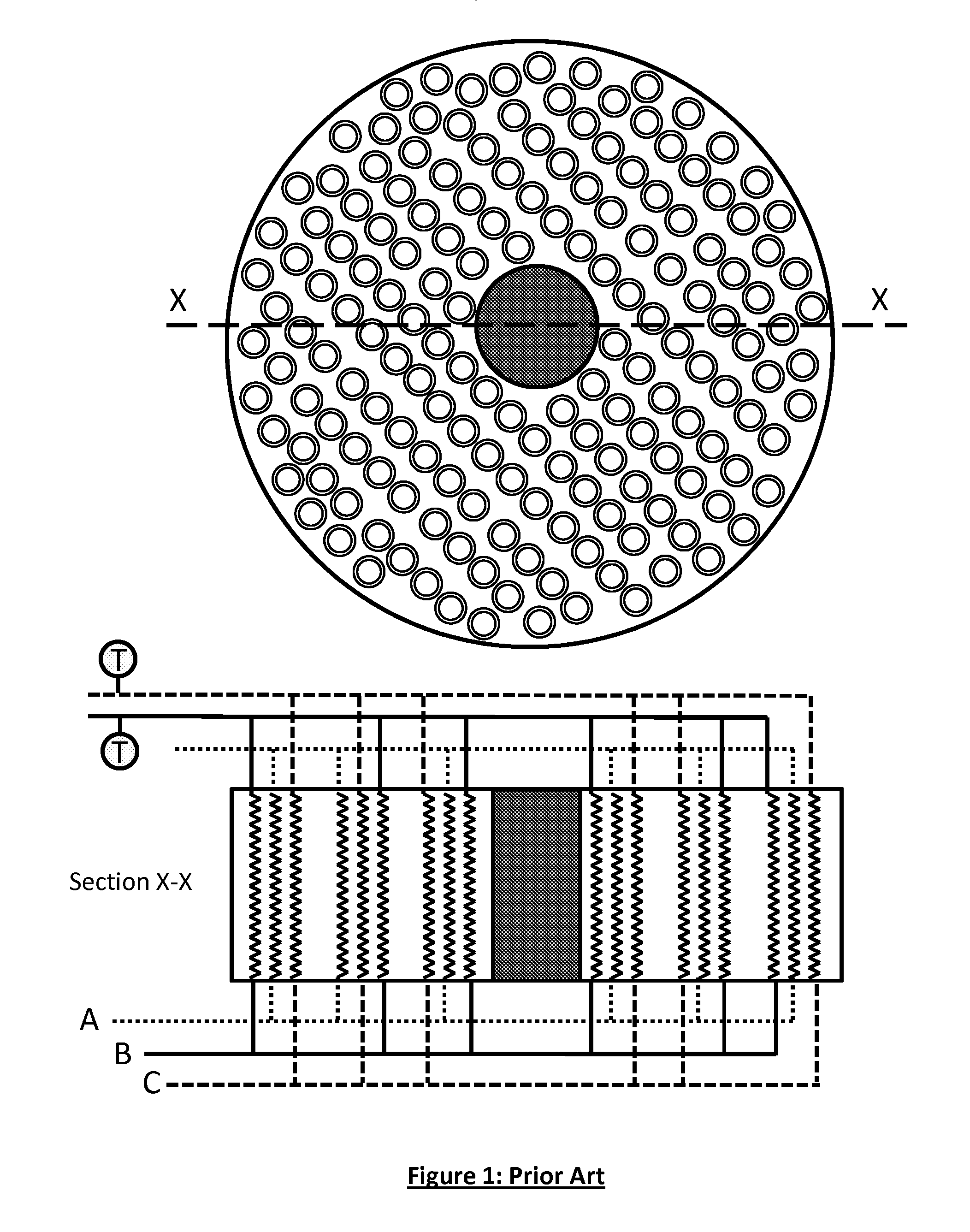

Moving Bed Heat Exchangers (known as MBHEs) are widely used in industry, on applications involving heat recovery (providing a high volumetric transfer area) and filtering (avoiding common operational problems in fixed bed or ceramic filters like the pressure drop increase during operation).

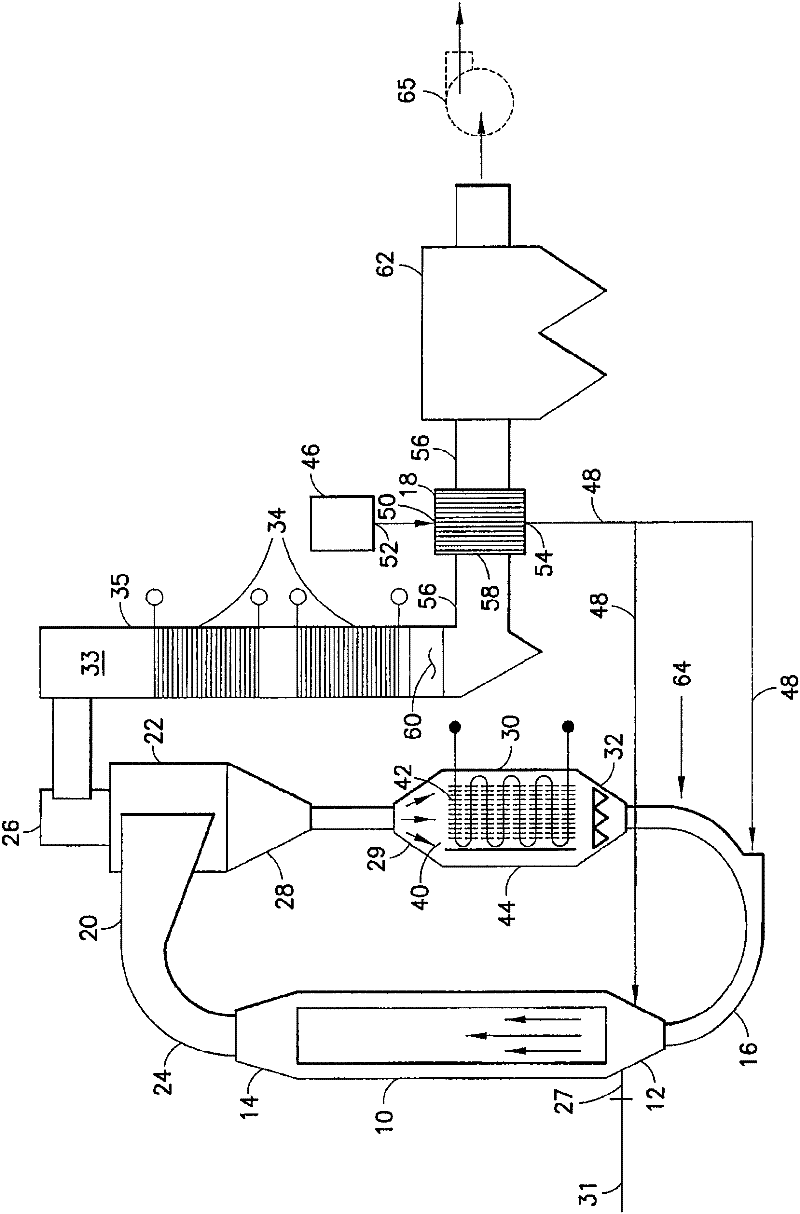

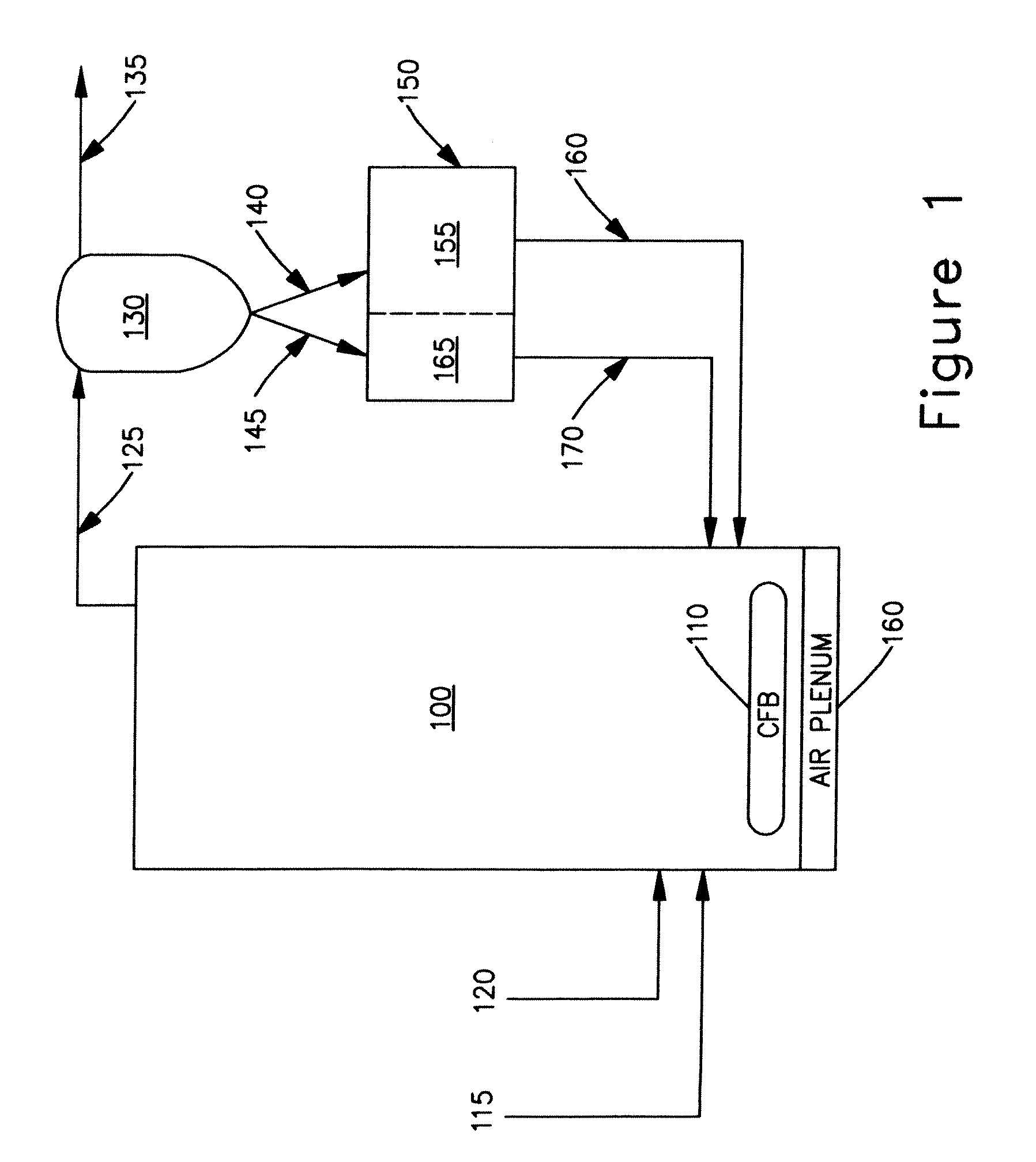

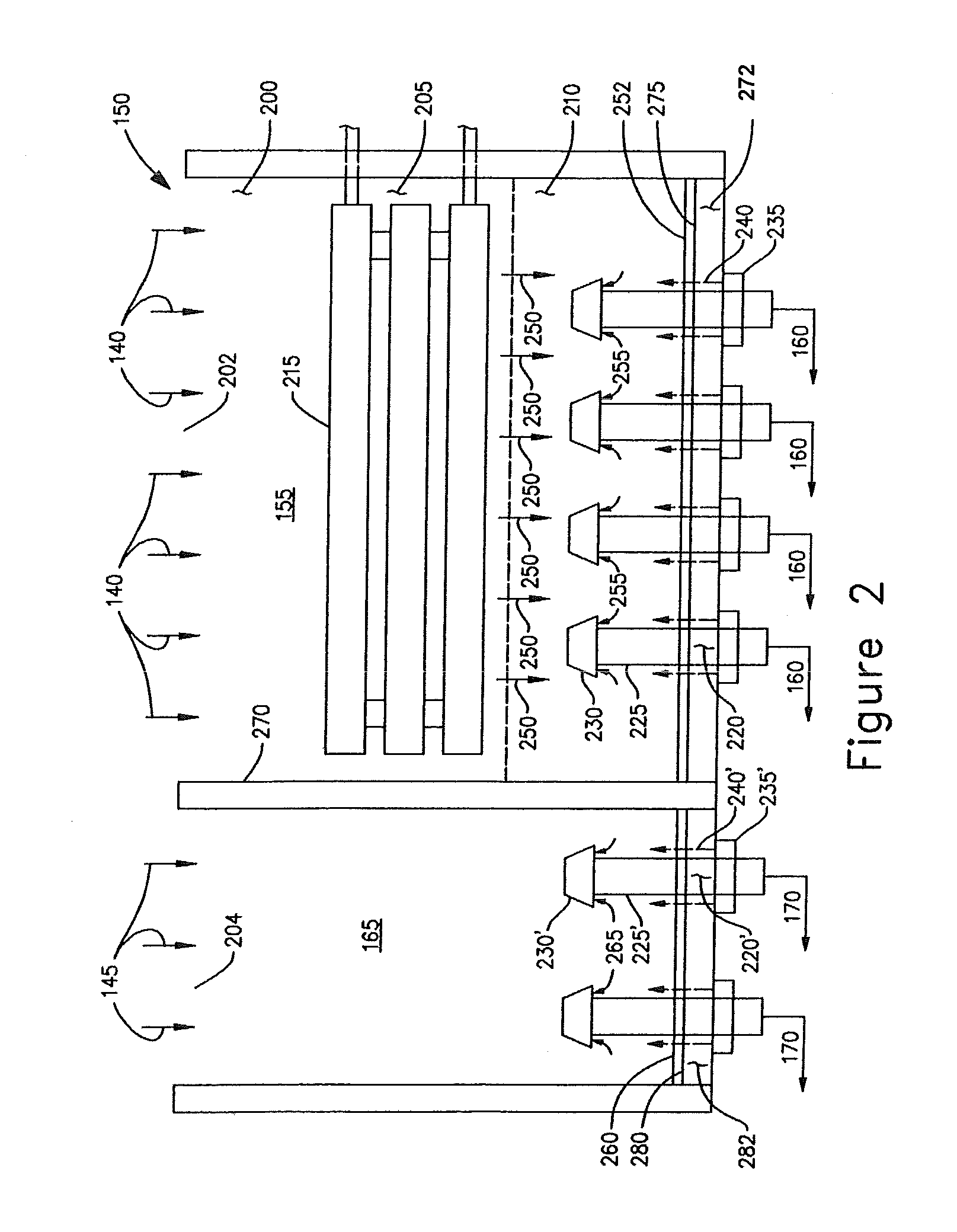

Moving bed heat exchanger for circulating fluidized bed boiler

ActiveUS20090151902A1Avoid Insufficient SealingSimple technologyFluidized bed combustionStationary tubular conduit assembliesWorking fluidFluidized bed

