Patents

Literature

37results about How to "Reduce quenching process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

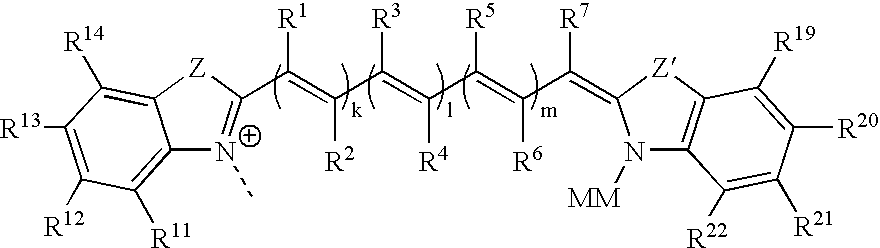

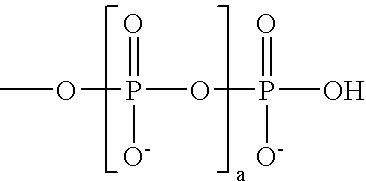

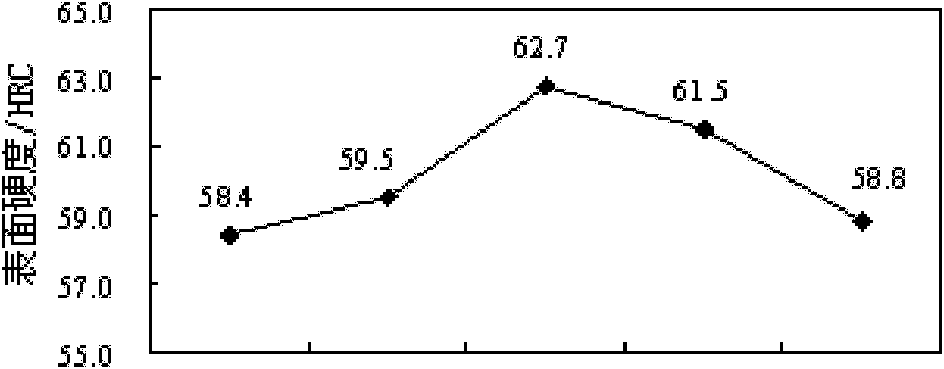

Mobility-Modifying Cyanine Dyes

InactiveUS6716994B1Easy to getGood water solubilityMethine/polymethine dyesSugar derivativesCyanineNucleotide

The present invention provides a novel class of fluorescent cyanine dye compounds that are modified at one of the hetercyclic ring nitrogen atoms with a mobility-modifying moiety that permits the electrophoretic mobilities of polynucleotides labeled with the mobility-modifying cyanine dyes to be adjusted or tuned in a predictable fashion while retaining enzymatic activity. The ability to predictably tune the relative electrophoretic mobilities of the dyes permits the creation of sets of mobility-matched fluorescent dyes of a variety of structures for a variety of applications, including fluorescence-based 4-color nucleic acid sequencing reactions.

Owner:APPL BIOSYSTEMS INC

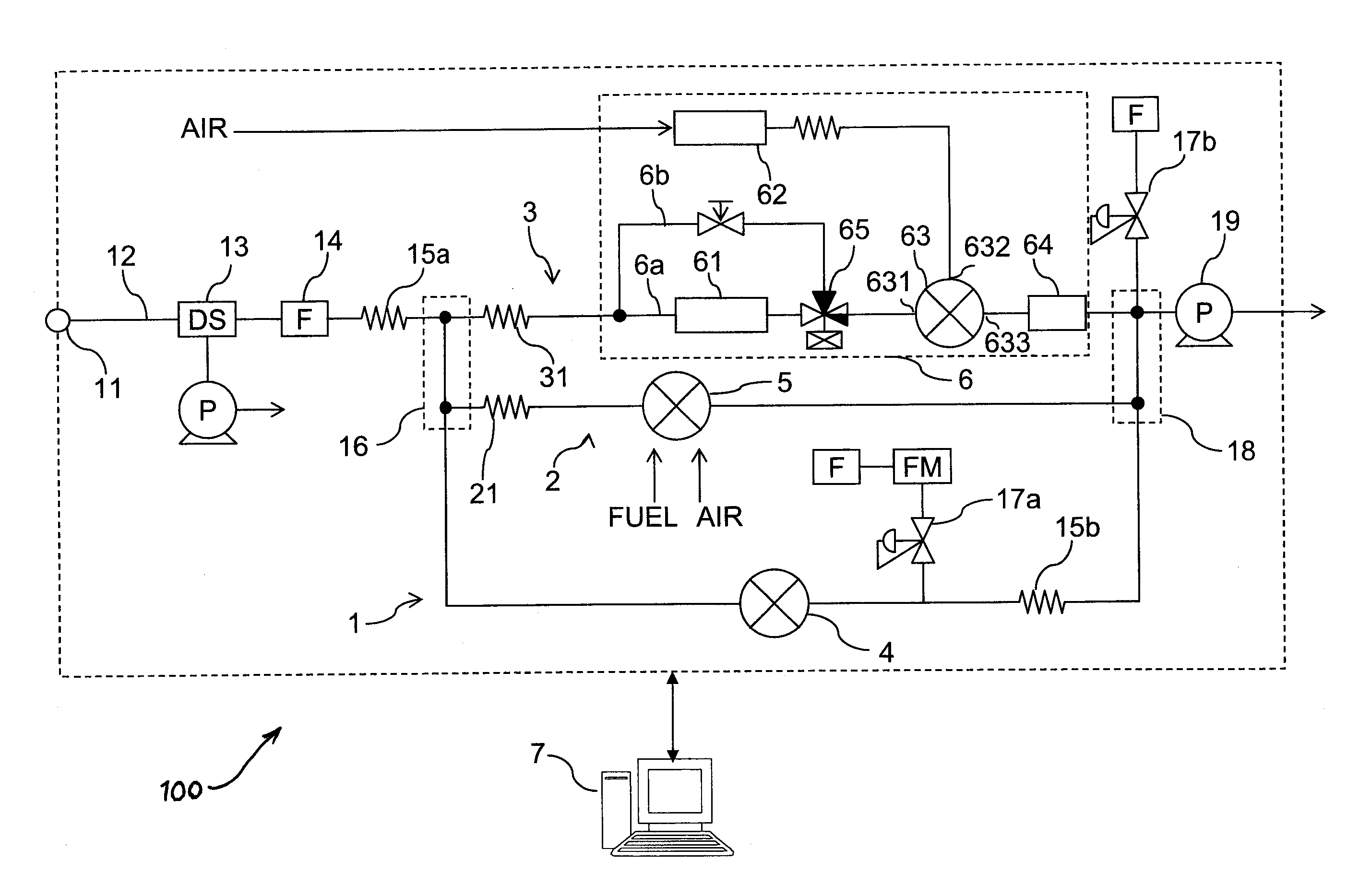

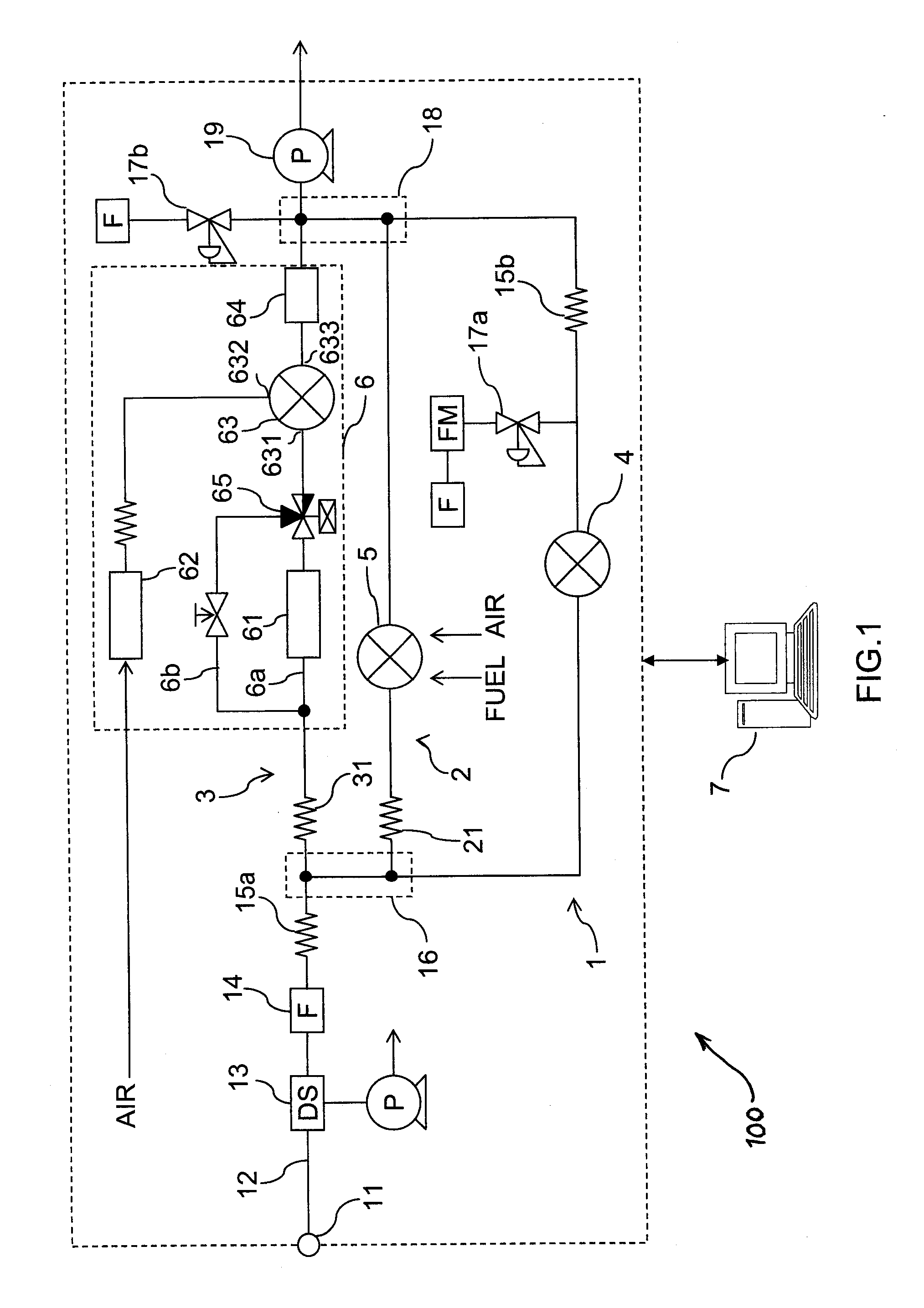

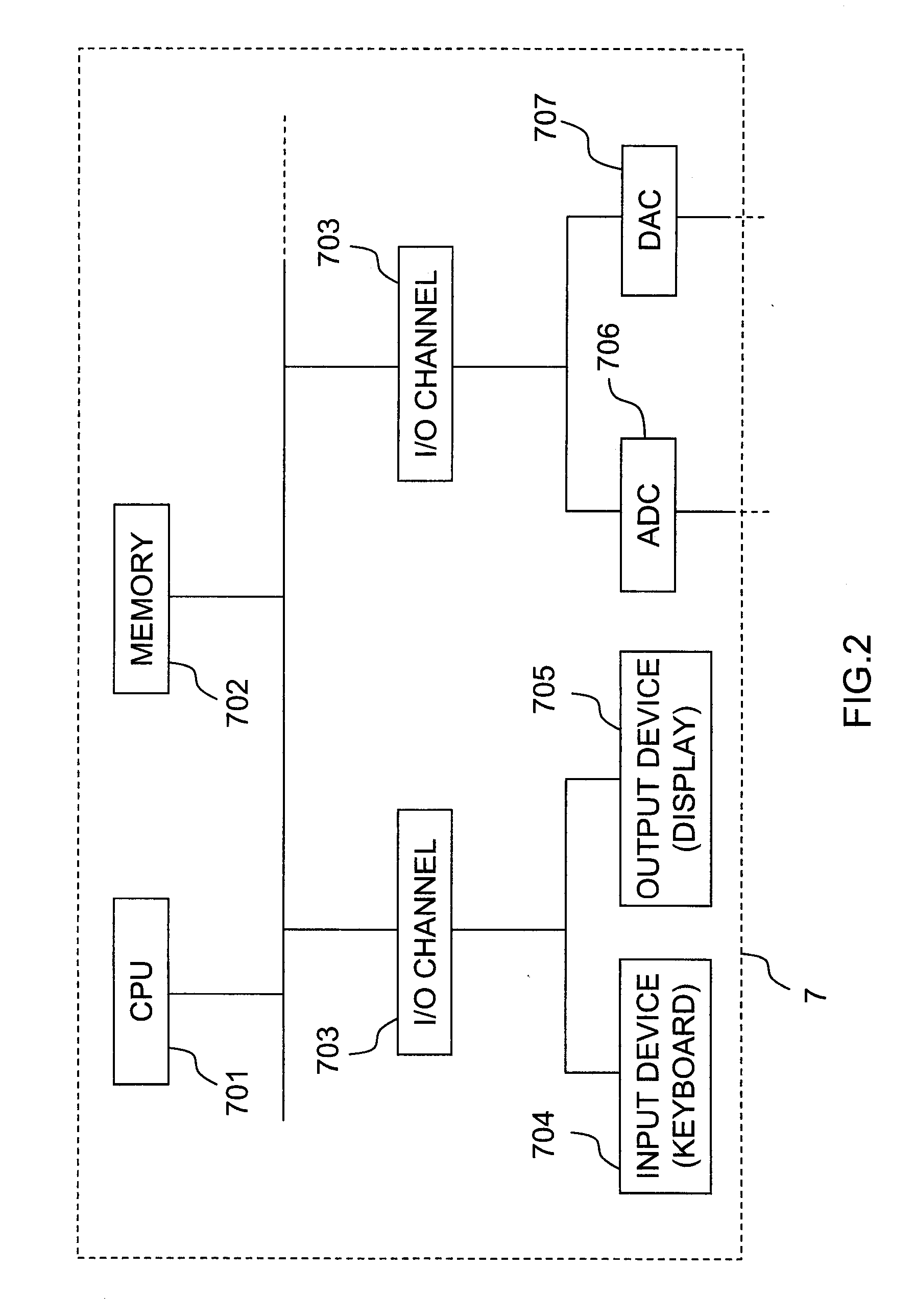

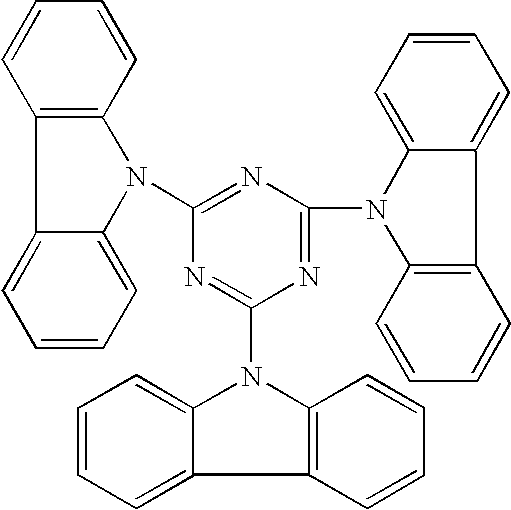

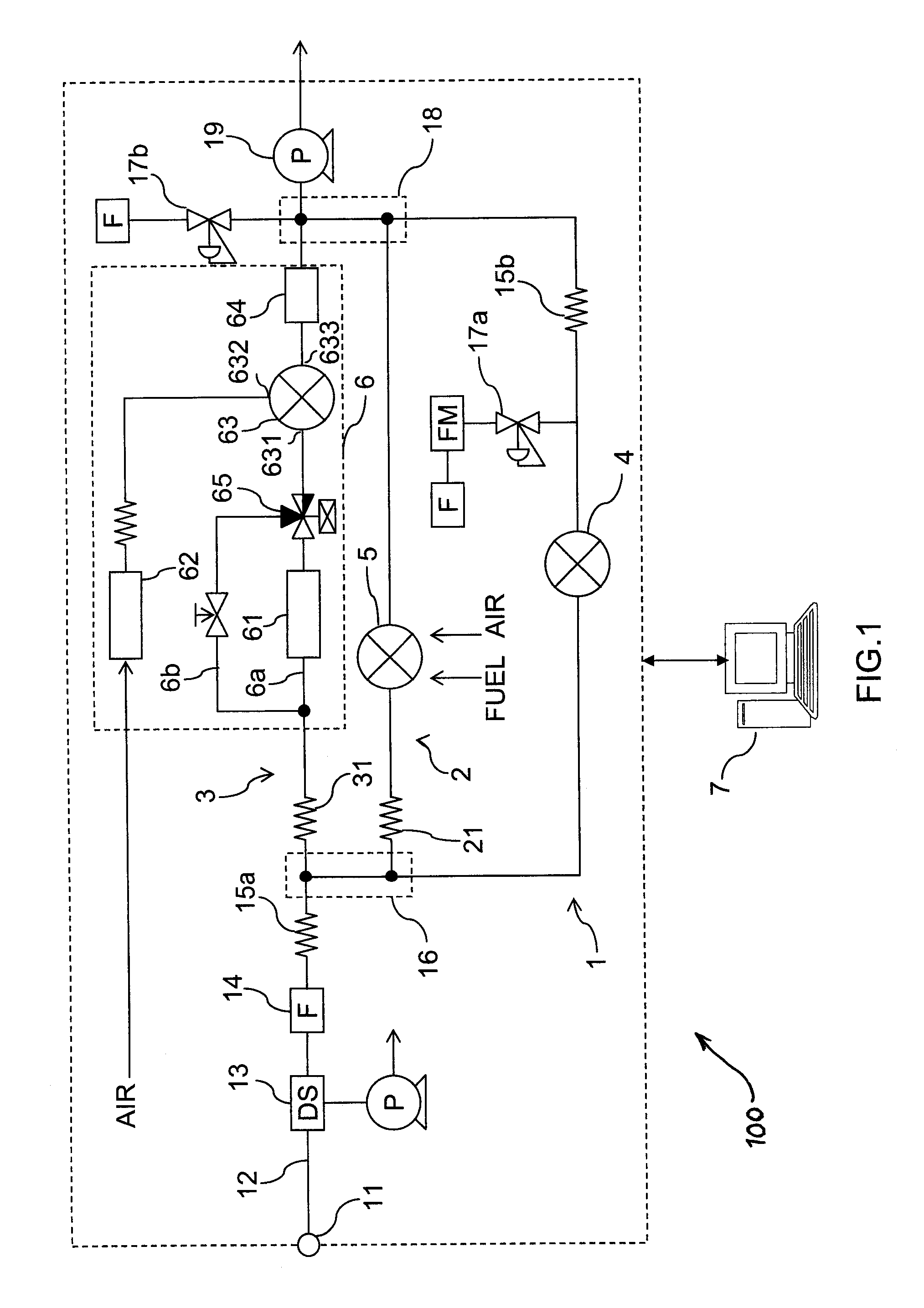

Exhaust gas component analyzer

ActiveUS20060236752A1High measurement accuracySave electricityAnalysing fluids using sonic/ultrasonic/infrasonic wavesInternal-combustion engine testingEngineeringInternal combustion engine

An exhaust gas analyzer includes a main flow path and at least one sub-flow path. Exhaust gas from an internal combustion engine is introduced to the main flow path; sub-flow paths are parallel to the main flow path. Plural kinds of analyzers are mounted on the main flow path and sub-flow paths to measure concentration of multiple components in the exhaust gas. Actual measurement values of the concentration for the measured components are obtained. A deviance from a true value generated to an actual measurement value due to a mutual influence of the measured components is corrected based on at least one actual measurement value.

Owner:HORIBA LTD

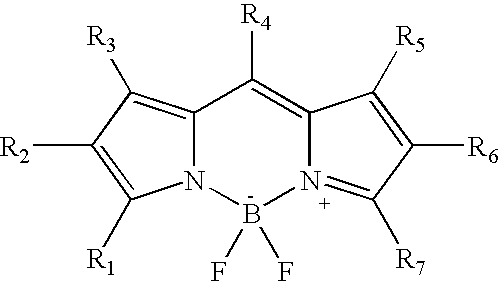

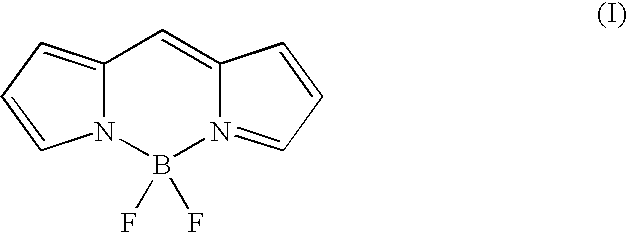

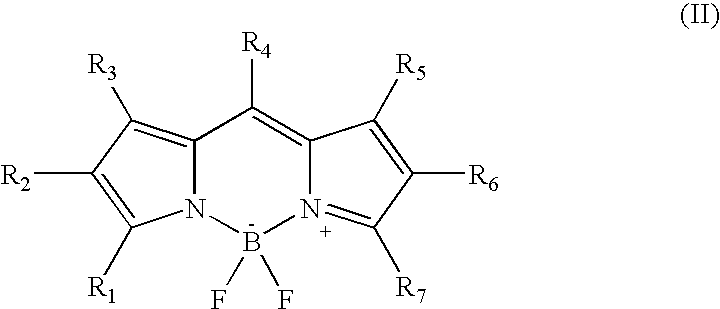

Two-photon absorbing dipyrromethenboron difluoride dyes and their applications

InactiveUS20040157231A1Reduce yieldImprove excitation efficiencySilicon organic compoundsMaterial analysis by observing effect on chemical indicatorBenzoxazoleFluorescence

The invention relates to a separation free bioanalytical assay method for measuring an analyte from a biological fluid or suspension comprising of microparticles as a bioaffinity binding solid phase, a biospecific secondary reagent labelled with a two-photon fluorescent dipyrrometheneboron difluoride dye, focusing the laser into the reaction suspension, measuring two-photon excited fluorescence from single microparticles when they randomly float or are guided by the radiation pressure of the excitation laser through the focal volume of the laser beam using a two-photon fluorescent dipyrrometheneboron difluoride dye. The dye has the structure (II): Either at least one of groups R1, R2, R3, R4, R5, R6 and R7 is a substituted or unsubstituted phenyl, thienyl, pyrrolyl, furanyl, oxazolyl, isoxazolyl oxadiazolyl, imidazolyl, benzoxazolyl, benzothiazolyl, benzimidazolyl, benzofuranyl, indolyl, conjugated ethenyl, dienyl or trienyl group, and at least one of the groups R1, R2, R3, R4, R5, R6 or R7 is substituted to yield a chemically reactive group that can be used for selective covalent linkage to other molecules, and at least one of the groups R1, R2, R3, R4, R5, R6 or R7 is substituted to yield a water-solubilizing group, and the remaining groups of R1, R2, R3, R4, R5, R6 and R7 are each independently selected from the group consisting of hydrogen, halogen, alkyl, cyano, carboxy, each of which can optionally be substituted; or groups R1, R2, R3, R5, R6 and R7 are substituted or unsubstituted alkyl groups, R4 is a hydrogen or a substituted or unsubstituted alkyl, and at least one of the groups R1, R2, R3, R4, R5, R6 or R7 is substituted to yield a chemically reactive group that can be used for selective covalent linkage to other molecules; and at least one of the groups R1, R2, R3, R4, R5, R6 or R7 is su

