Heating head heat exchanger of solar Stirling engine

A Stirling engine and heating head technology, which is applied in the direction of using solar energy to generate mechanical power, machines/engines, and hot gas variable capacity engine devices, can solve the problems of high casting cost, high overall cost, low qualification rate, etc. The effect of improving the quality and accuracy of the elbow, increasing the pass rate and cost share, and improving the product pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

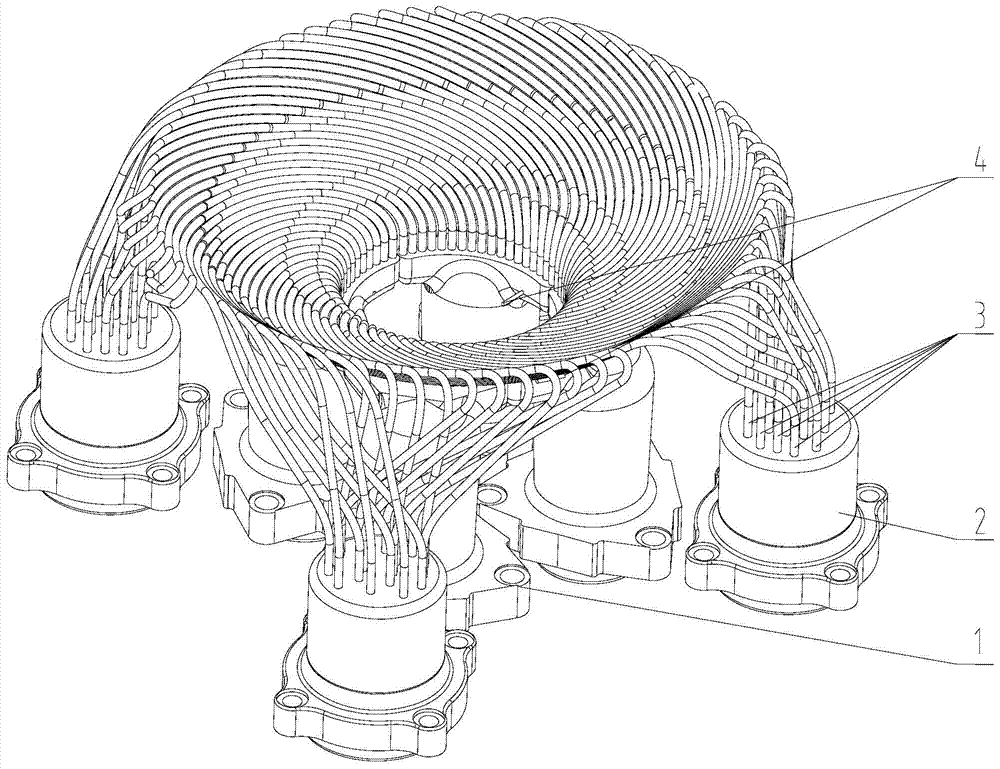

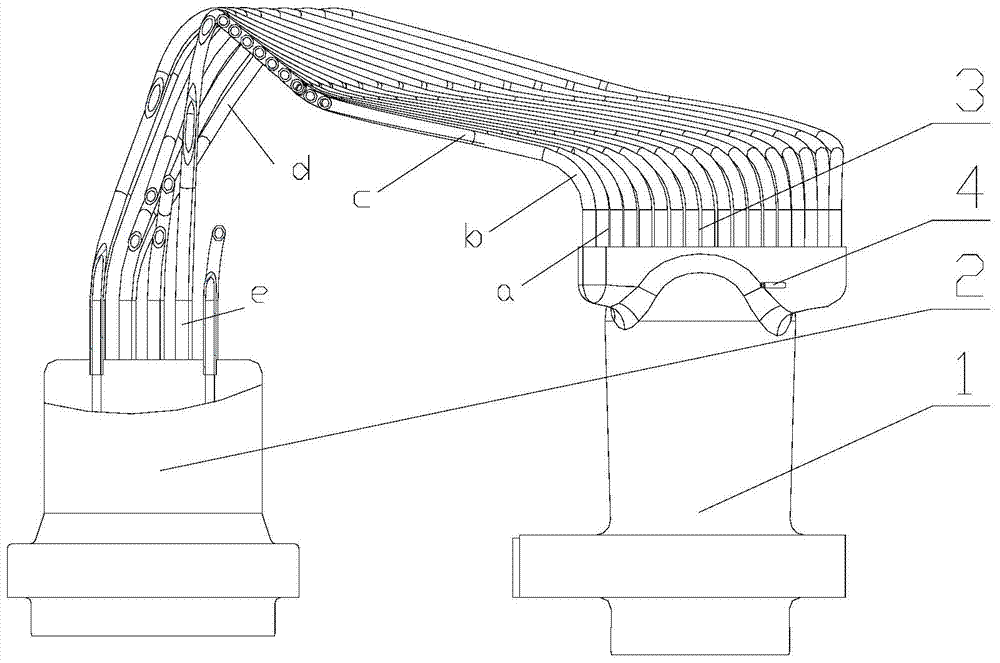

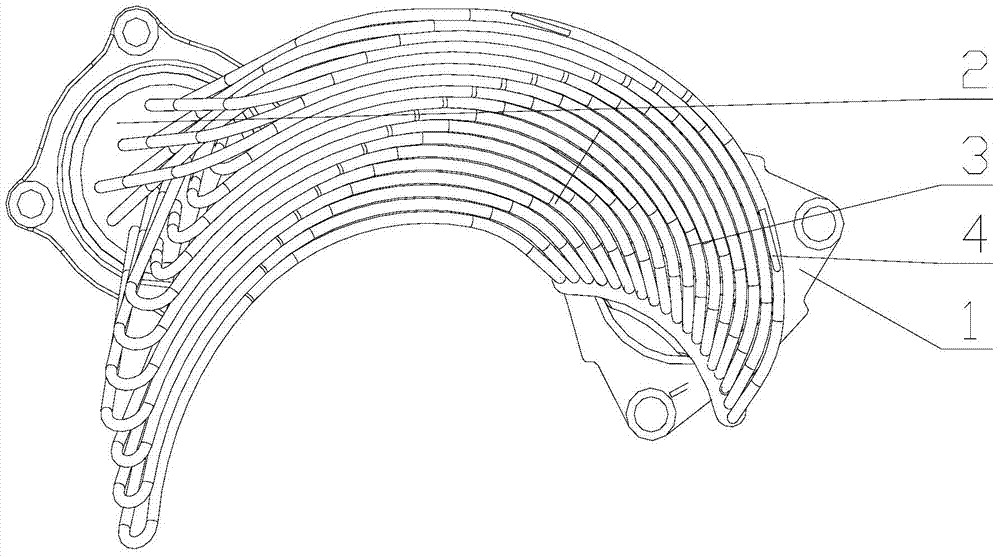

[0034] The specific embodiment of the present invention is as shown in the accompanying drawings, a solar Stirling engine heating head heat exchanger; it is characterized in that the solar Stirling engine heating head heat exchanger is composed of four groups of heating head assembly circular arrays; heating The head assembly includes a piston cavity 1, a heat recovery cavity 2, a heating pipe 3, and a temperature sensor 4; the piston cavity and the heat recovery cavity 2 are installed on the engine, and the piston cavity and the heat recovery cavity 2 are installed on the The relative phase angle at the body installation position is 90°; N heating tubes 3 are installed between each pair of piston chambers and the regenerating chamber 2, forming a sun light receiving curved surface composed of N heating tubes 3 arranged and combined; A plurality of temperature sensors 4 are respectively installed in the piston chamber and the heating tube 3 .

[0035] The lower part of the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com