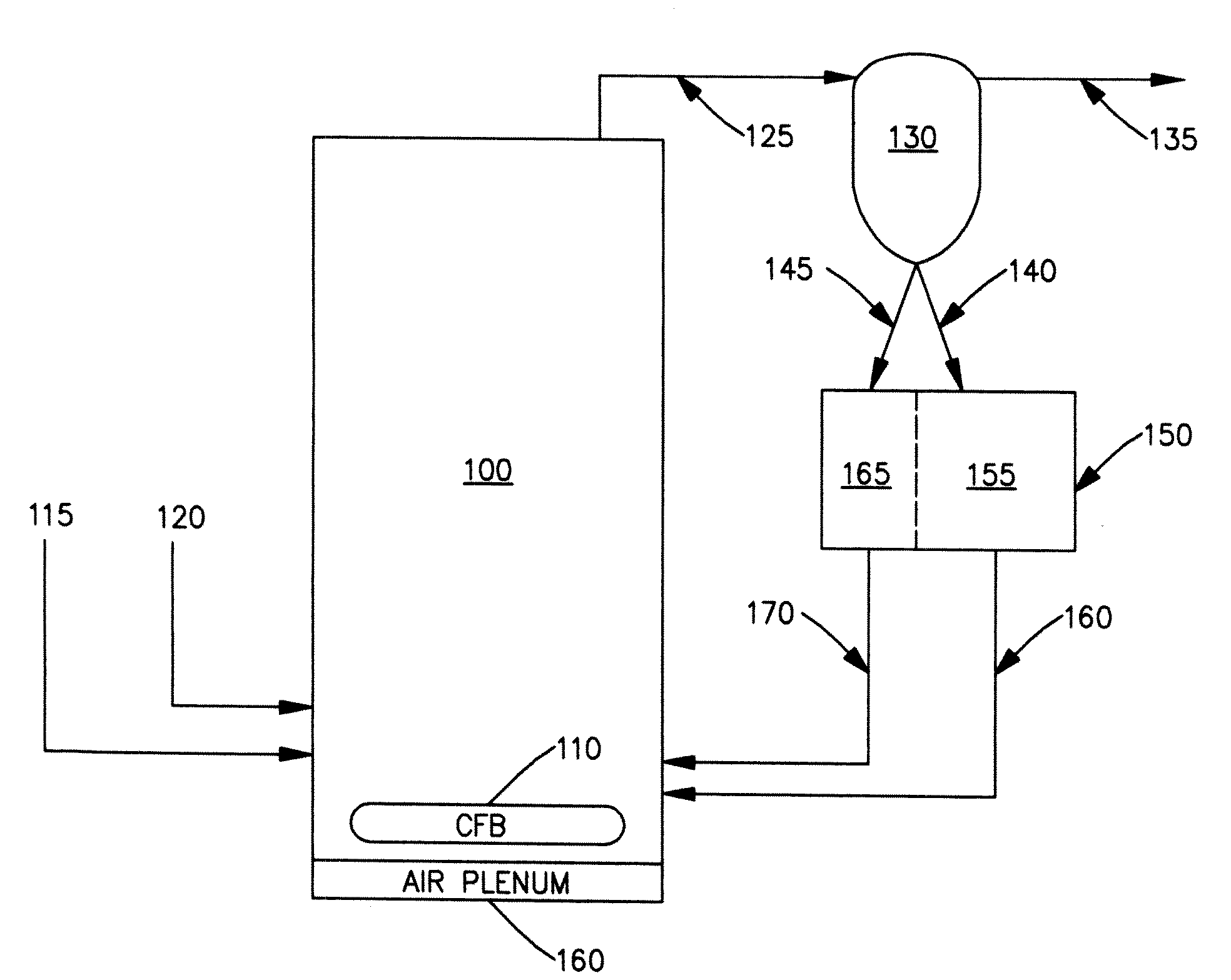

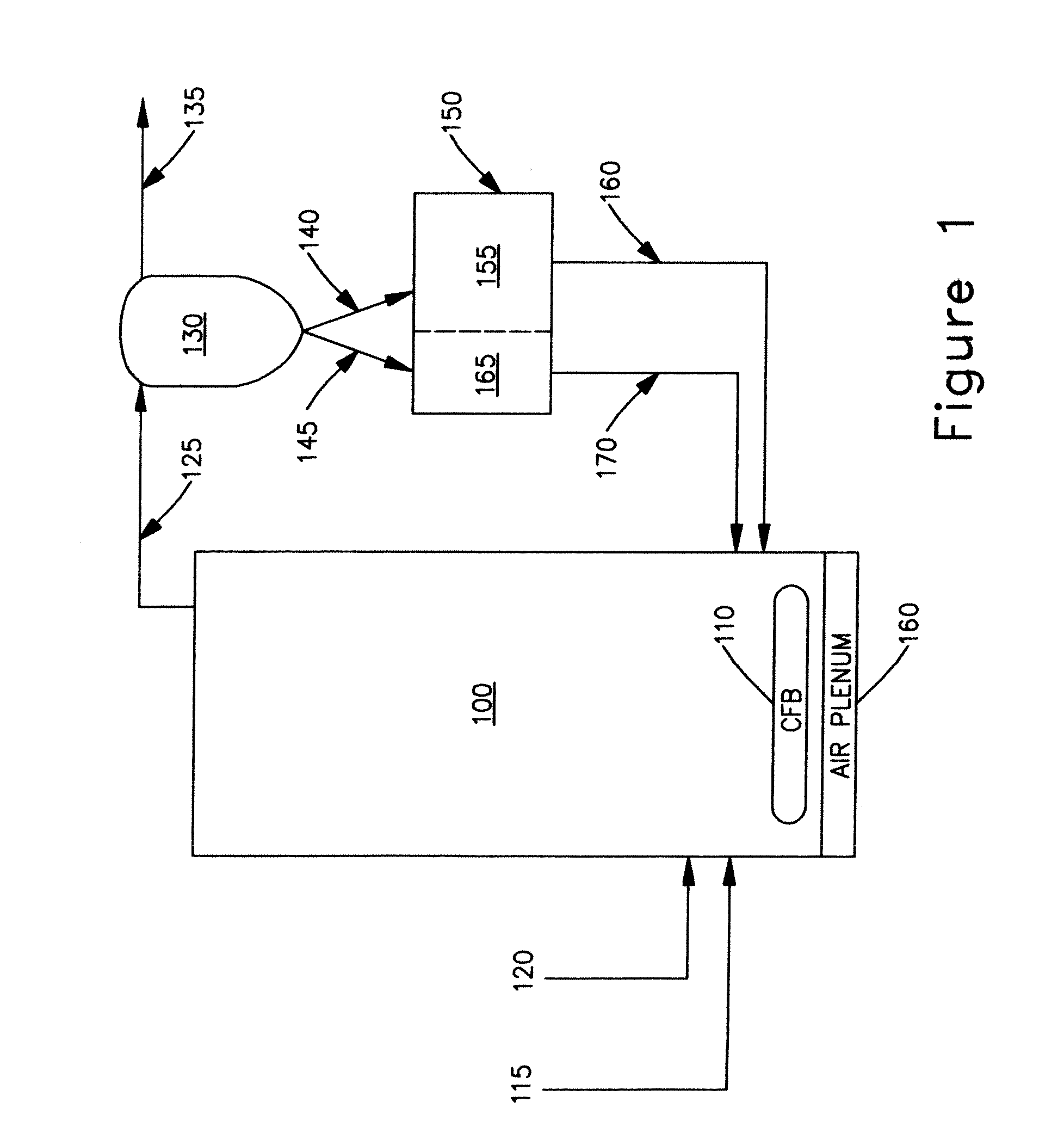

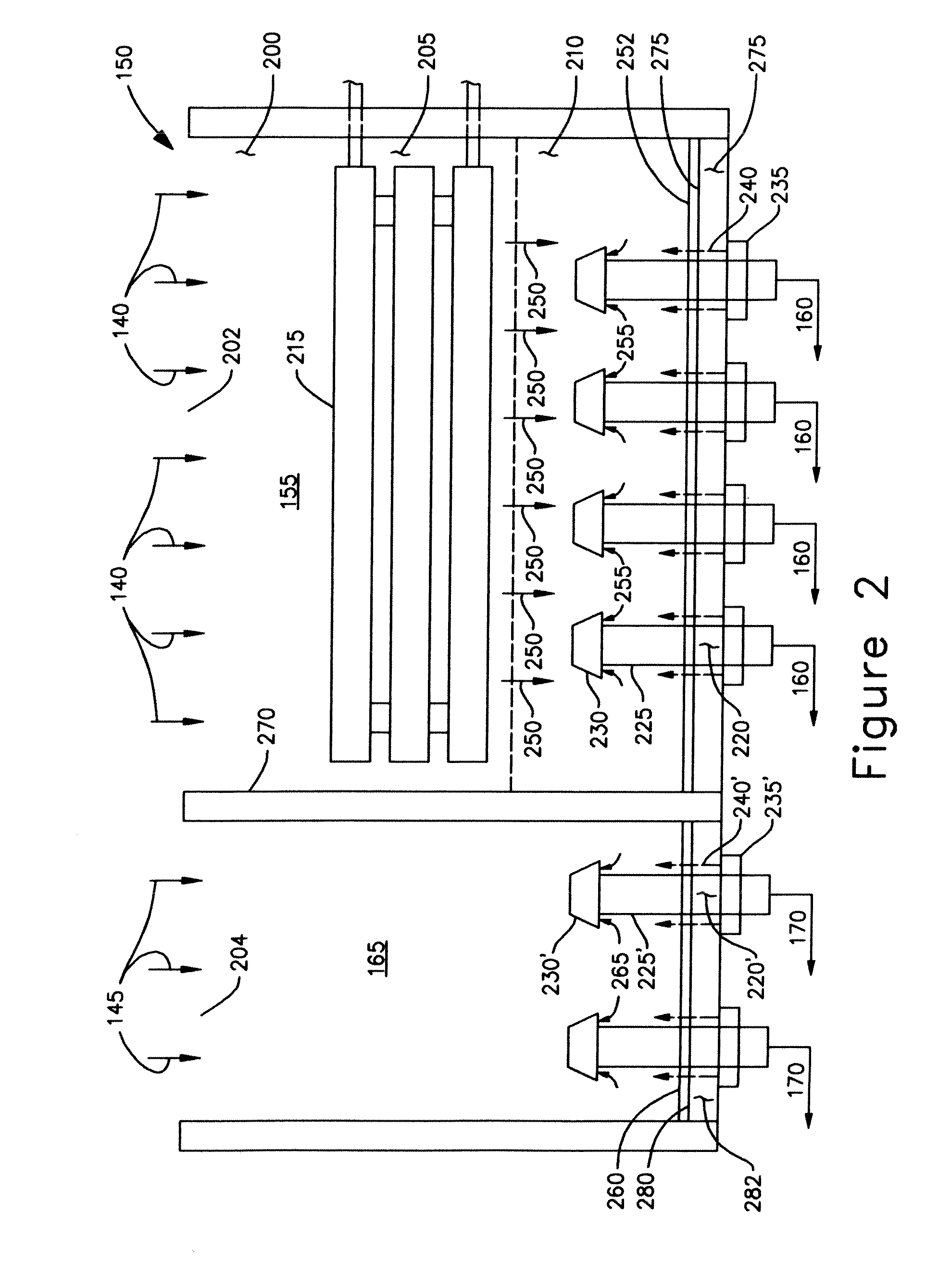

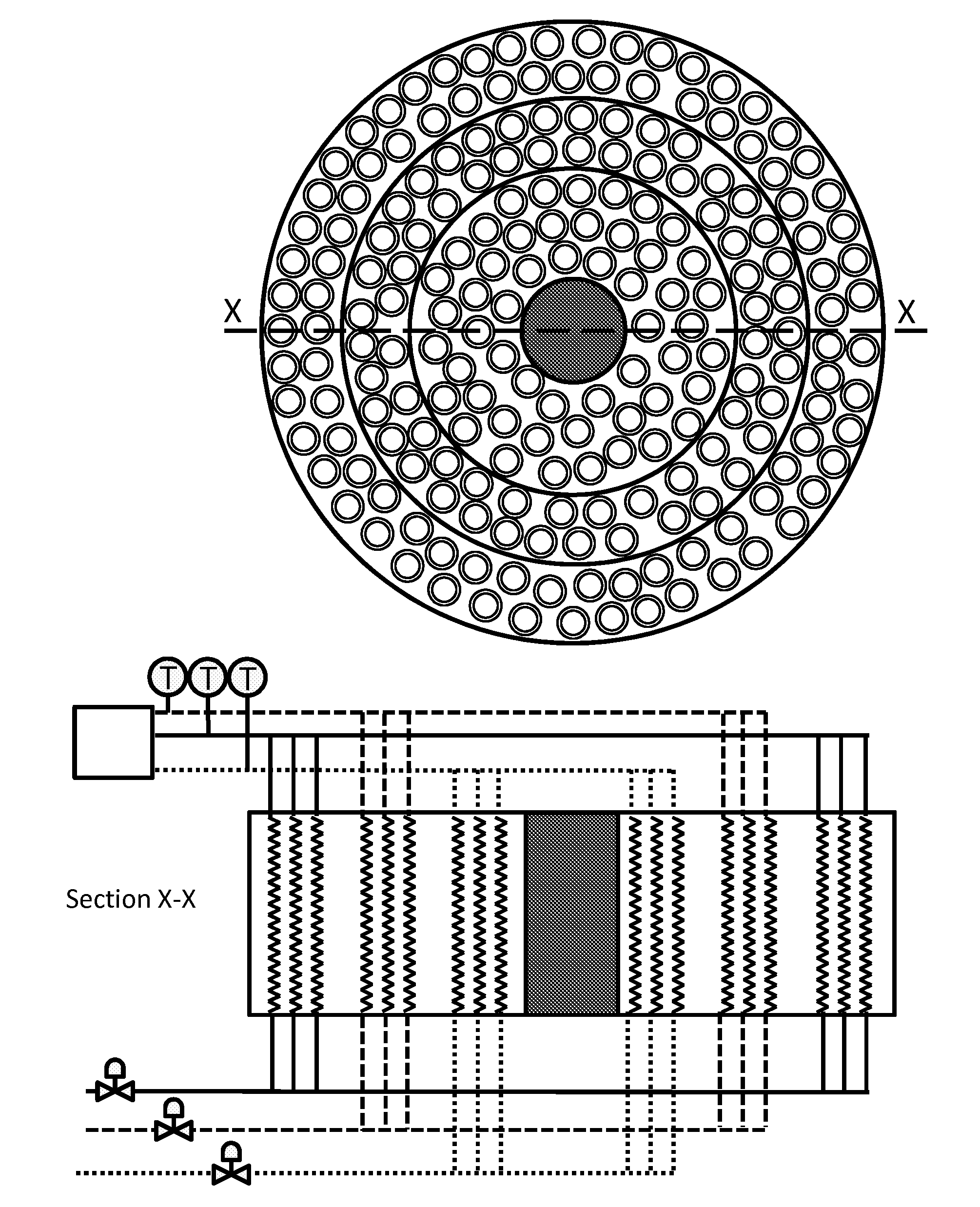

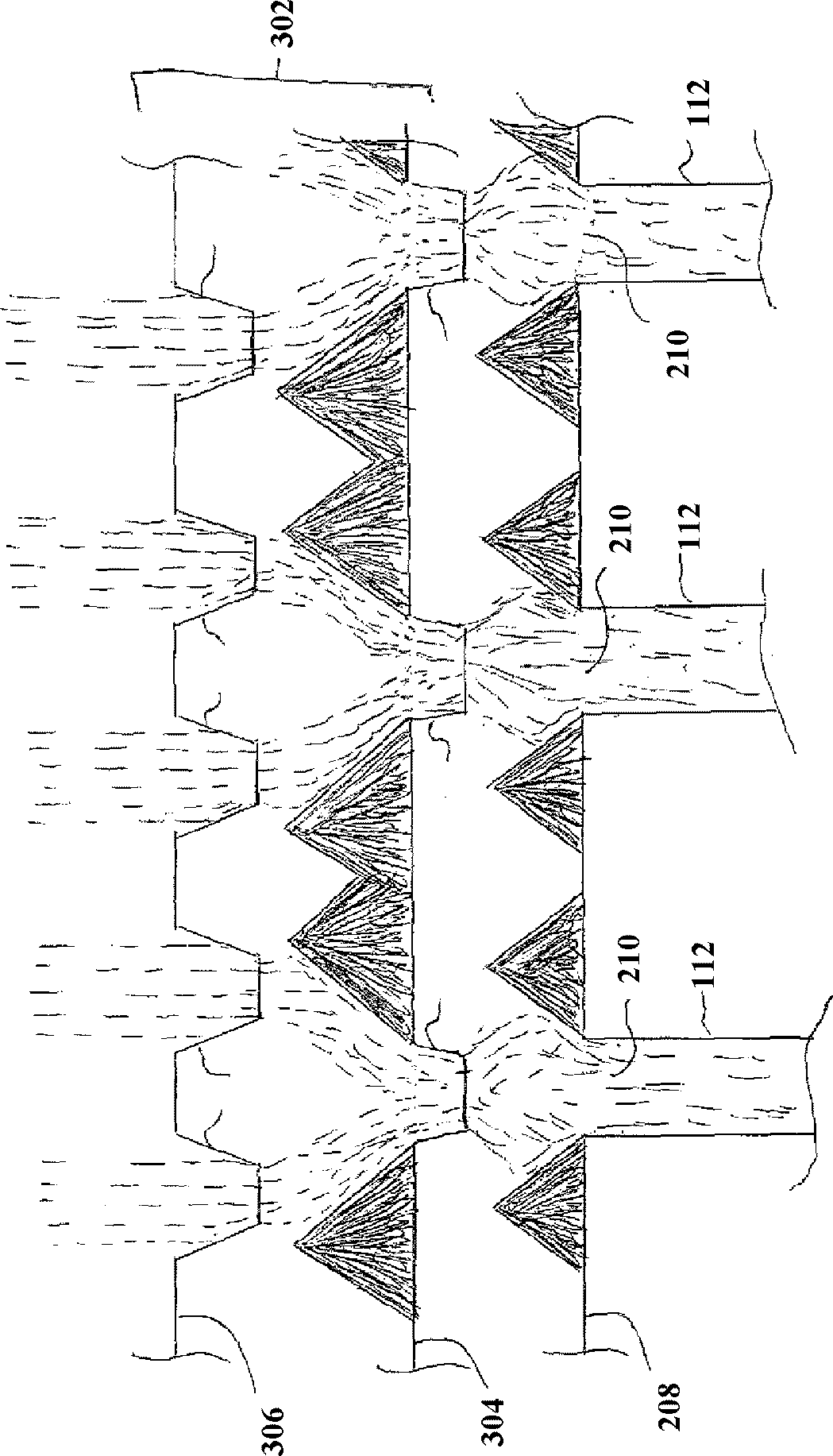

A moving bed heat exchanger (155) includes a vessel having an upper portion (200), a lower portion (210) with a floor (272) including a discharge opening therein, and an intermediate portion (205). The vessel directs a gravity flow of hot ash particles (140) received thereby from the upper portion (200) through the intermediate portion (205) to the floor (272) of the lower portion (210) of the vessel, where the hot ash particles (140) are collected. Tubes in the intermediate portion (205) of the vessel direct a flow of working fluid in a direction substantially orthogonal to the direction of the gravity flow of the hot ash particles (140) through the intermediate portion (205) of the vessel such that heat from the hot ash particles (140) is transferred to the working fluid thereby cooling the hot ash particles (140).

Owner:GENERAL ELECTRIC TECH GMBH

Main heat exchanger and a process for cooling a tube side stream

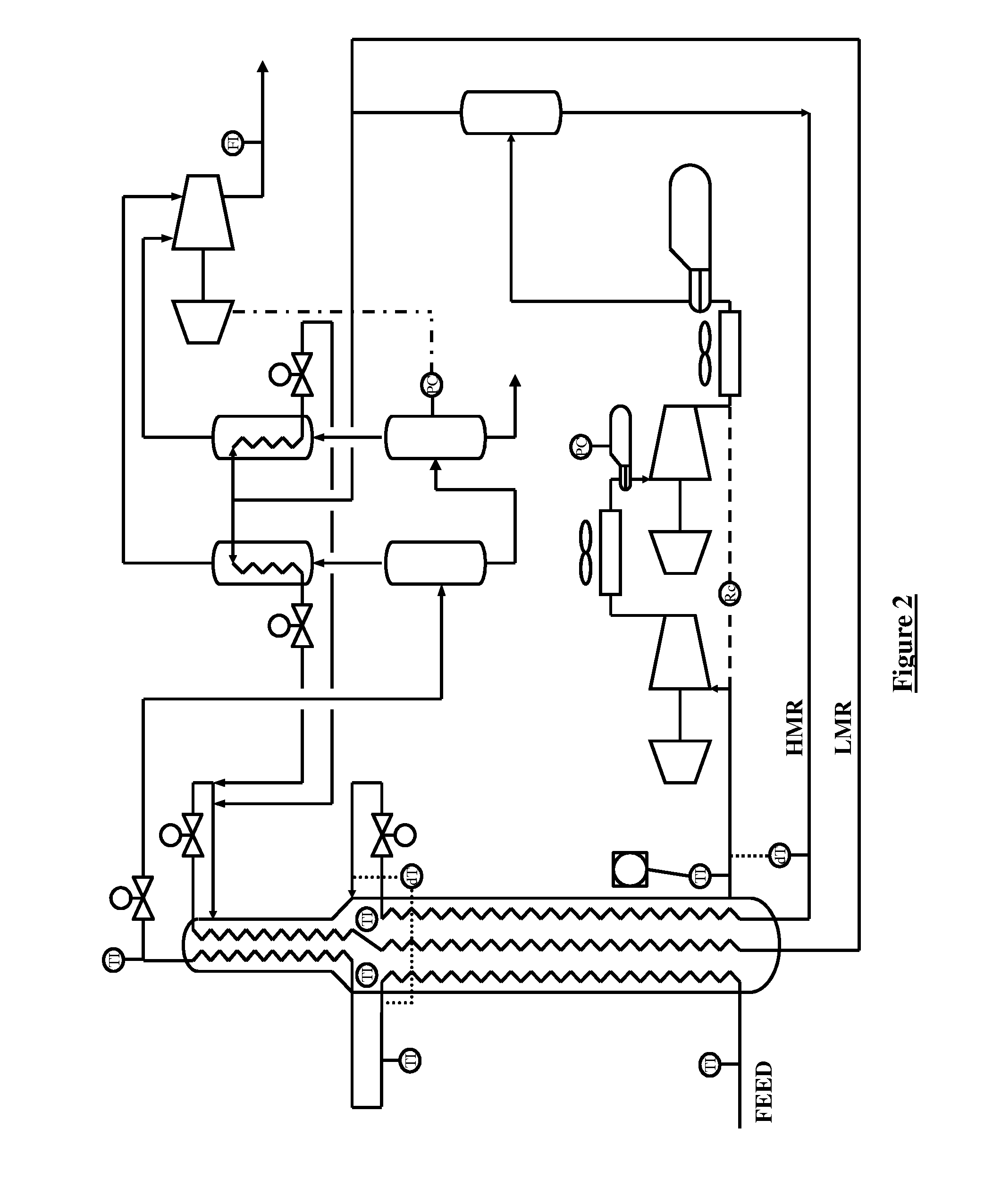

ActiveUS20130068431A1Maximize temperatureReduce pressureSolidificationLiquefactionProcess engineeringRefrigerant

A process for cooling a tube side stream in a main heat exchanger is described. The process comprises: a) supplying a first mass flow of a tube side stream to a first zone of individual tubes in the tube bundle; b) supplying a second mass flow of the tube side stream to a second zone of individual tubes in the tube bundle, the second zone being offset from the first zone; c) supplying a refrigerant stream on the shell side for cooling the first and second mass flows; d) removing the evaporated refrigerant stream from the warm end of the main heat exchanger; and, e) adjusting the first mass flow of the tube side stream relative to the second mass flow of the tube side stream to maximise the temperature of the removed evaporated refrigerant stream.

Owner:LINDE AG

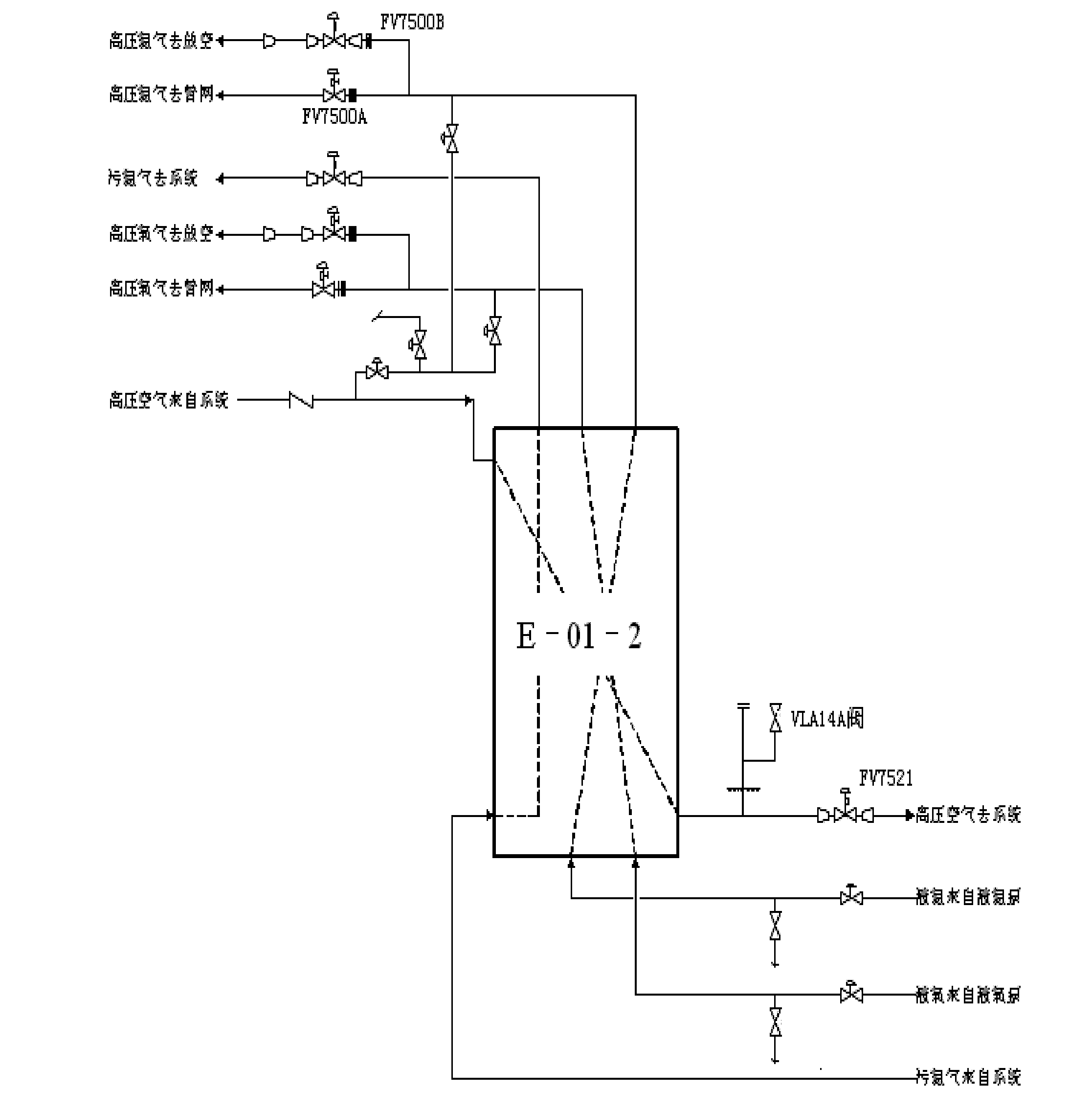

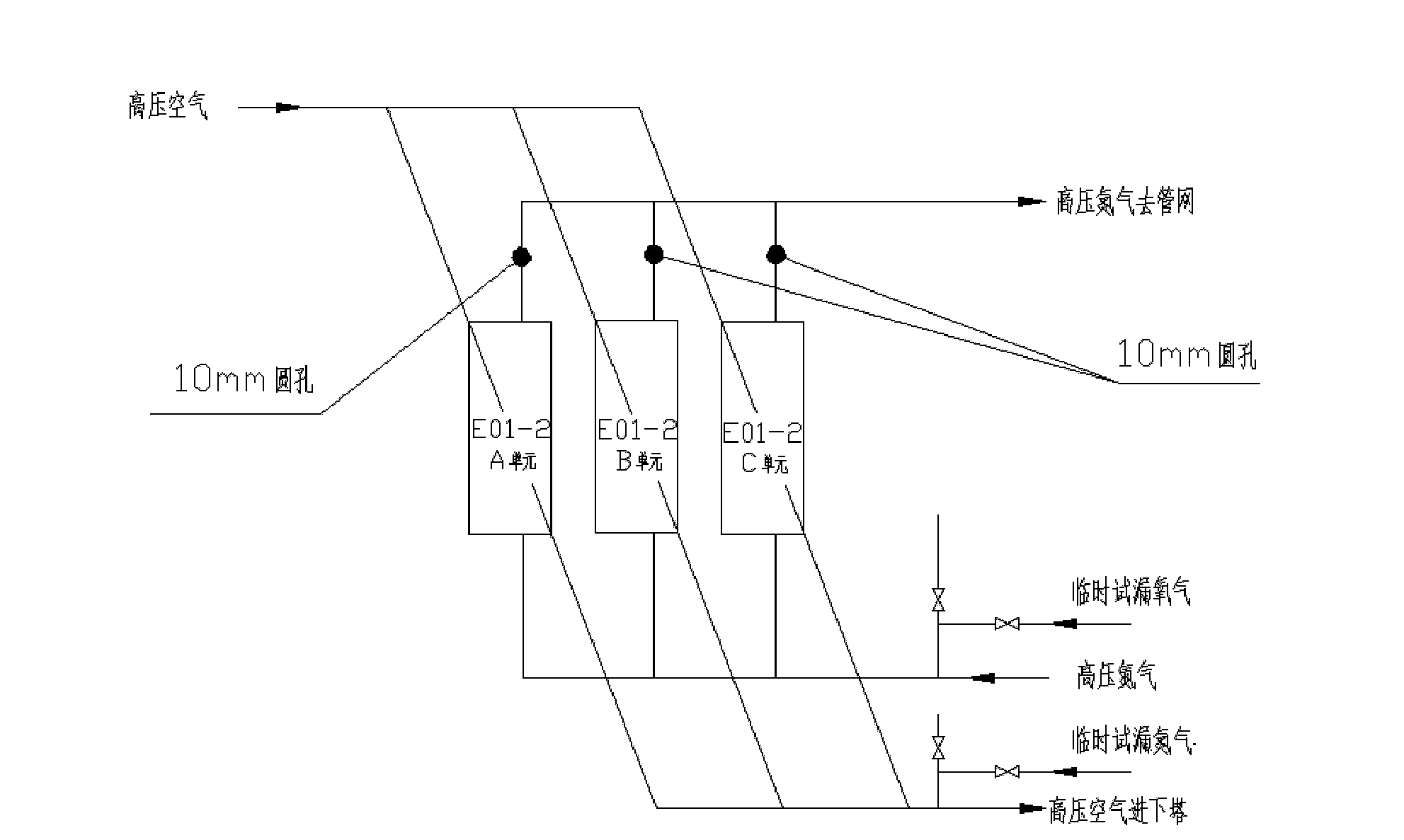

Leakage check method for main heat exchanger leakage of air separation plant

The invention relates to a leakage check method for the main heat exchanger leakage of an air separation plant. After an instrument error is removed and ice chest skimming sand is removed, the leakage check method comprises the following steps: sealing a liquid nitrogen inlet manifold at the bottom of a main heat exchanger and a high-pressure nitrogen gas discharging manifold at the top of the main heat exchanger; shutting off a high-pressure air manifold inlet valve at the top of the main heat exchanger and a high-pressure air manifold discharging valve at the bottom of the main heat exchanger; introducing high-pressure temporary leakage check nitrogen by the high-pressure air discharging manifold at the bottom of the main heat exchanger, wherein the pressure of the temporary leakage check nitrogen is above 3.2MPa; and finally, analyzing purity pollution. The method can be used for quickly and accurately judging which unit has air leakage, and therefore maintenance efficiency can be improved and loss brought by equipment faults is reduced.

Owner:ANHUI HUAIHUA

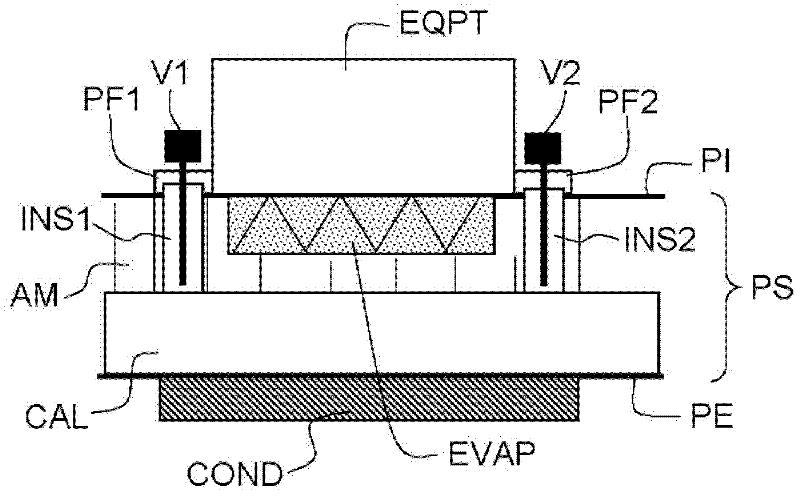

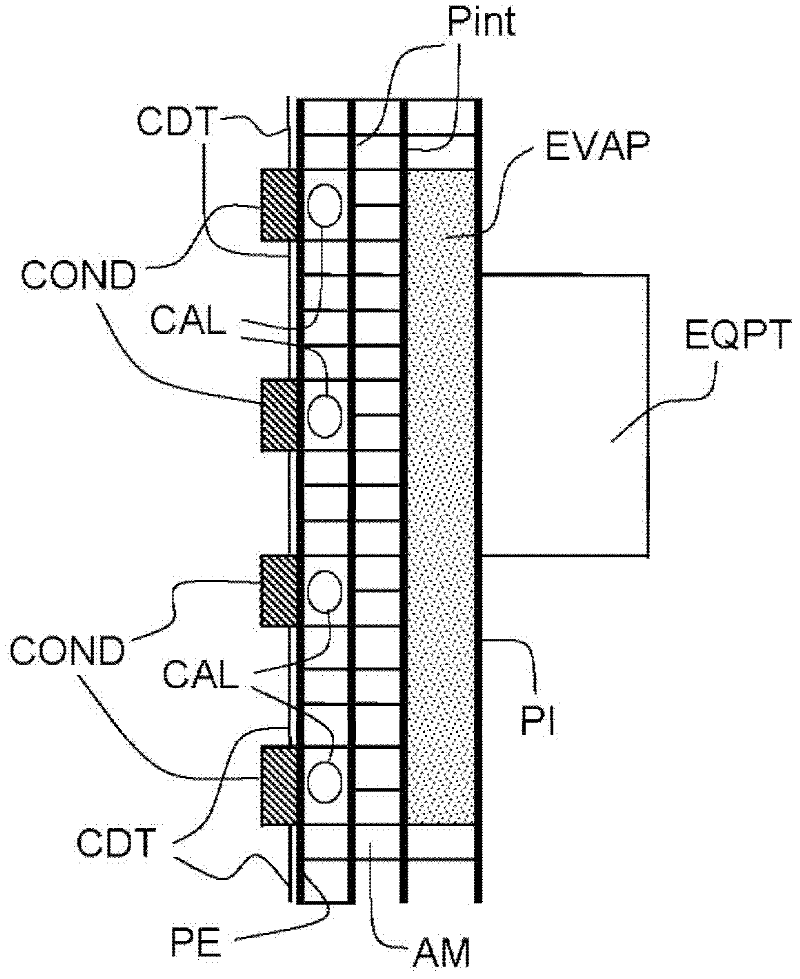

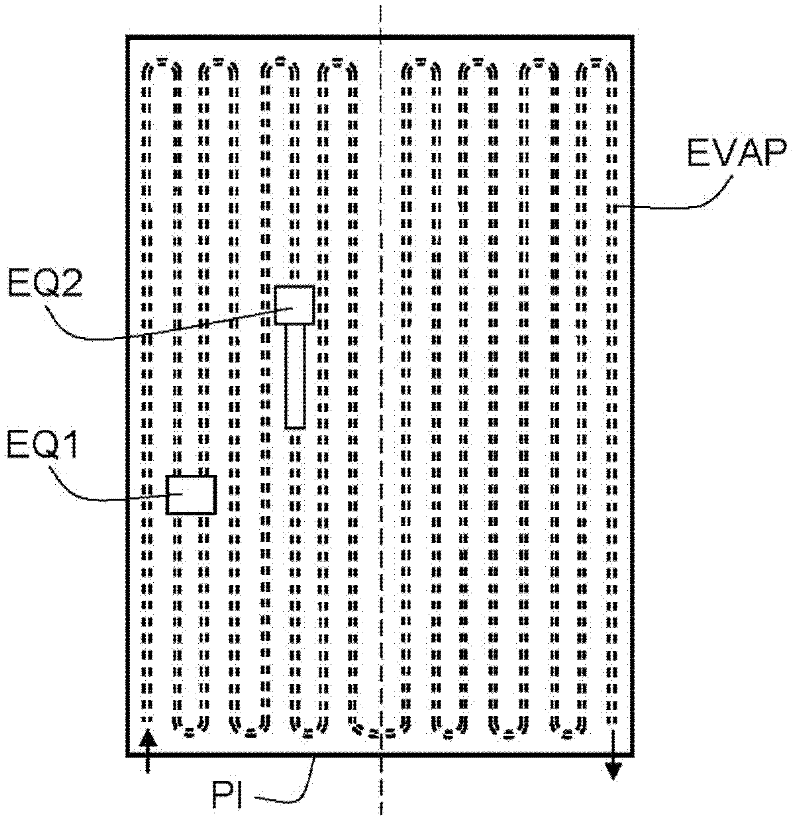

Structural satellite panel with integrated heat exchangers

InactiveCN102673803AEasy to manufactureLow costCosmonautic partsArtificial satellitesPlate heat exchangerEngineering