Owner:ARCTIC DIAGNOSTICS

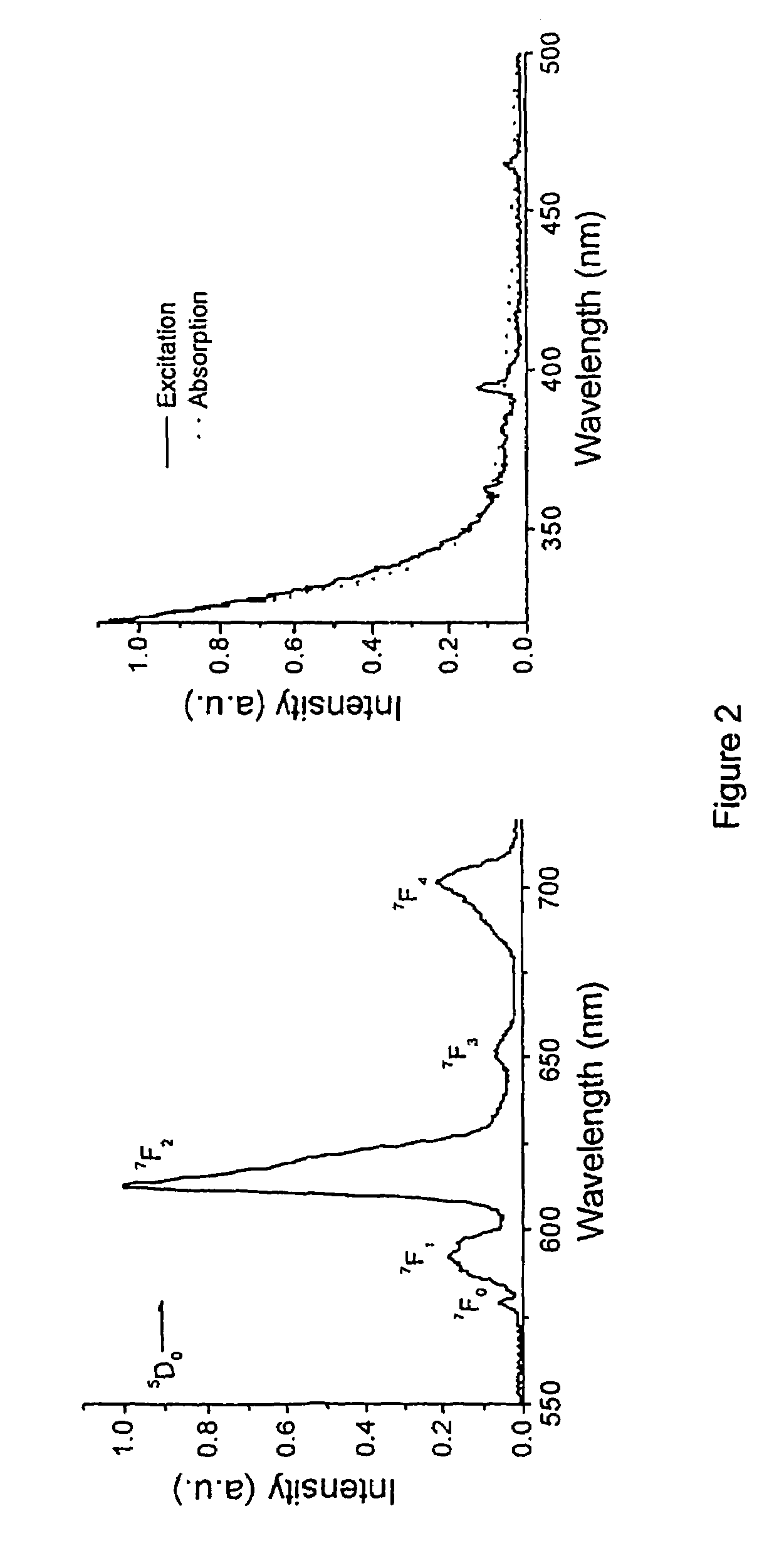

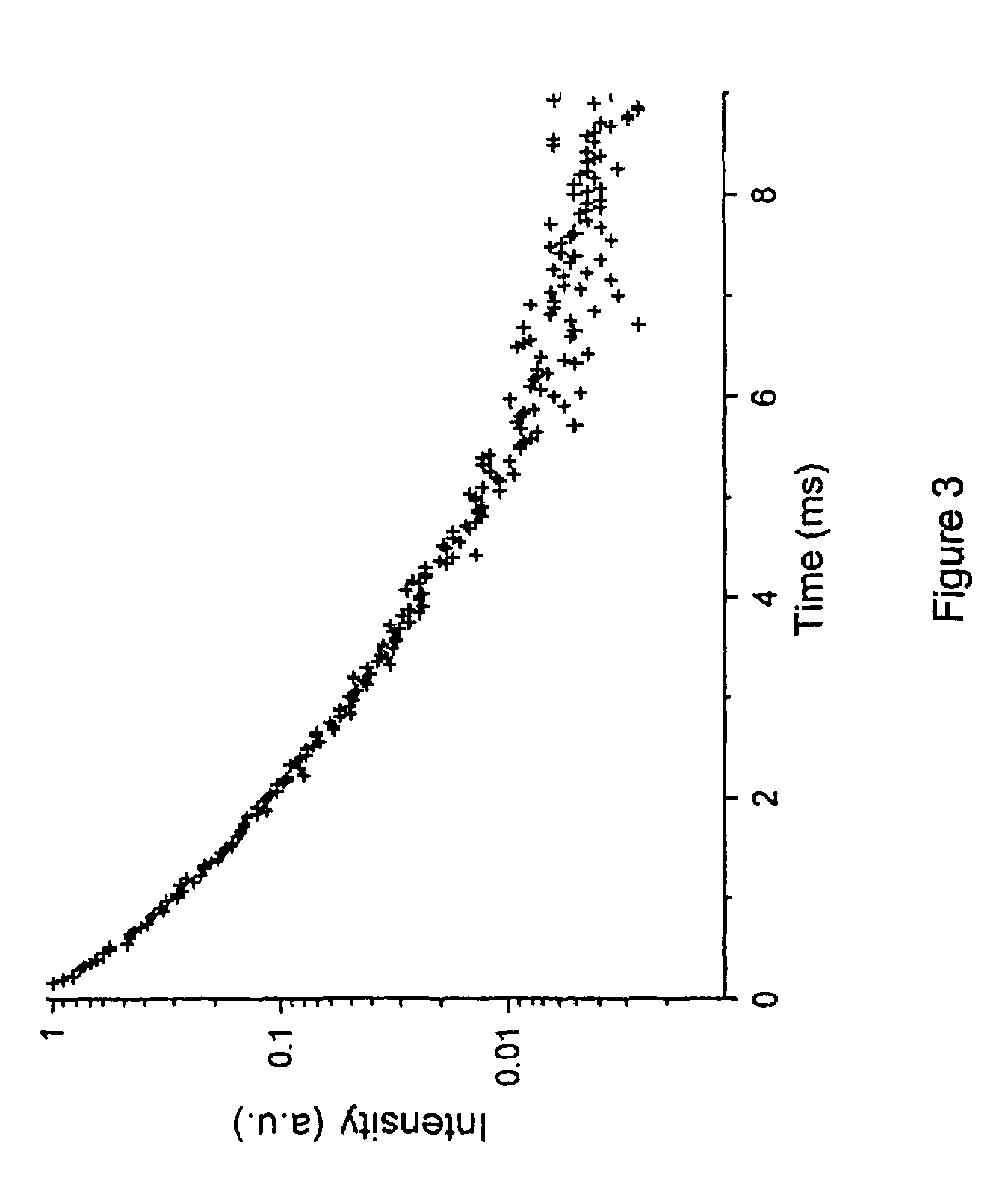

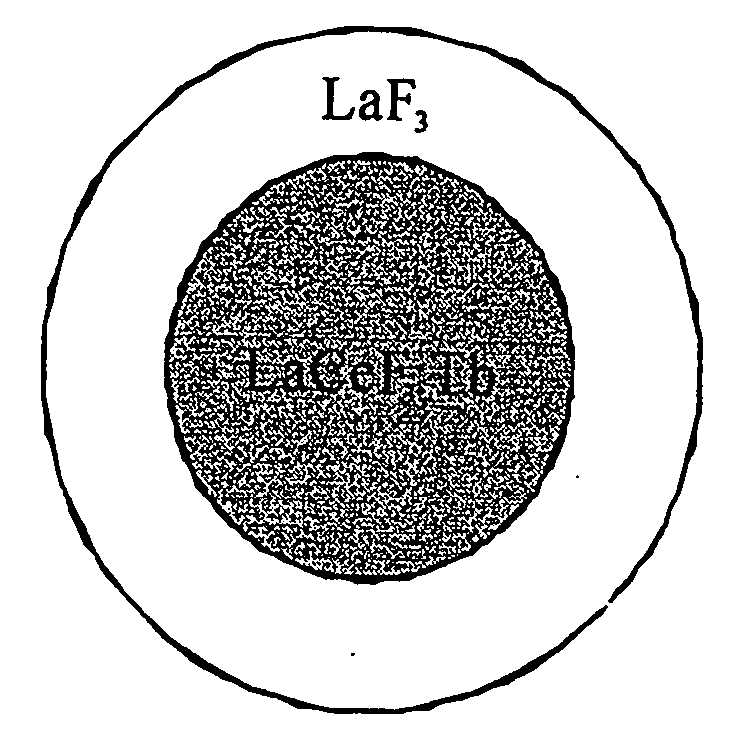

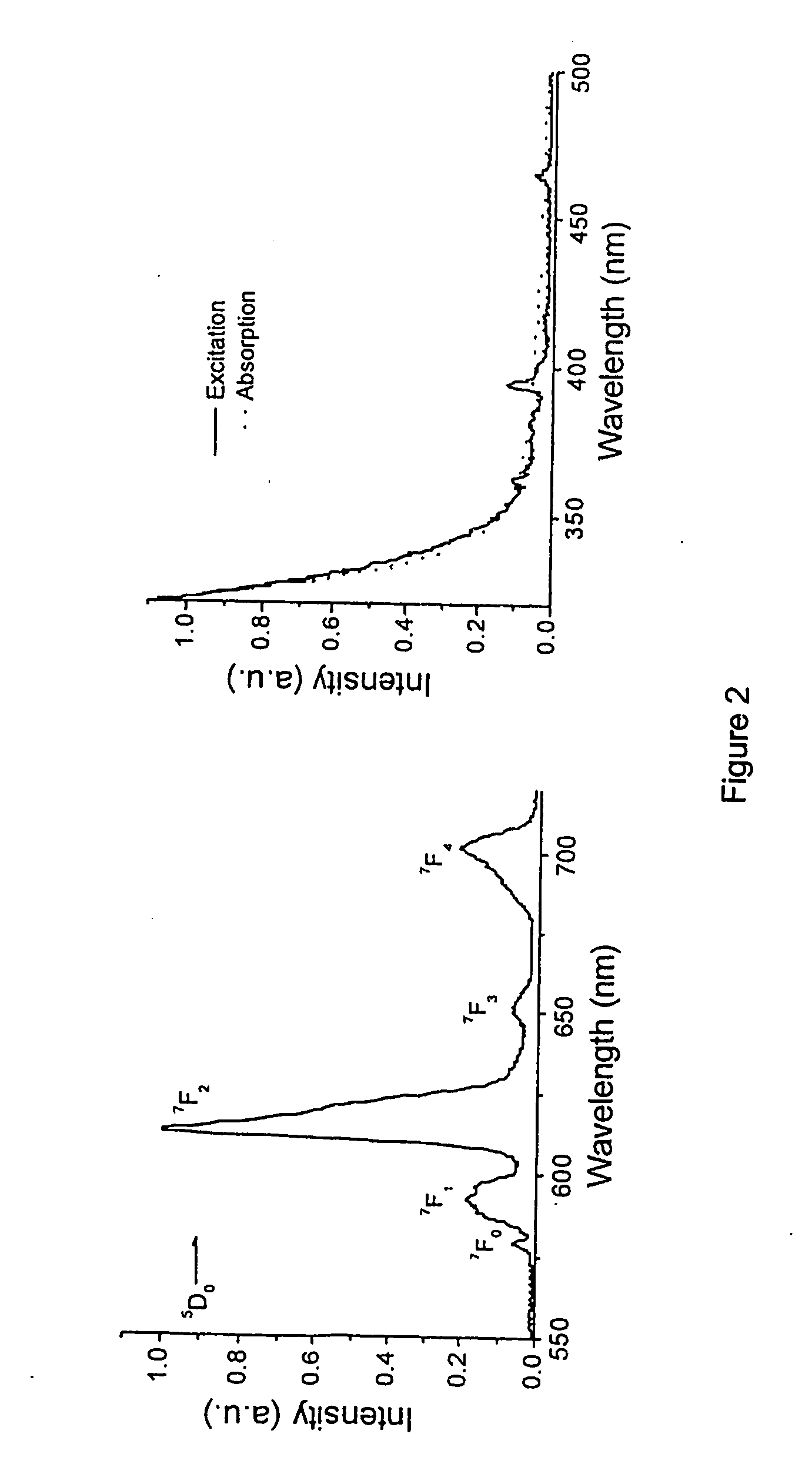

Lanthanide (III)-doped nanoparticles and their applications

InactiveUS7550201B2Reduce quenching processLiquid surface applicatorsDigital data processing detailsNanoparticleLanthanide

A photonic material comprising a core and an envelope is provided for use in telecommunications, diagnostics, imaging and other applications. In its simplest form, the core comprises at least one nanoparticle. The nanoparticle comprises an inorganic material and at least one luminescent ion, wherein the inorganic material is suitably selected to bind the luminescent ion. The envelope comprises a suitably selected organic stabilizing layer that overlays the core. The core and envelope may have a shell located between them.

Owner:UNIV OF VICTORIA INNOVATION & DEVMENT

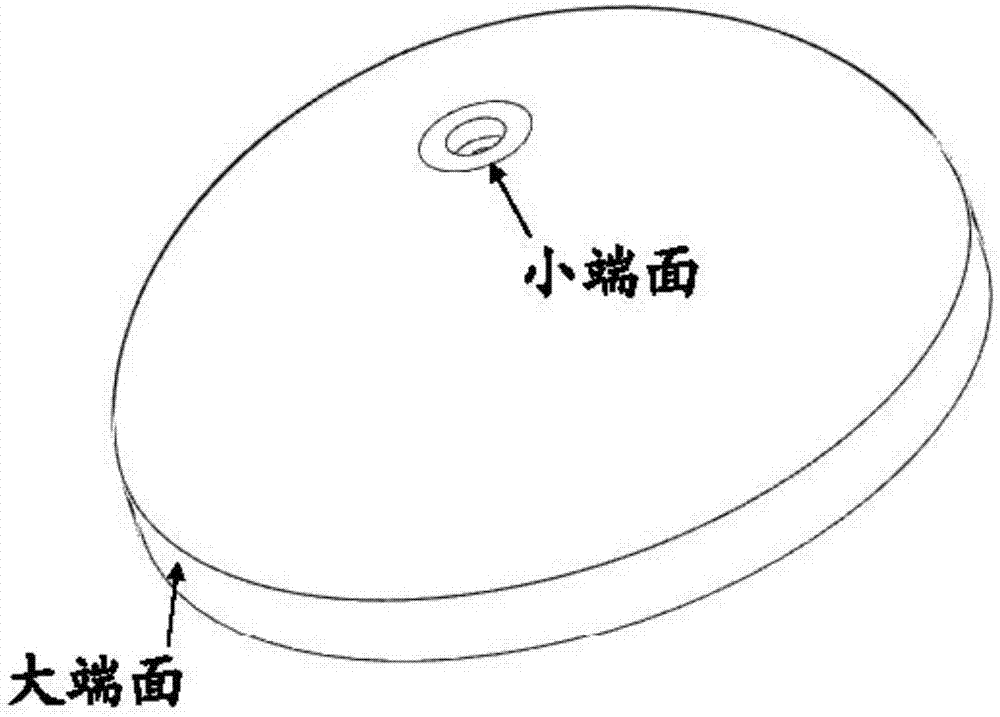

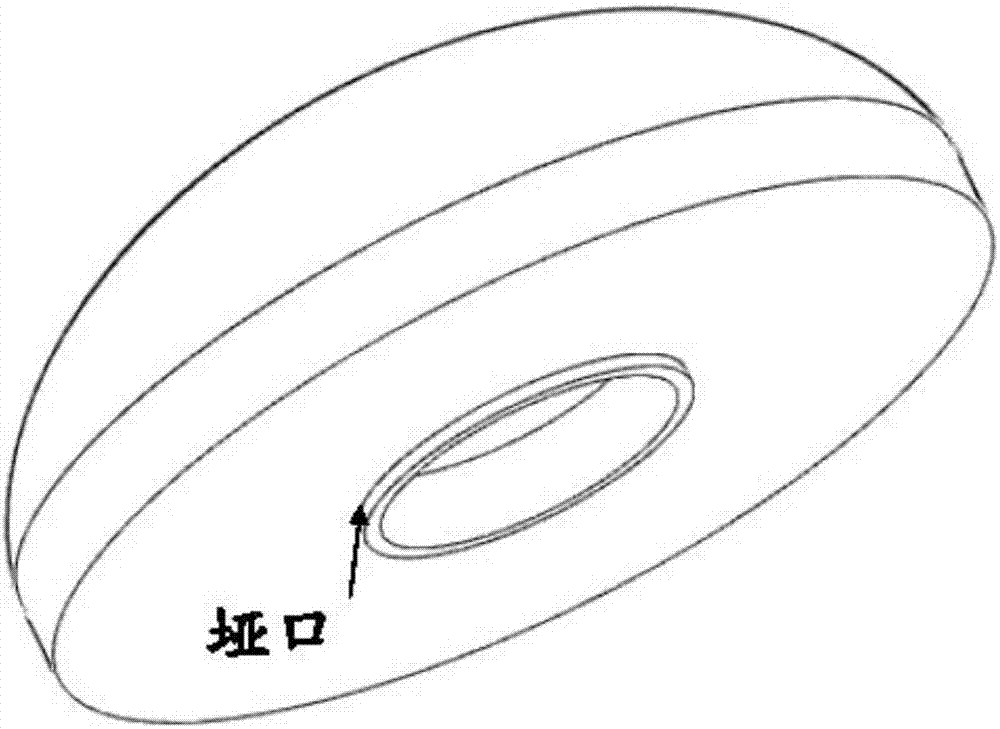

Heat treatment deformation control method for large-diameter and large-modulus elliptical molded surface container semispherical shell

ActiveCN107513677APrevent collapseSmall quenching deformationFurnace typesHeat treatment process controlQuenchingAqueous solution

The invention relates to a heat treatment deformation control method for a large-diameter and large-modulus elliptical molded surface container semispherical shell and belongs to the technical field of container manufacturing. By means of the heat treatment deformation method, due to the fact that an integrated quenching and aging heat treatment tool is designed, the elliptical molded surface container semispherical shell and the heat treatment tool can be tightly matched, the quenching transfer time is shortened, the phenomenon that the top of the shell collapses and pits happen in the circumferential direction of the shell during quenching is avoided, quenching and time aging deformation is reduced, and therefore the heat treatment performance of the elliptical molded surface container semispherical shell can be ensured; and meanwhile, the subsequent machining precision of the shell is also ensured. In addition, a UCON water solution with the concentration ranging from 6% to 10% is adopted in the method to serve as a quenching medium, dynamic flowing of the water solution is maintained, the cooling speed and uniformity of the shell are ensured, meanwhile, quenching deformation is also controlled, and therefore the product precision is ensured.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Lanthanide (III) - Doped Nanoparticles And Their Applications

InactiveUS20070274664A1Reduce quenching processLiquid surface applicatorsDigital data processing detailsNanoparticleLanthanide

A photonic material comprising a core and an envelope is provided for use in telecommunications, diagnostics, imaging and other applications. In its simplest form, the core comprises at least one nanoparticle. The nanoparticle comprises an inorganic material and at least one luminescent ion, wherein the inorganic material is suitably selected to bind the luminescent ion. The envelope comprises a suitably selected organic stabilizing layer that overlays the core. The core and envelope may have a shell located between them.

Owner:UNIV OF VICTORIA INNOVATION & DEVMENT

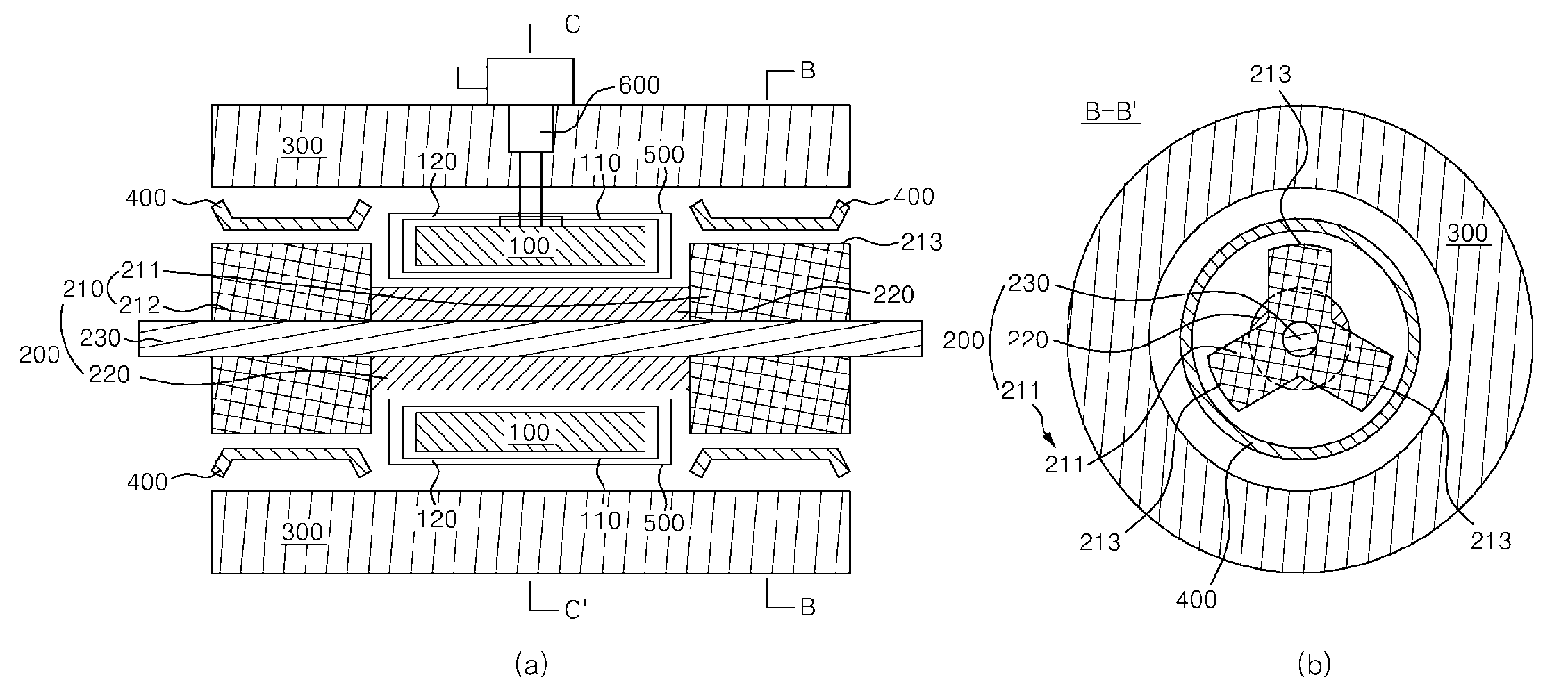

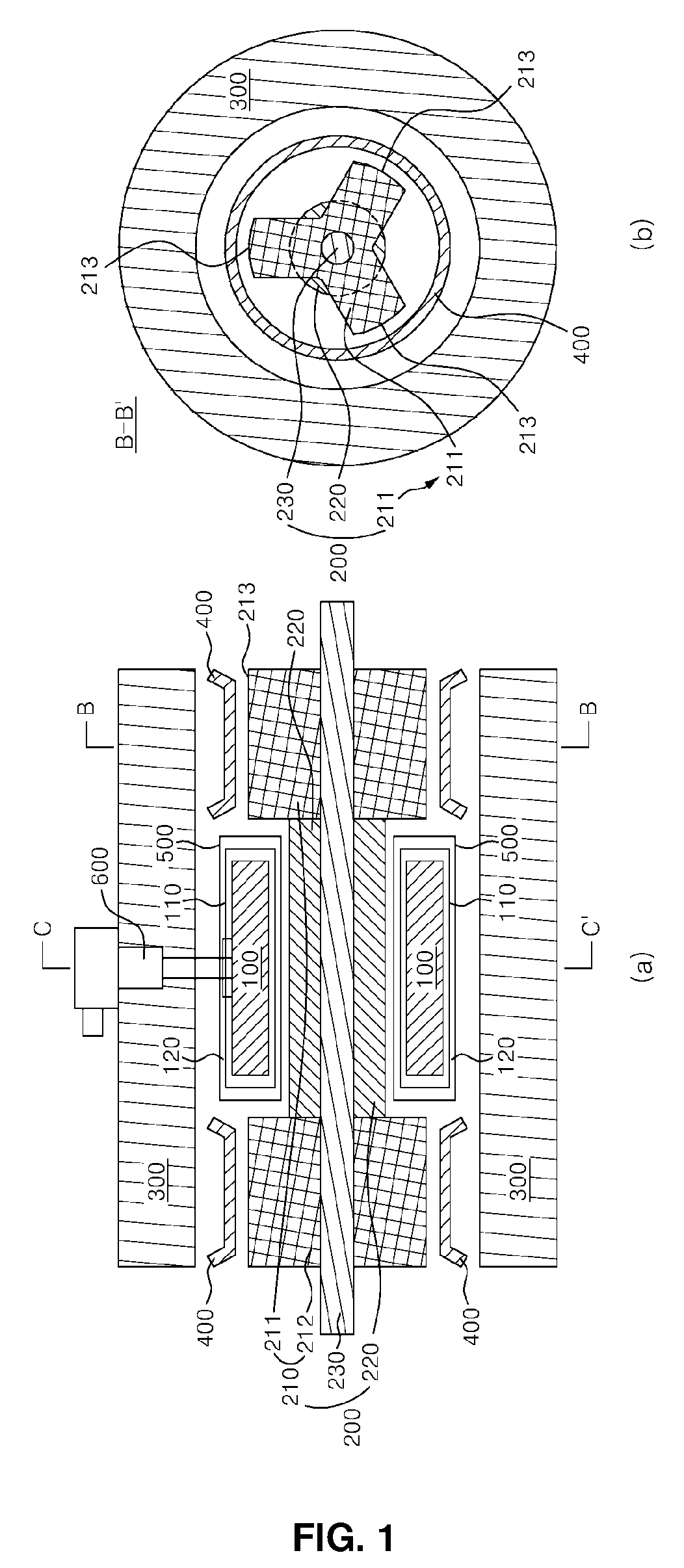

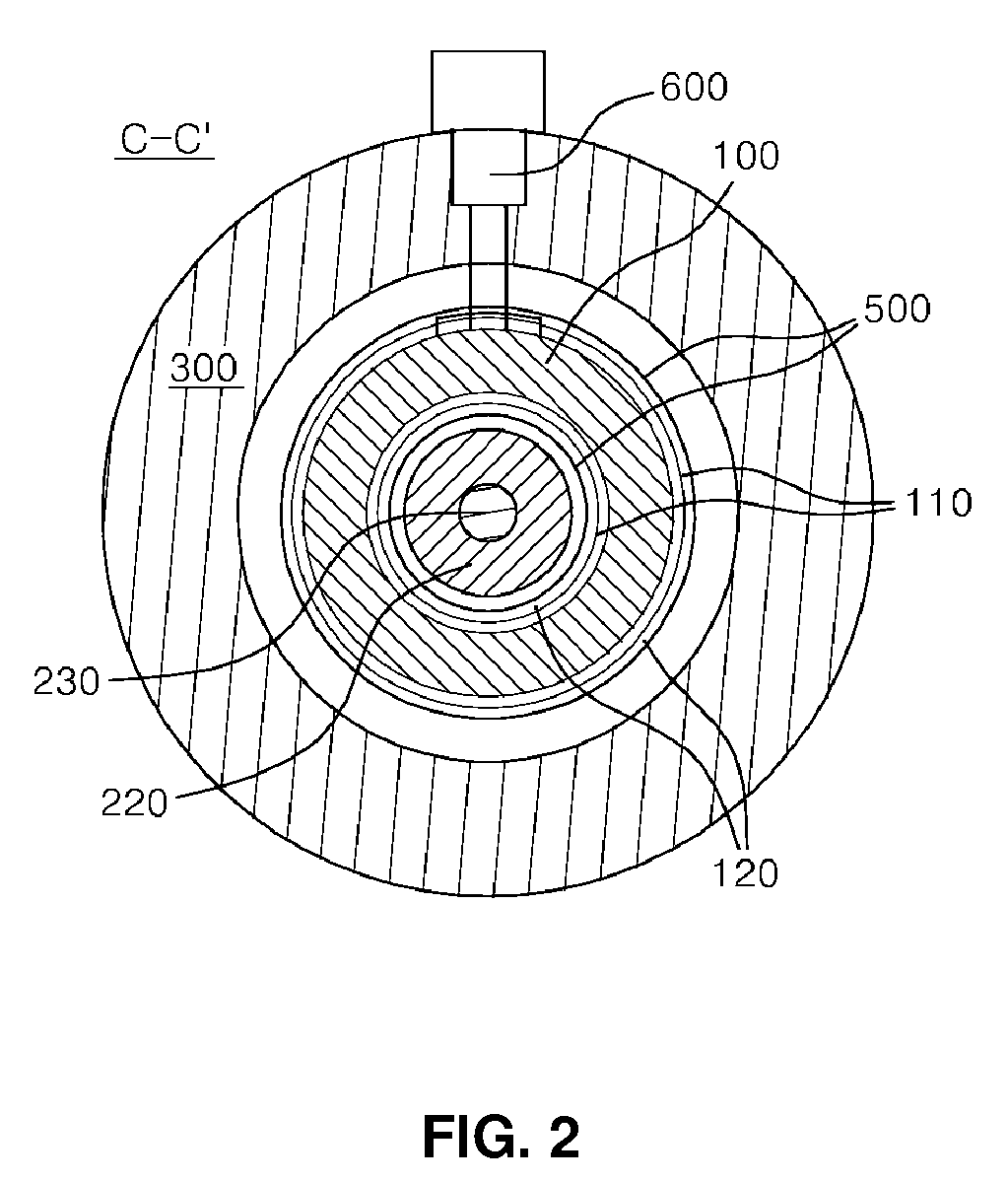

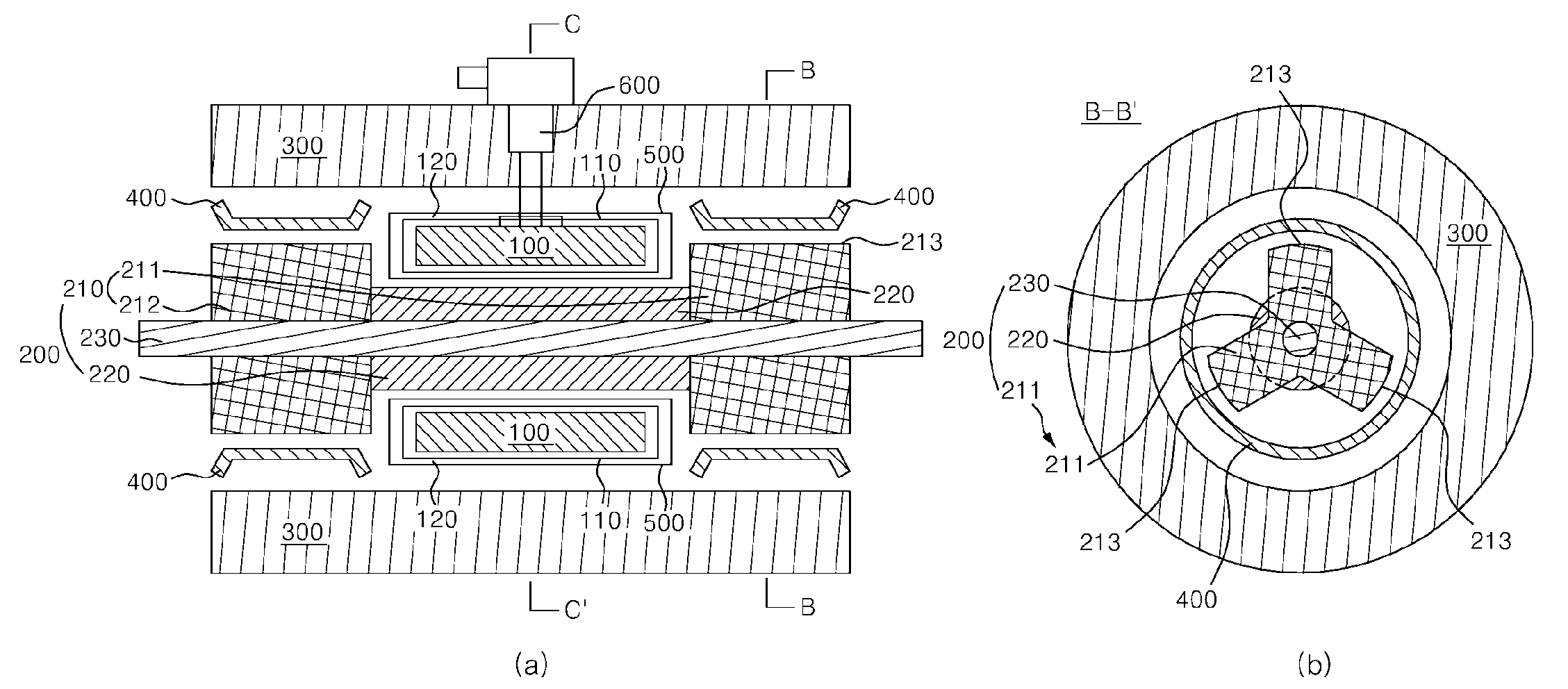

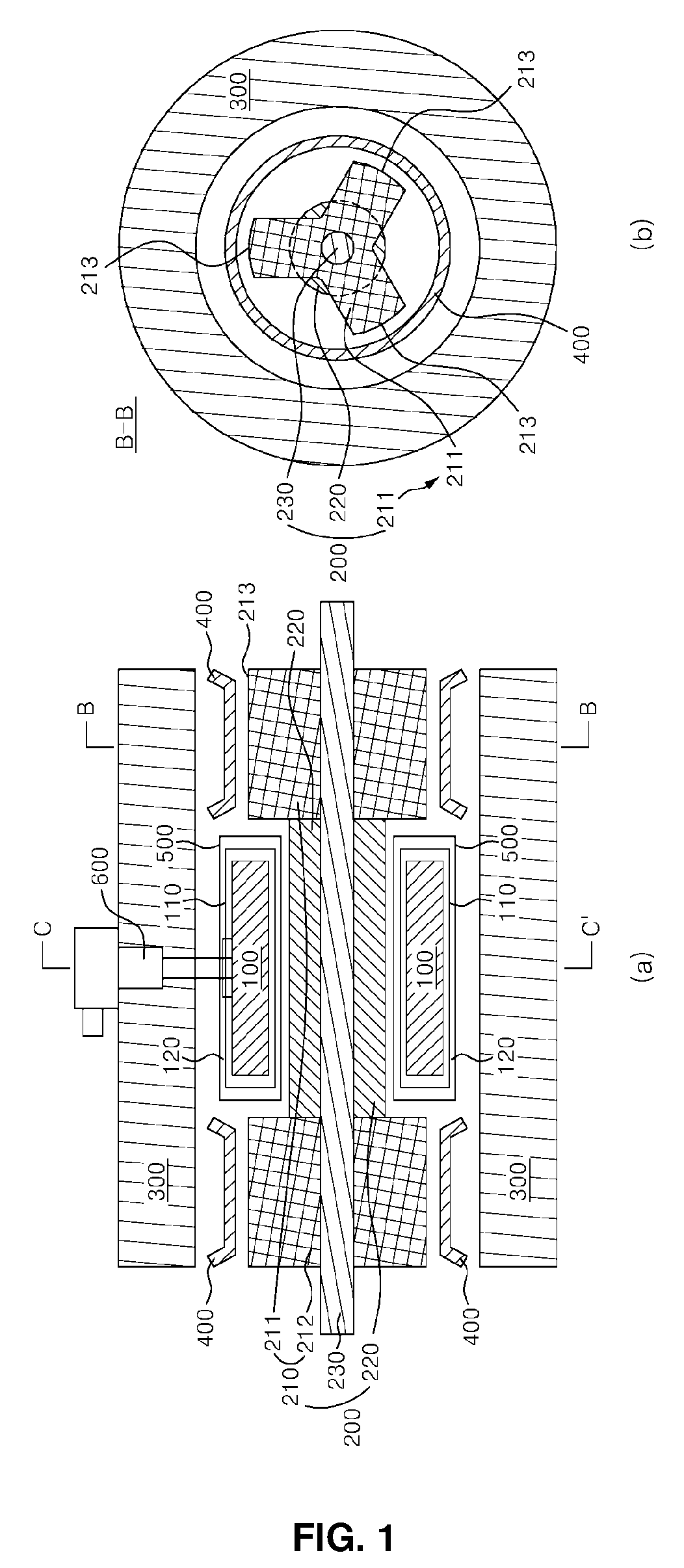

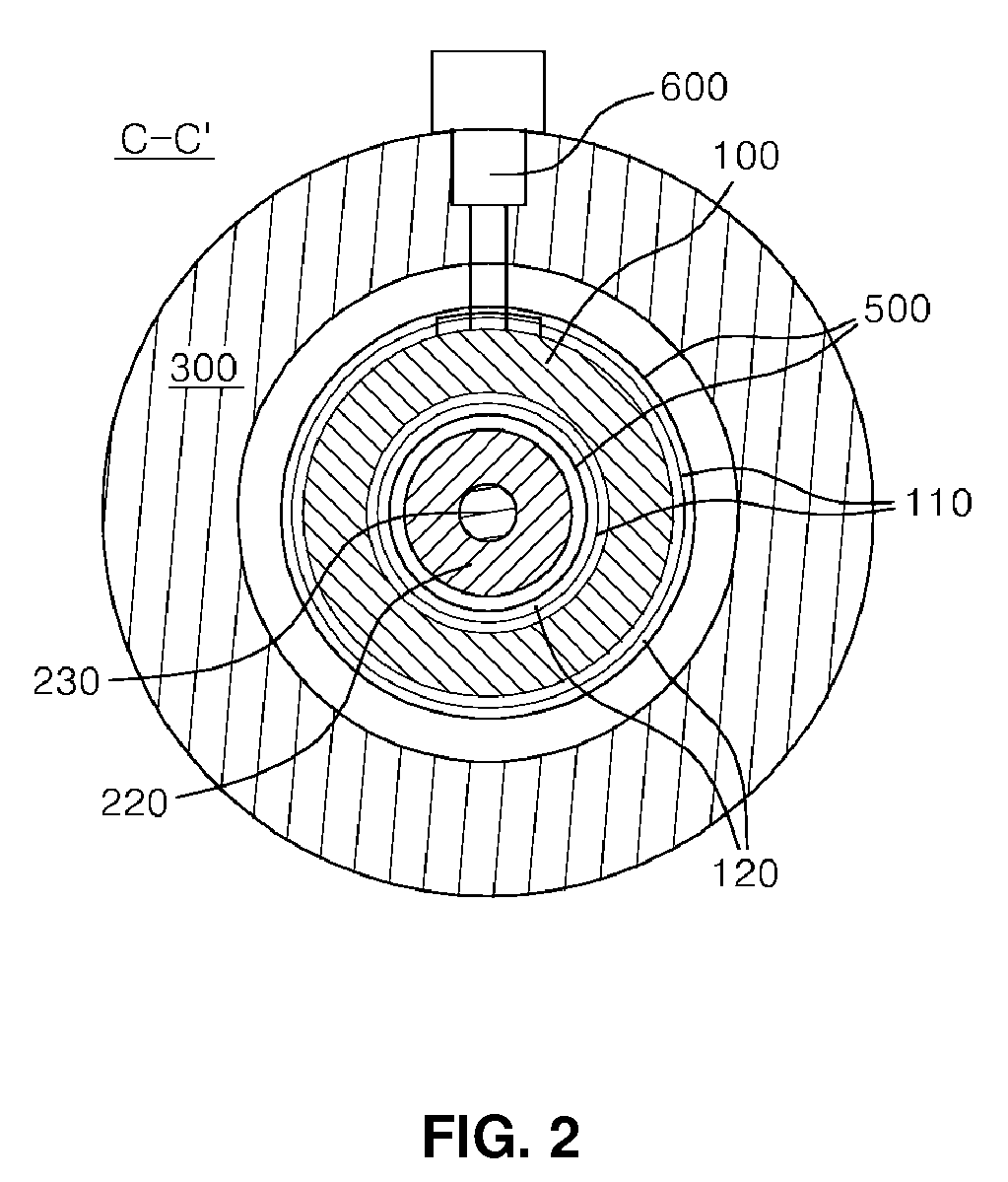

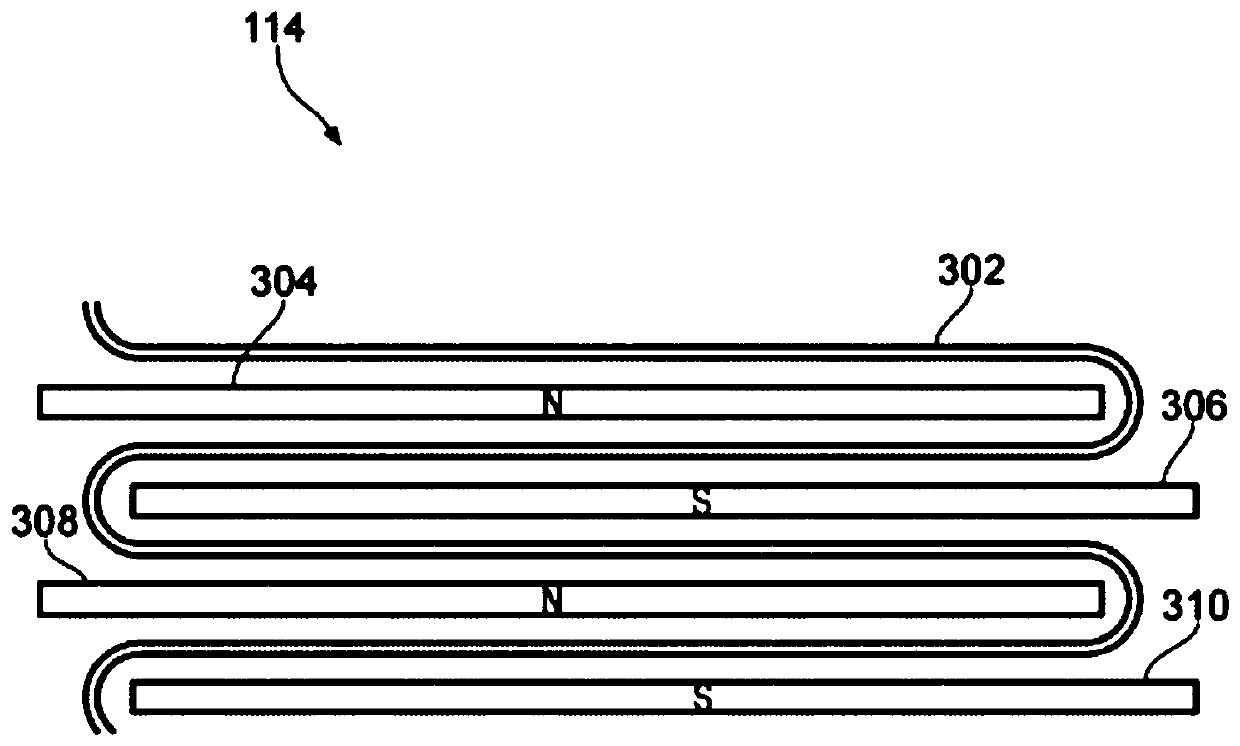

Superconducting synchronous machine

ActiveUS20090093369A1Designed for simplicity and ease of useImprove reliabilitySuperconductors/hyperconductorsMagnetic circuit rotating partsThree-phaseConductor Coil

Disclosed herein is a superconducting field coil of a homopolar type superconducting synchronous machine. The superconducting synchronous machine includes a superconducting field coil which comprises a single or double pancake coil formed by winding a superconducting wire, a core-type rotor which is made of a magnetic material, and an armature winding excited to three phases on a surface of a core of a stator. The field coil of the homopolar type superconducting synchronous machine is not rotated when the machine is in operation. Thus, there is no part for coupling the rotating field coil to a stationary cryo-cooler for cooling a refrigerant, so that the structure is simple, reliability is high, and various cooling methods are available.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