Owner:THALES SA

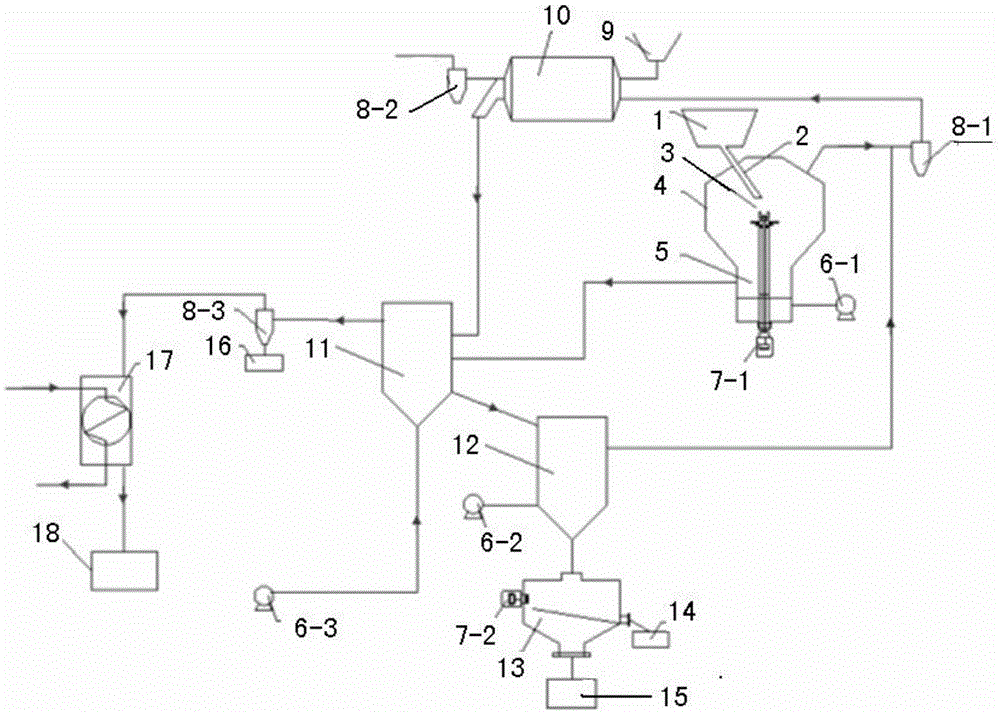

Device and method of utilizing blast furnace slag as heat carrier to prepare biomass oil

InactiveCN105567342AAchieve recyclingAchieve waste heatLiquid carbonaceous fuelsHydrocarbon oils treatmentChemical industryHeat carrier

The invention discloses a device and method of utilizing blast furnace slag as a heat carrier to prepare biomass oil. The device comprises a granulating cavity, a dryer, a pyrolysis reactor, a counterflow moving bed heat exchanger, a vibration separator and a condensation separator, a granulator is arranged in the granulation cavity, and a blast furnace slag fluidizing cabin is arranged at the bottom of the granulation cavity. The device is characterized in that the granulation cavity is used for smashing and granulating blast furnace slag through the granulator to obtain blast furnace slag grains; at the same time, the blast furnace slag fluidizing cabin outputs fluidizing air to exchange heat with the blast furnace slag grains, the blast furnace slag grains after heat exchange are output into the pyrolysis reactor, and generated high-temperature flue gas is output into the dryer to dry microalgae biomass; the pyrolysis reactor is used for mixing microalgae powder with granulated blast furnace slag grains, and the microalgae powder is pyrogasified to generate biomass pyrolysis gas. The device and method can be widely applied in the field of power, environment protection, chemical industry and steel and iron.

Owner:CHONGQING UNIV

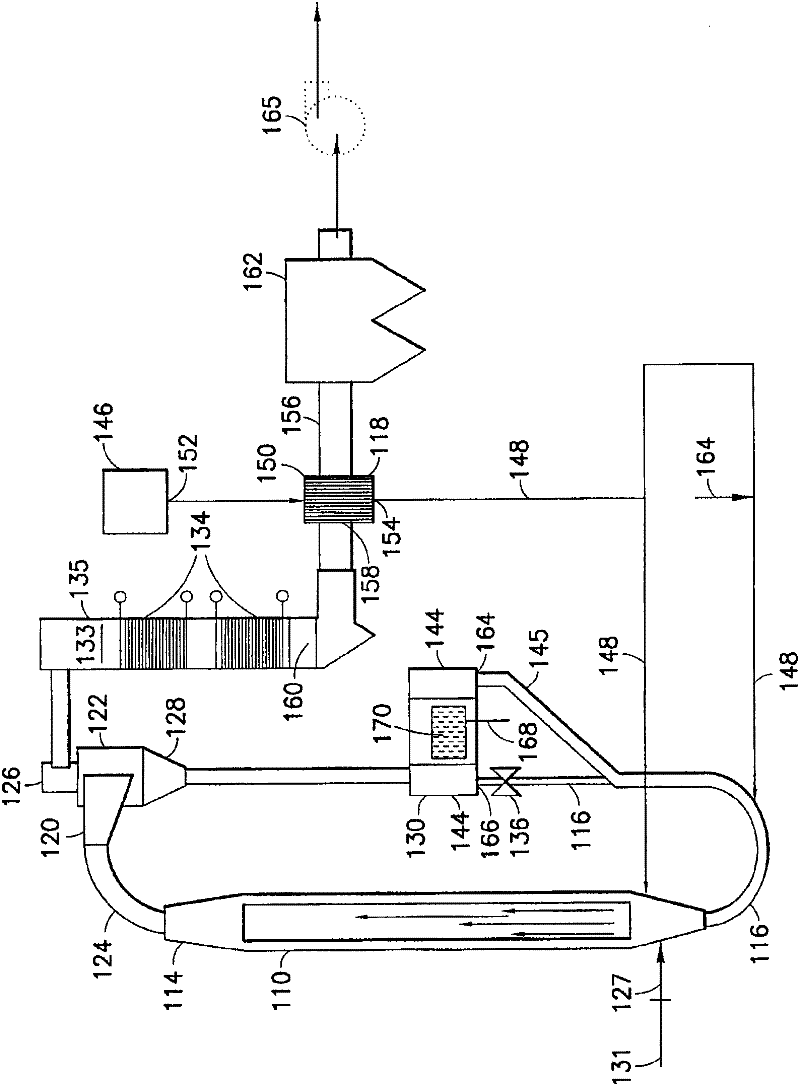

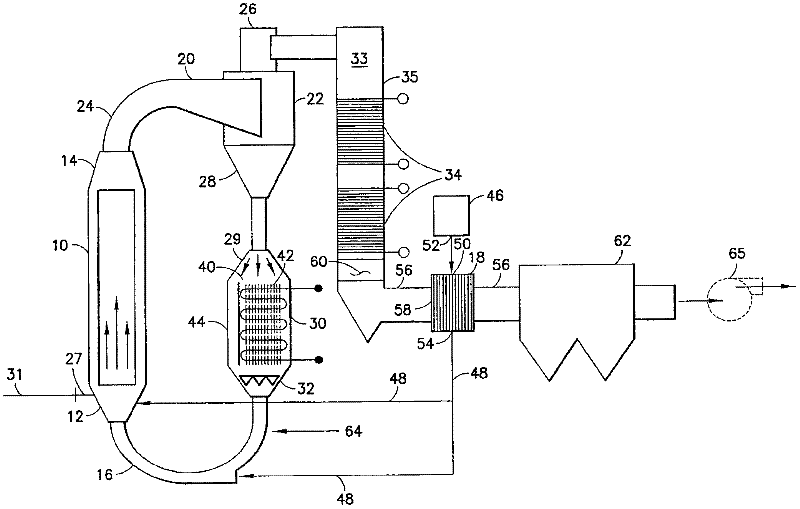

Oxygen fired steam generator

InactiveCN102449395AFluidized bed combustionIndirect carbon-dioxide mitigationPlate heat exchangerNuclear engineering

In a method for operating a steam generator, a transport reactor is provided. Only a substantially pure oxygen feed stream is introduced into the transport reactor in an amount sufficient to maintain the transport reactor at or above a specific system load. The specific load is the system load when only the substantially pure oxygen feed stream is provided to the transport reactor at a minimum flow velocity for operating the transport reactor. A fuel is combusted in the presence of the substantially pure oxygen feed stream to produce a flue gas, which contains solid material. The solid material is separated from the flue gas and passed to a heat exchanger. The heat exchange may be one of a moving bed heat exchanger or a fluidized bed heat exchanger. The solid material is directed to the transport reactor to contribute to the combustion process.

Owner:GENERAL ELECTRIC TECH GMBH

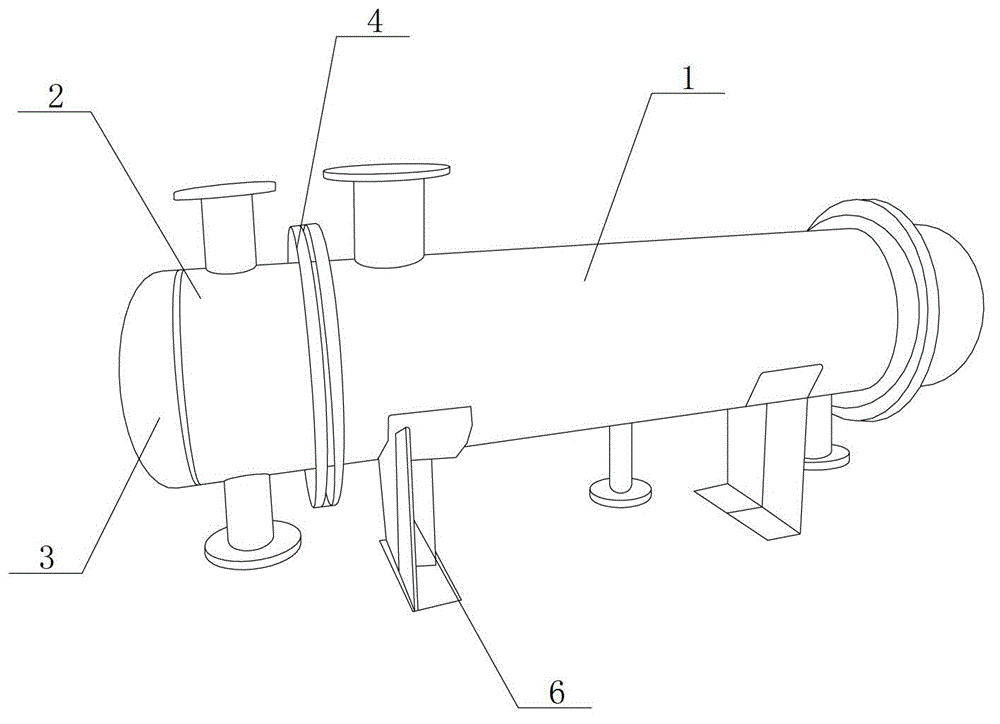

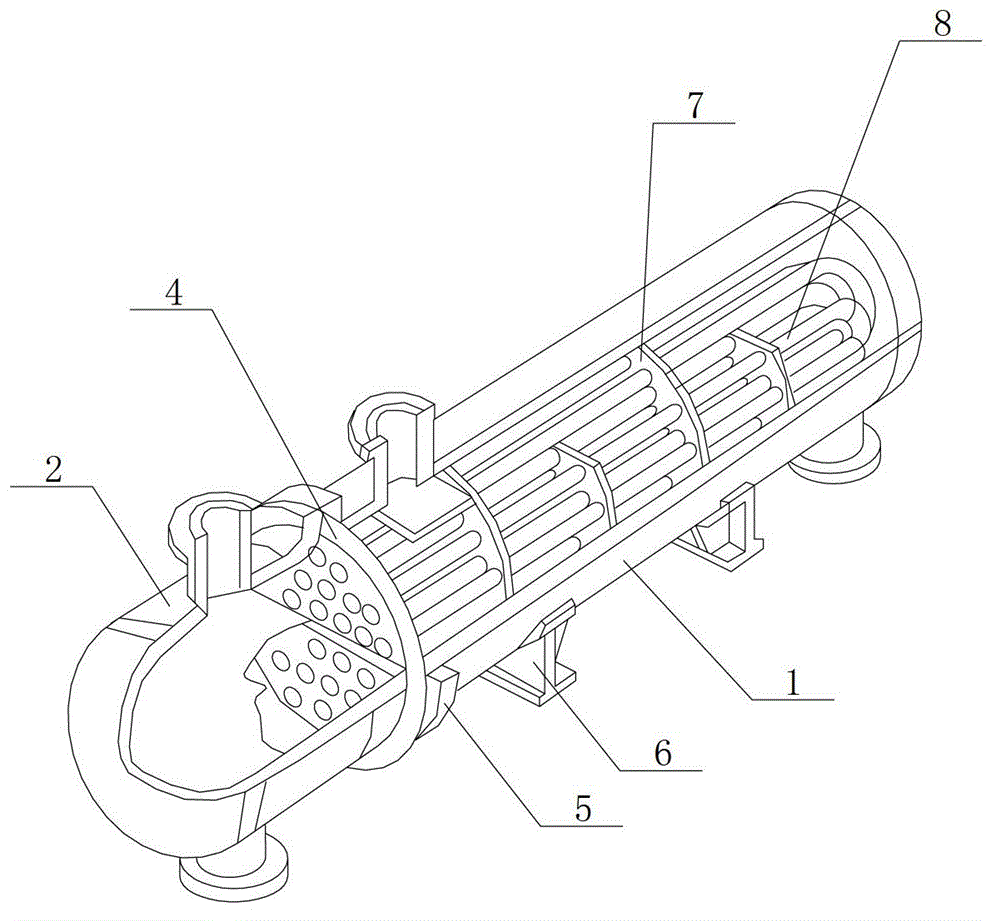

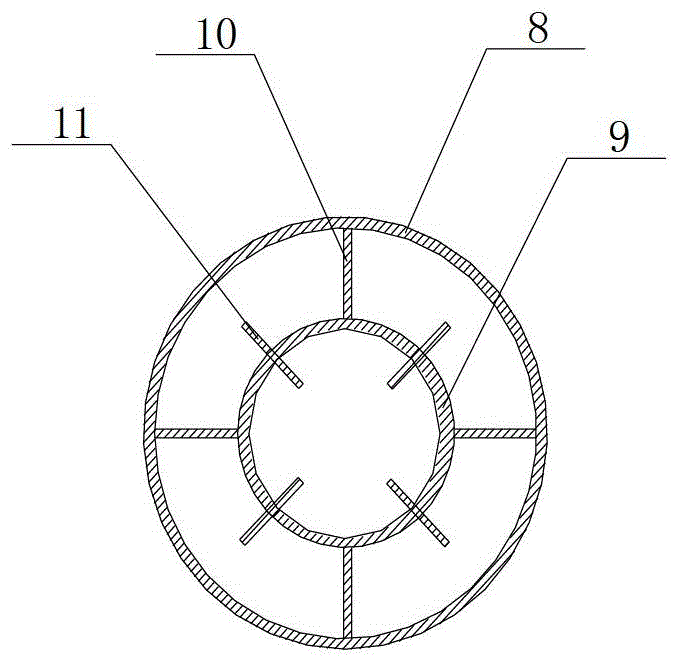

Novel heat exchanger

InactiveCN104019681AReasonable structural designNovel shapeChemical industryStationary tubular conduit assembliesChemical industryEngineering

The invention provides a novel heat exchanger, and relates to the technical field of heat exchange and refrigeration air conditioner mechanical equipments. One end of a shell (1) is provided with a tube box (2), and a tube box cover (3) is arranged on one side of the tube box (2). A tube plate (4) is arranged on the other side of the tube box (2), and a flange (5) is arranged on one side of the tube plate (4). A plurality of supports (6) are evenly arranged at the bottom of the shell (1), and a baffle plate (7) and an outer tube (8) are arranged in the other end of the shell (1). An inner tube (9) is arranged in the outer tube (8), a supporting body (10) is axially arranged in a loop space formed by the outer tube (8) and the inner tube (9), and a plurality of heat exchange fins (11) are evenly arranged in the axial direction on the wall of the inner tube (9). The novel heat exchanger is reasonable in structural design, novel in appearance, convenient to produce, capable of achieving the good heat exchange capacity and improving the heat exchange efficiency, and applicable to the fields of the chemical industry, the pharmacy and the like.

Owner:KUNSHAN RUIHENGFENG TECH CONSULTING

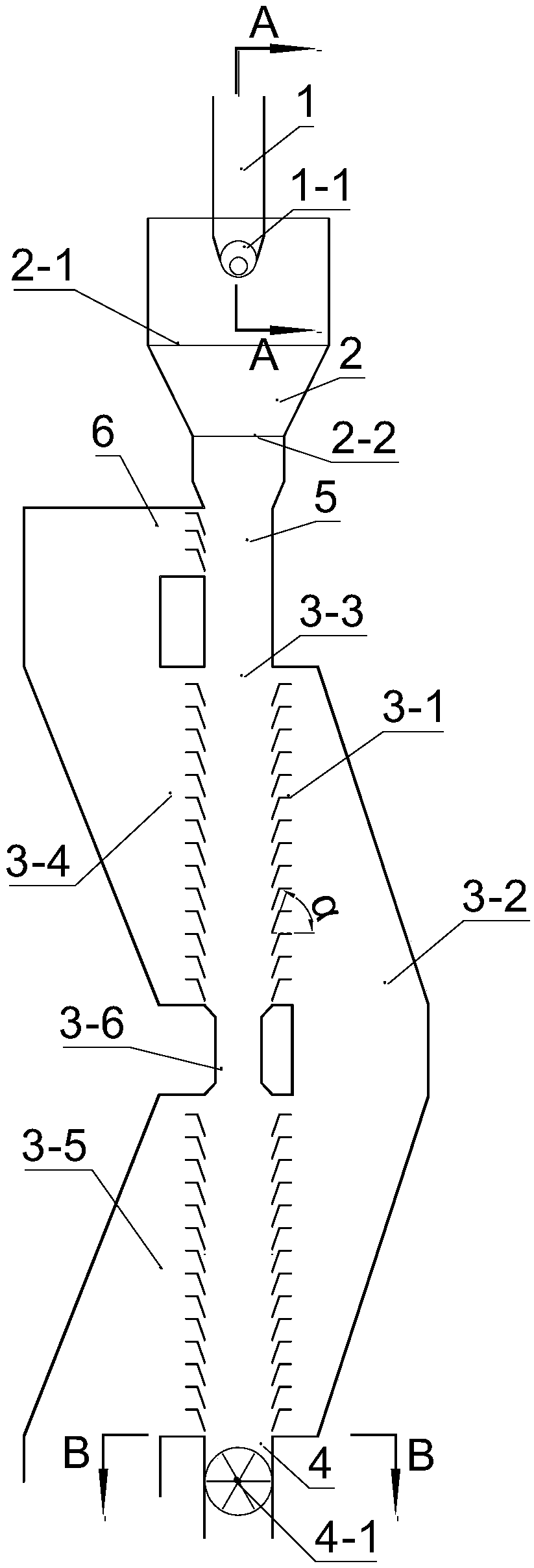

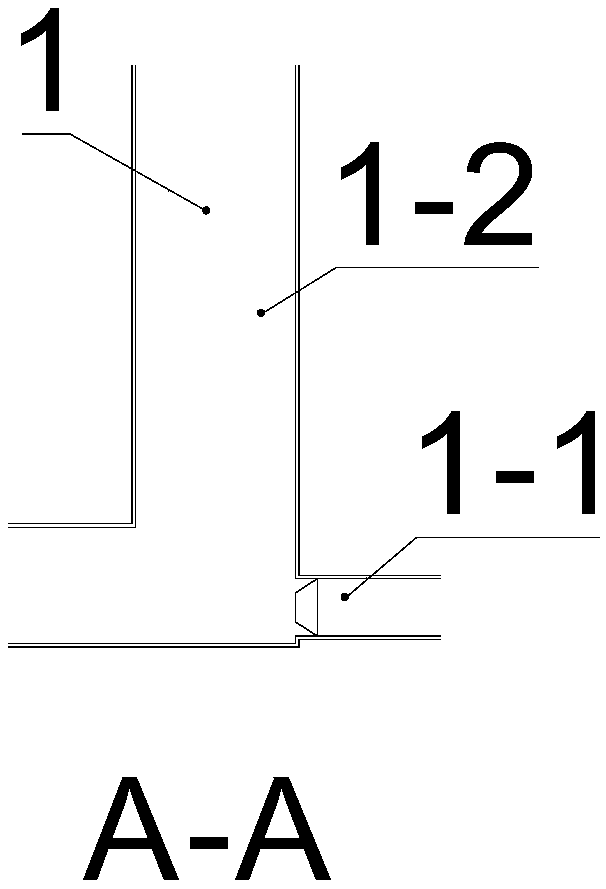

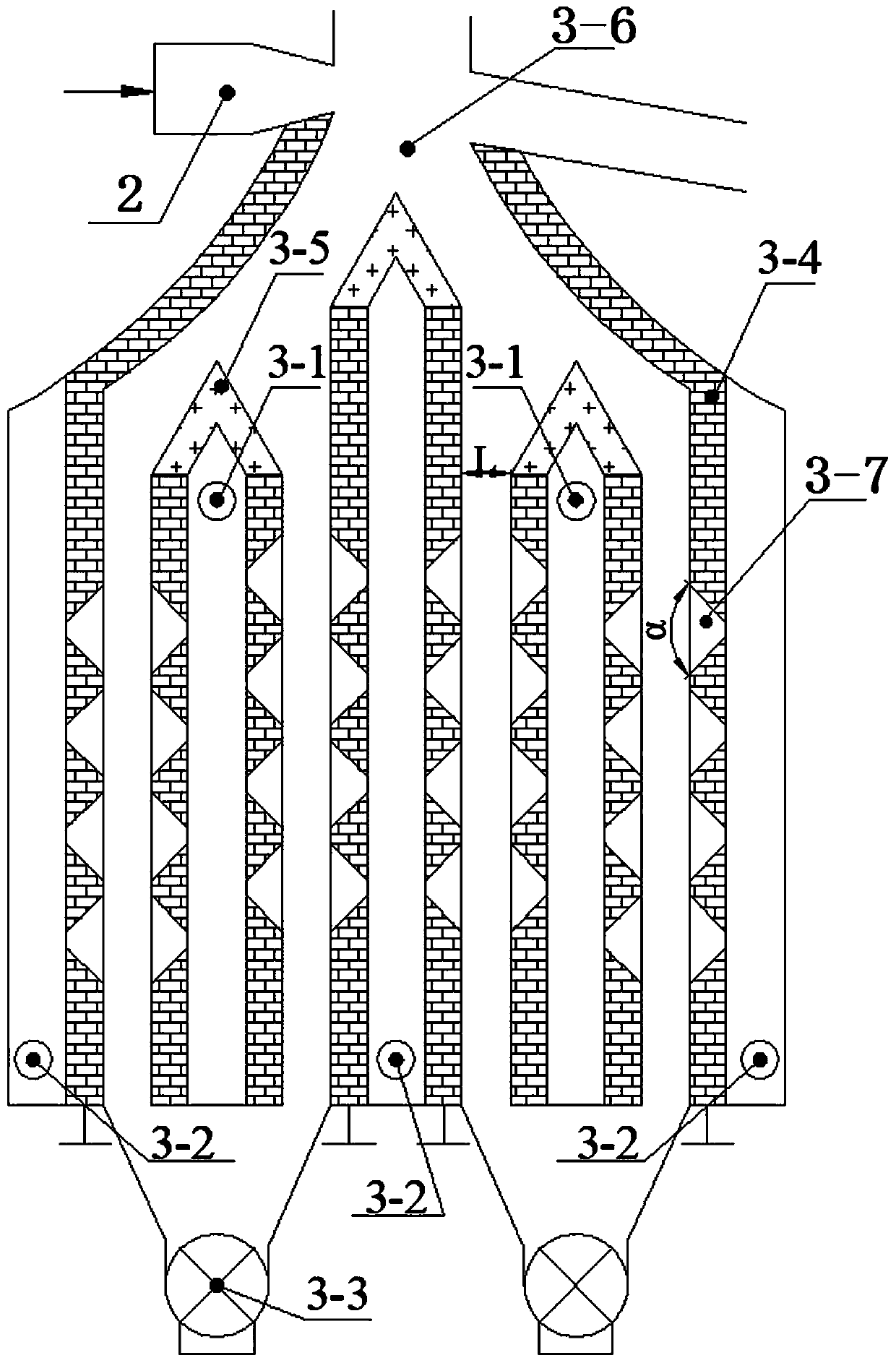

Circulating fluidized bed boiler bottom slag waste heat recovery device

ActiveCN108800118ALow flow resistanceImprove heat transfer coefficientFluidized bed combustionApparatus for fluidised bed combustionSlagEngineering

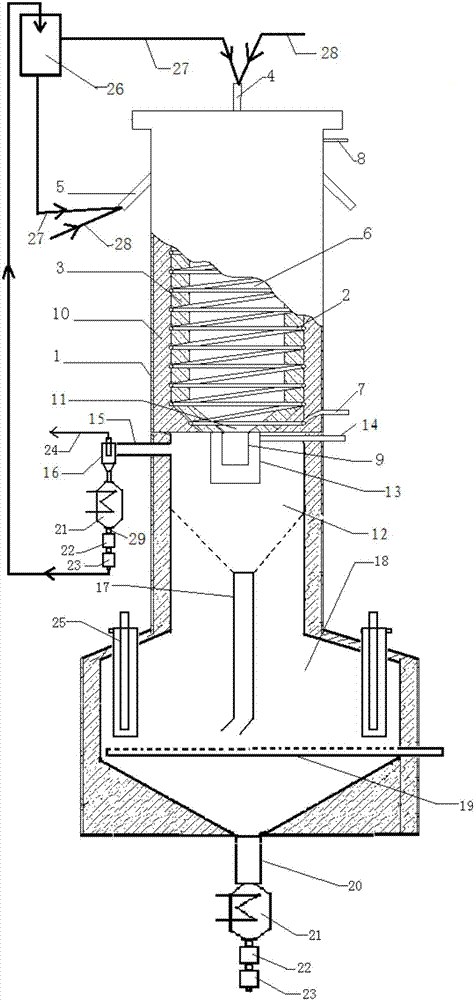

A circulating fluidized bed boiler bottom slag waste heat recovery device comprises an L-shaped ash control valve (1), a sorting section pipeline (2), a cross-flow moving bed heat exchanger (3) and aslag discharging device (4), wherein the sorting section pipeline (2) is a big-end-up opening contraction pipeline, the upper portion of the sorting section pipeline (2) is provided with a sorting section inlet (2-1), and the lower portion of the sorting section pipeline (2) is provided with a sorting section outlet (2-2); the cross-flow moving bed heat exchanger (3) is composed of a separation flow guide plate (3-1), a cooling flue (3-2) and a bottom slag channel (3-3), the upper portion of a cross-flow moving bed is connected with the sorting section pipeline outlet through a slag feeding pipe (5), and the width of the bottom slag channel (3-3) of the cross-flow moving bed is 200-2000 mm; the bottom slag flowing speed is controlled by the slag discharging device (4), meanwhile, after being pressurized by a recycling fan, flue gas transversely passes through the bottom slag channel in an S shape through the separation flow guide plate (3-1), and the included angle (alpha) between theinclined section of the separation flow guide plate (3-1) and the horizontal direction is 20-80 degrees. According to the circulating fluidized bed boiler bottom slag waste heat recovery device, the recirculating flue gas is adopted as a heat exchange medium, the vast majority of heat of the bottom slag is recovered back into a boiler, continuous stable operation of the waste heat recovery deviceis ensured, boiler ash slag physical heat losses are decreased, and the boiler efficiency is improved.

Owner:CHONGQING UNIV

Coal coke Y-shaped entrained-flow bed cleaning high-efficiency gasifying technology

InactiveCN107118808AWide adaptability of coal typesImprove conversion rateGasification processes detailsCombined combustion mitigationSlagFluidized bed

The invention provides a coal coke Y-shaped entrained-flow bed cleaning high-efficiency gasifying technology. In the coal coke Y-shaped entrained-flow bed cleaning high-efficiency gasifying technology, a gasifying furnace, a gas and ash separator, a fluidized bed heat exchanger, a moving bed heat exchanger and the like are arranged, wherein the gasifying furnace is separated into a gasifying chamber and a chilling chamber, and the gasifying chamber and the chilling chamber are separated by a sectional conical seal head; a casing of the gasifying chamber is sequentially provided with a heat insulation material layer, a cooling sleeve and an abrasion-resistant material layer from exterior to interior; the bottom part of the gasifying chamber is provided with a cooling liquid inlet, and the top part of the gasifying chamber is provided with a cooling liquid outlet; a top spray nozzle is arranged at the center of the top part of the gasifying chamber, and three or more side spray nozzles are uniformly arranged at the upper part in the circumference direction; the center of the sectional conical seal head is provided with a gasifying product outlet, and the gasifying product outlet is communicated into the chilling chamber; a chilling spray head is arranged at the outside of the gasifying product outlet, a solid slag discharge pipe is arranged at the center of the conical seal head at the bottom part of the chilling chamber, the solid slag discharge pipe is communicated into the fluidized bed heat exchanger, the upper part of the chilling chamber is provided with a crude synthetic gas outlet, and the crude synthetic gas outlet is communicated into the gas and ash separator; the moving bed heat exchanger and two stages of lock hopper dischargers are respectively arranged at the outlets of the fluidized bed heat exchanger and the gas and ash separator; the residual heat of the gasifying product is fully utilized to solve the problems of black water and salt-containing wastewater.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

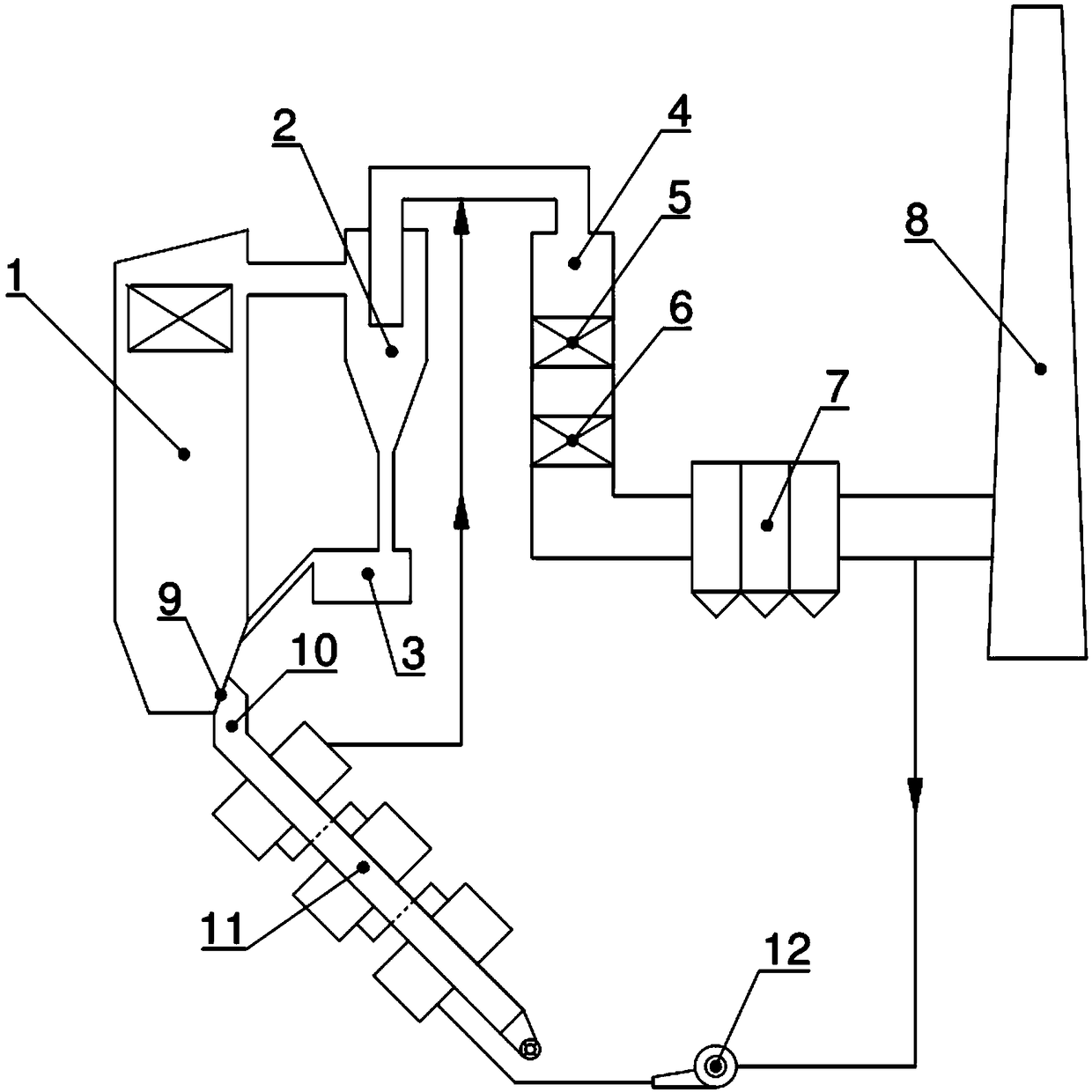

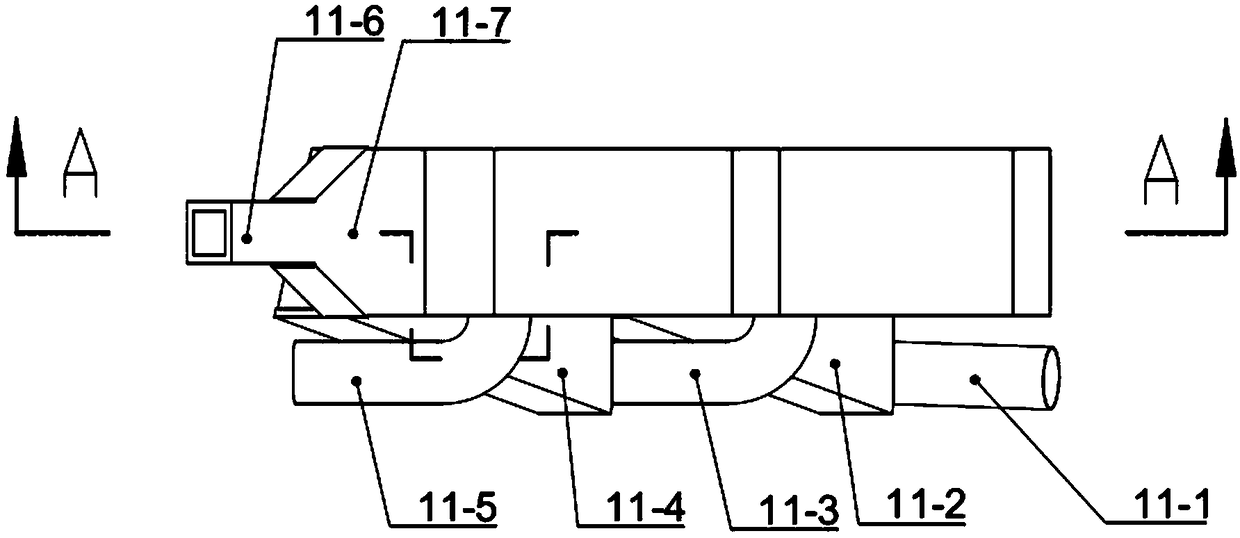

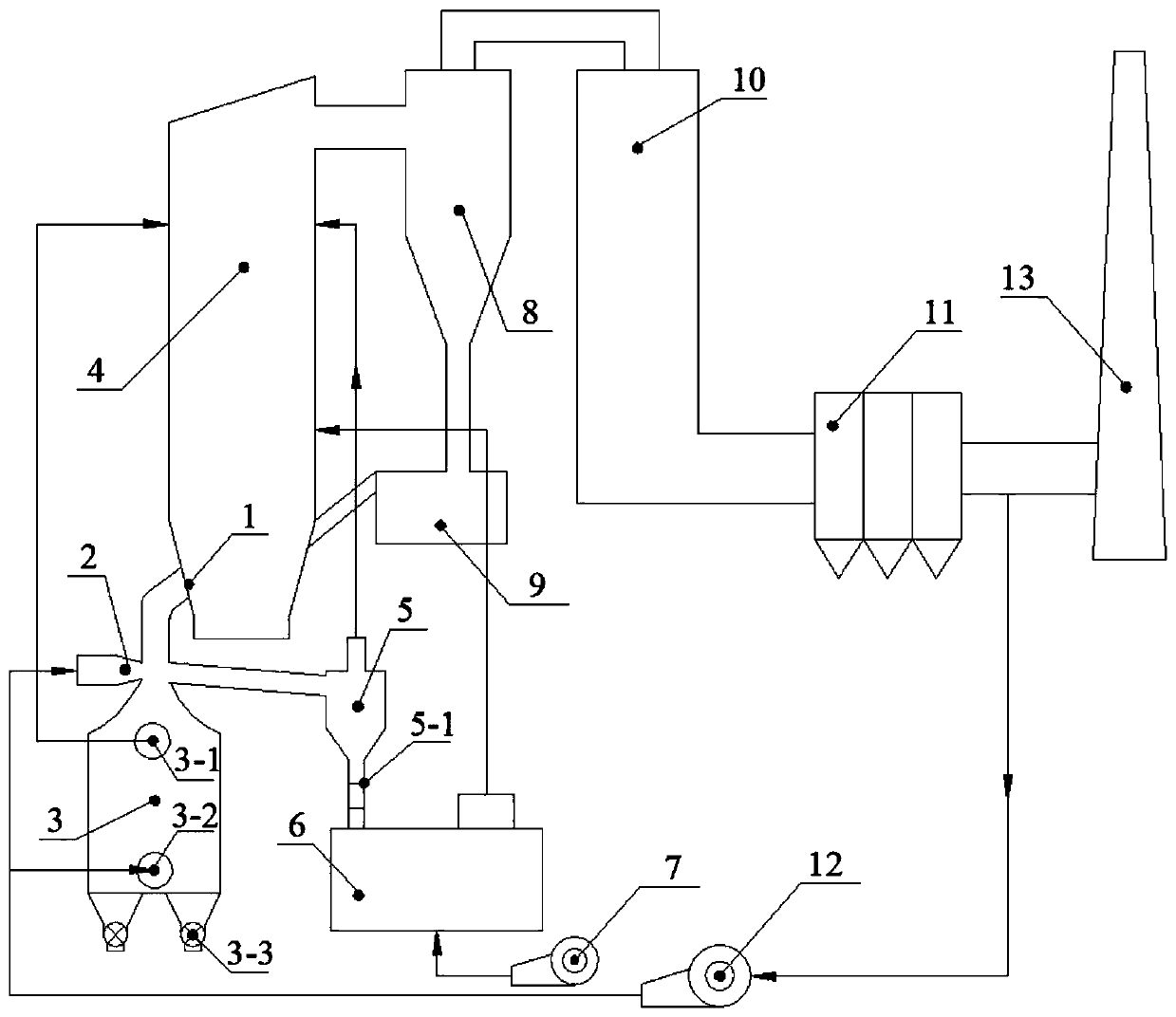

Waste heat recovery device for bottom slag of circulating fluidized bed boiler

InactiveCN108980820AReduce the temperatureIncrease contact timeFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

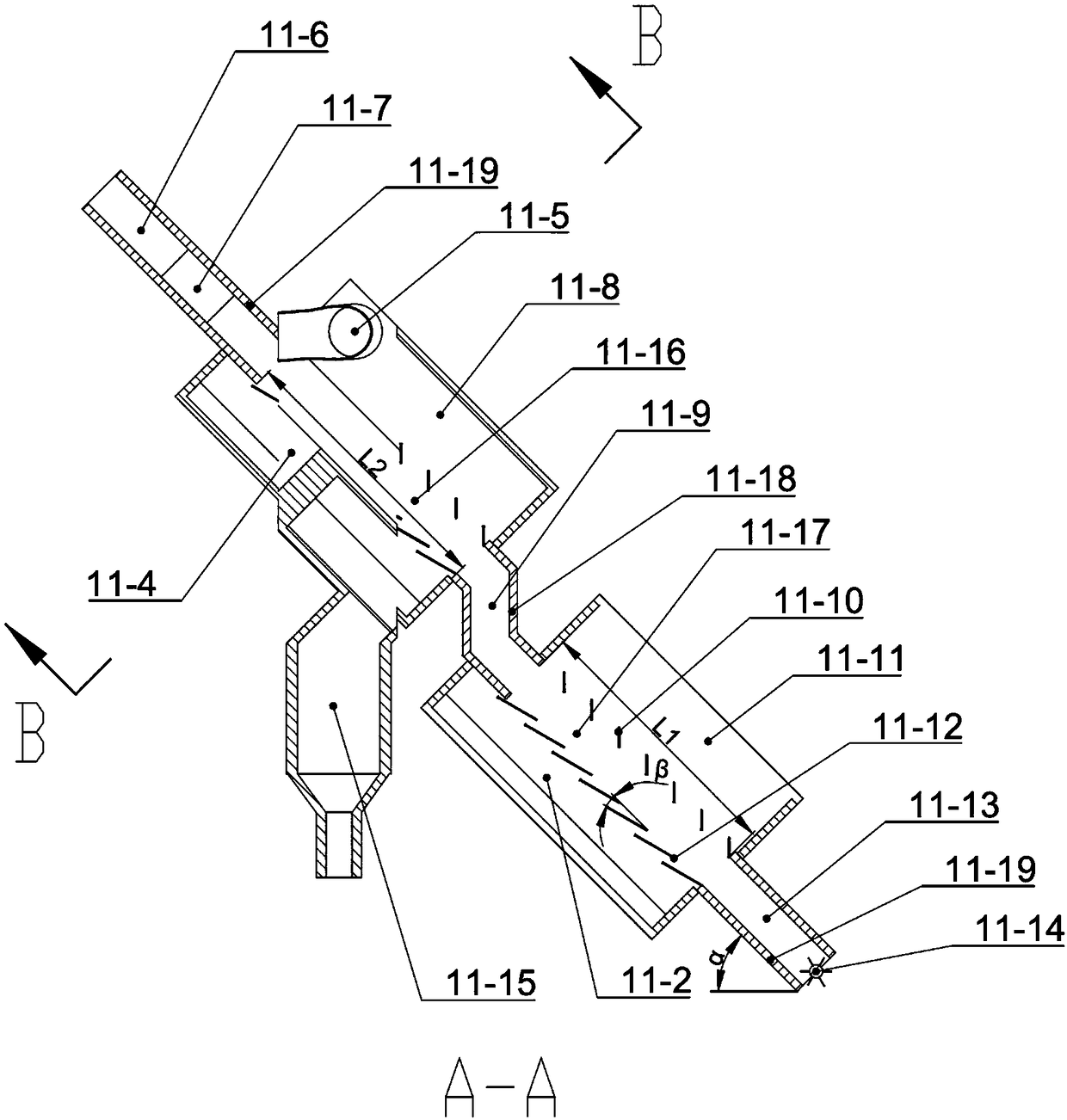

The invention discloses a waste heat recovery device for bottom slag of a circulating fluidized bed boiler. The waste heat recovery device comprises a slag discharging pipe (9) and an inclined movingbed heat exchanger (11) and is characterized in that the inclined moving bed heat exchanger (11) is integrally in an inclined form, each of an upper cross-flow section (11-16) and a lower cross-flow section (11-17) is composed of upper flow guide plates (11-10) and lower flow guide plates (11-12) and is provided with an upper air chamber and a lower air chamber, the upper air chamber (11-11) of the lower cross-flow section and the lower air chamber (11-4) of the upper cross-flow section are connected through an air chamber connecting smoke pipe (11-3), the lower air chamber (11-4) of the uppercross-flow section is provided with a bottom slag collecting box (11-15), an ash channel middle sealing and pressing section (11-9) is arranged between the two cross-flow sections, and an ash channellower sealing and pressing section (11-13) is arranged below the lower cross-flow section (11-17). According to the waste heat recovery device, recycled flue gas is adopted as a heat exchange medium,most of the heat of the bottom slag is recycled to the proper position of a hearth (1) or a tail flue (4), and therefore the physical heat loss of boiler ash is reduced, and the boiler efficiency isimproved.

Owner:CHONGQING UNIV

High-temperature bottom slag cooling and afterheat recycling device of circulating fluidized bed boiler

PendingCN109827172ALow flow resistanceImprove heat transfer efficiencyFluidized bed combustionIndirect carbon-dioxide mitigationFluidized bedBoiler slag

The invention provides a high-temperature bottom slag cooling and afterheat recycling device of a circulating fluidized bed boiler. The device comprises the circulating fluidized bed boiler, a recirculation smoke fan, a cross flow moving bed heat exchanger and a rotary jet nozzle; a boiler slag discharge port is formed in the lower end of the circulating fluidized bed boiler; the cross flow movingbed heat exchanger comprises a bottom slag inlet and boiler walls; the bottom slag inlet communicates with the boiler slag discharge port through a slag inlet pipe; the recirculation smoke fan communicates with the slag inlet pipe through the rotary jet nozzle; the boiler walls are arranged in the cross flow moving bed heat exchanger side by side; bottom slag runners are formed between two adjacent boiler walls; each boiler wall is provided with a gradual increasing channel communicating with two adjacent bottom slag runners; smoke inlets and smoke outlets are staggered between the boiler walls; spiral slag discharge devices are arranged at the bottoms of the boiler walls; and bottom slag flow homogenizing devices are arranged at the tops of the boiler walls. The device can efficiently recover physical sensible heat of thick and fine particles in bottom slag, reduces the system energy consumption, and recovers part of fine particle bottom slag.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