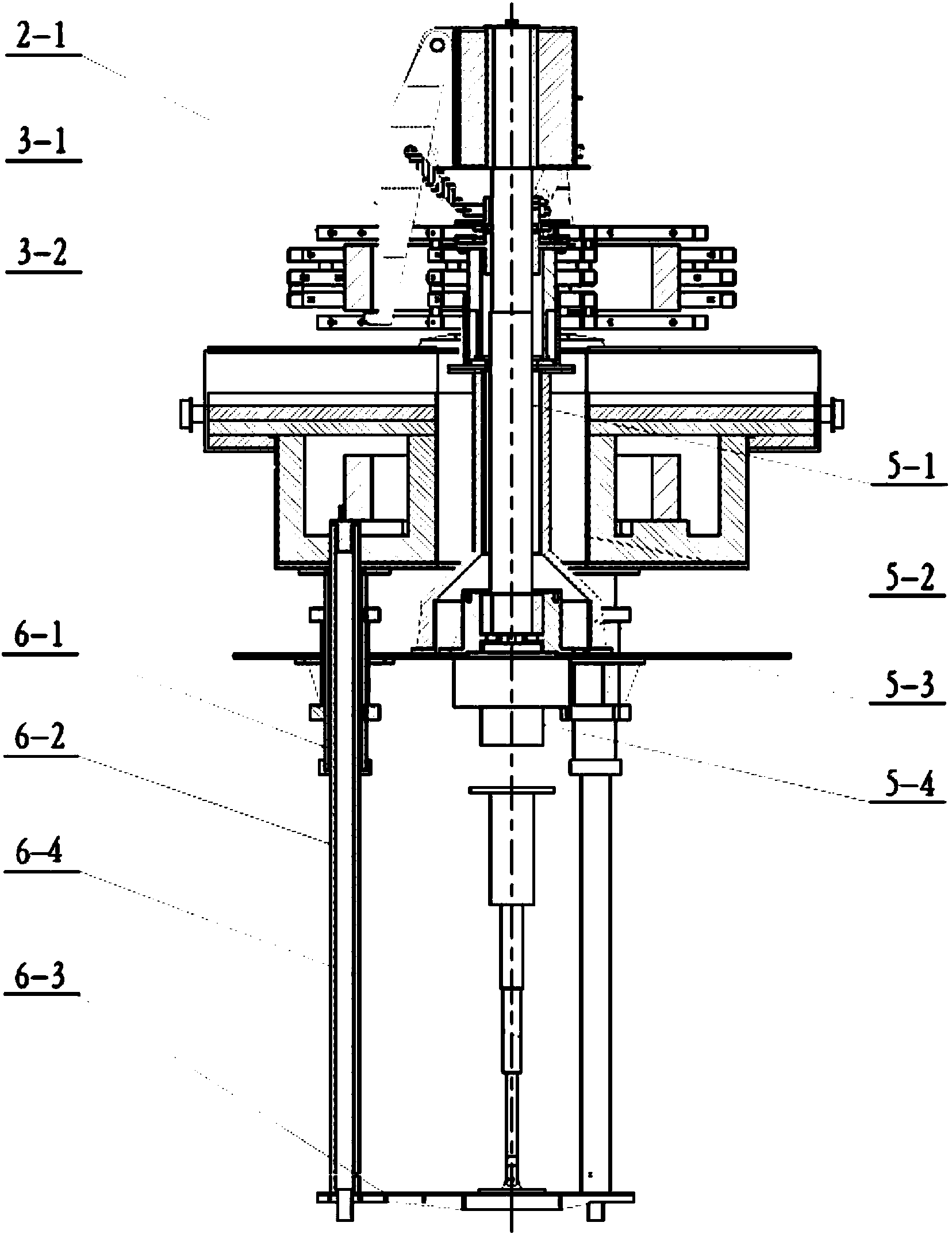

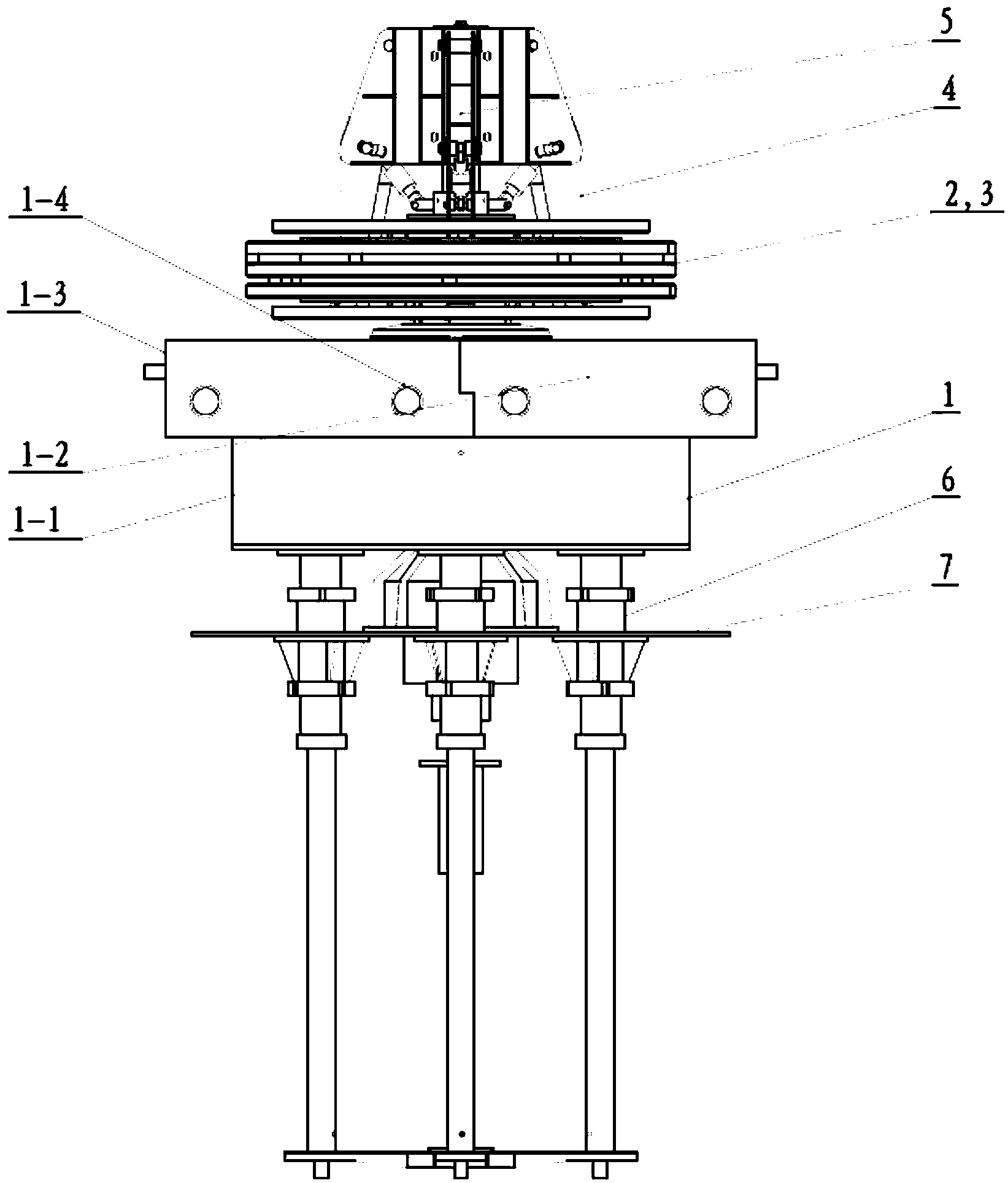

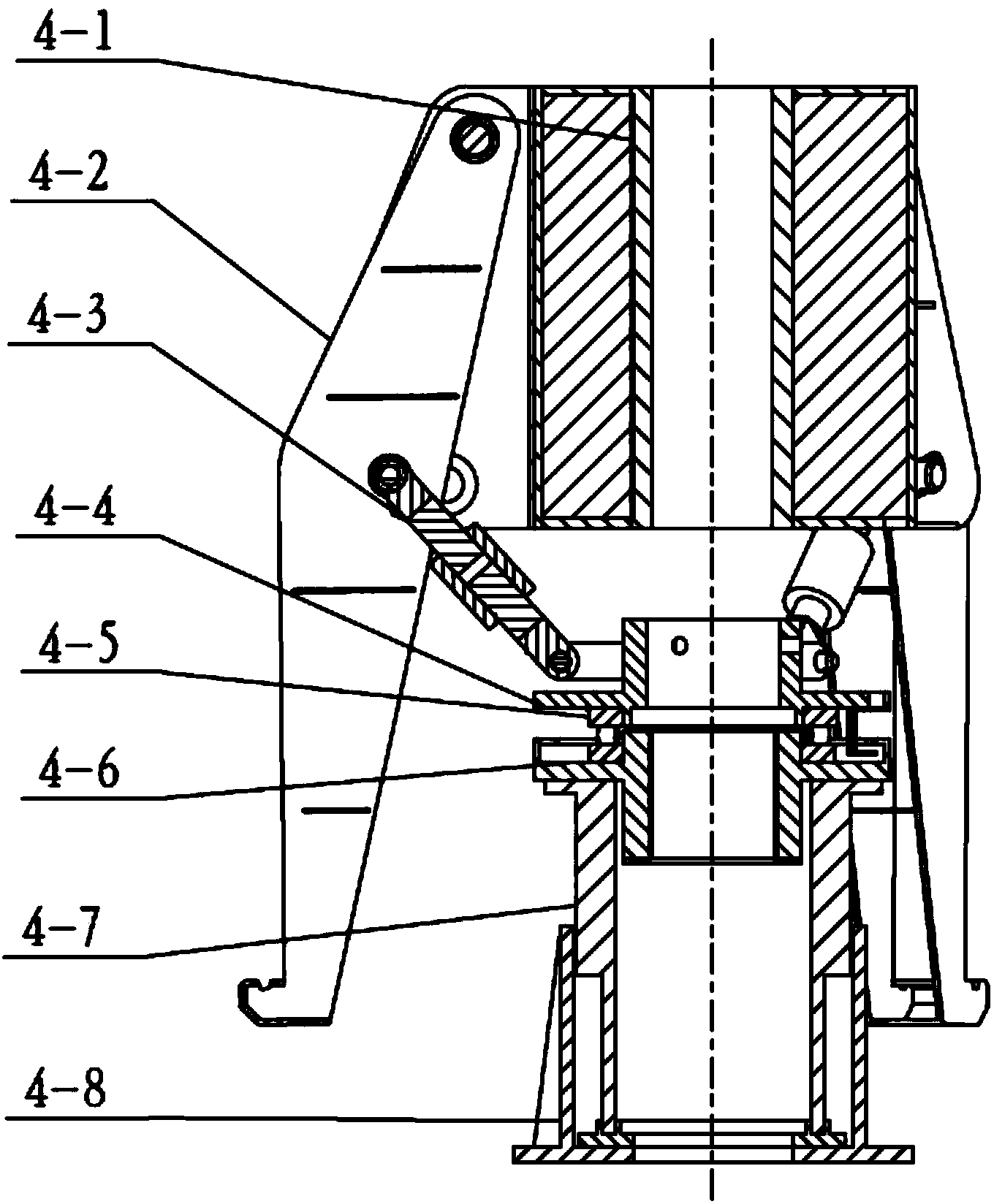

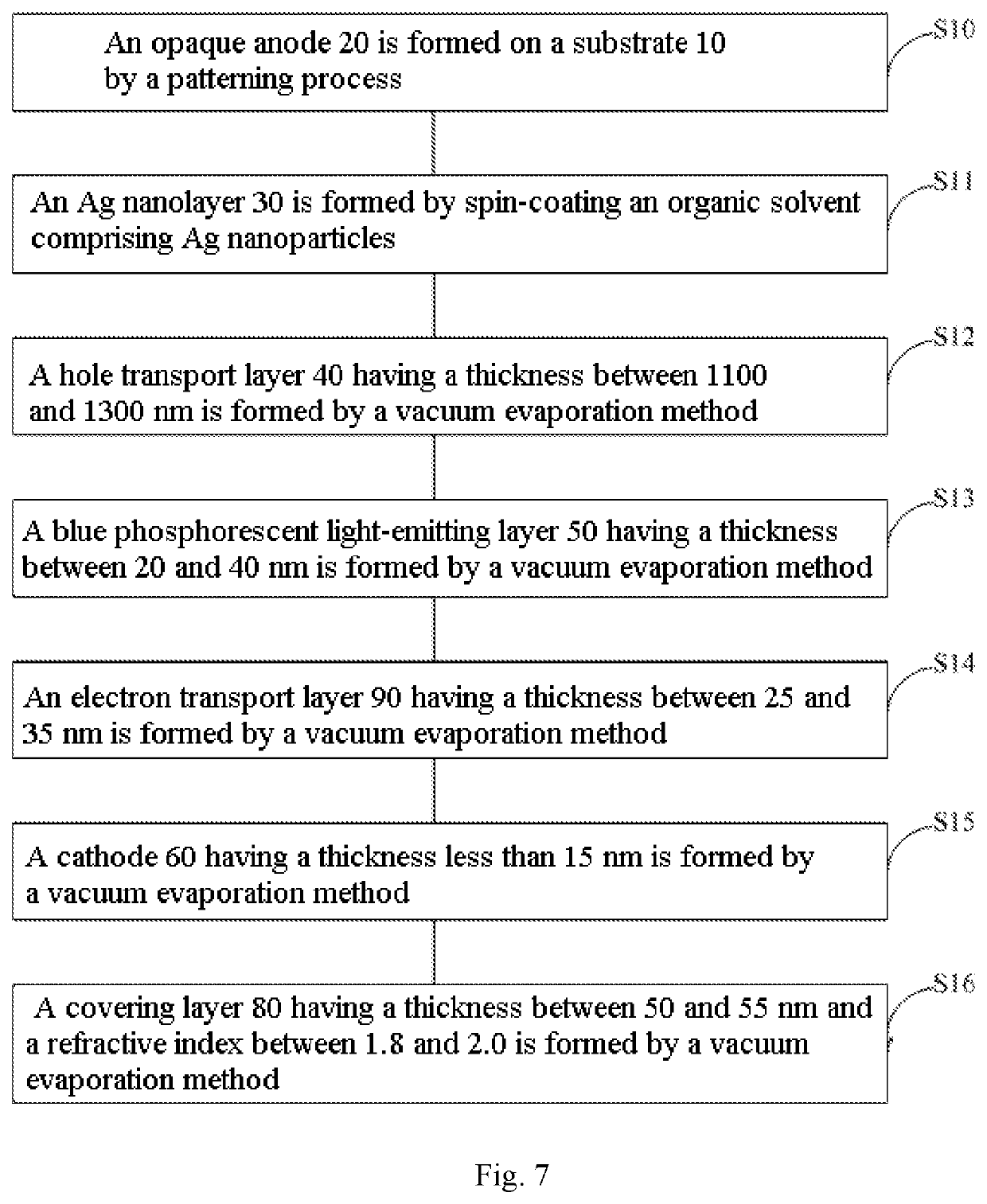

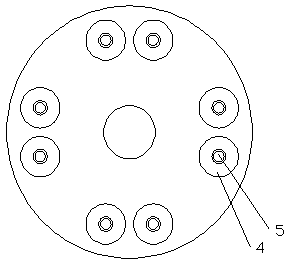

Aluminum alloy ring part spray-quenching equipment and using method thereof

ActiveCN104313274AEliminate Radial DistortionImprove performanceFurnace typesHeat treatment furnacesSupporting systemAutomatic control

Owner:CENT SOUTH UNIV

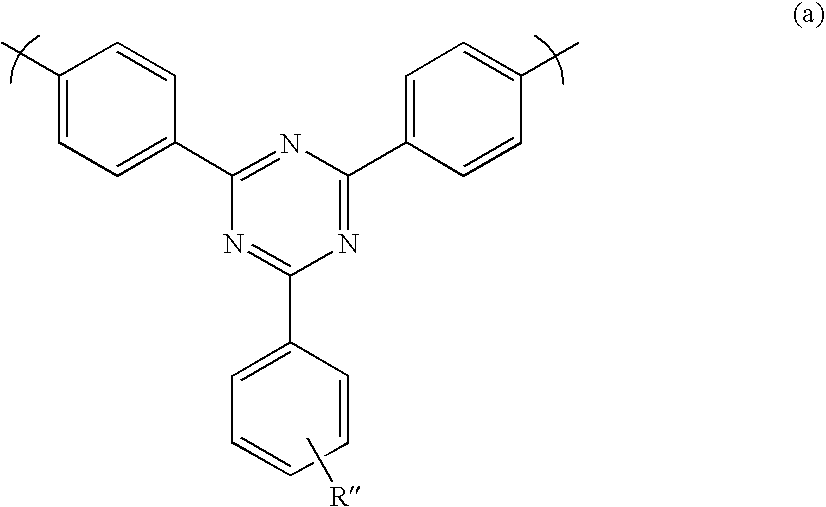

Compounds for use in Opto-Electrical Devices

InactiveUS20100013377A1Maintain good propertiesGood physical propertiesIndium organic compoundsDischarge tube luminescnet screensOpto electronicElectrical devices

A composition for use in fabricating opto-electrical devices comprising a solution processable triazine host material and a phosphorescent moiety.

Owner:SUMITOMO CHEM CO LTD +1

Vehicle exhaust gas analyzer

ActiveUS7454950B2Save electricityHigh sensitivityAnalysing fluids using sonic/ultrasonic/infrasonic wavesTesting/calibration apparatusExhaust fumesEngineering

An exhaust gas analyzer includes a main flow path and at least one sub-flow path. Exhaust gas from an internal combustion engine is introduced to the main flow path; sub-flow paths are parallel to the main flow path. Plural kinds of analyzers are mounted on the main flow path and sub-flow paths to measure concentration of multiple components in the exhaust gas. Actual measurement values of the concentration for the measured components are obtained. A deviance from a true value generated to an actual measurement value due to a mutual influence of the measured components is corrected based on at least one actual measurement value.

Owner:HORIBA LTD

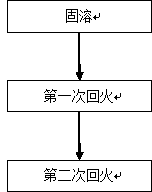

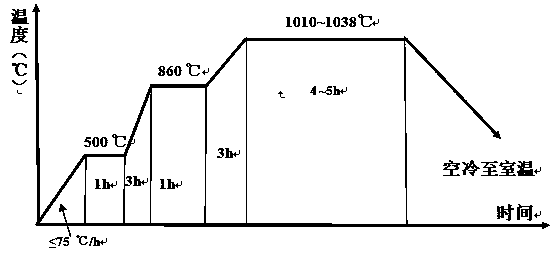

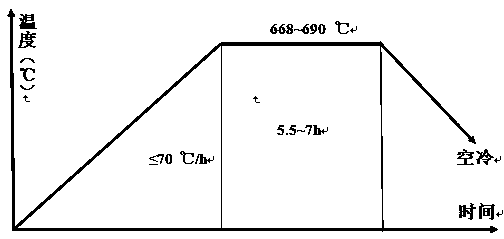

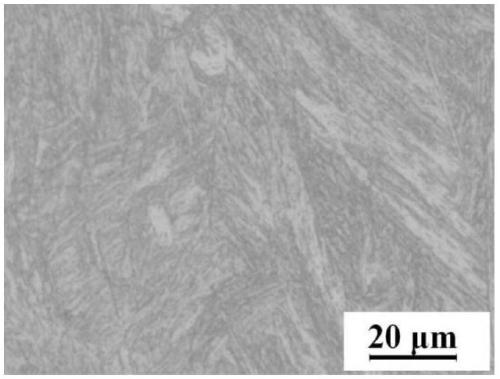

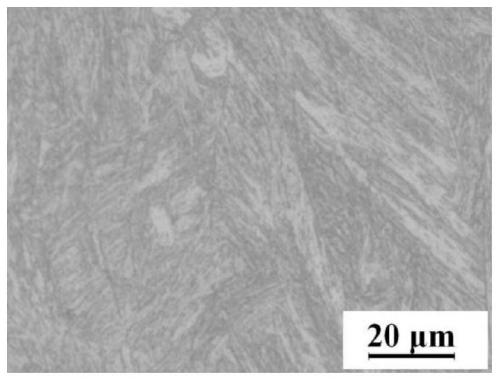

High-temperature forged martensitic stainless steel heat treatment method

ActiveCN103740913AMeet the mechanical performance requirementsPrevent precipitationMartensitic stainless steelDissolution

The invention relates to a high-temperature forged martensitic stainless steel heat treatment method. The method comprises the following steps: placing a forged piece into a furnace, and then performing solid dissolution, first tempering and second tempering for heat treatment; and by selecting the temperature of the heat treatment process, the time control and heat treatment equipment, the requirements of mechanical properties of clients are met, the number of times of quenching and tempering is reduced, and the energy is saved. By adopting an air cooling process and two-section tempering, the precipitation of residual austenitic items is avoided; and by directly heating to the hot melting temperature for austenitizing, then performing air-cooling and selecting the reasonable tempering temperature, the production of stress is avoided, and the performances of material from normal temperature to high temperature are stabilized according to memory principles.

Owner:隆英(常州)特钢科技有限公司

Superconducting synchronous machine

ActiveUS8204562B2Designed for simplicity and ease of useImprove stability and reliabilitySuperconductors/hyperconductorsMagnetic circuit rotating partsThree-phaseCondensed matter physics

Disclosed herein is a superconducting field coil of a homopolar type superconducting synchronous machine. The superconducting synchronous machine includes a superconducting field coil which comprises a single or double pancake coil formed by winding a superconducting wire, a core-type rotor which is made of a magnetic material, and an armature winding excited to three phases on a surface of a core of a stator. The field coil of the homopolar type superconducting synchronous machine is not rotated when the machine is in operation. Thus, there is no part for coupling the rotating field coil to a stationary cryo-cooler for cooling a refrigerant, so that the structure is simple, reliability is high, and various cooling methods are available.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

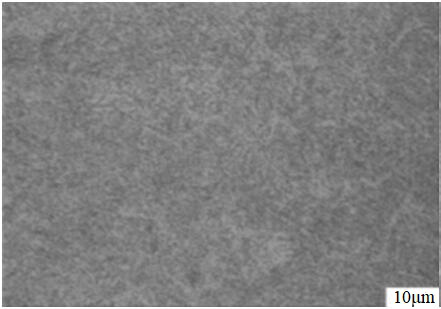

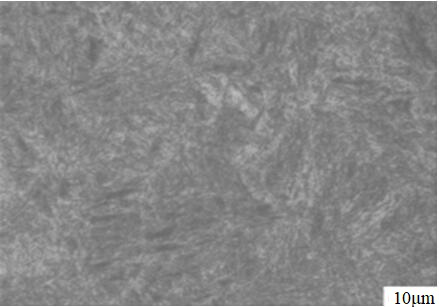

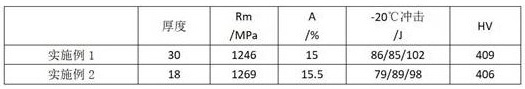

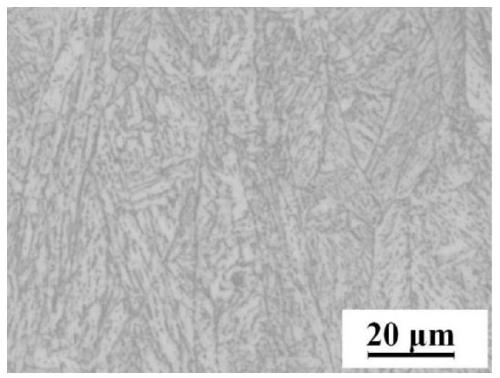

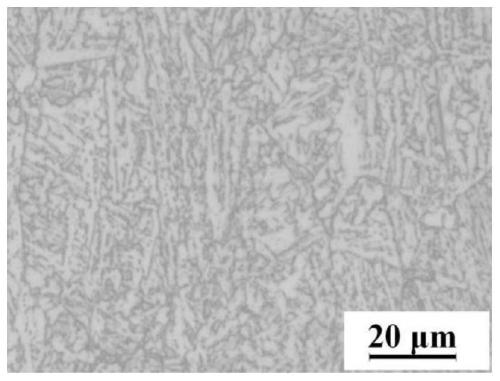

Direct quenching type yield 800 MPa level structure steel plate and production method thereof

The invention discloses a direct quenching type yield 800 MPa level structure steel plate and a production method thereof. The steel plate comprises chemical components including, by mass percent, 0.05%-0.09% of C, 0.16%-0.20% of Si, 1.05%-1.15% of Mn, smaller than or equal to 0.01% of P, smaller than or equal to 0.003% of S, 0.015%-0.025% of Nb, 0.45%-0.55% of Cr, 0.3%-0.4% of Ni, 0.001%-0.0015%of B, 0.01%-0.02% of Ti, 0.02%-0.05% of Alt and the balance Fe and inevitable impurities. The production method comprises the procedures of smelting, continuous casting, heating, rolling, online direct quenching and tempering air cooling. The steel plate has the low carbon equivalent and welding crack sensitivity index and excellent low-temperature impact toughness and welding performance and canbe used in the fields such as hydropower stations, ships, ocean platforms and engineering machines.