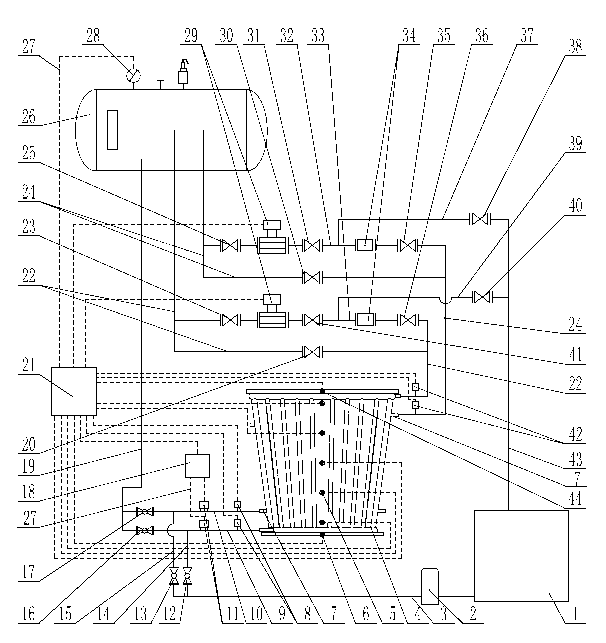

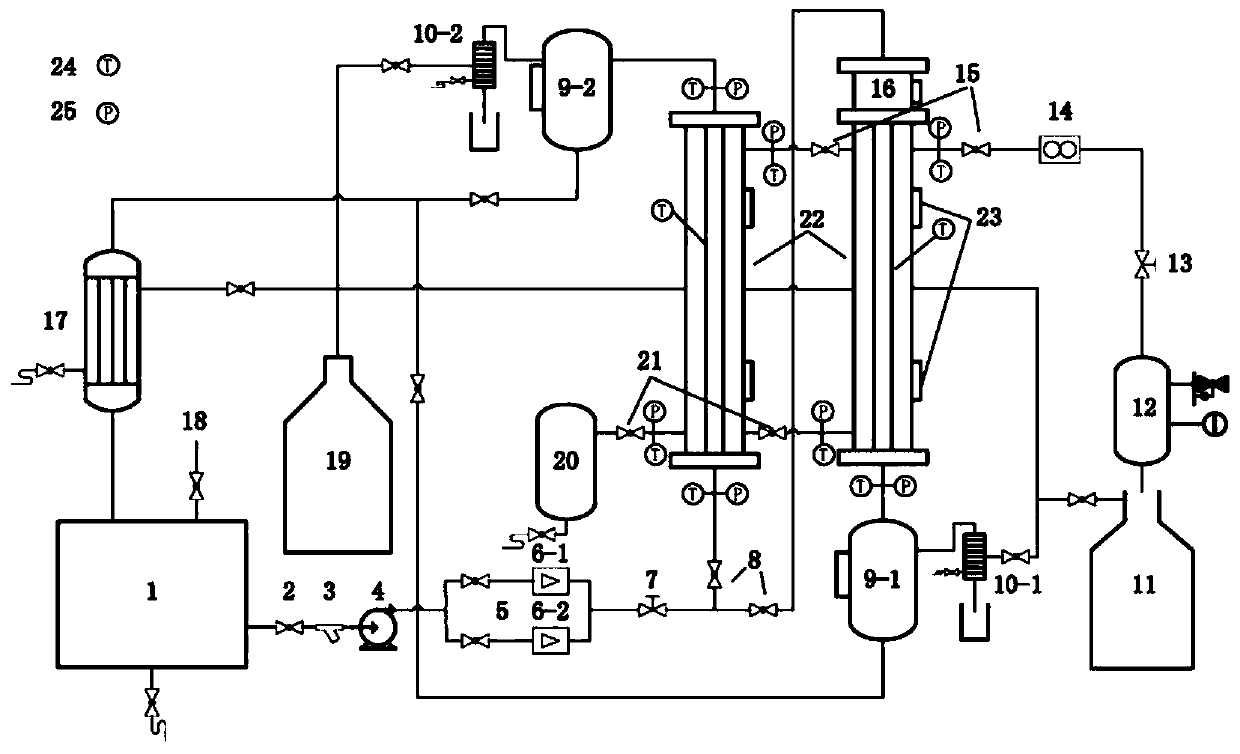

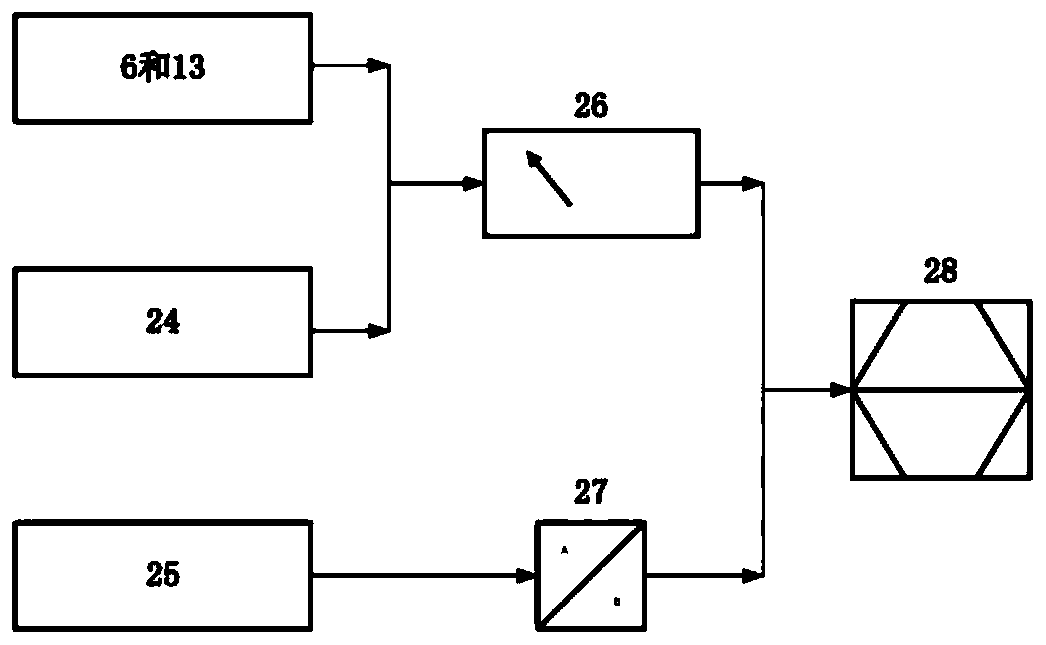

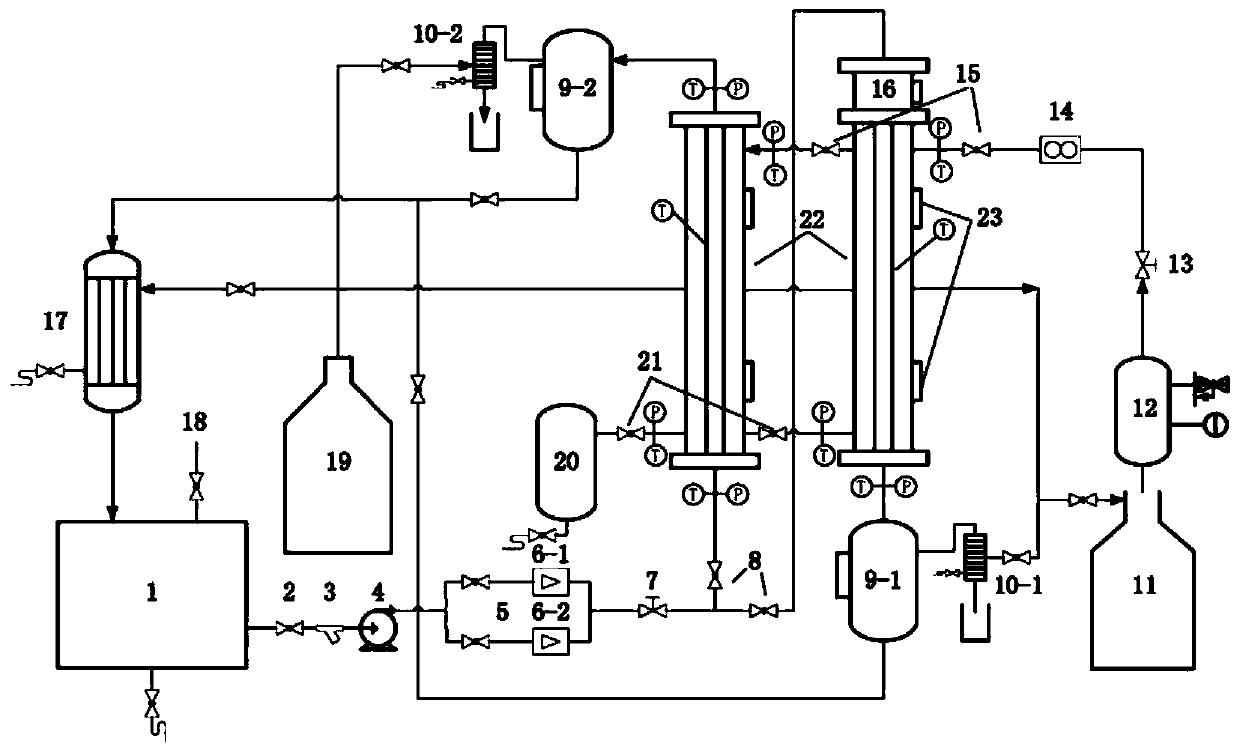

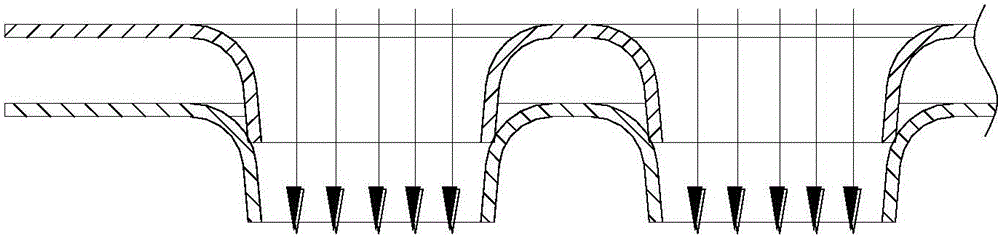

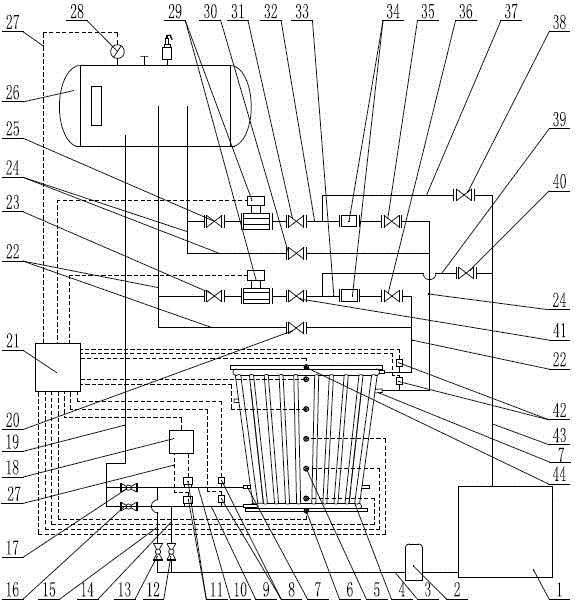

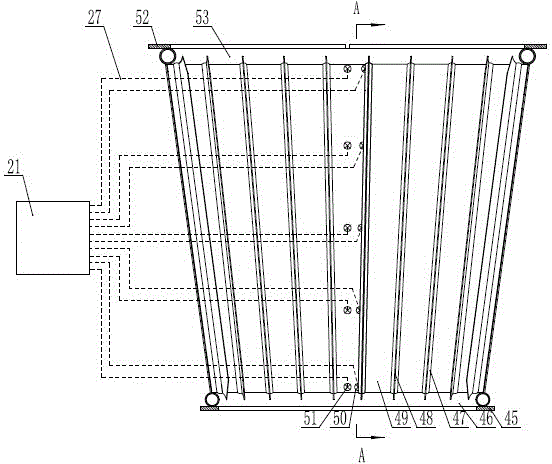

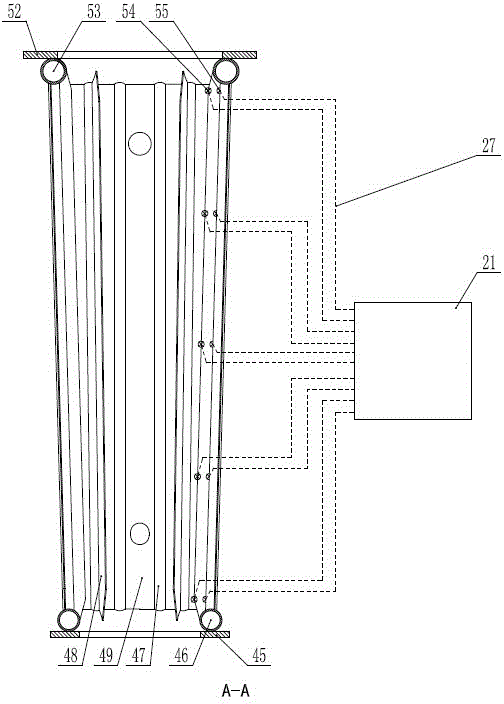

Online test system of high temperature calcined coke heat exchanger

ActiveCN102998138AEasy to measureFacilitate the study of heat transfer mechanismsMaterial heat developmentStructural/machines measurementElectrical resistance and conductanceUltrasonic sensor

An online test system of a high temperature calcined coke heat exchanger belongs to the technical field of waste heat utilization of solid high temperature materials and is characterized in that a high temperature calcined coke waste heat utilizing water-steam circulation system is connected with a water-steam parameter test system and a material temperature test system. The water-steam parameter test system comprises a first heat resistor (8), a second heat resistor (42), an ultrasonic flowmeter (18), a two-phase-flow flowmeter (29) and a sight glass (34), the first heat resistor (8) and ultrasonic sensors (11) are arranged on an outer heat exchange water inlet pipe (9) between a third adjusting valve (16) and an outer heat exchanger (4), the first heat resistor (8) and an ultrasonic sensor (11) are arranged on an inner heat exchanger water inlet pipe (10) between a fourth adjusting valve (17) and an inner heat exchanger (7), and the two ultrasonic sensors (11) are connected with the ultrasonic flowmeter (18) through signal wires (27). The online test system is capable of conducting comprehensive performance tests on high temperature calcined coke special heat exchangers on a pot type calcining furnace.

Owner:SHANDONG UNIV OF TECH

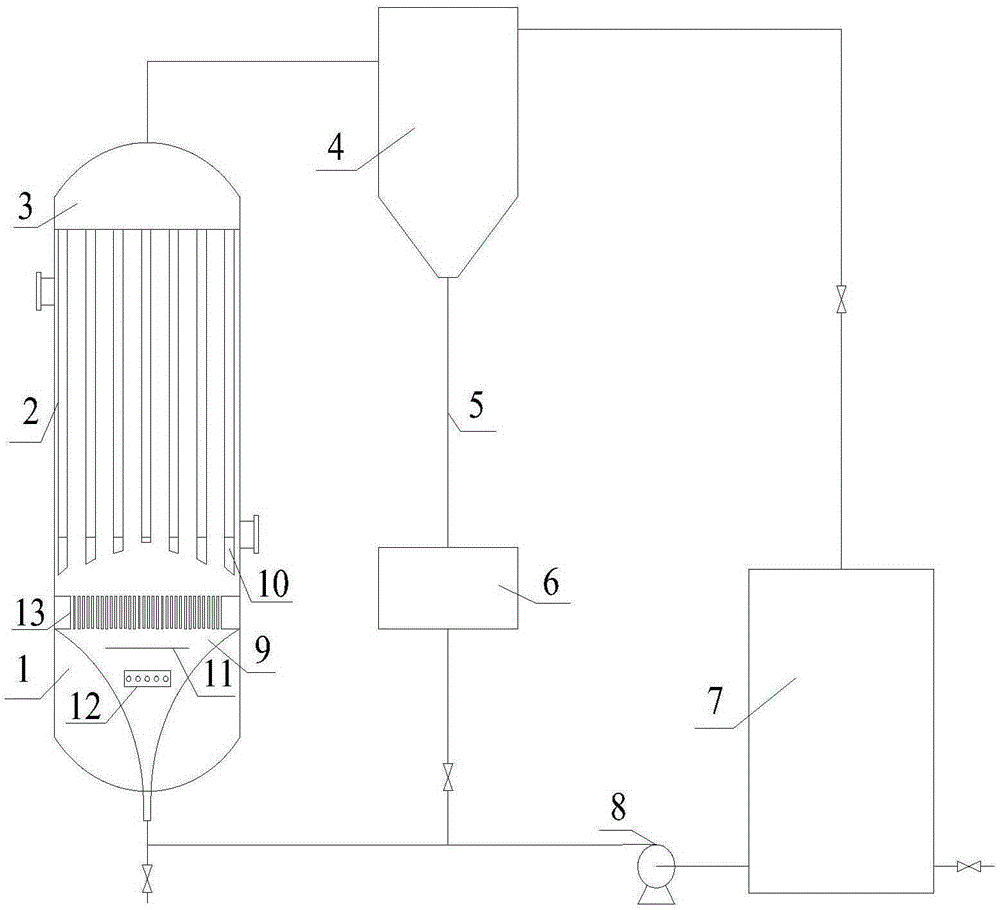

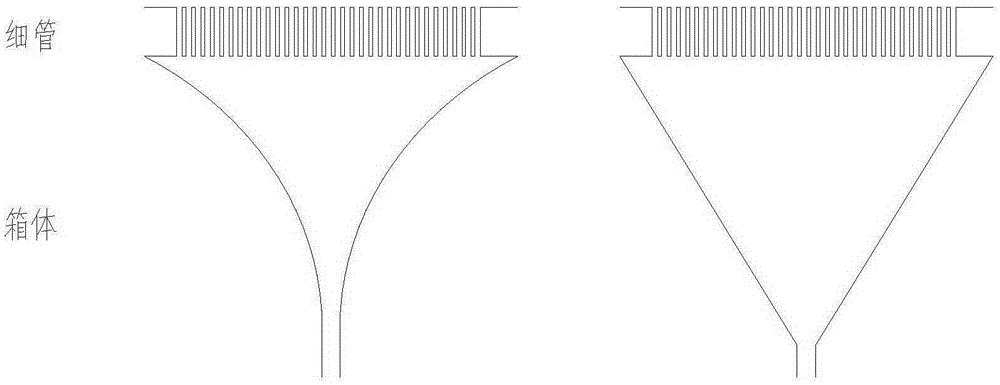

Liquid phase heat exchange fluidized bed heat exchanger

ActiveCN106595349AImprove technical effectCorrosion preventionStationary tubular conduit assembliesPlate heat exchangerFluidized bed

The invention relates to a liquid phase heat exchange fluidized bed heat exchanger, and is mainly used for solving the technical problem that in the traditional technology, the tube side of an overhead heat exchanger of an atmospheric and vacuum distillation unit is prone to scale formation, and after long-period usage, the heat exchange effect is obviously reduced. The liquid phase heat exchange fluidized bed heat exchanger comprises a lower tubular box 1, heat exchanger column tubes 2, an upper tubular box 3, a solid-liquid separator 4, a downcomer 5, a solid particle tank 6, a liquid storage tank 7, a liquid circulating pump 8, a distribution box 9, lower edge casing pipes 10, a distribution plate 11, a distribution disc 12 and thin tubes 13. The outlet of the distribution box 9 is connected with the thin tubes 13, the heat exchanger column tubes 2 are connected with the upper tubular box 3, the upper tubular box 3 is connected with the solid-liquid separator 4, solid particles enter the solid particle tank 6 through the downcomer 5, and then return to the lower tubular box 1, and liquid enters the liquid storage tank 7, and is sent to the lower tubular box 1 through the liquid circulating pump 8. By employing the above technical scheme, the above technical problem is well solved, and the operation period of the overhead heat exchanger of the atmospheric and vacuum distillation unit can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lifting film type evaporator comprehensive test experiment system

PendingCN109855900ASolution areaSolve resource problemsStructural/machines measurementPressure stabilizationComparative test

The invention discloses a lifting film type evaporator comprehensive test experiment system. The system comprises a cooling medium pipeline unit, a steam pipeline unit, a test heat exchanger unit anda data measurement and control unit, wherein the cooling medium pipeline unit comprises a heating water tank, a centrifugal pump, a turbine flowmeter, a small heat exchanger, various valves and linkage pipelines; the steam pipeline unit comprises a steam generator, a pressure stabilization tank, a steam regulation valve, a vortex shedding flowmeter, a condensation tank, various valves and linkagepipelines; the test heat exchanger unit comprises a main heat exchanger, a gas-liquid separator, a plate type heat exchanger and the linkage pipelines; the data measurement and control unit comprisesflow measurement and control, temperature measurement and control, pressure measurement and control and condensate measurement. The lifting film type evaporator comprehensive test experiment system provided by the invention is compact in structure, convenient to operate, low-cost in operation, reliable in performance, capable of accurately simulating operation work conditions of a lifting film type evaporation / reboiler under various working conditions, capable of preforming comparative test for heat transfer performance of a liquid film type evaporation / reboiler after optimization of flowingand heat transfer elements, and capable of providing theoretical foundation for design.

Owner:WUXI CHEM EQUIP CO LTD

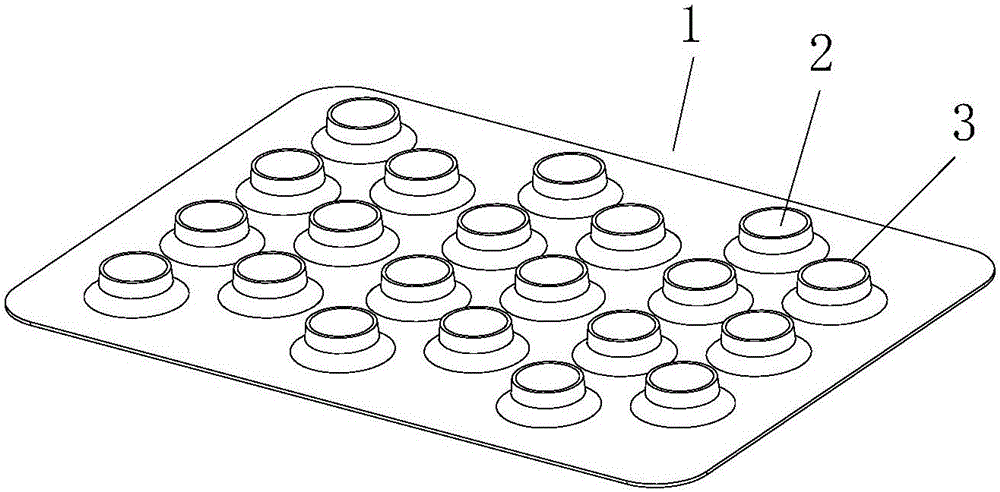

a heat exchanger

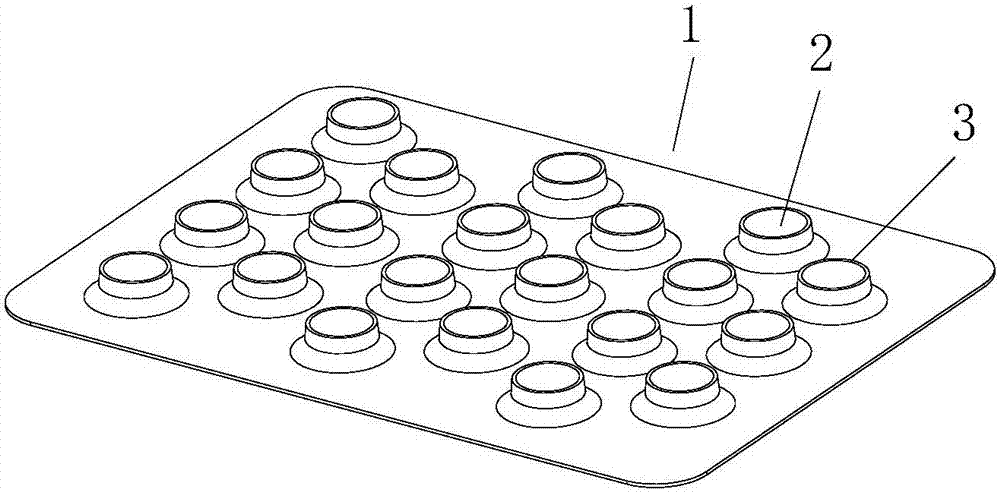

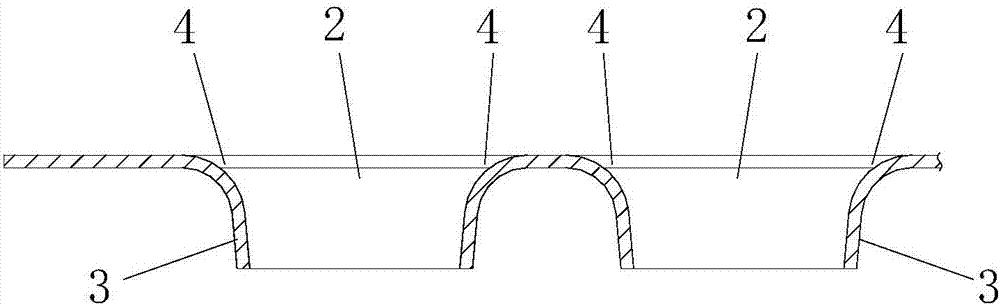

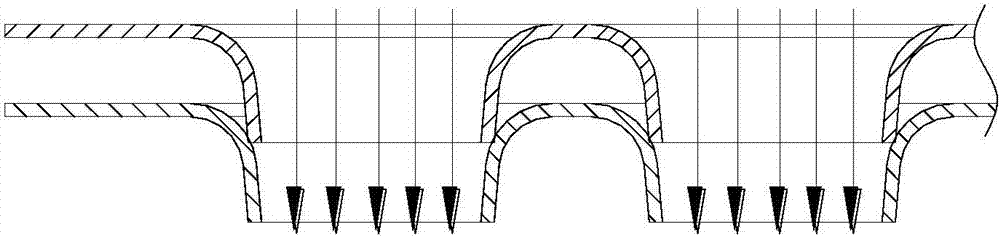

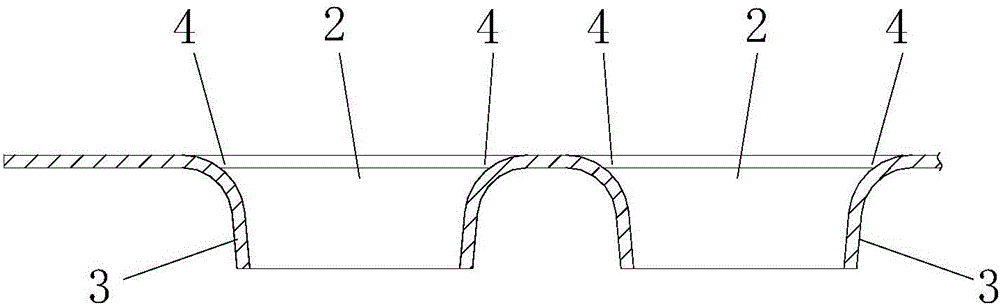

ActiveCN105841512BSimple structureReduce manufacturing costStationary conduit assembliesTubular elementsEngineeringMoving bed heat exchanger

The invention discloses a heat exchanger which is formed by stacking laminations. Each lamination is provided with at least one flanging hole. One side of each flanging hole extends outwards and is higher than the surface of the corresponding lamination to form an insertion connection part, and the other side of each flanging hole forms a connected part. After the laminations are stacked, the insertion connection parts of the lower laminations and the connected parts of the upper laminations are connected in a sealing mode to form pipeline space. The pipeline spaces are equivalent to inner channels of pipelines in the prior art, pipelines of a finned heat exchanger in the prior art are omitted, the structure of the heat exchanger is simplified, and production cost of the product can be effectively reduced. The pipeline spaces are composed of the insertion connection parts and the connected parts on the laminations, the material of the pipeline spaces and the material of the laminations are the same, and no media exist, so that thermal resistance is low, heat exchange efficiency can be effectively improved, and the heat exchanger has the advantages of being small in thermal resistance, high in heat exchange efficiency, convenient to manufacture, wide in application range and the like.

Owner:佛山市威沃热能科技有限公司

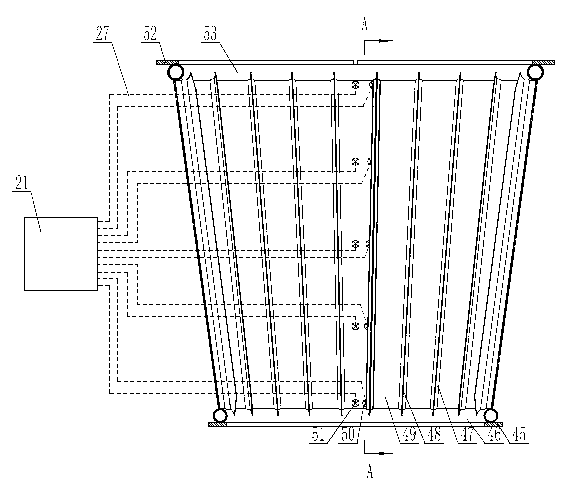

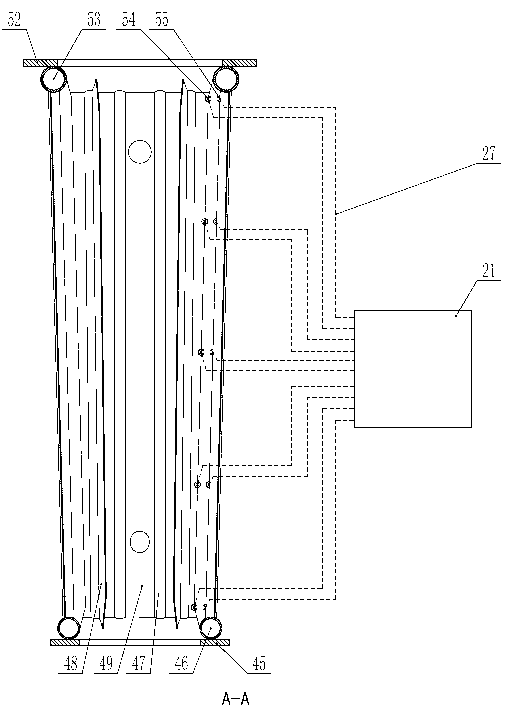

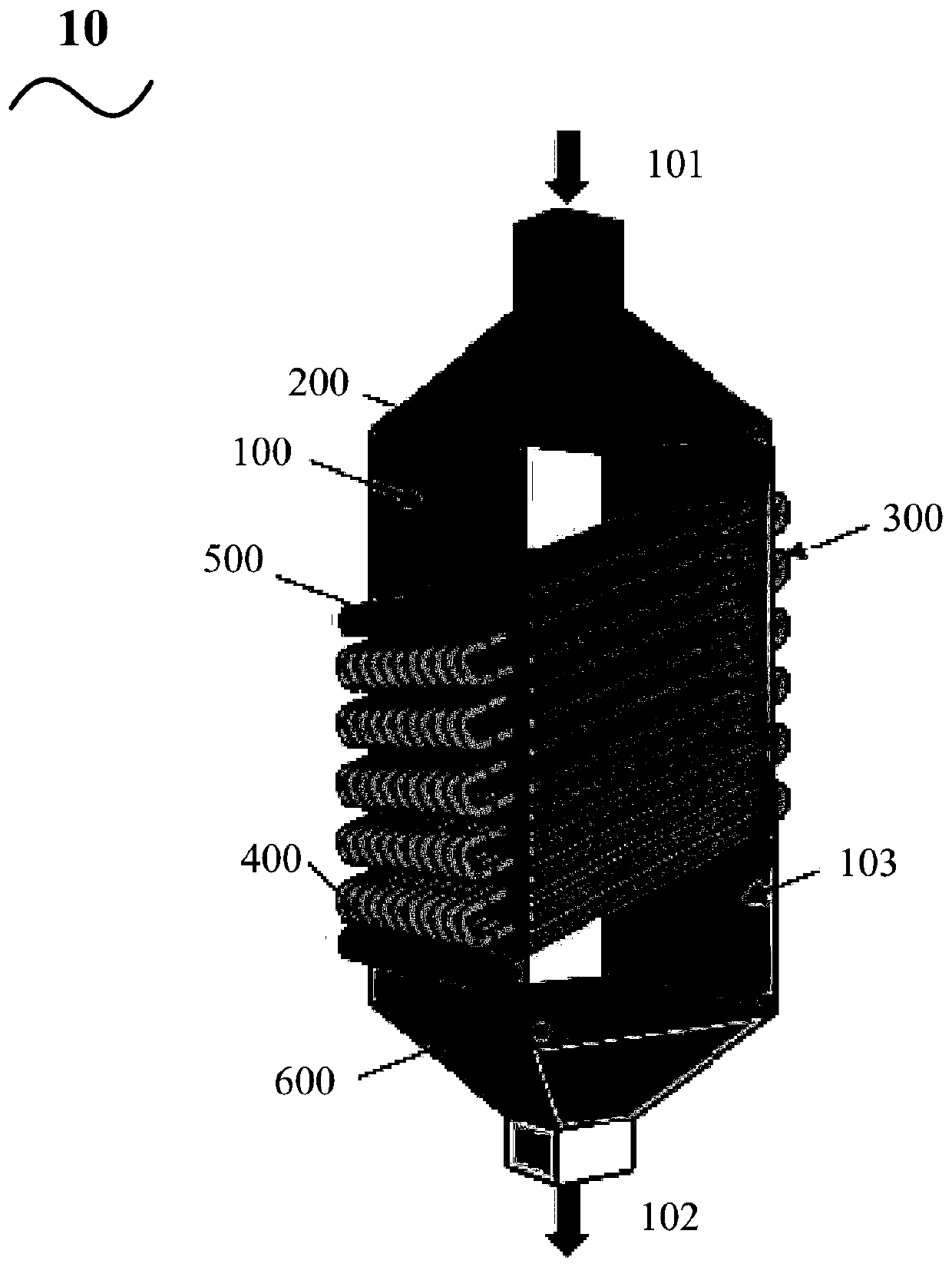

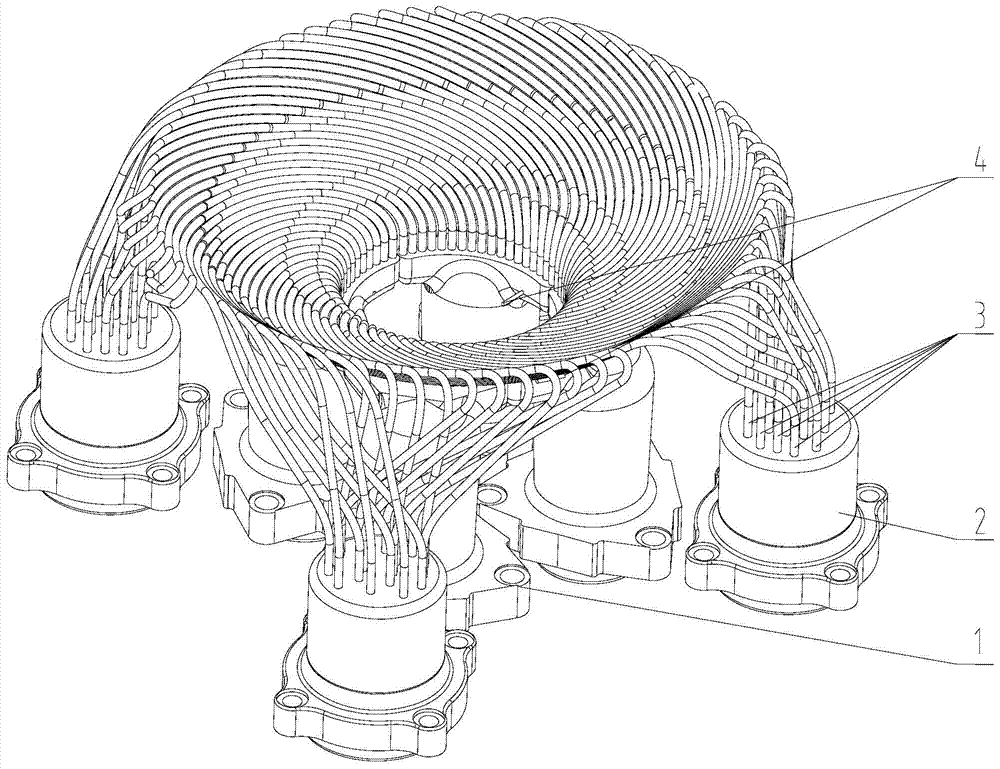

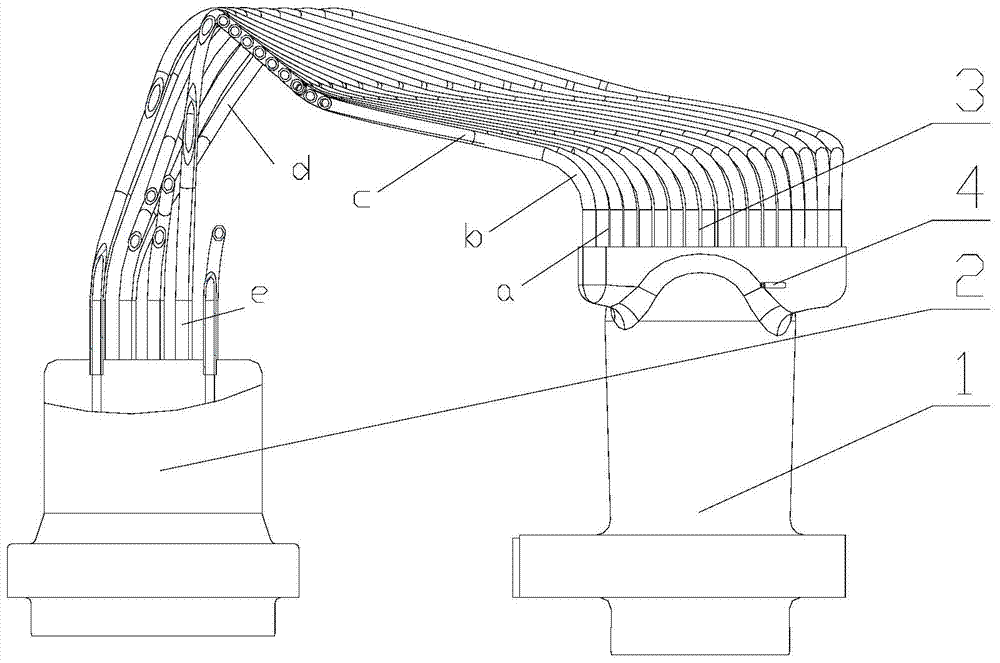

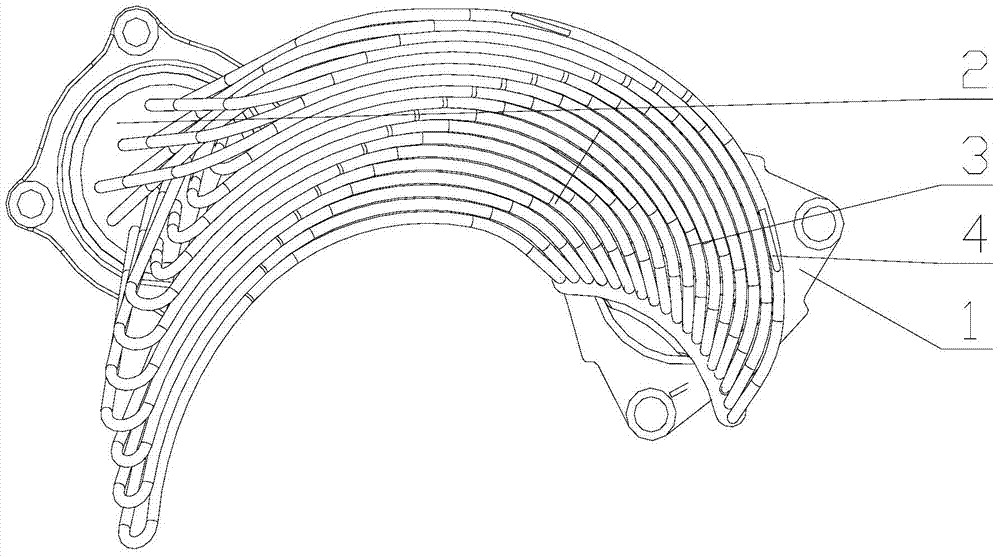

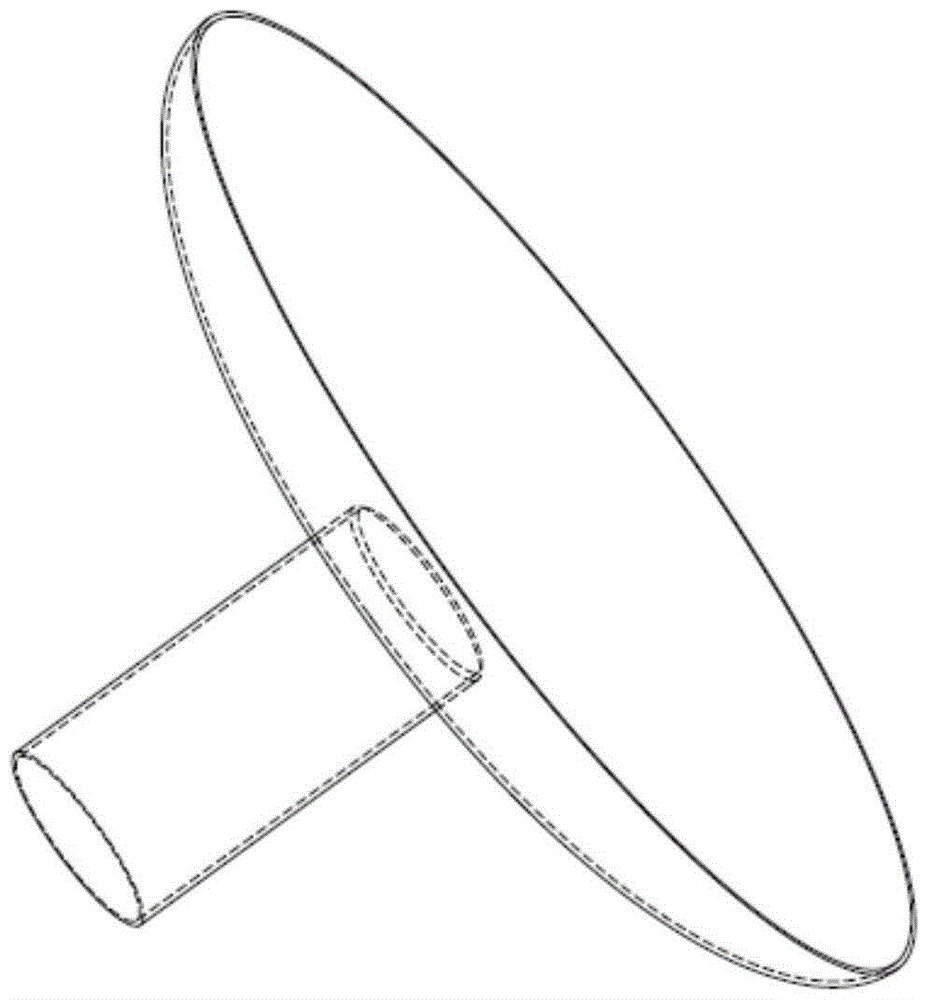

Inclined tubulation particle/supercritical CO2 moving bed heat exchanger

The invention discloses an inclined staggered tubulation particle / supercritical CO2 moving bed heat exchanger. The moving bed heat exchanger comprises a moving bed main body, inlet supercritical CO2 gas distribution pipes, outlet supercritical CO2 gas collecting pipes, supercritical CO2 serpentine heat exchange pipes, a particle distributor and a particle collecting hopper, wherein the moving bedmain body is used for providing a heat exchange place for the high-temperature particles and the supercritical CO2 in the pipe, the inlet supercritical CO2 gas distribution pipes are used for uniformly distributing the low-temperature supercritical CO2 in each heat exchange pipe, the outlet supercritical CO2 gas collecting pipes are used for collecting high-temperature supercritical CO2 gas, the supercritical CO2 serpentine heat exchange pipes are installed in the moving bed main body according to the preset inclination angle, and are used for providing a heat exchange channel for the supercritical CO2 in the pipe and eliminating accumulation of particles in the pipe, the particle distributor is used for uniformly entering the high-temperature particles into the moving bed main body, and the particle collecting hopper is used for collecting the falling low-temperature particles. According to the heat exchanger, by changing the inclination angle and the arrangement structure of the heatexchange pipes in the moving bed heat exchanger, the turbulence of the particles is enhanced, the contact surface and the heat exchange coefficient are increased, and the efficiency of the heat exchanger is greatly improved.

Owner:TSINGHUA UNIV

Heating head heat exchanger of solar Stirling engine

InactiveCN104265499AUniform energy supplyReduce in quantityFrom solar energyHot gas positive displacement engine plantsSolar lightRelative phase

The invention provides a heating head heat exchanger of a solar Stirling engine and relates to a transduction component applied to a solar optothermal Stirling engine. The heating head heat exchanger is characterized by being composed of four heating head assemblies arranged in circular array, wherein the heating head assembly comprises a piston cavity, a back heating cavity, heating tubes and temperature sensors; each piston cavity and each back heating cavity are mounted on the engine by a relative phase angle of 90 degrees; N heating tubes are mounted between the piston cavity and the back heating cavity of each pair so that a solar light receiving curved surface formed by use of the N heating tubes arranged together can be formed; a plurality of temperature sensors are arranged in each piston cavity and on the heating tubes, respectively. The heating head heat exchanger of the solar Stirling engine has the characteristics of novel and simple structure, simple and convenient manufacturing, reduction of manufacturing difficulty, increase of yield, reduction of manufacturing cost and the like, and is a novel heating head heat exchanger integrated with economic efficiency and practicability.

Owner:DALIAN GREAT OCEAN NEW ENERGY DEV

Heat exchanger

ActiveCN105841512ASimple structureReduce manufacturing costStationary conduit assembliesTubular elementsEngineeringMoving bed heat exchanger

The invention discloses a heat exchanger which is formed by stacking laminations. Each lamination is provided with at least one flanging hole. One side of each flanging hole extends outwards and is higher than the surface of the corresponding lamination to form an insertion connection part, and the other side of each flanging hole forms a connected part. After the laminations are stacked, the insertion connection parts of the lower laminations and the connected parts of the upper laminations are connected in a sealing mode to form pipeline space. The pipeline spaces are equivalent to inner channels of pipelines in the prior art, pipelines of a finned heat exchanger in the prior art are omitted, the structure of the heat exchanger is simplified, and production cost of the product can be effectively reduced. The pipeline spaces are composed of the insertion connection parts and the connected parts on the laminations, the material of the pipeline spaces and the material of the laminations are the same, and no media exist, so that thermal resistance is low, heat exchange efficiency can be effectively improved, and the heat exchanger has the advantages of being small in thermal resistance, high in heat exchange efficiency, convenient to manufacture, wide in application range and the like.

Owner:佛山市威沃热能科技有限公司

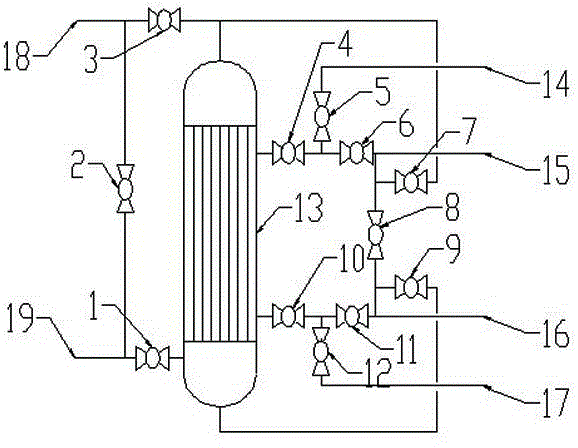

Novel heat exchanger

InactiveCN105783578ASolve the problem of single heat transfer methodTo achieve the purpose of saving energy and reducing consumptionHeat exchange apparatusEngineeringHot Temperature

A novel heat exchanger comprises a heat exchanger body. A material B feeding pipeline communicates with the lower portion of one side of the heat exchanger body and is provided with a first valve. A material B discharging pipeline communicates with the upper portion of one side of the heat exchanger body and is provided with a third valve. The material B discharging pipeline communicates with the material B feeding pipeline through a pipeline with a second valve. A material A feeding pipeline communicates with the lower portion of the other side of the heat exchanger body and is provided with a tenth valve and an eleventh valve. According to the novel heat exchanger, the problem that the heat exchange manner of an existing heat exchanger is single can be solved. Multiple heat exchange manners that a refrigerant or a heating medium exchanges heat with high-temperature materials or low-temperature materials, and the low-temperature materials exchange heat with the high-temperature materials can be utilized at the same time, and the purposes of energy saving and consumption reducing are achieved.

Owner:HUBEI XINGFA CHEM GRP CO LTD

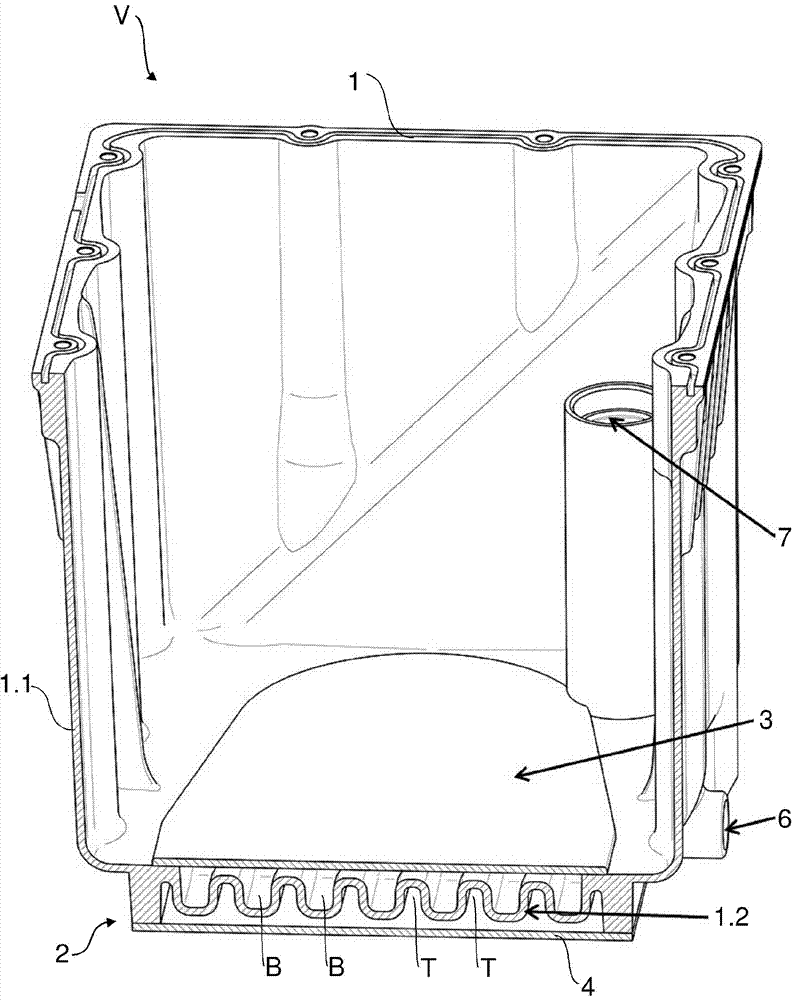

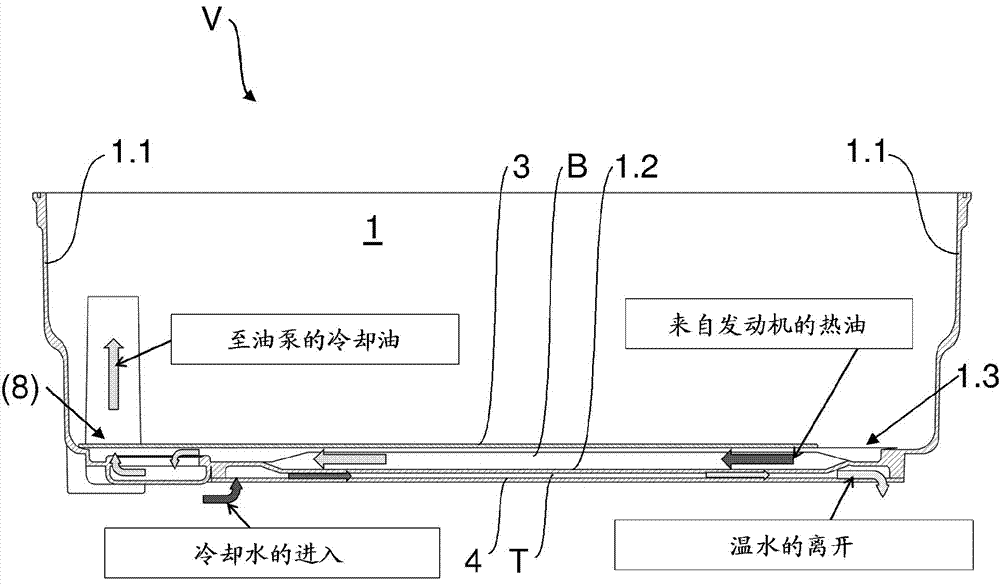

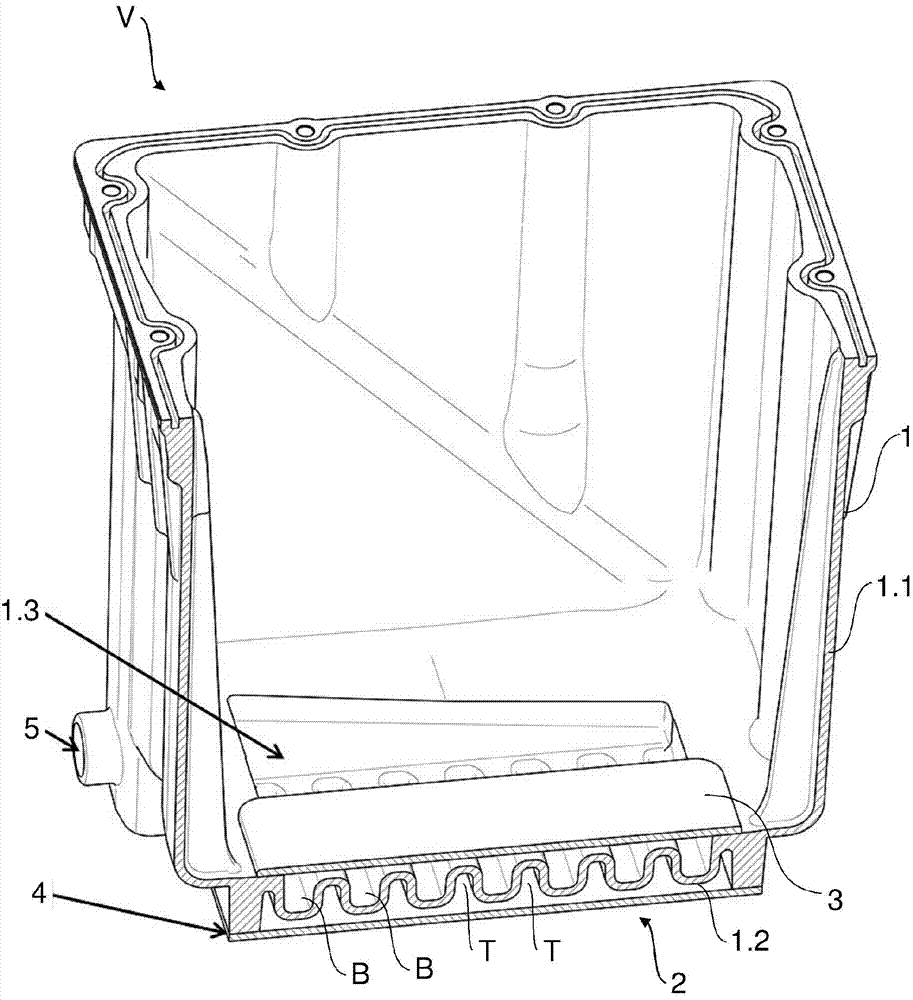

Housing element with integrated heat exchanger

A device (V) is provided, in particular an oil sump, for an engine and / or a transmission arrangement. The device (V) includes a housing element (1) for the formation of a side wall structure (1.1) and for holding an operating fluid and a heat exchanger (2) for heat exchange with the operating fluid, the heat exchanger configured to be supplied with temperature control fluid and having a heat exchange element (1.2). The heat exchange element (1.2) forms at least one through-flow duct (B) for the through flow of the operating fluid and at least one through-flow duct (T) for the through flow of the temperature control fluid.