Owner:HEBEI IRON AND STEEL

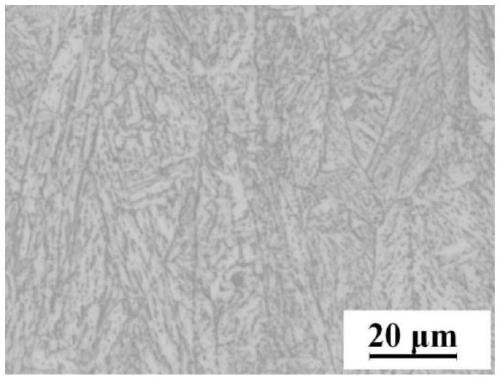

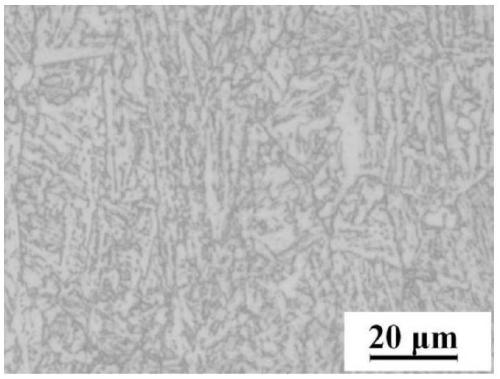

OLED with metal complexes having a high quantum efficiency

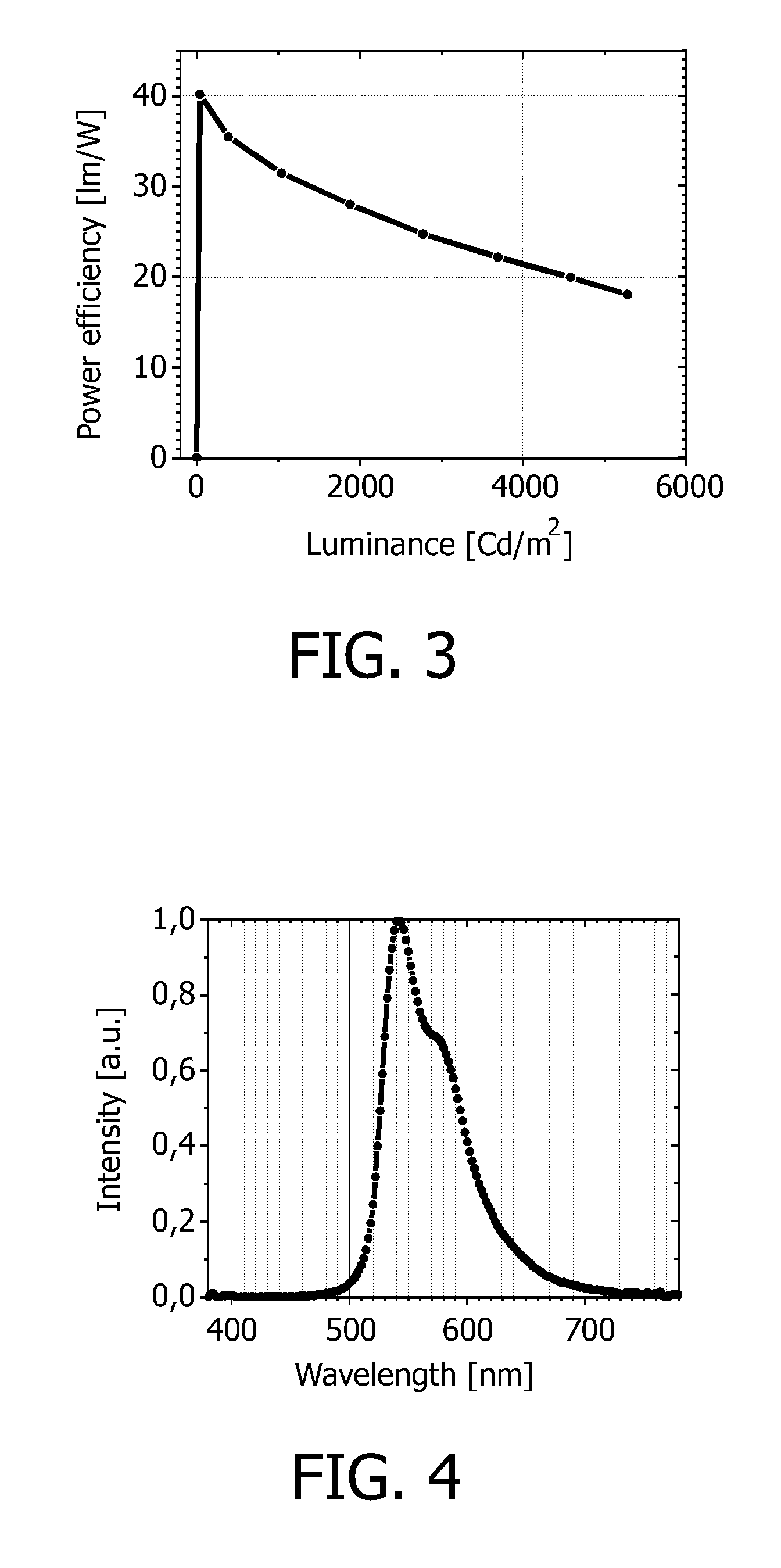

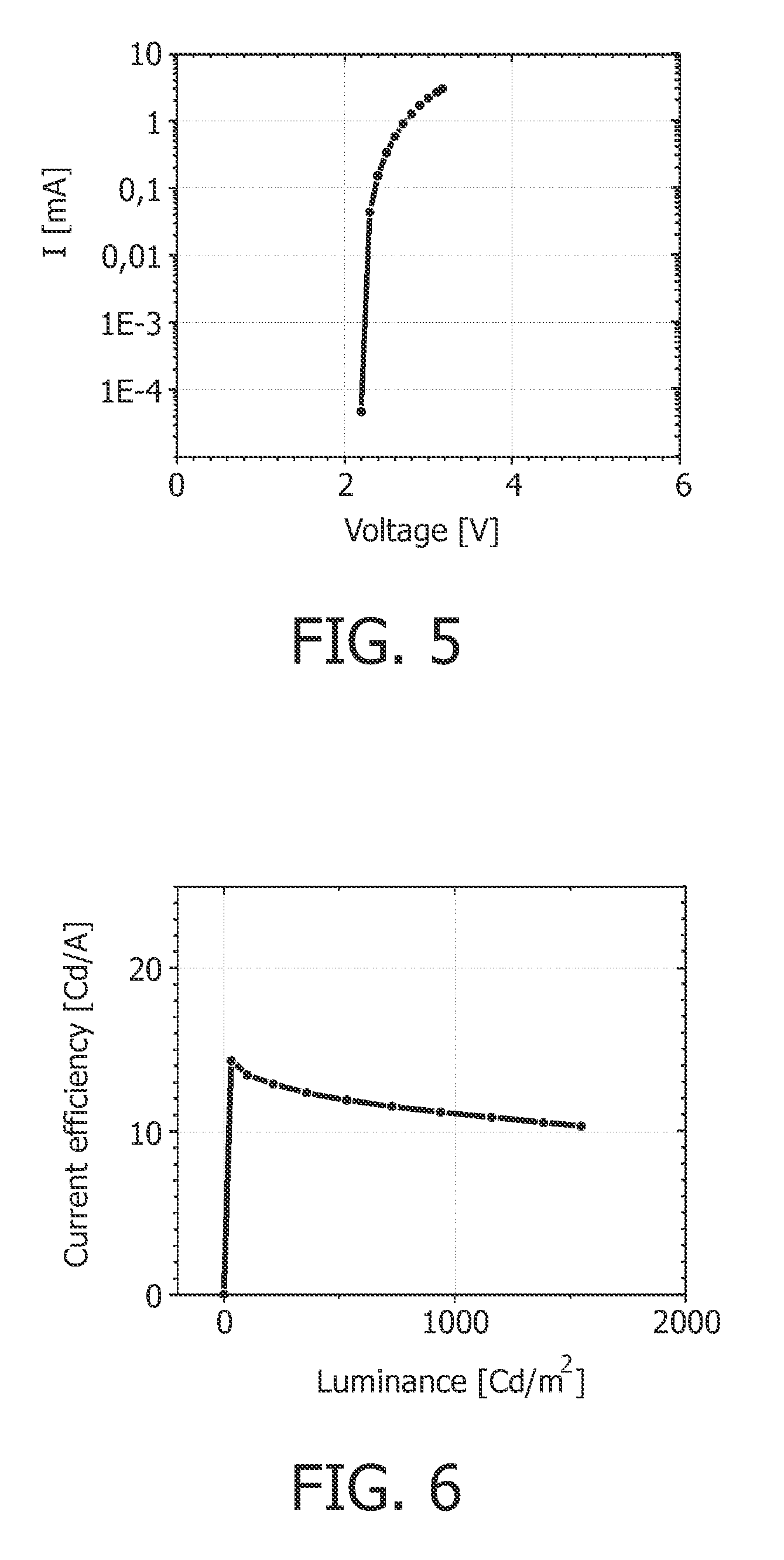

InactiveUS20100109515A1Improve efficiencyEfficient use ofDischarge tube luminescnet screensElectroluminescent light sourcesQuantum efficiencyTriplet state

The present invention is directed to the field of organic light emitting diode (OLED) electroluminescent devices comprising a light-emitting layer containing an organic metal coordination compound with tailored ligands of the general structure (1) where (2) is a N-containing heterocycle comprising one or more cycle and where (3) is a unit with a triplet energy of at least 22,220 cm−1.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

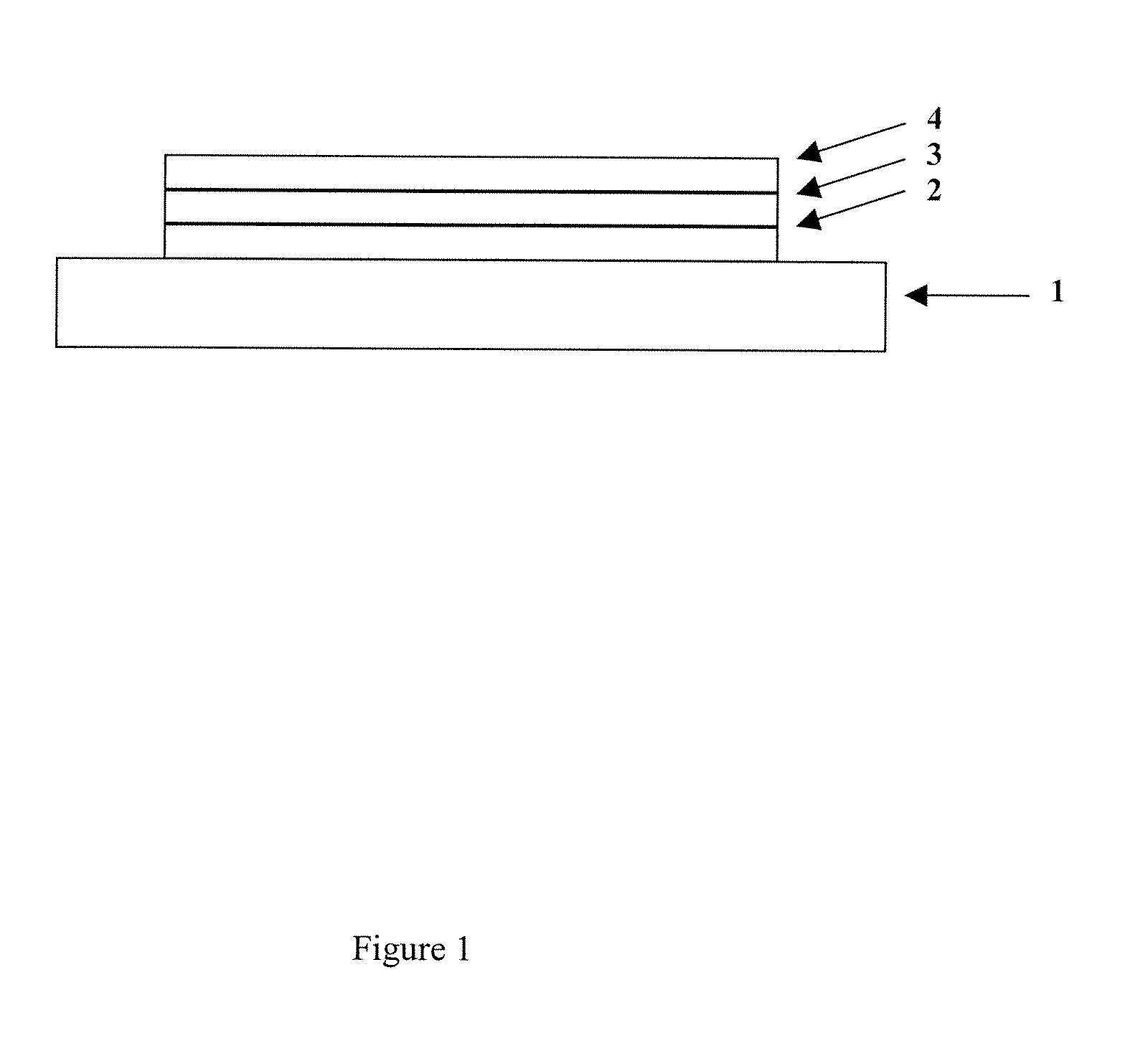

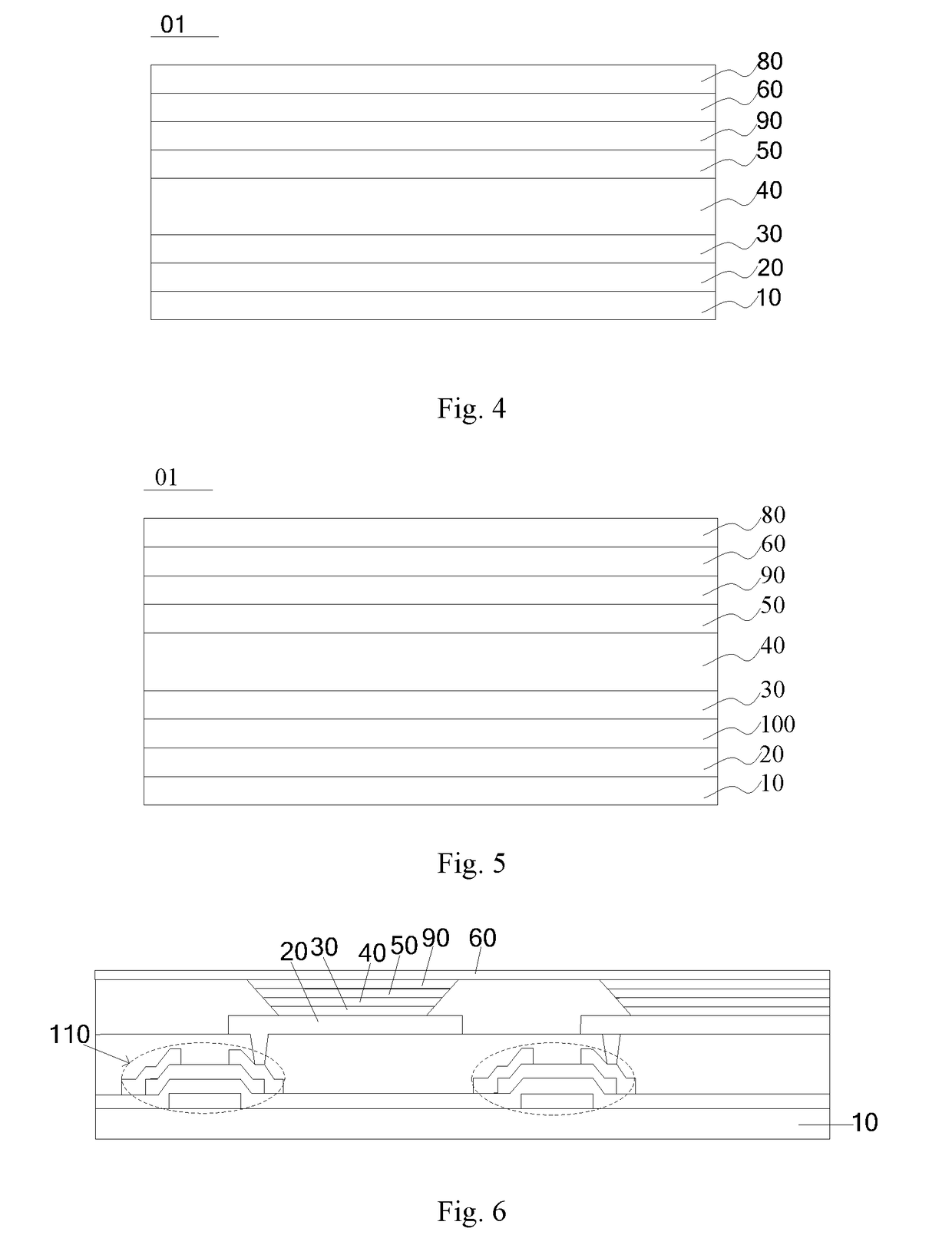

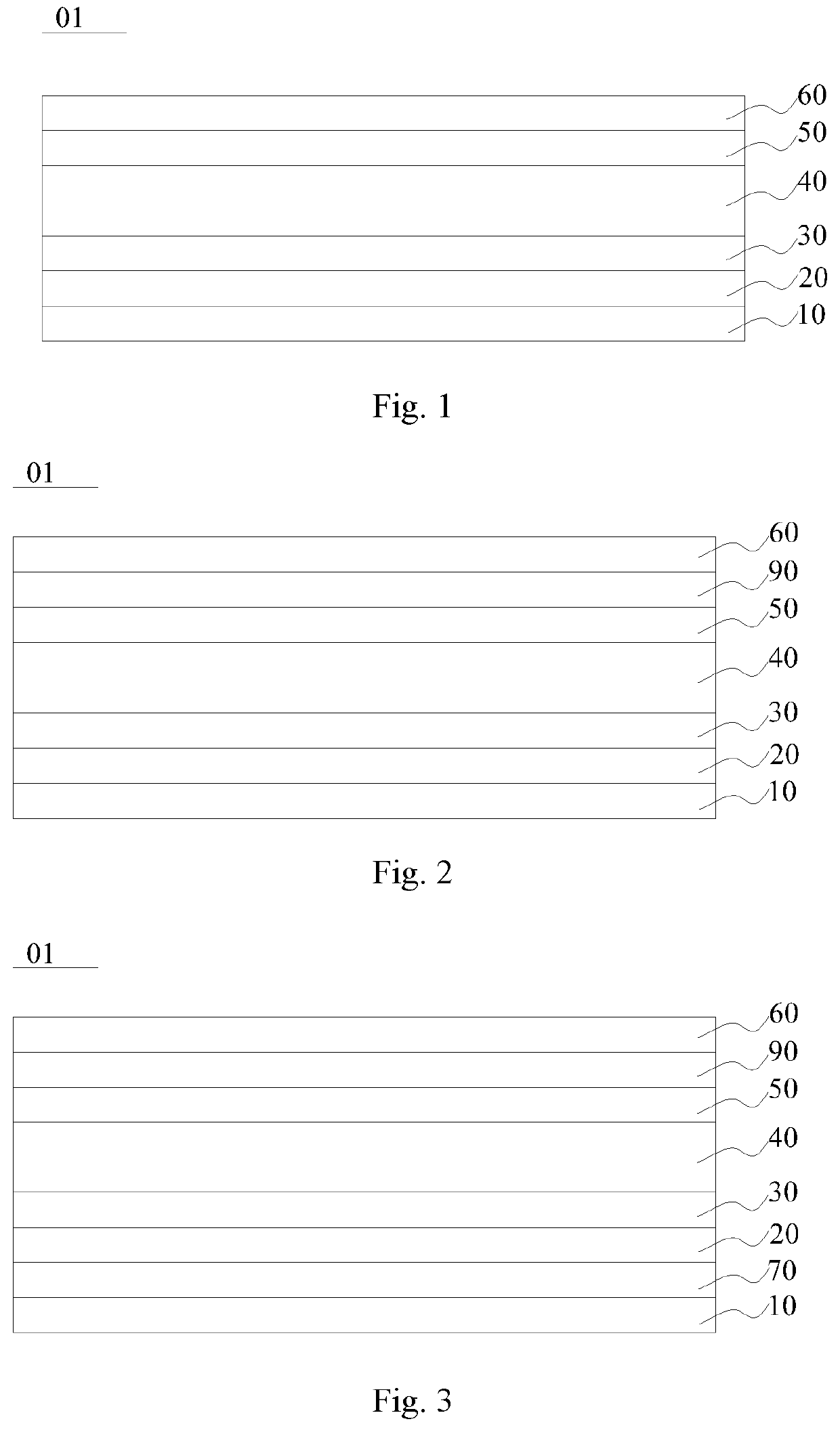

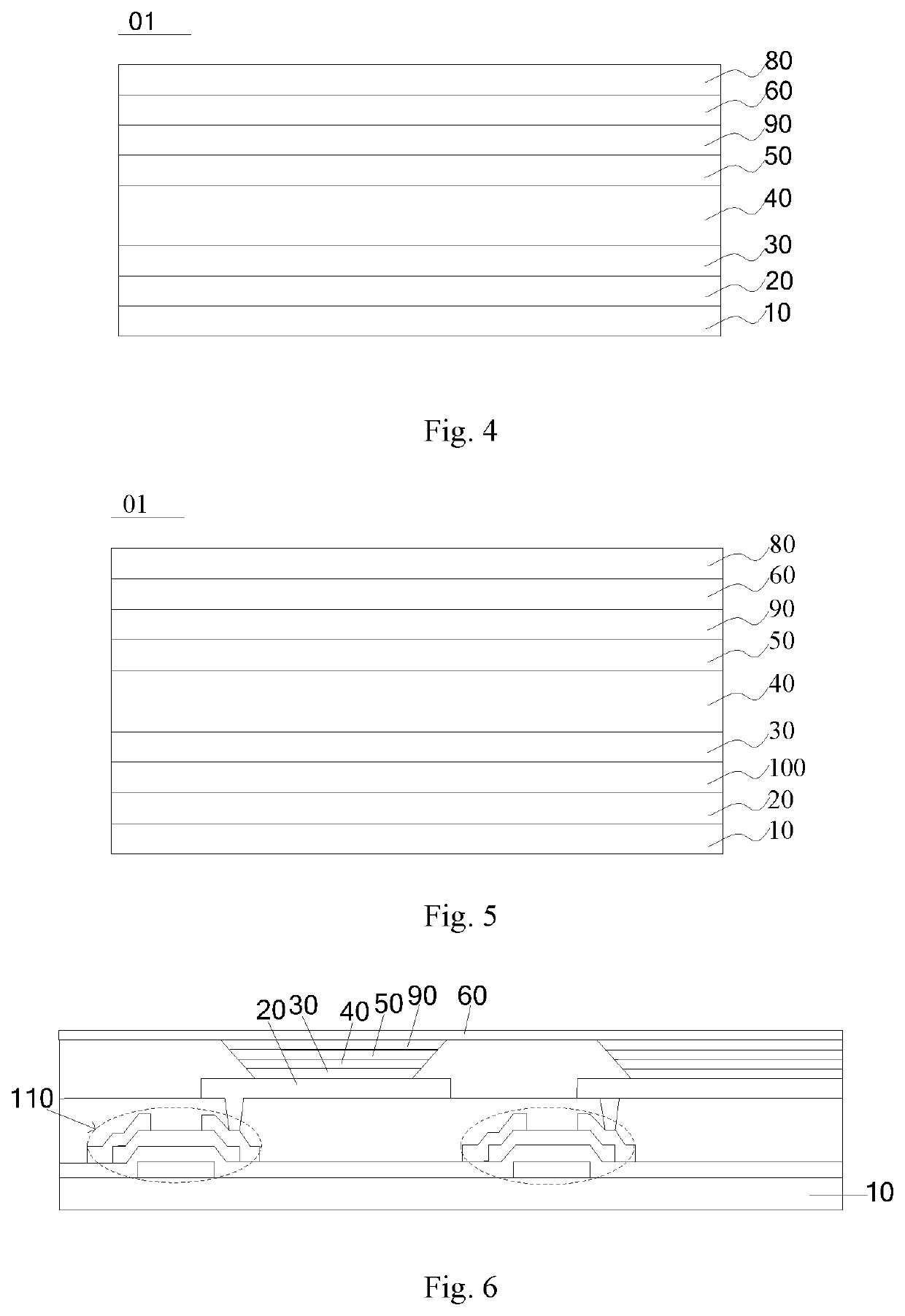

OLED light-emitting device, production method thereof and display apparatus

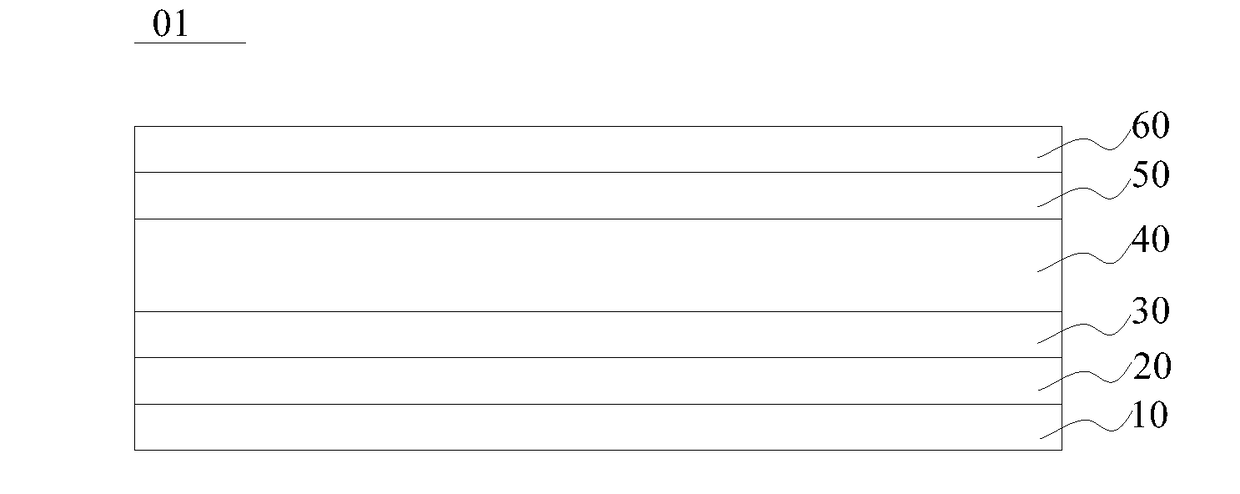

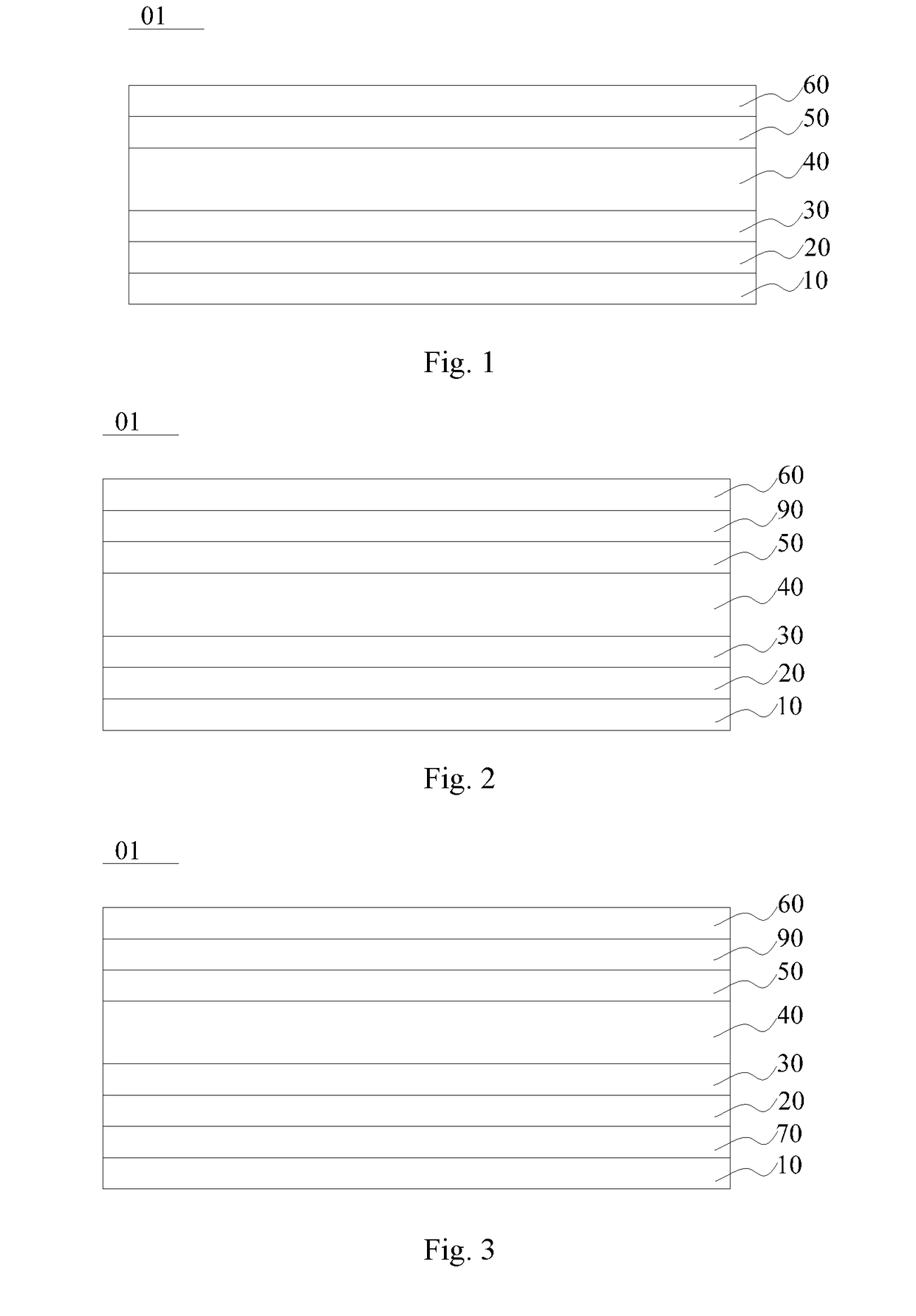

ActiveUS20180212201A1Improve internal quantum efficiencyEnhance speed of spontaneous radiationSolid-state devicesSemiconductor/solid-state device manufacturingQuantum efficiencySurface plasmon

This disclosure provides an OLED light-emitting device, a production method thereof as well as a display apparatus, and relates to the technical field of OLED display, which can enhance the internal quantum efficiency of a blue OLED light-emitting device. This OLED light-emitting device comprises a substrate, and an anode, a hole transport layer, a blue light-emitting layer and a cathode provided on the substrate; the OLED light-emitting device further comprises an Ag nanolayer located between the anode and the hole transport layer; wherein the blue light-emitting layer is a blue phosphorescent light-emitting layer; the absorption spectrum of the Ag nanolayer overlaps the emission spectrum of the blue phosphorescent light-emitting layer, and the blue phosphorescent light-emitting layer is located within the penetration depth of surface plasma of Ag nanoparticles in the Ag nanolayer. It is used in the production of a blue OLED light-emitting device and a display apparatus comprising the same.