Owner:MAN NUTZFAHRZEUGE AG

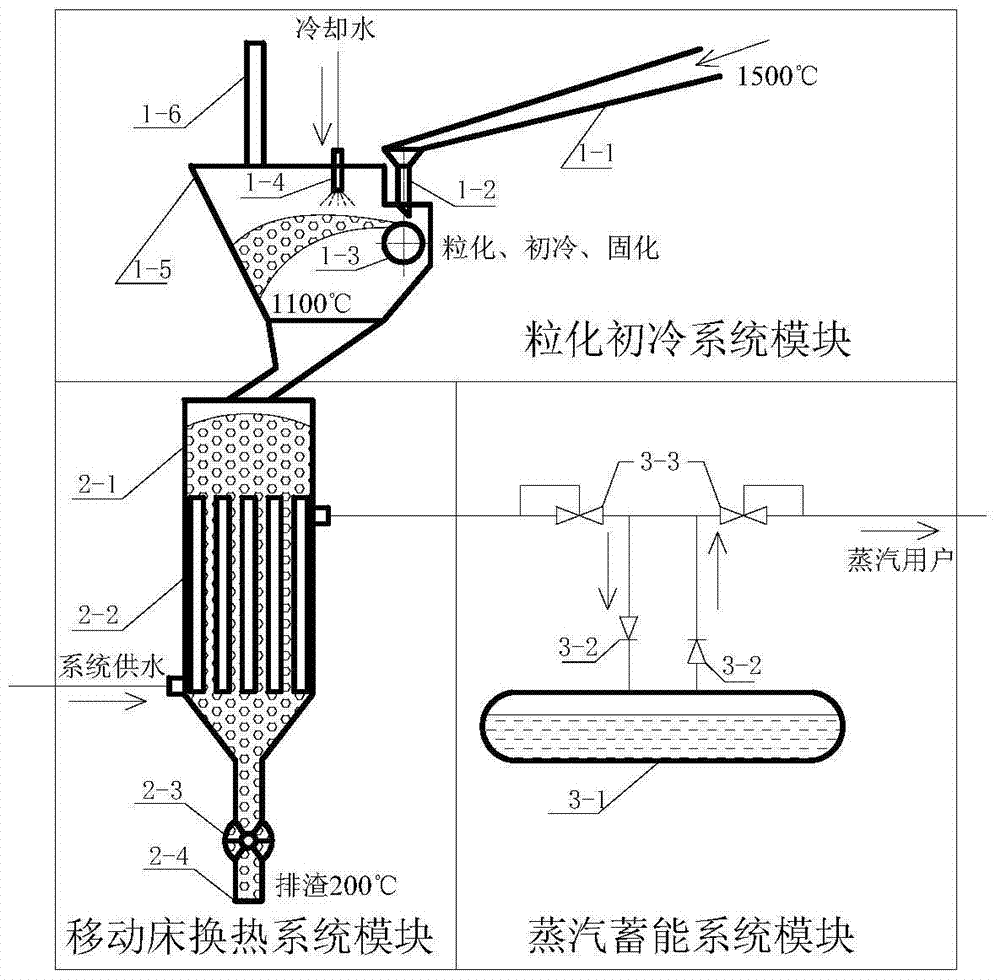

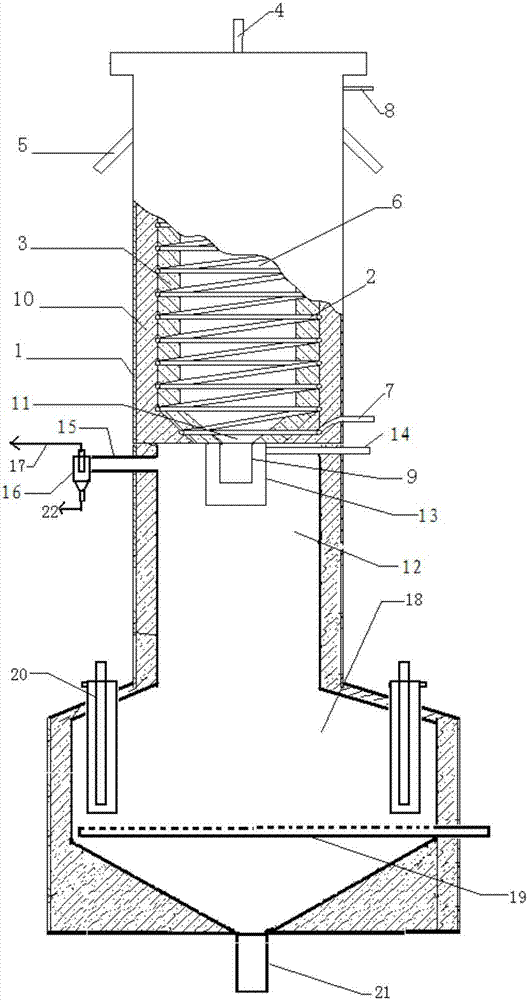

Metallurgical slag waste heat recovery equipment and method

ActiveCN104946826BReduce water consumptionIncreasing energy efficiencyRecycling and recovery technologiesMetallurgical slagWater vapor

The invention discloses metallurgical slag waste heat recovery equipment and a method. The metallurgical slag waste heat recovery equipment comprises a granulation primary-cooling system module and a moving bed heat exchange system module, wherein the granulation primary-cooling system module comprises a metallurgical slag tank, a hopper feeder, a granulation wheel, an atomizer and a granulation primary-cooling box body; the moving bed heat exchange system module comprises a slag storage bin, a moving bed heat exchanger and a slag discharge wheel; high-temperature molten metallurgical slag is fed to the granulation wheel through the hopper feeder from the metallurgical slag tank from top to bottom, is crushed through the granulation wheel and flies out in the tangential direction, the metallurgical slag is in contact with cooling water mist provided by the atomizer in the flying process and subjected to water quenching to generate surface-cured metallurgical slag particles and water vapor, the metallurgical slag particles enter the slag storage bin and the water vapor is discharged out; and the metallurgical slag particles in the slag storage bin are constantly supplied to the moving bed heat exchanger, the moving bed heat exchanger is provided with a shell and a pipeline, the metallurgical slag particles move in the shell from top to bottom, the pipeline is arranged in the shell and water flows in the pipeline from bottom to top. The invention further provides a method adopting the equipment.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

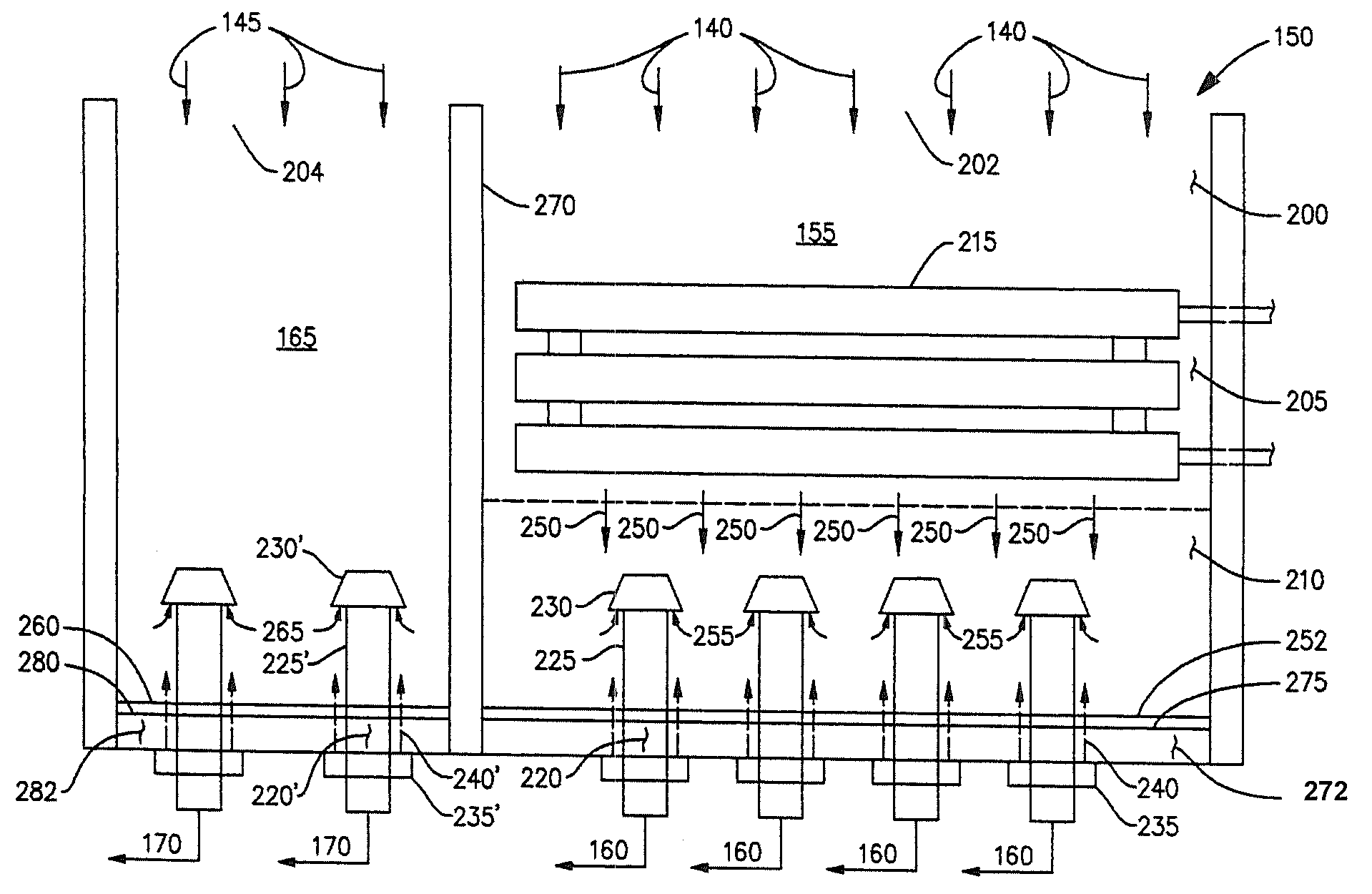

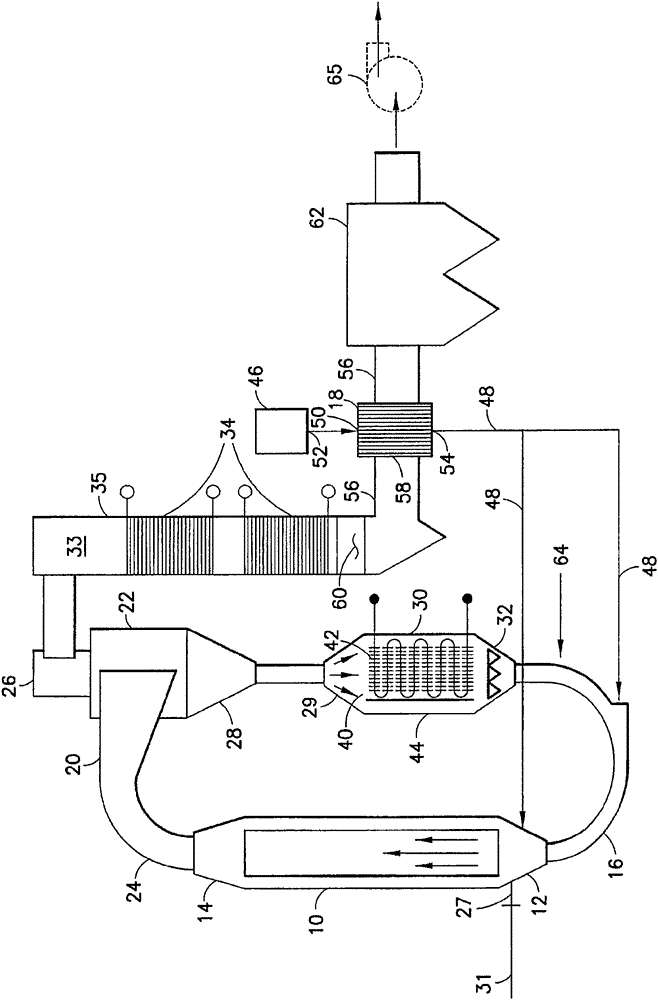

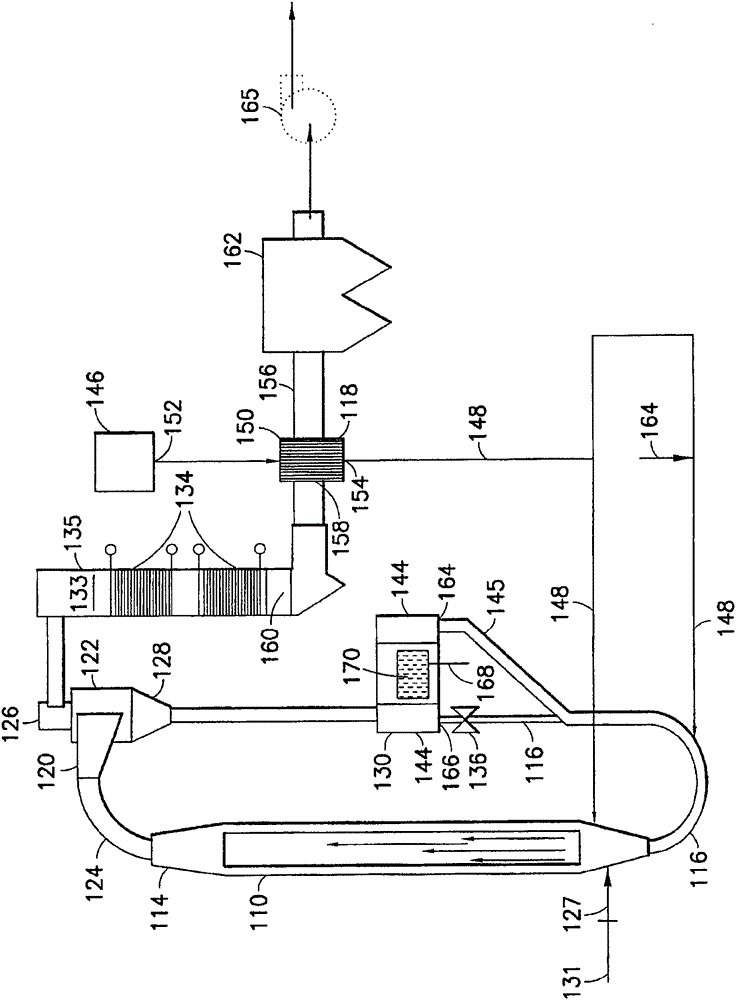

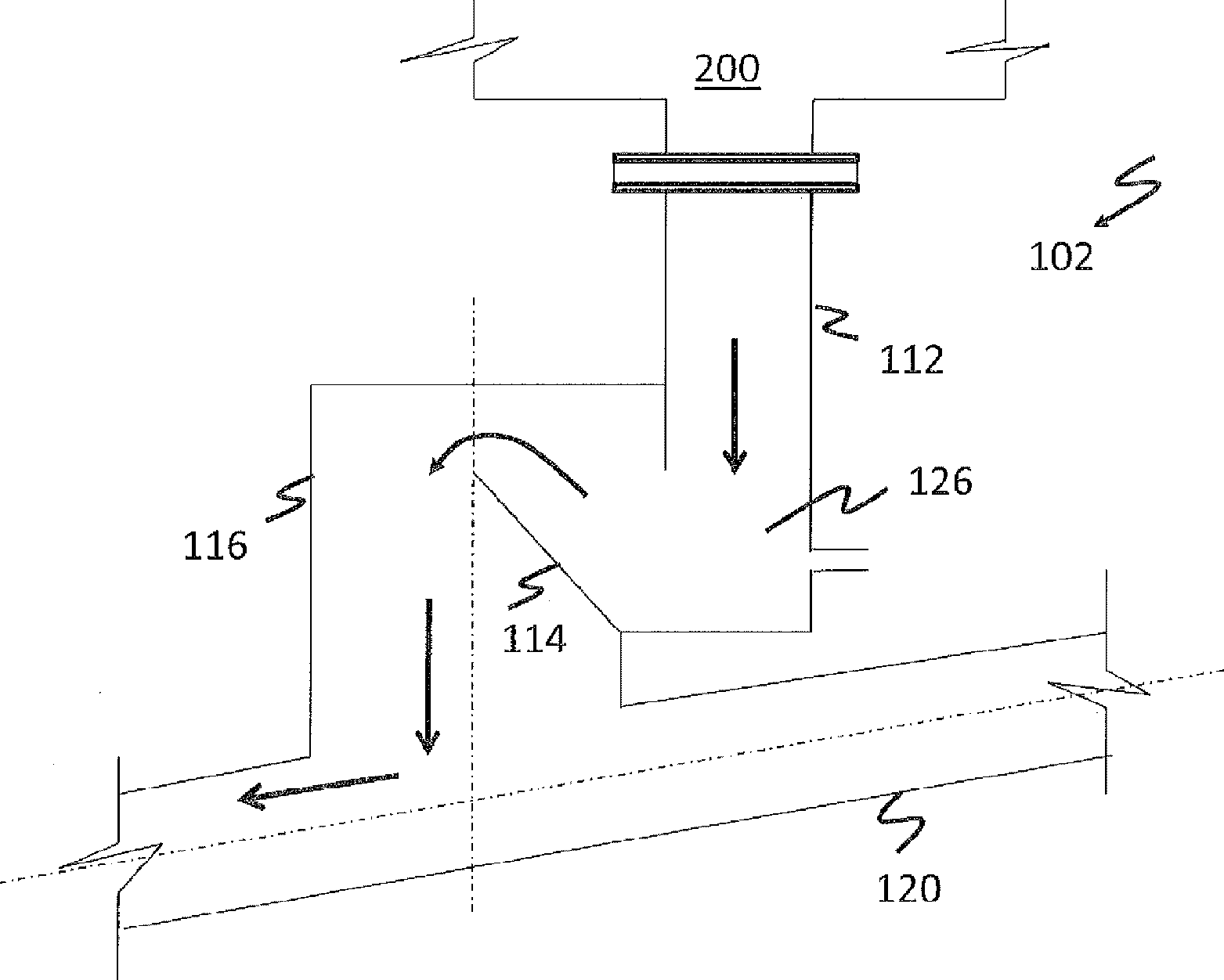

Moving bed heat exchanger for circulating fluidized bed boiler

ActiveUS9163829B2Simple technologyFluidized bed combustionStationary tubular conduit assembliesWorking fluidFluidized bed

A moving bed heat exchanger (155) includes a vessel having an upper portion (200), a lower portion (210) with a floor (272) including a discharge opening therein, and an intermediate portion (205). The vessel directs a gravity flow of hot ash particles (140) received thereby from the upper portion (200) through the intermediate portion (205) to the floor (272) of the lower portion (210) of the vessel, where the hot ash particles (140) are collected. Tubes in the intermediate portion (205) of the vessel direct a flow of working fluid in a direction substantially orthogonal to the direction of the gravity flow of the hot ash particles (140) through the intermediate portion (205) of the vessel such that heat from the hot ash particles (140) is transferred to the working fluid thereby cooling the hot ash particles (140).

Owner:GENERAL ELECTRIC TECH GMBH

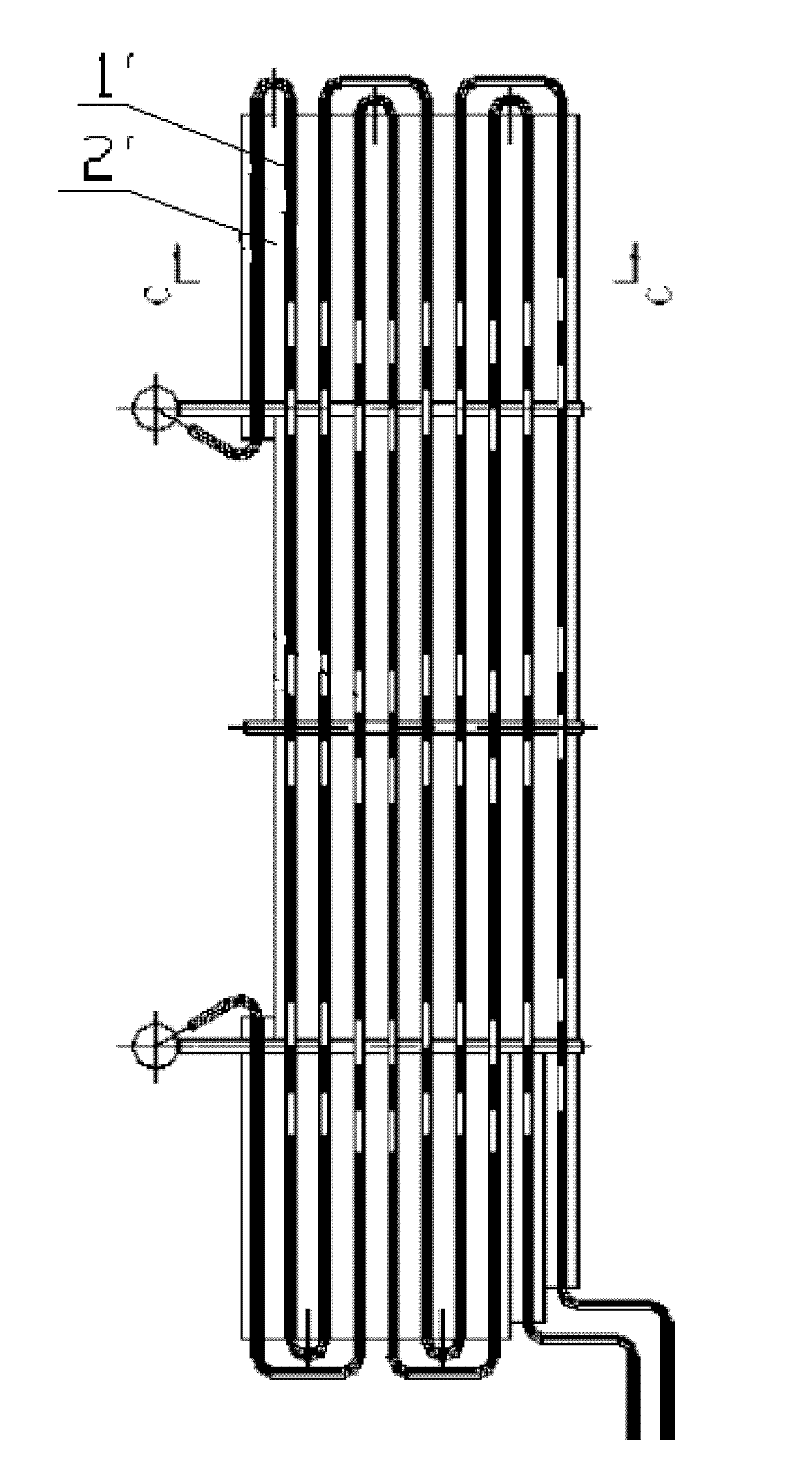

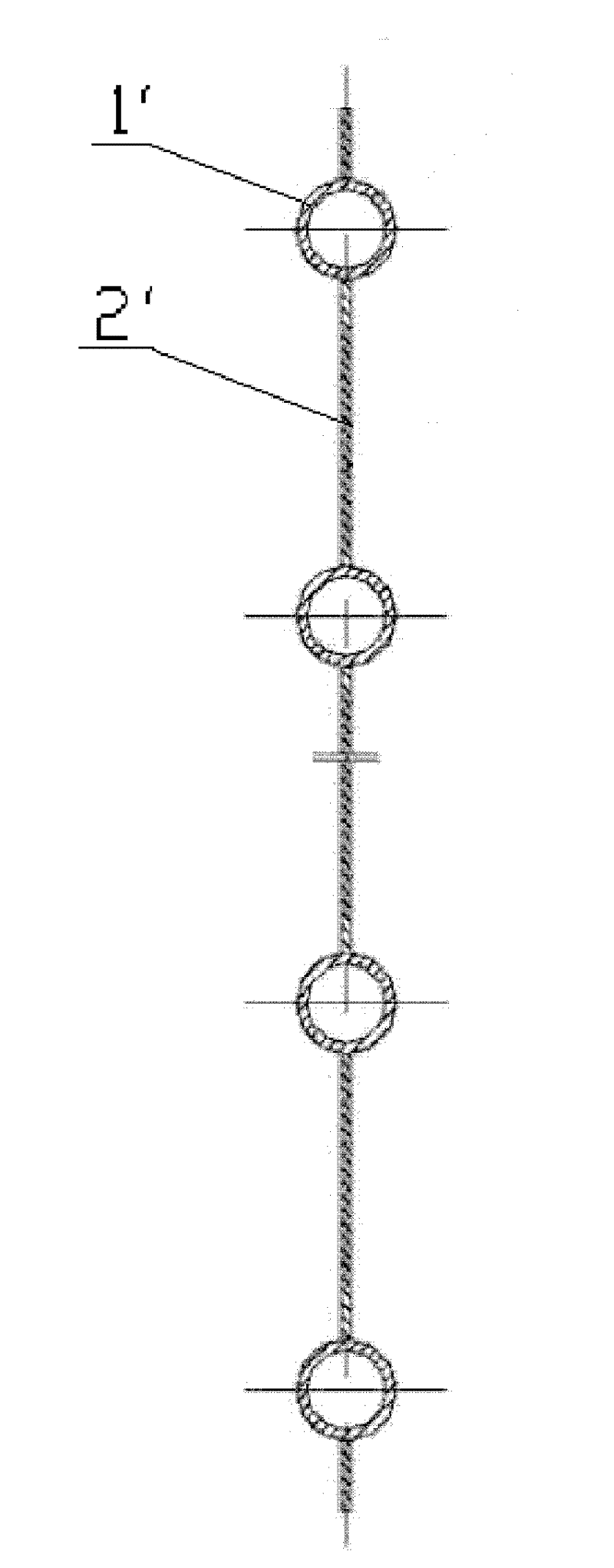

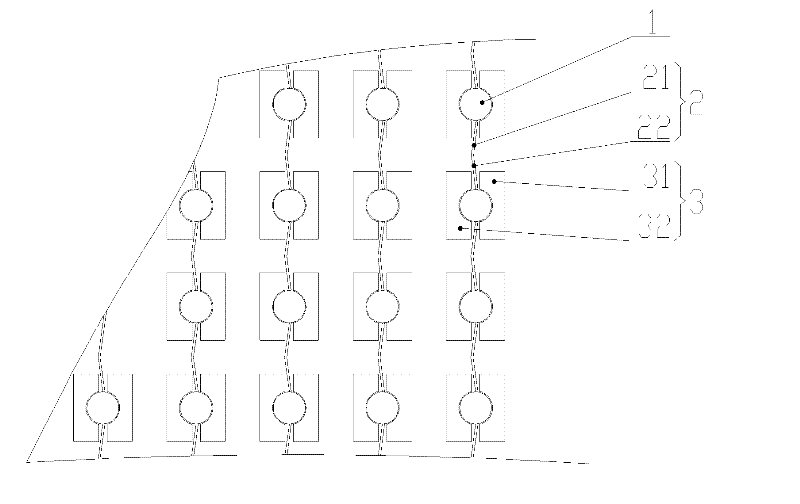

Heat exchange tube and smoke heat exchanger

ActiveCN102183166BTake up a lot of spaceIncrease the heat exchange areaStationary conduit assembliesTubular elementsEngineeringRadiant heat exchange

The invention discloses a heat exchange tube. The heat exchange tube comprises a snake-shaped tube which is bent to form a plurality of heat exchange tube sections (1); axial heat exchange fins (2) are connected with both sides of each of the heat exchange tube sections (1) respectively along the axial direction; a plurality of radial heat exchange fins (3) are connected with the heat exchange tube sections (1); and each of the radial heat exchange fins (3) comprises a first heat exchange fin section (31) and a second heat exchange fin section (32) which are connected with both sides of the corresponding heat exchange tube section (1) along the radial direction and clamp the corresponding radial heat exchange fin (2) in a gap between the first heat exchange fin section (31) and the secondheat exchange fin section (32). Due to the structural design of the heat exchange tube, the heat exchange area of the heat exchange tube can be increased effectively on the basis of not increasing ornot increasing the occupied area in a large scale, so that the heat exchange efficiency of the heat exchange tube can be improved obviously. The invention also discloses a smoke heat exchanger comprising the heat exchange tube.