Owner:BOE TECH GRP CO LTD +1

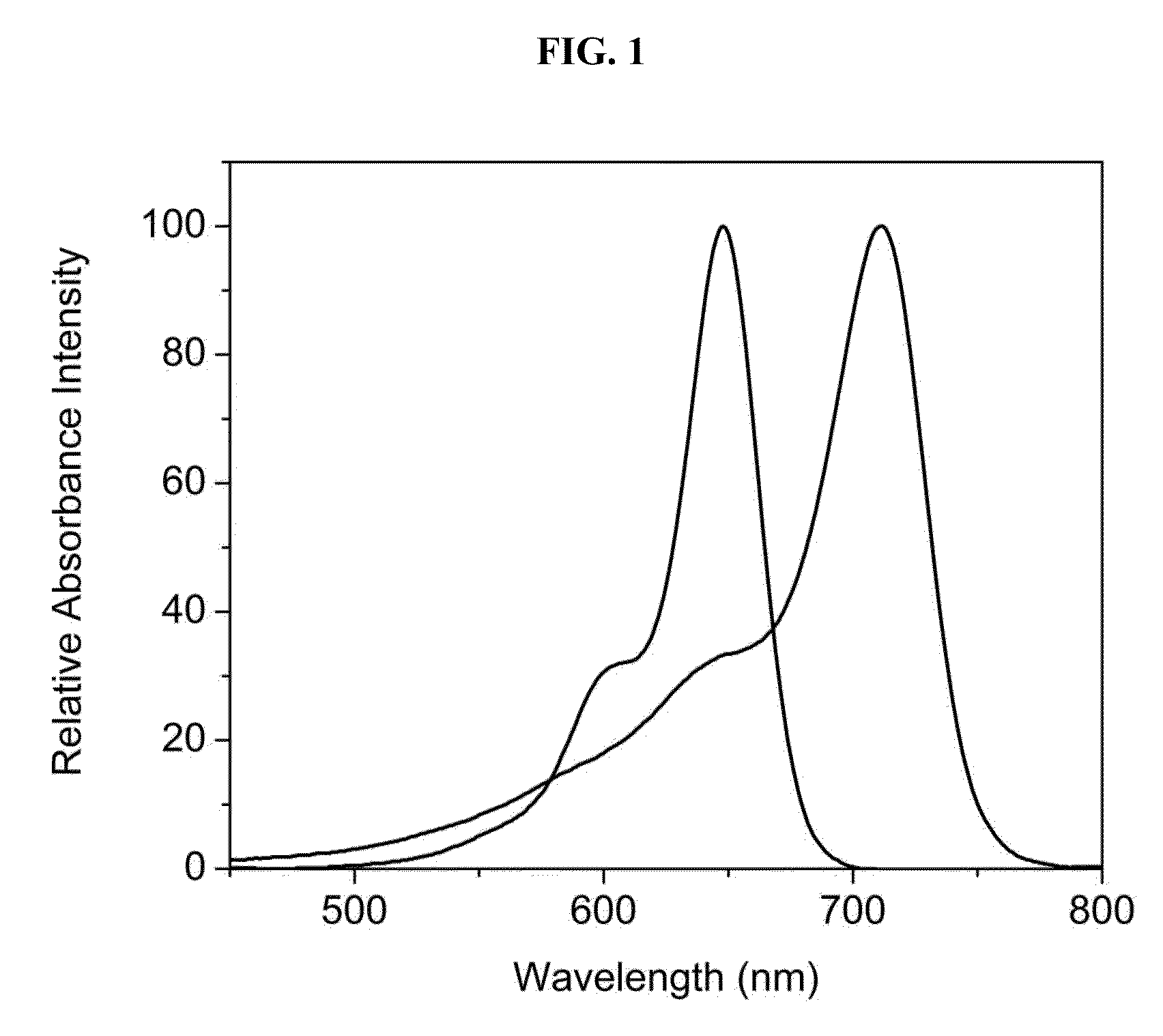

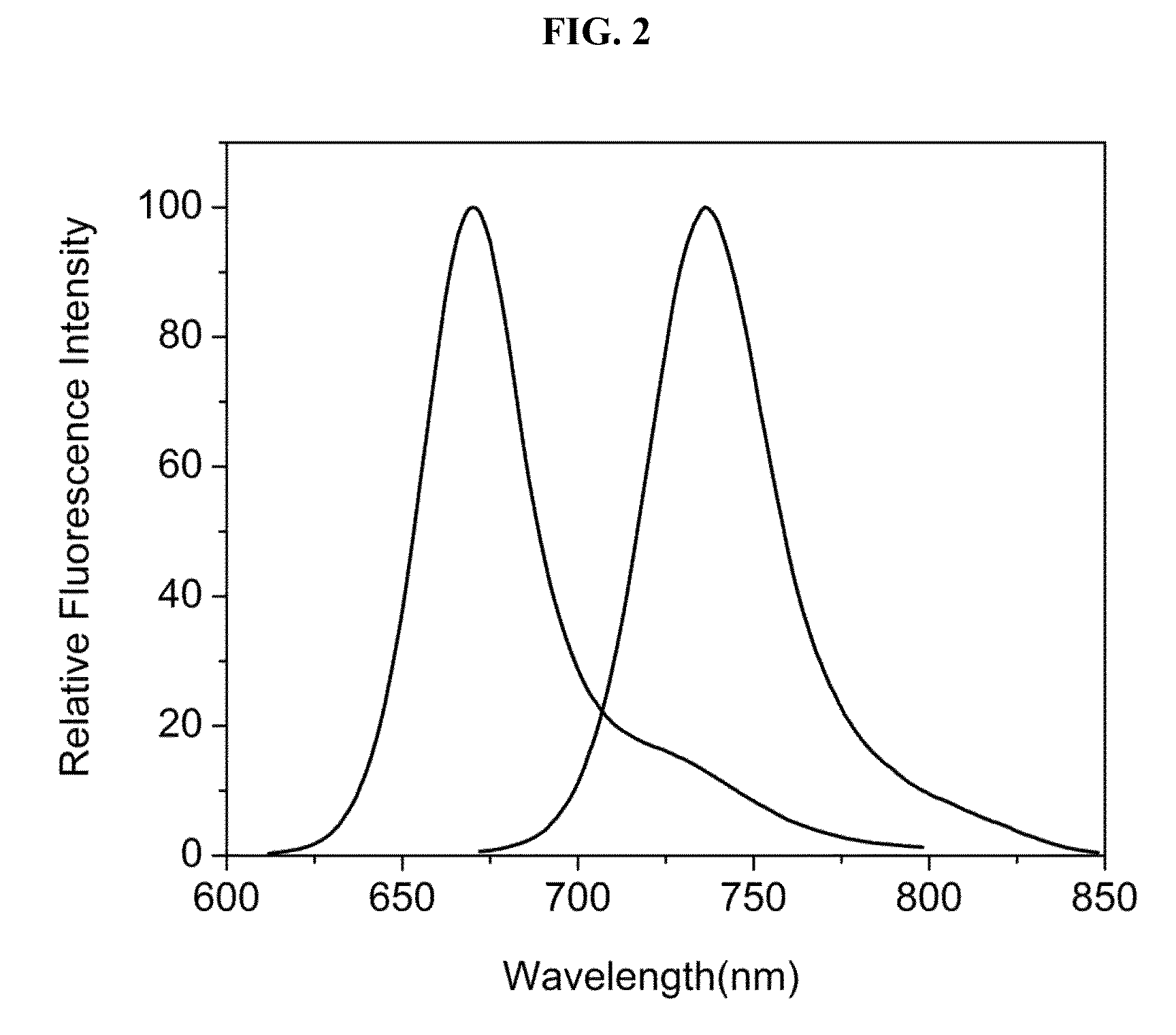

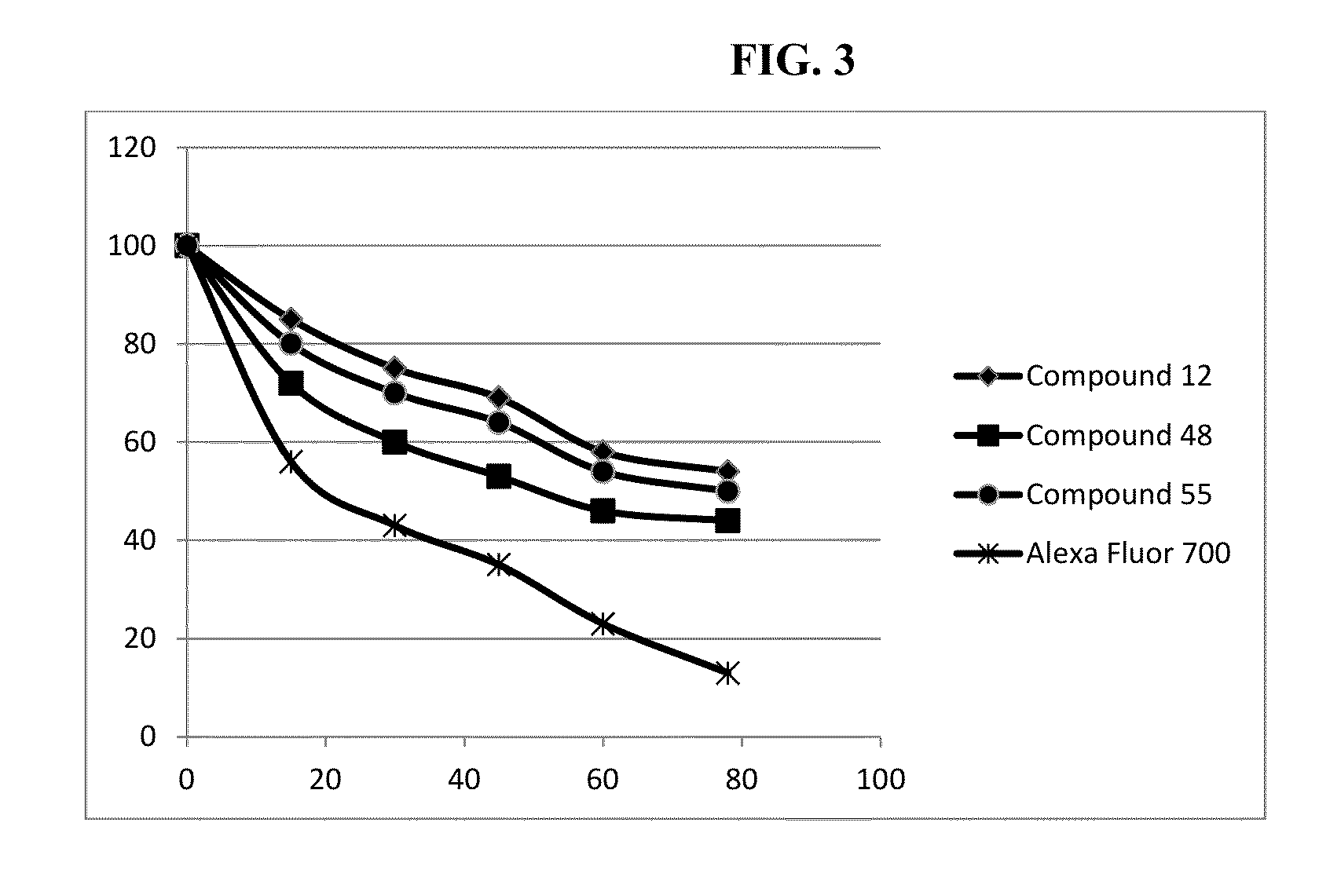

Hydroxamate substituted azaindoline-cyanine dyes and bioconjugates of the same

ActiveUS9012643B2High sensitivityReduce distractionsMethine/polymethine dyesOrganic chemistryEnergy transferAnalyte

Hydroxamate substituted azaindoline cyanine dyes, conjugates thereof and methods of using the same are provided. The subject cyanine dyes include an azaindoline ring having a hydroxamate substituent. The dyes may further include a reactive group moieties (RGM) and / or a water soluble group. Also provided are conjugates of the subject dyes. Also provided are tandem conjugates including a fluorescent protein capable of energy transfer to the dye. Methods of detecting an analyte in a sample by contacting the sample with a detection reagent are provided. The detection agent may be a dye-conjugate that specifically binds the analyte, or may be a reactive dye which conjugates to the analyte. Also provided are compositions, e.g., kits, etc., incorporating such dyes which facilitate use in such methods.

Owner:BECTON DICKINSON & CO

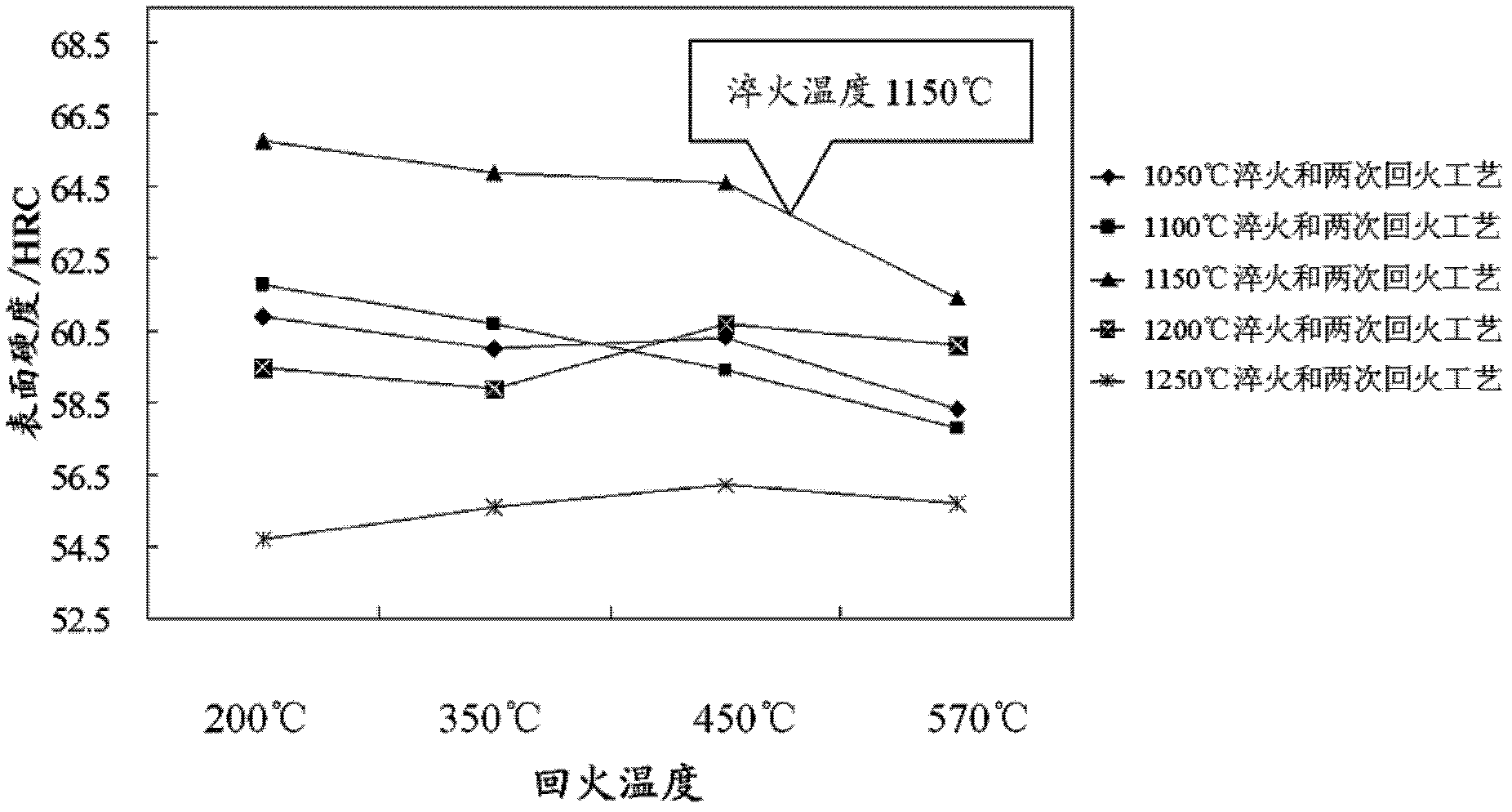

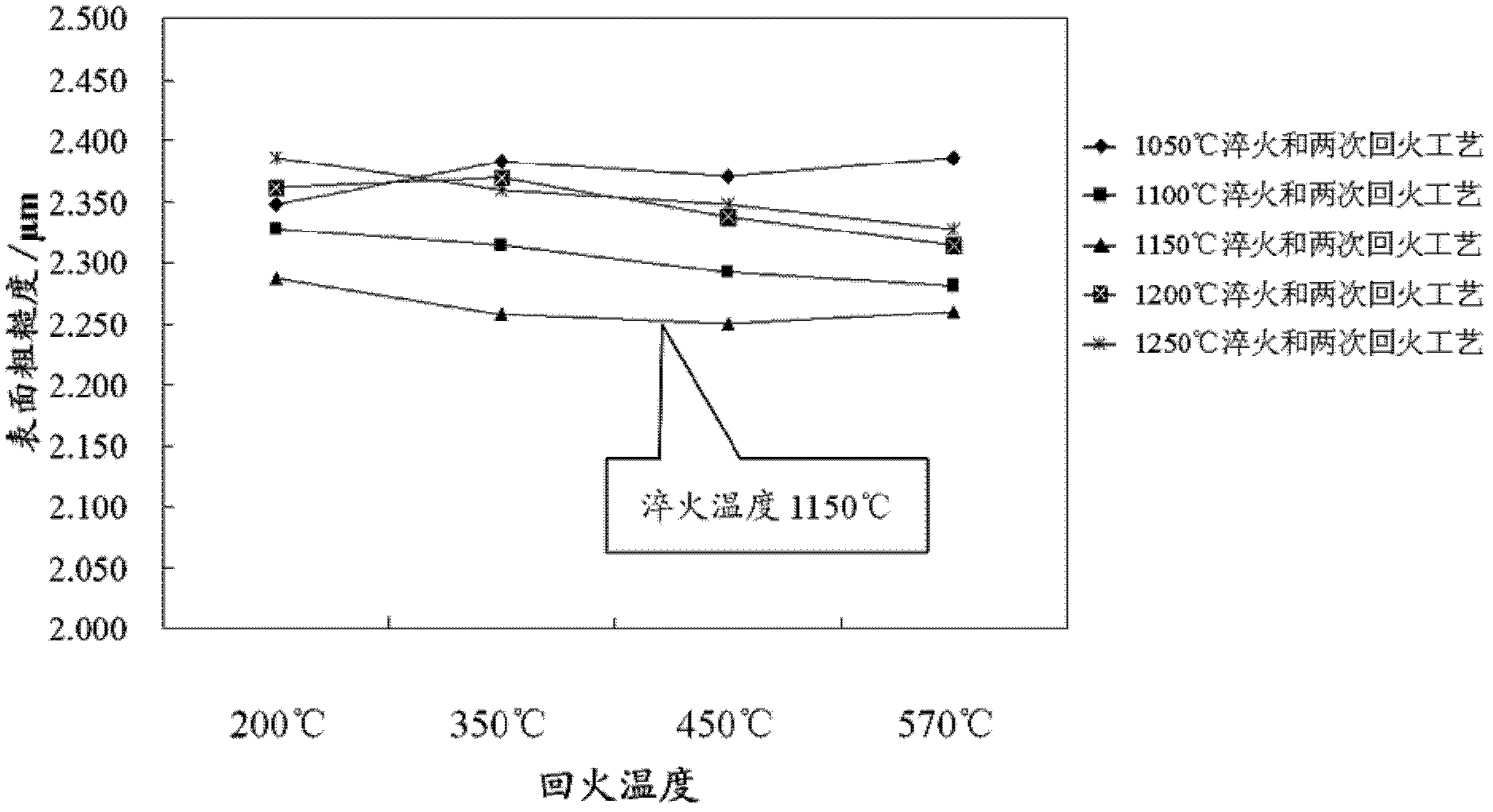

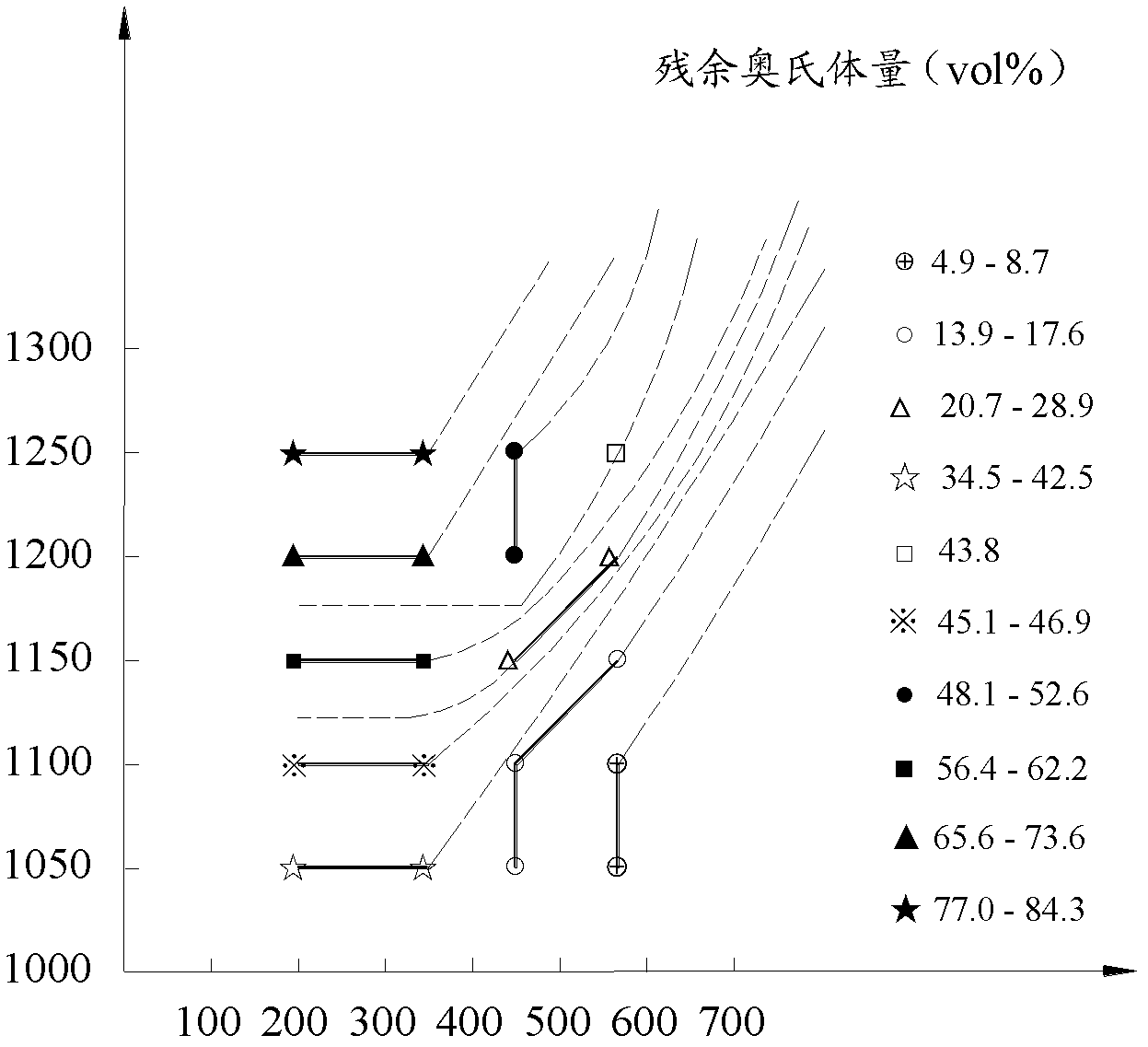

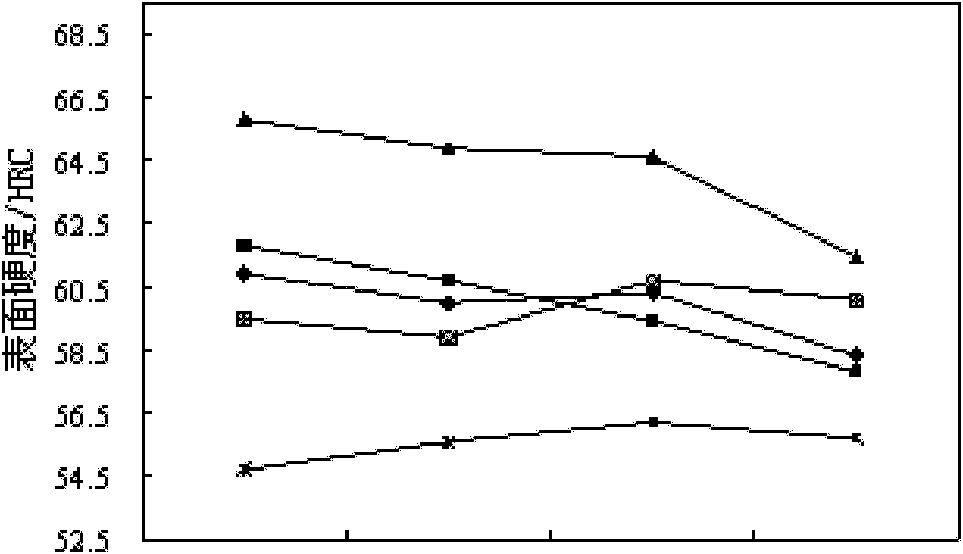

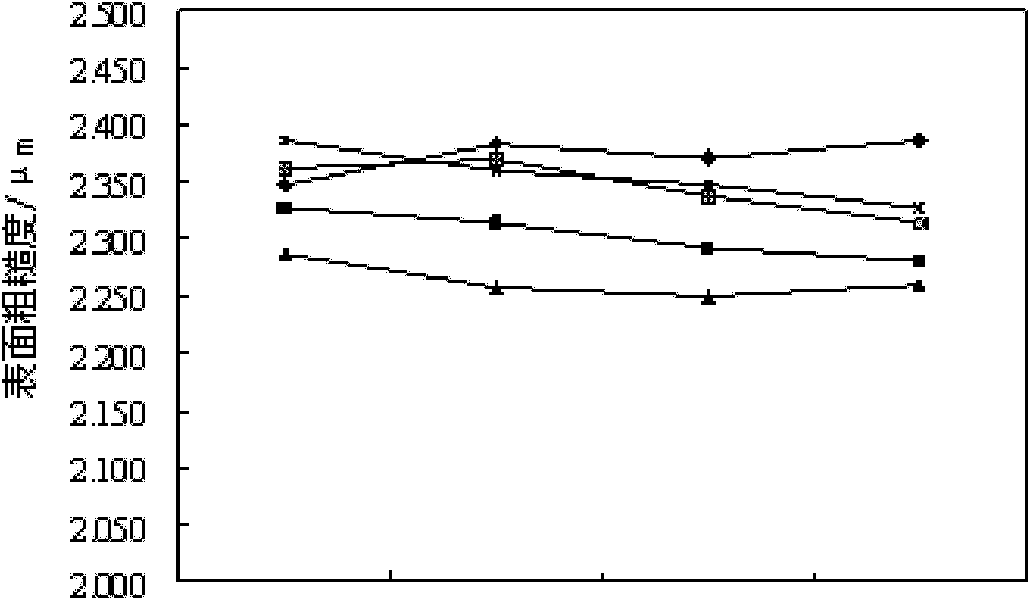

High-speed steel W18Cr4V die-casting die heat-treatment process

Owner:SHANGHAI MARITIME UNIVERSITY

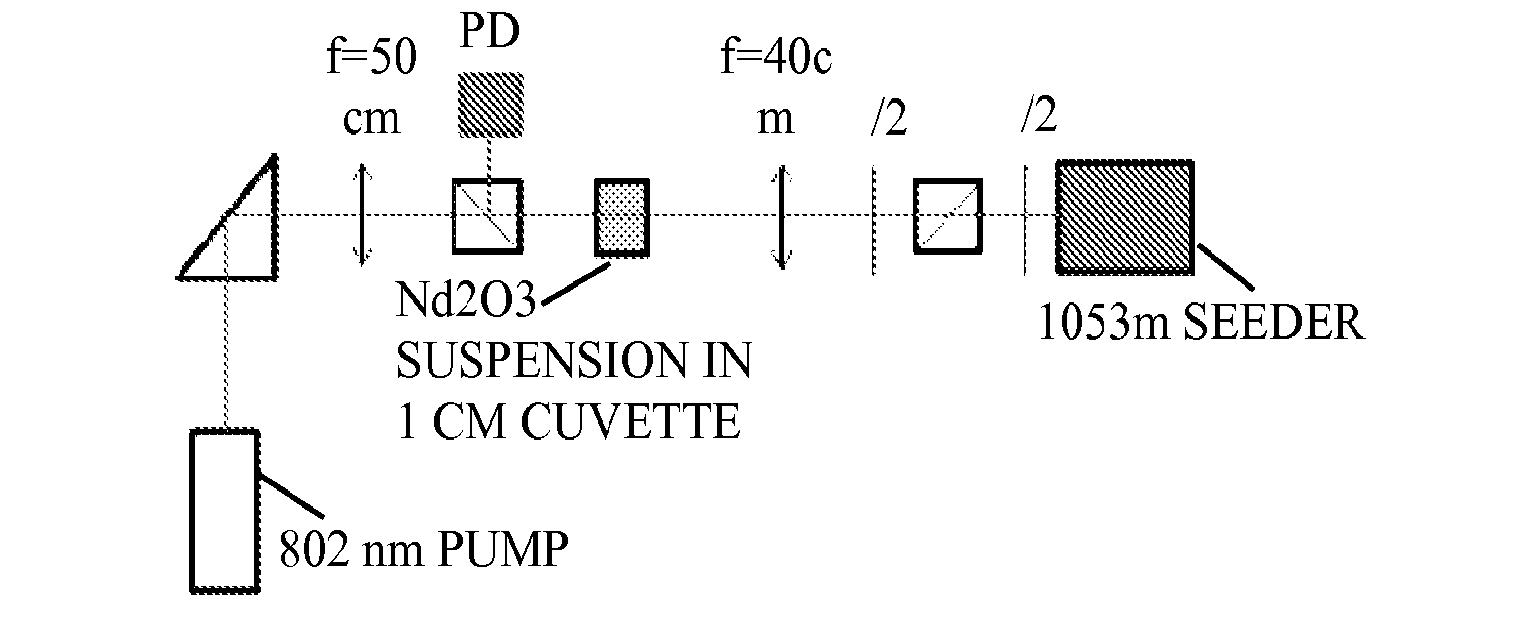

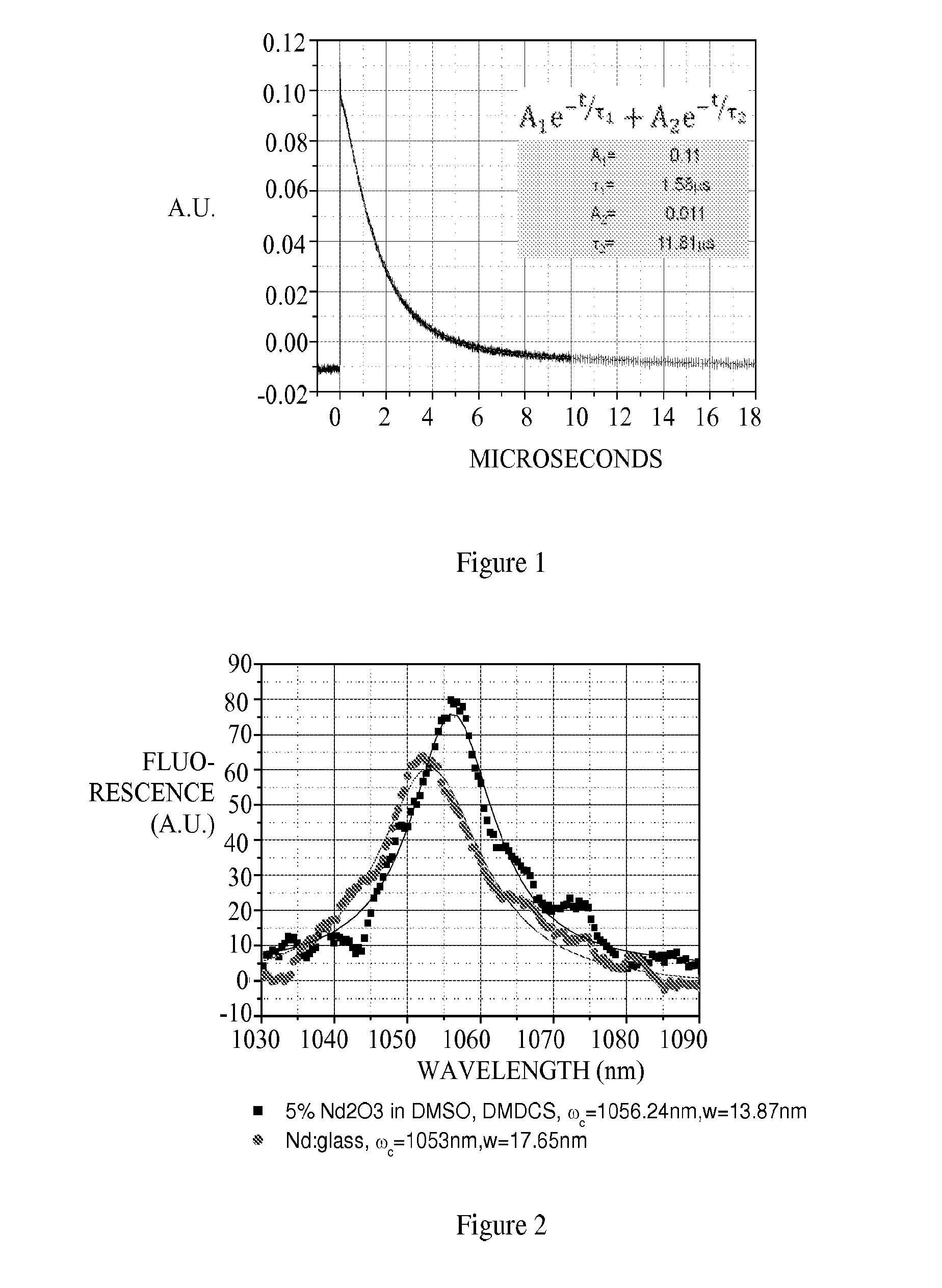

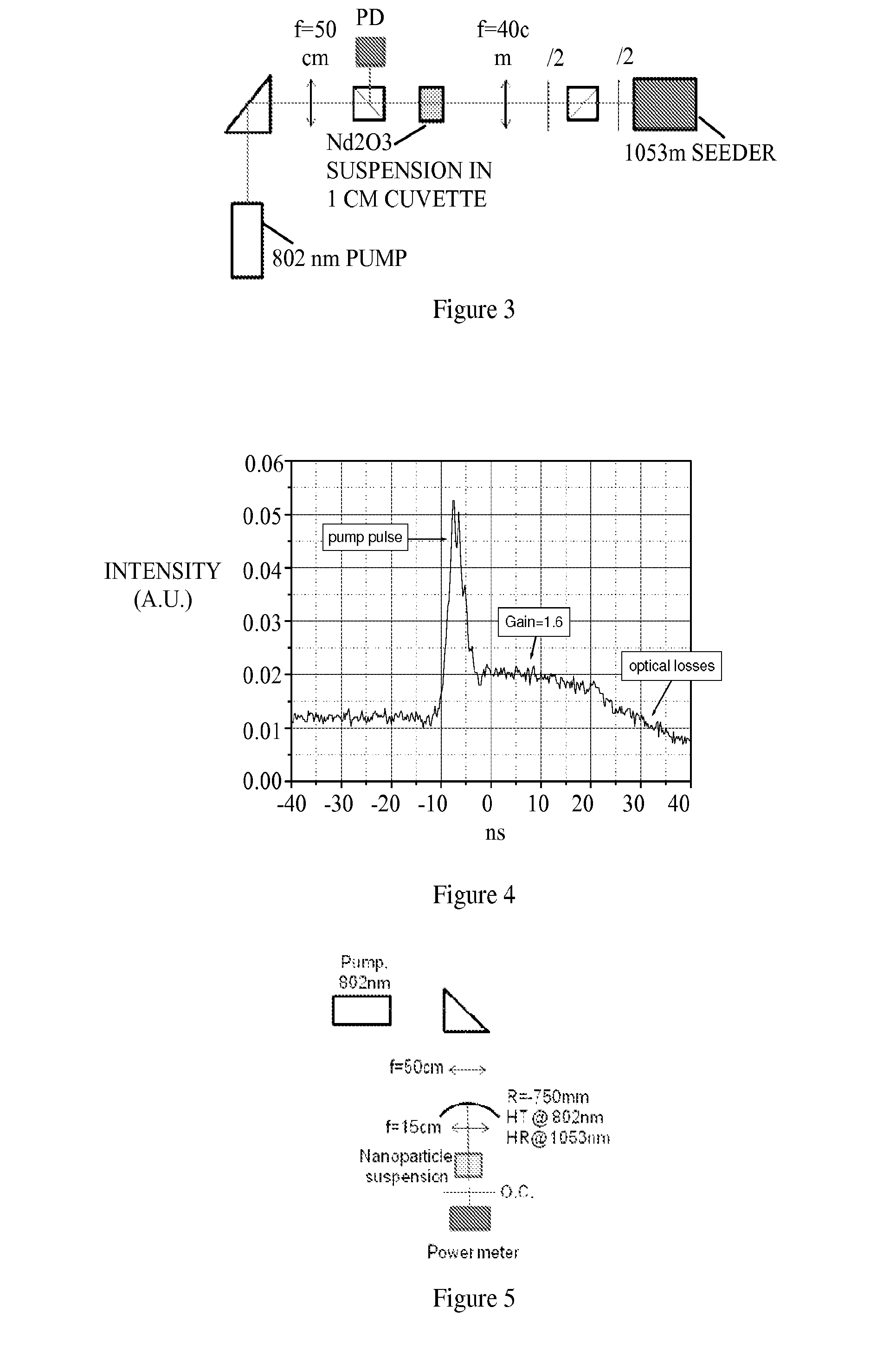

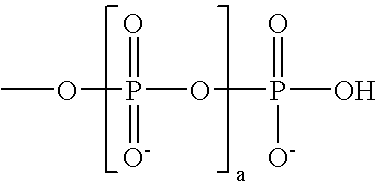

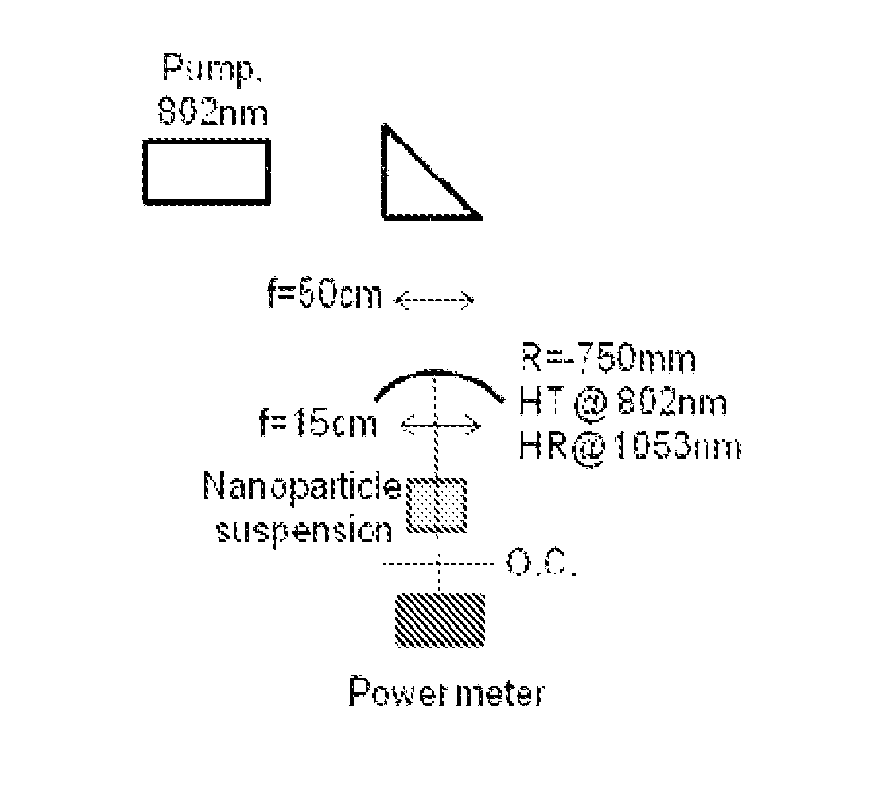

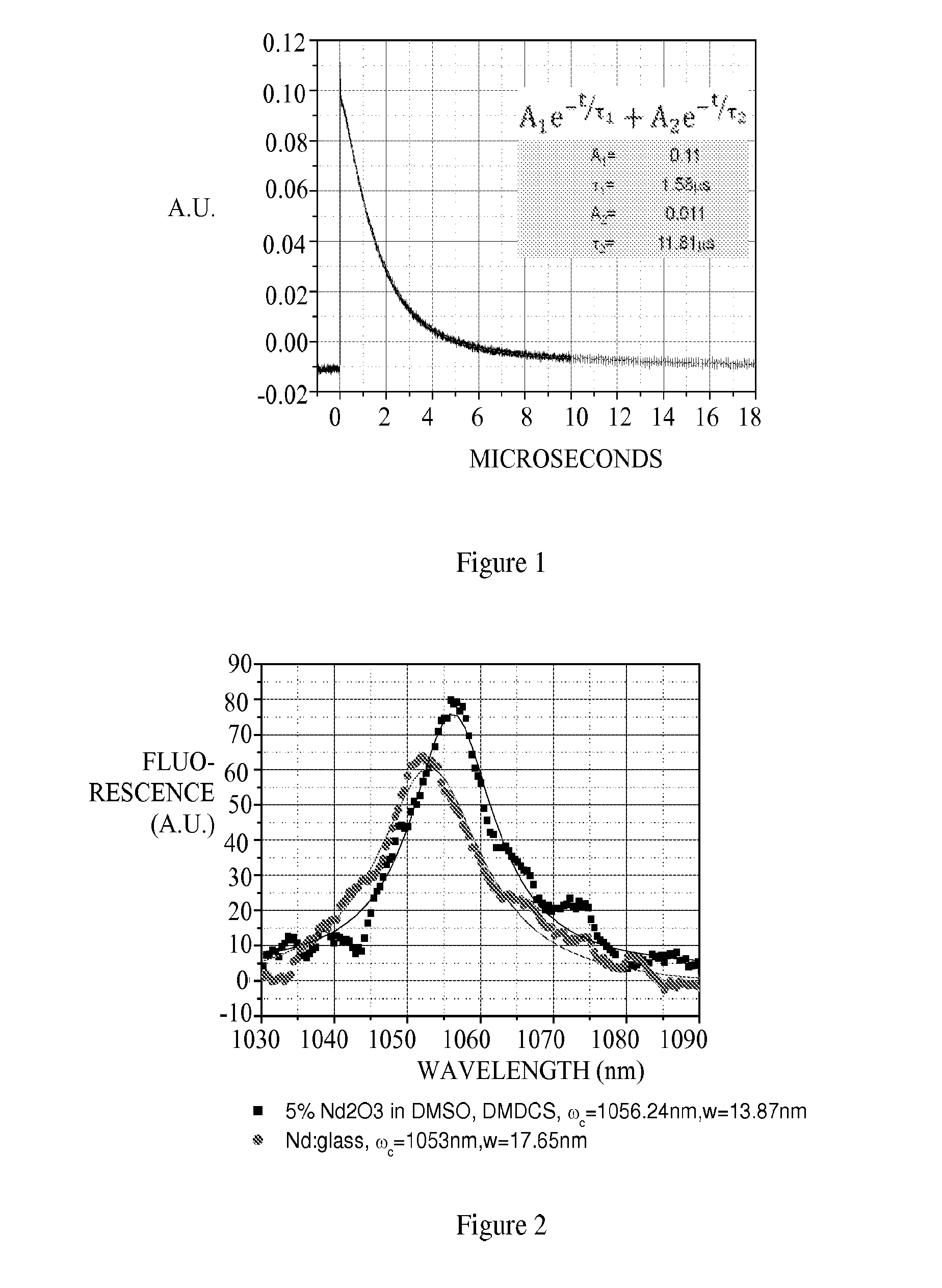

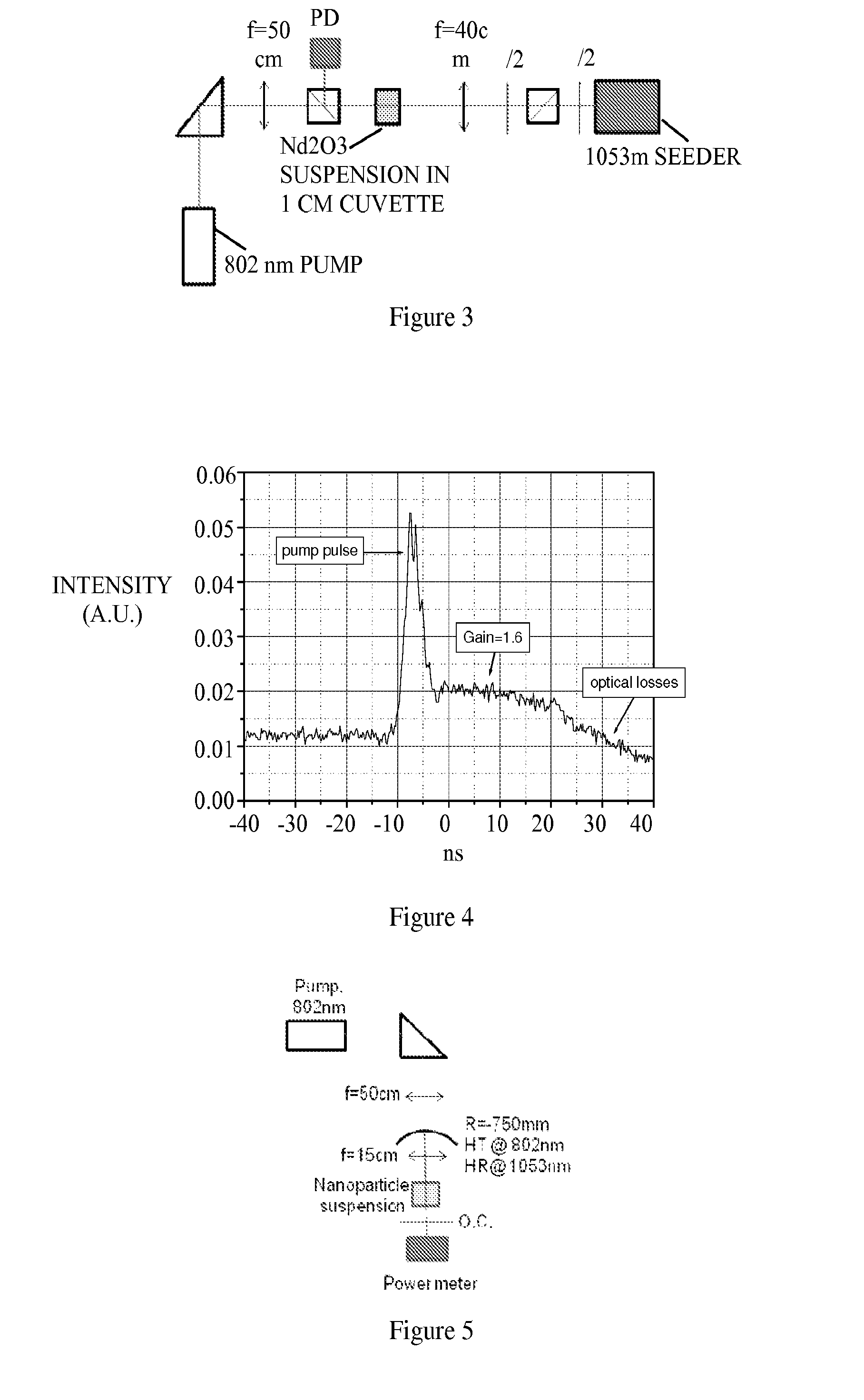

Aerosol laser

InactiveUS20140348199A1Reduced optical distortionReduce quenching processActive medium materialGas laser constructional detailsCuvetteNanoparticle

A laser device including lasing materials composed of nanoparticles in an aerosol phase. One example is Nd2O3 in DMDCS with DMSO which is sprayed into a cuvette, measures have to be taken to prevent for aggregation. The fluorescence life-time is significantly shorter compared to nanoparticles dissolved in a liquid.