Owner:FUJIAN LONGKING

Dry granulation and cinder discharge type Y-type entrained flow bed gasifier

InactiveCN107090312ASimple structureExtended service lifeGasification processes detailsCombined combustion mitigationSyngasFluidized bed

The invention provides a dry granulation and cinder discharge type Y-type entrained flow bed gasifier, which mainly comprises a gasifier, a gas-cinder separator, a fluidized bed heat exchanger, a moving bed heat exchanger and the like, and the gasifier is divided into a gasifying chamber and a chilling chamber, which are partitioned by a sectioned conical end enclosure in the middle; the shell of the gasifying chamber is composed of a heat-insulating material layer, a cooling jacket and a wear-resistant material layer sequentially from the outside to the inside; the bottom of the gasifying chamber is provided with a coolant inlet, and the top is provided with a coolant outlet; a top nozzle is arranged at the center of the top of the gasifying chamber, and more than three side nozzles are evenly arranged along the circumference on the upper part; the center of the sectioned conical end enclosure is provided with a gasified product discharge outlet, which leads into the chilling chamber; a chilling nozzle is arranged outside the gasified product discharge outlet, the upper part of the chilling chamber is provided with a crude syngas outlet connected into the gas-cinder separator, and the fluidized bed heat exchanger is arranged on the bottom of the chilling chamber. The residual heat of gasified product is sufficiently utilized, and the problem of black water and salt-containing wastewater is eliminated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

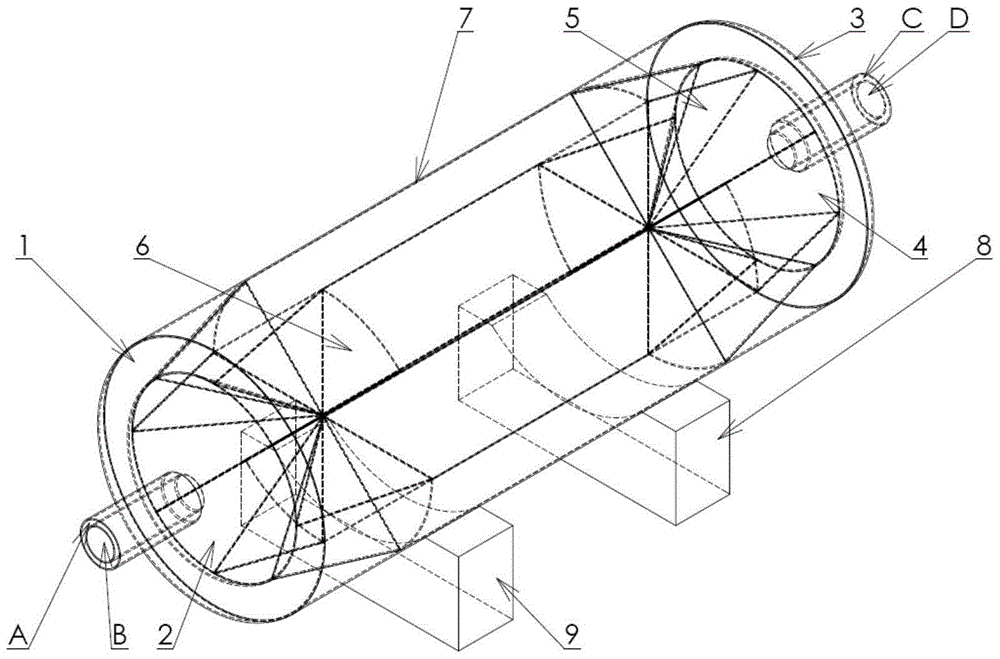

A new type of full countercurrent rotating non-mixing heat exchanger

ActiveCN104180693BReduce weightSimple structureMoving conduit heat exchangersEngineeringTemperature difference

The invention discloses a novel total-reverse-flow rotary non-mixing heat exchanger. The novel total-reverse-flow rotary non-mixing heat exchanger is characterized in that portions, except for a heat exchanger base, of the heat exchanger can rotate in service procedures, and the heat exchanger comprises a heat exchanger barrel, flow channel converters, inner seal heads of the heat exchanger, outer seal heads of the heat exchanger and the heat exchanger base; total-reverse-flow non-mixing rotary heat exchange effects can be realized for two channels of fluids, and the purpose of improving the heat exchange effects can be achieved. The heat exchanger barrel is a cylindrical barrel with two or an even number of internal barriers, the even number is larger than 2, the barrel is uniformly divided into an even number of equal portions by the barriers, a fan-shaped flow channel is formed by each left barrier, the corresponding right barrier and a cylindrical barrel portion sandwiched by the left barrier and the right barrier, and the flow channel converters are used as flow channel conversion devices. The novel total-reverse-flow rotary non-mixing heat exchanger has the advantages that the heat exchanger is used in fluid heat exchange places and is high in heat exchange efficiency, average heat exchange temperature difference and outlet temperature uniformity and free of mixing among the heat exchange fluids; the novel total-reverse-flow rotary non-mixing heat exchanger is wide in application and can be applied to heat transfer enhancement or temperature homogenization among different fluids in industrial application, and the like.

Owner:TIANJIN UNIV

Oxy-combustion steam generator

InactiveCN102449395BFluidized bed combustionIndirect carbon-dioxide mitigationPlate heat exchangerFlue gas

In one method for operating a steam generator, a transport reactor is provided. Only a substantially pure oxygen feed stream is introduced into the transport reactor in an amount sufficient to maintain the transport reactor at or above a specified system load. The specified load refers to the system load when the only substantially pure oxygen feed stream is supplied to the transfer reactor at the minimum flow rate used to operate the transfer reactor. In the presence of a feed stream of substantially pure oxygen, the fuel is combusted to produce a flue gas comprising solid matter. Solid matter is separated from the flue gas and sent to a heat exchanger. The heat exchanger may be one of a moving bed heat exchanger or a fluidized bed heat exchanger. Solid matter is directed to a transport reactor to aid in the combustion process.

Owner:GENERAL ELECTRIC TECH GMBH

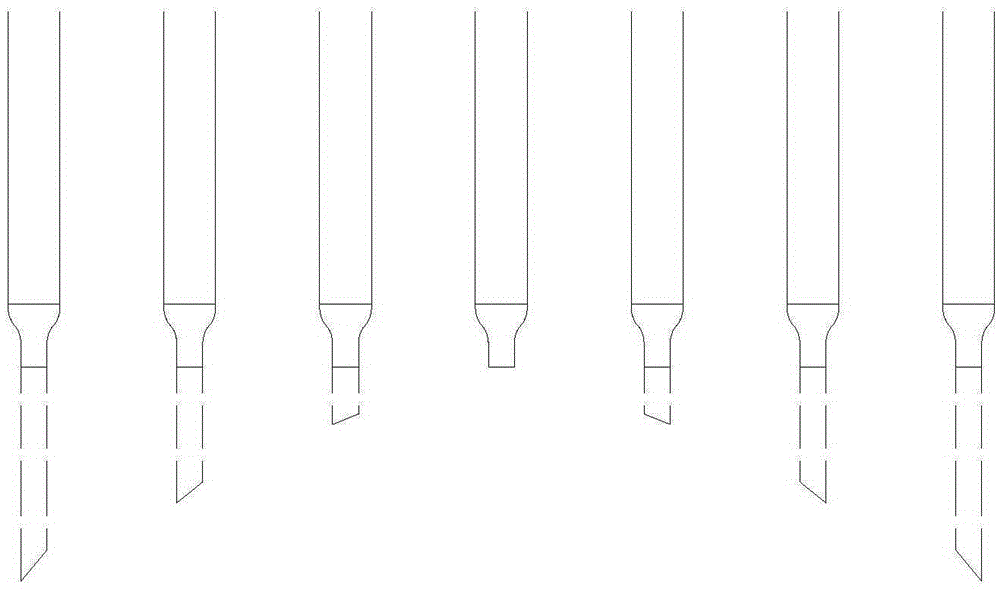

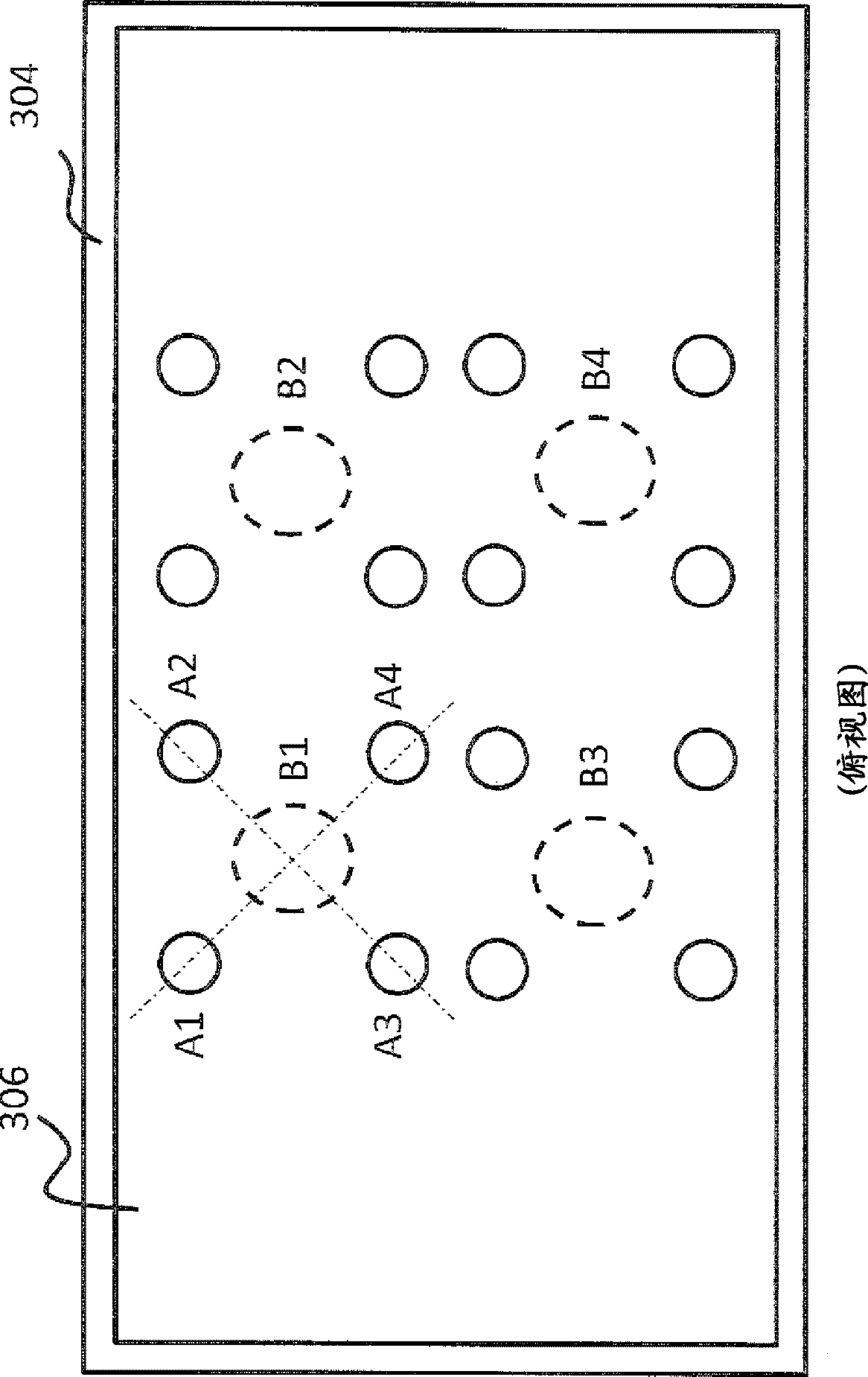

Orifice plate for controlling solids flow, methods of use thereof and articles comprising the same

Disclosed herein is an orifice plate comprising one or more plates having orifices disposed therein; the orifices being operative to permit the flow of solids from a moving bed heat exchanger to a solids flow control system; where the orifice plate is downstream of a tube bundle of the moving bed heat exchanger and upstream of the solids flow control system and wherein the orifice plate is operative to evenly distribute the flow of solids in the solids flow control system.

Owner:GENERAL ELECTRIC TECH GMBH

Heat exchange heat pipe of water heater

InactiveCN106813396AGuaranteed heat transfer efficiencySolving Welding DifficultiesFluid heatersCombustion chamberWater flow

The invention discloses a water heater heat exchange heat pipe, which is characterized in that it comprises a combustion chamber 1 and a main heat exchanger 2, and the main heat exchanger 2 has heat exchange pipes 3 and heat exchange fins 4. The combustion chamber 1 is surrounded by more than one hollow plate, the hollow plate of the combustion chamber 1 communicates with the heat exchange tube 3, there is water flowing in the hollow plate and the heat exchange tube 3 for heat exchange, and the cross section of the hollow plate can be hollow and circular , prismatic, rectangular and other geometric shapes. By adopting the above solution, the present invention has a simple structure, maintains the heat exchange efficiency of the thin-walled heat exchange tube, and simultaneously solves the problem of welding between the heat exchange tube and the tube sheet.

Owner:李苗苗

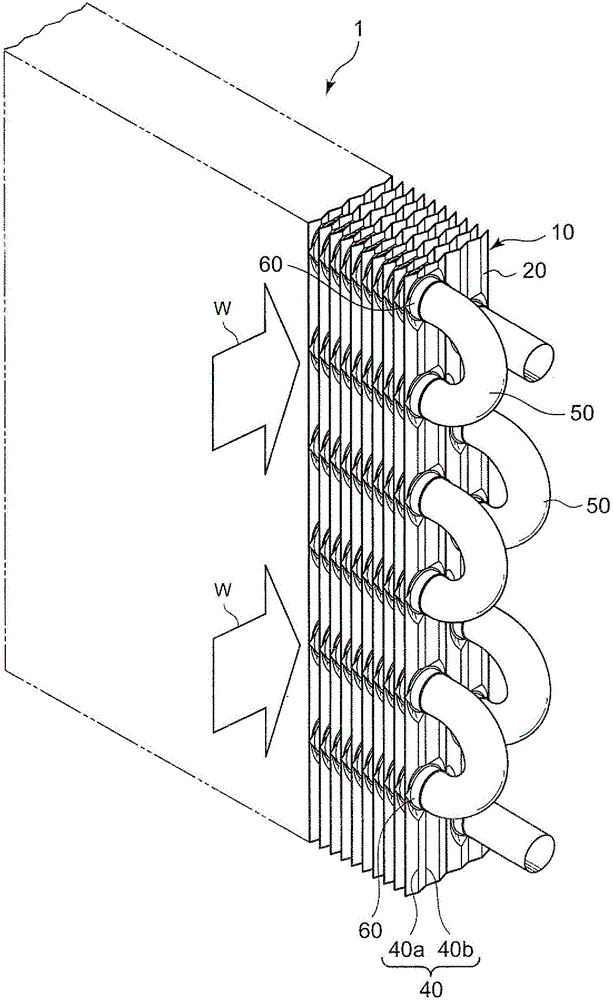

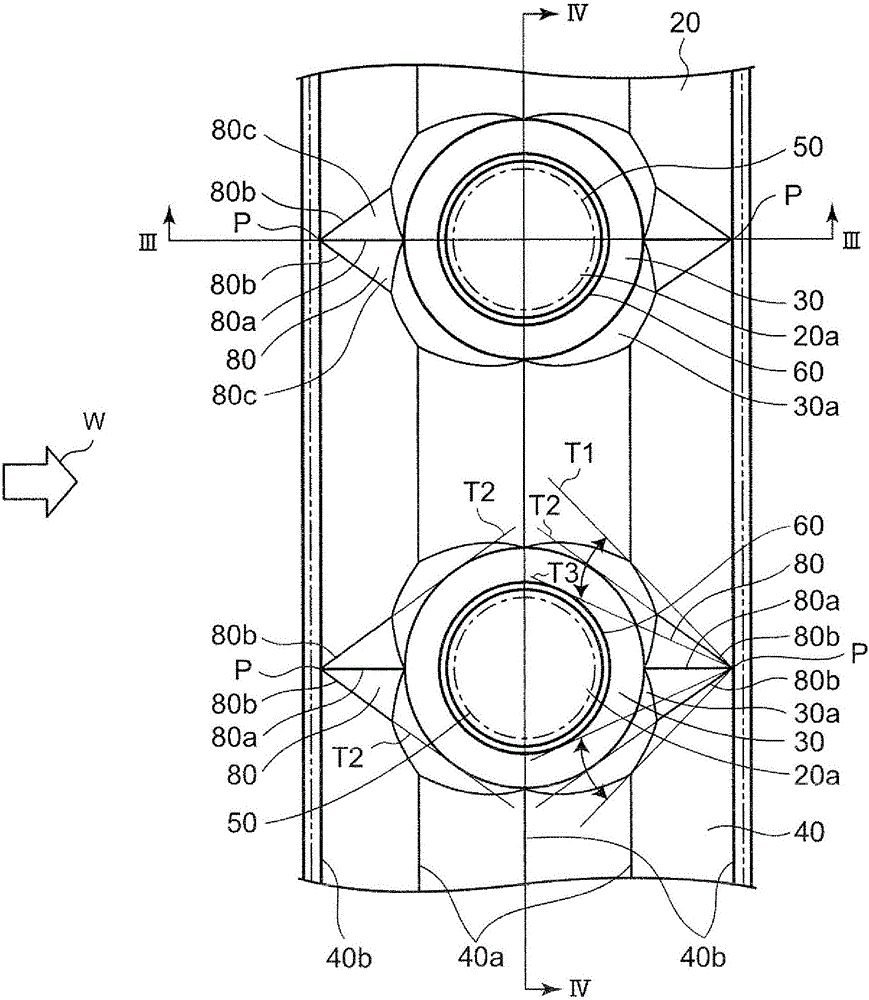

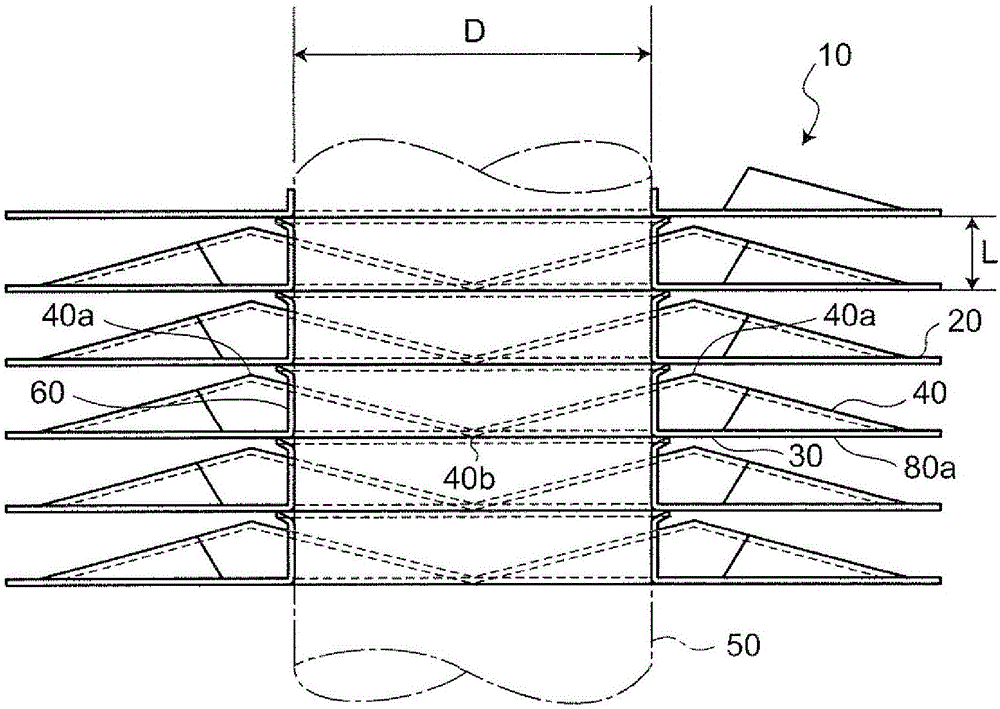

Finned tube heat exchanger

ActiveCN103608639BSpeed up the flowImprove heat transfer performanceHeat exhanger finsStationary conduit assembliesEngineeringTubes types

Provided is a fin tube heat exchanger in which multiple stacked fins are formed into a particular shape so as to make the air flow between the fins smoother and which exhibits excellent heat transfer performance by increasing the ridge lines that are the lines of intersection between surfaces in order to enhance the heat transfer performance between the fins and the air flow. A fin tube heat exchanger wherein: stacked heat-transfer fins each have a wedge-shaped dent (80) on the upstream wind side and the downstream wind side of a fin collar (60); the dent (80) is configured from a first ridge line (80a) extending in the column direction in the upstream wind side and downstream wind side of the fin collar (60), and two second ridge lines (80b) which are arranged in the shape of a V and which derive from the vertex (P) of the first ridge line (80a) and a ridge line (40b) on the valley side extending in the step direction; and two V-shaped slanted planes are formed by means of the first ridge line (80a) and the second ridge lines (80b).

Owner:PANASONIC CORP

Online test system of high temperature calcined coke heat exchanger

ActiveCN102998138BEasy to measureFacilitate the study of heat transfer mechanismsMaterial heat developmentStructural/machines measurementElectrical resistance and conductanceUltrasonic sensor

An online test system of a high temperature calcined coke heat exchanger belongs to the technical field of waste heat utilization of solid high temperature materials and is characterized in that a high temperature calcined coke waste heat utilizing water-steam circulation system is connected with a water-steam parameter test system and a material temperature test system. The water-steam parameter test system comprises a first heat resistor (8), a second heat resistor (42), an ultrasonic flowmeter (18), a two-phase-flow flowmeter (29) and a sight glass (34), the first heat resistor (8) and ultrasonic sensors (11) are arranged on an outer heat exchange water inlet pipe (9) between a third adjusting valve (16) and an outer heat exchanger (4), the first heat resistor (8) and an ultrasonic sensor (11) are arranged on an inner heat exchanger water inlet pipe (10) between a fourth adjusting valve (17) and an inner heat exchanger (7), and the two ultrasonic sensors (11) are connected with the ultrasonic flowmeter (18) through signal wires (27). The online test system is capable of conducting comprehensive performance tests on high temperature calcined coke special heat exchangers on a pot type calcining furnace.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com