Owner:STATE OF ISRAEL - SOREQ NUCLEAR RES CENT

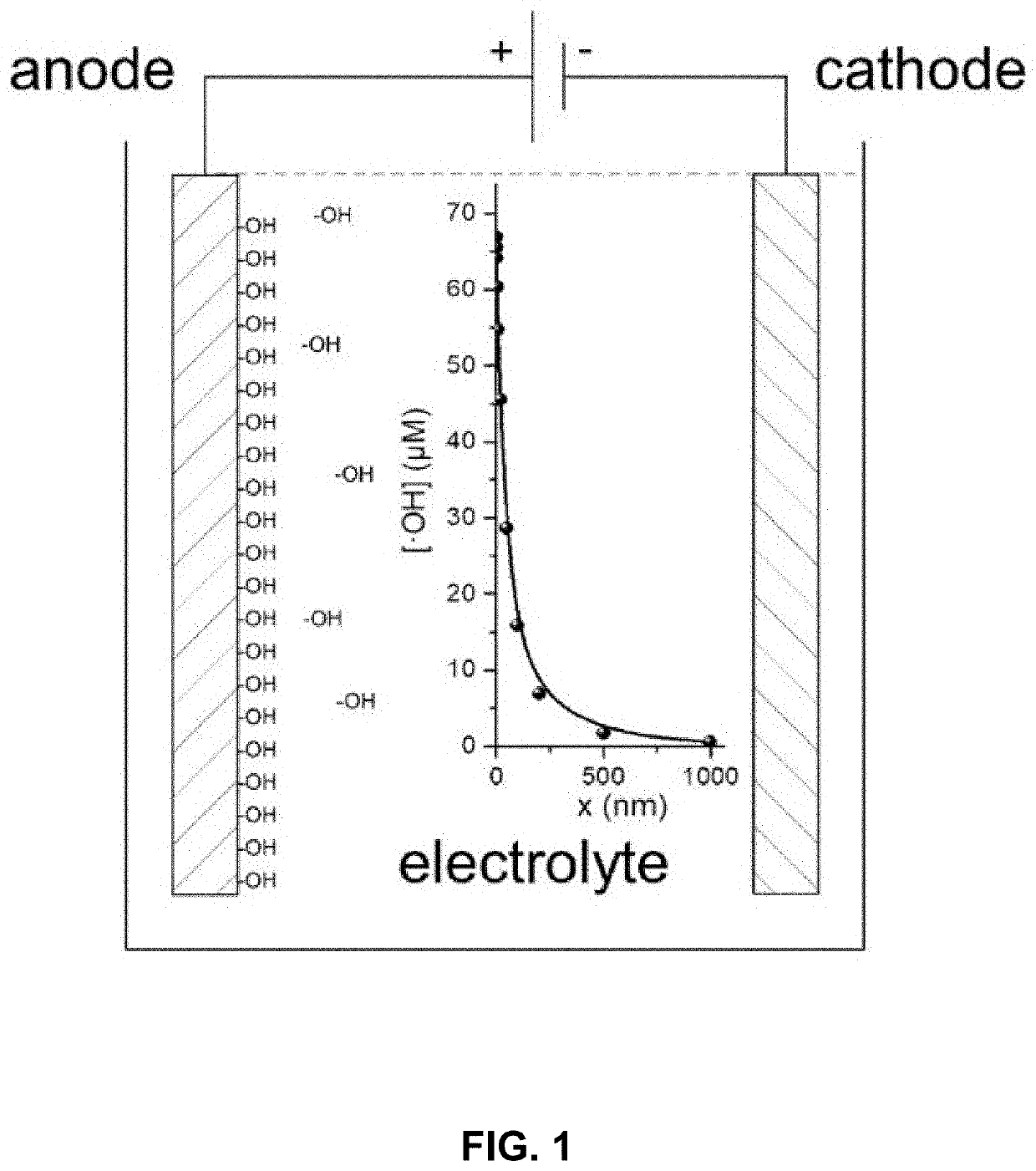

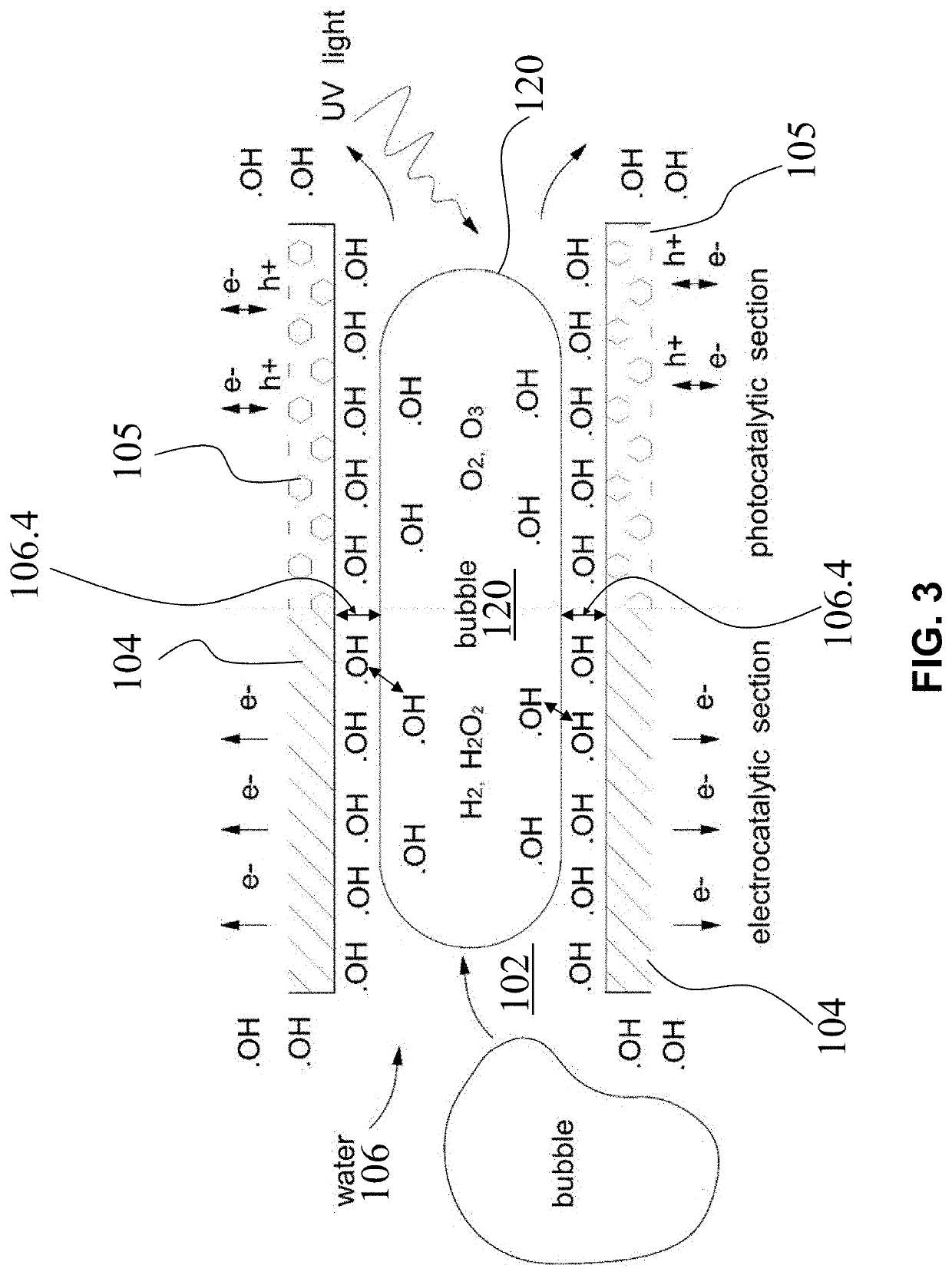

"Super-Bubble" Electro-Photo Hybrid Catalytic System for Advanced Treatment of Organic Wastewater

PendingUS20220227645A1Facilitate coatingDeposition/growth/coating easyPhysical/chemical process catalystsWater/sewage treatment by irradiationEnvironmental chemistryHydroxyl radical

The systems and methods for wastewater treatment comprise a porous substrate with photocatalytic material(s), and optionally electrocatalytic material(s), for generation of hydroxyl radicals that decompose contaminants in wastewater. The systems and methods intentionally facilitate the photocatalytic and / or electrocatalytic generation of oxygen bubbles, which facilitate an increase in concentration of hydroxyl radicals and shrink the liquid layer of wastewater at photocatalytic and / or electrocatalytic surfaces where hydroxyl radicals are generated in order to decrease quenching of hydroxyl radicals and simultaneously increase utilization or efficiency of the hydroxyl radicals for decomposition of contaminants. In embodiments, the systems and methods prolong hydroxyl radical lifetime and enhance water treatment performance for residential, commercial, municipal, medical, and / or industrial applications. In embodiments, oxygen bubbles generated on surfaces are compressed into pores or microchannels where they store generated hydroxyl radicals to prolong their lifetime in the gas phase and exchange hydroxyl radicals with the adjacent liquid layer.

Owner:CALIFORNIA INST OF TECH

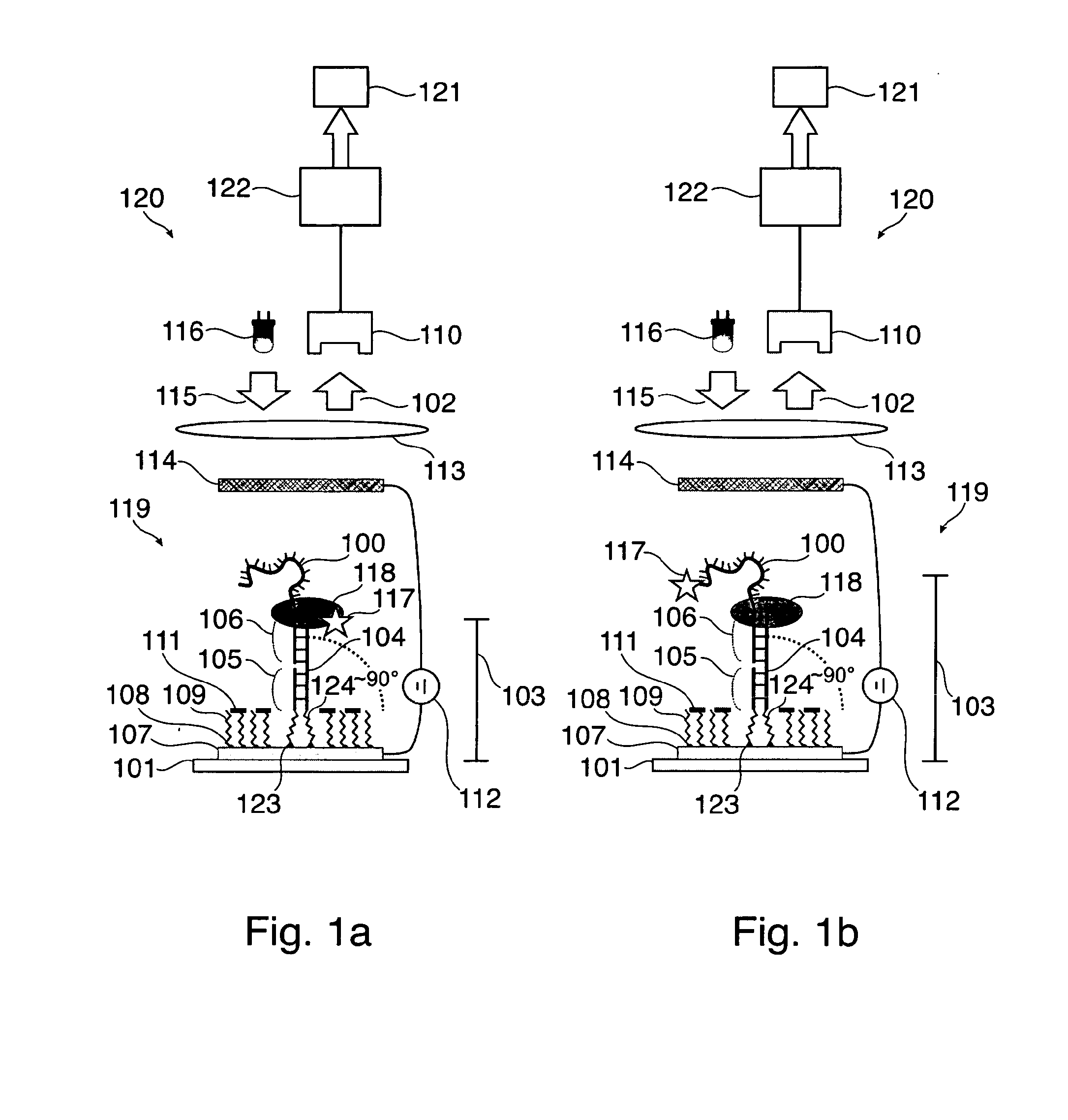

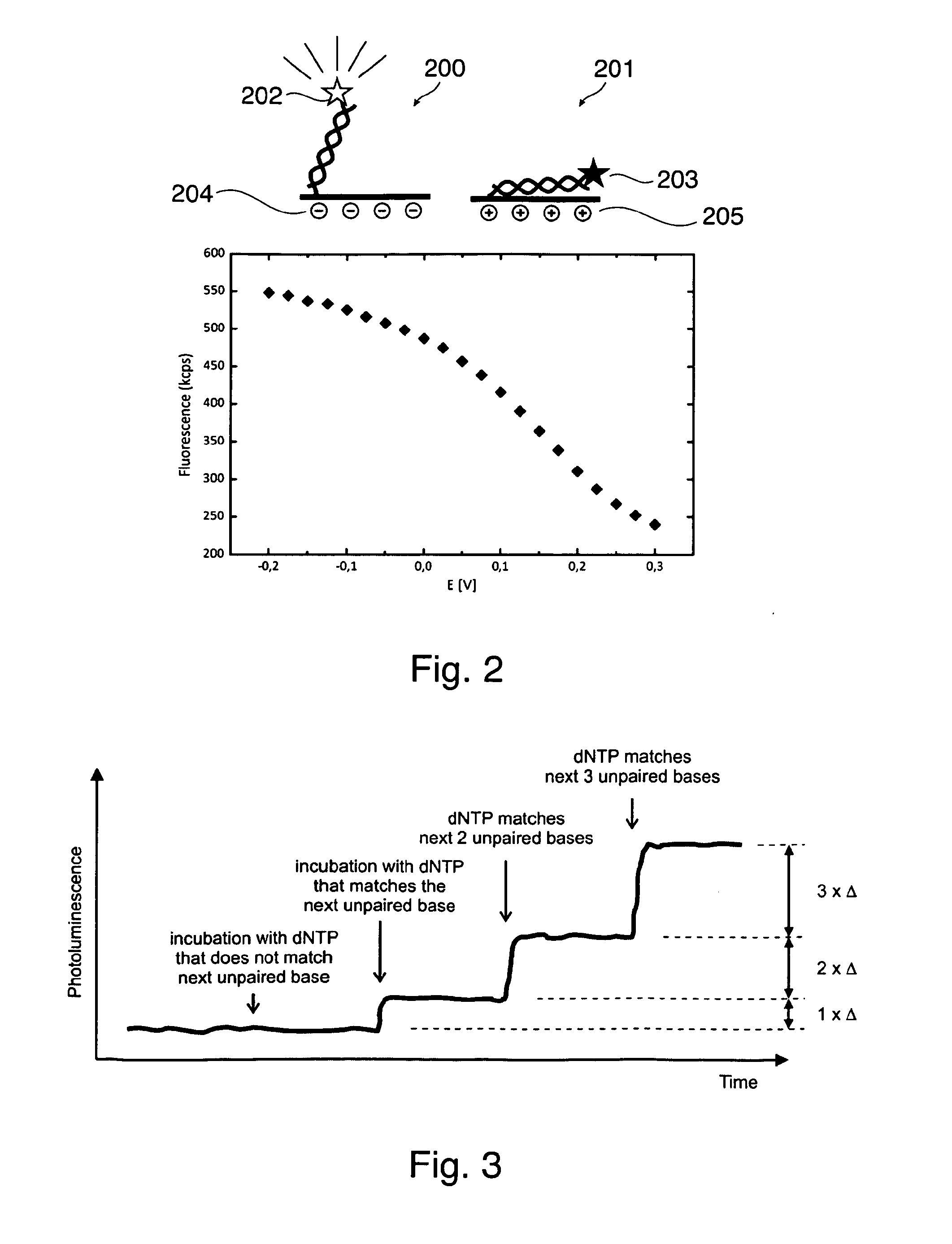

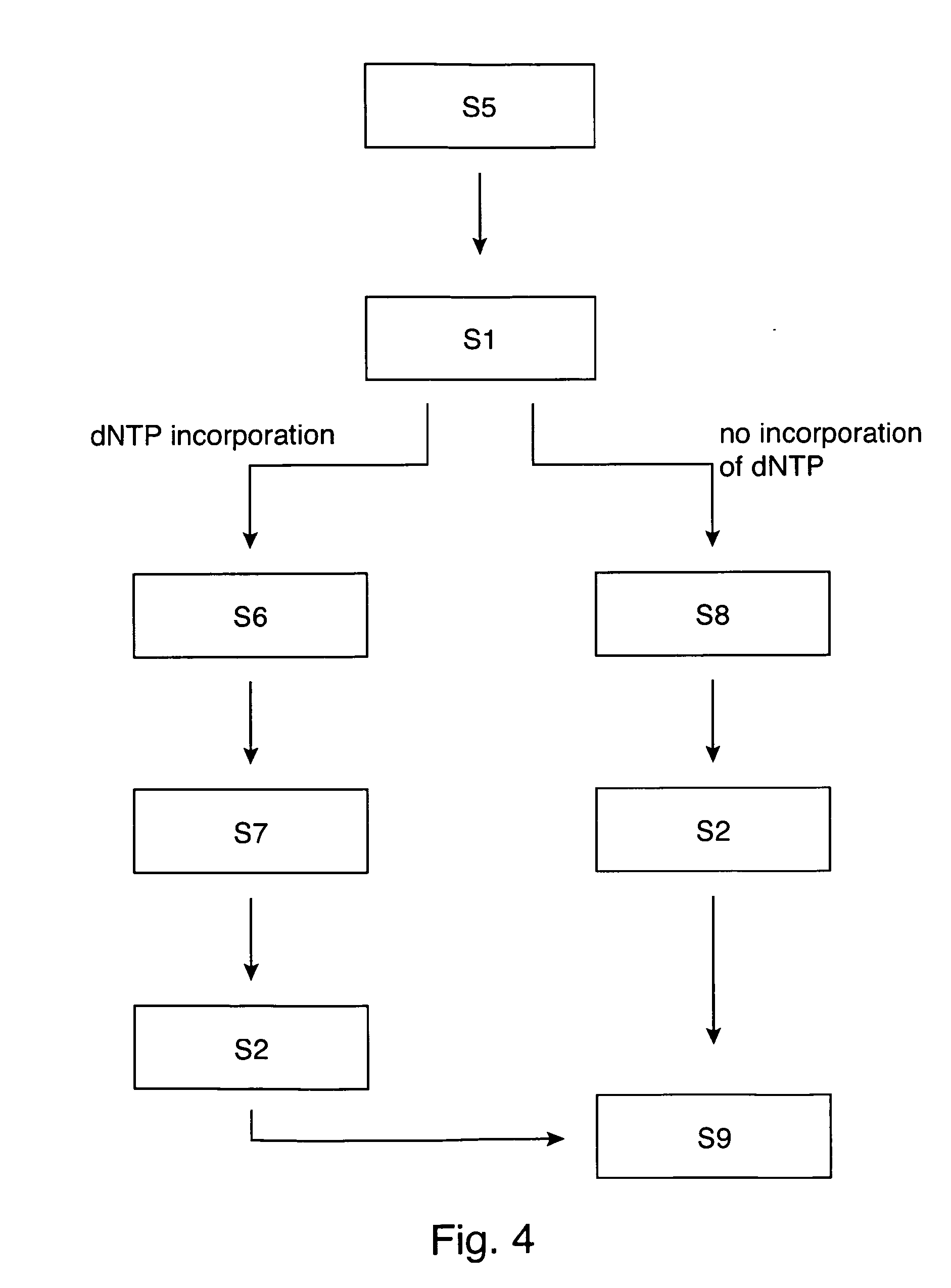

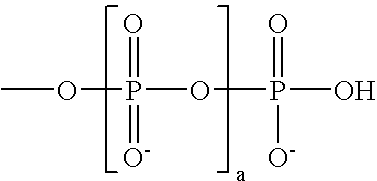

Method for sequencing a template nucleic acid immobilized on a substrate

ActiveUS20150368705A1Enhanced signalReduce quenching processBioreactor/fermenter combinationsBiological substance pretreatmentsLabel freeElectric field

The present invention is directed to sequencing of nucleic acids. A method is provided for sequencing based on immobilized nucleic acid on a surface. Advantageously, a long range detection mechanism is used for detecting, whether a nucleotide provided to the substrate of a biochip has been incorporated into the immobilized template nucleic acid. Various different alignment means are provided by the present invention which can be used for facilitating a rigidly locking of the orientation of the DNA complex, which complex comprises the template nucleic acid, the primer and the capture nucleic acid. Various different linker systems may be used to immobilize the DNA complex at a first and a second strand end, such that the desired alignment of the DNA complex is achieved. Also co-adsorbed molecules on the substrate surface can be used for such an aligning measure. Additionally, or alternatively, an electrical field may be applied for repelling the DNA complex from the electrode and for facilitating a vertical DNA complex orientation. Advantageously, label-free nucleotides can be used, if desired.

Owner:XDYNAMIC BIOSENSORS GMBH

High-speed steel heat treatment process applied in manufacturing field of moulds

The invention discloses a high-speed heat treatment process applied in manufacturing field of moulds. One time of quenching at 1250 DEG C-1280 DEG C and three or four times of tempering heat treatment at 550 DEG C-570 DEG C in the prior art is changed into a process comprising one time of quenching at 1180 DEG C-1230 DEG C and two times of tempering heat treatment at 300 DEG C-400 DEG C, so that the process can ensure that high-speed steel obtains higher hardness and lower surface roughness; the heat treatment time of the process in the invention is 60% of the original heat treatment time, the quenching and tempering temperatures are reduced, the energy consumption is reduced, and a better economic processing precision is achieved. Besides, the high-speed steel treated in the process can be applied to mould products, and the service life and the strength of the high-speed steel are both obviously longer and higher than those of prior engineering steel profiles.

Owner:SHANGHAI MARITIME UNIVERSITY

Mobility-modifying cyanine dyes

InactiveUS20050107617A1Easy to getGood water solubilityMethine/polymethine dyesSugar derivativesCyanineNucleic acid sequencing

The present invention provides a novel class of fluorescent cyanine dye compounds that are modified at one of the hetercyclic ring nitrogen atoms with a mobility-modifying moiety that permits the electrophoretic mobilities of polynucleotides labeled with the mobility-modifying cyanine dyes to be adjusted or tuned in a predictable fashion while retaining enzymatic activity. The ability to predictably tune the relative electrophoretic mobilities of the dyes permits the creation of sets of mobility-matched fluorescent dyes of a variety of structures for a variety of applications, including fluorescence-based 4-color nucleic acid sequencing reactions.

Owner:APPLERA

Aerosol Laser

InactiveUS9214780B2Wider spectral windowReduce distortionLaser arrangementsActive medium materialCuvetteNanoparticle

A laser device including lasing materials composed of nanoparticles in an aerosol phase. One example is Nd2O3 in DMDCS with DMSO which is sprayed into a cuvette, measures have to be taken to prevent for aggregation. The fluorescence life-time is significantly shorter compared to nanoparticles dissolved in a liquid.

Owner:STATE OF ISRAEL - SOREQ NUCLEAR RES CENT

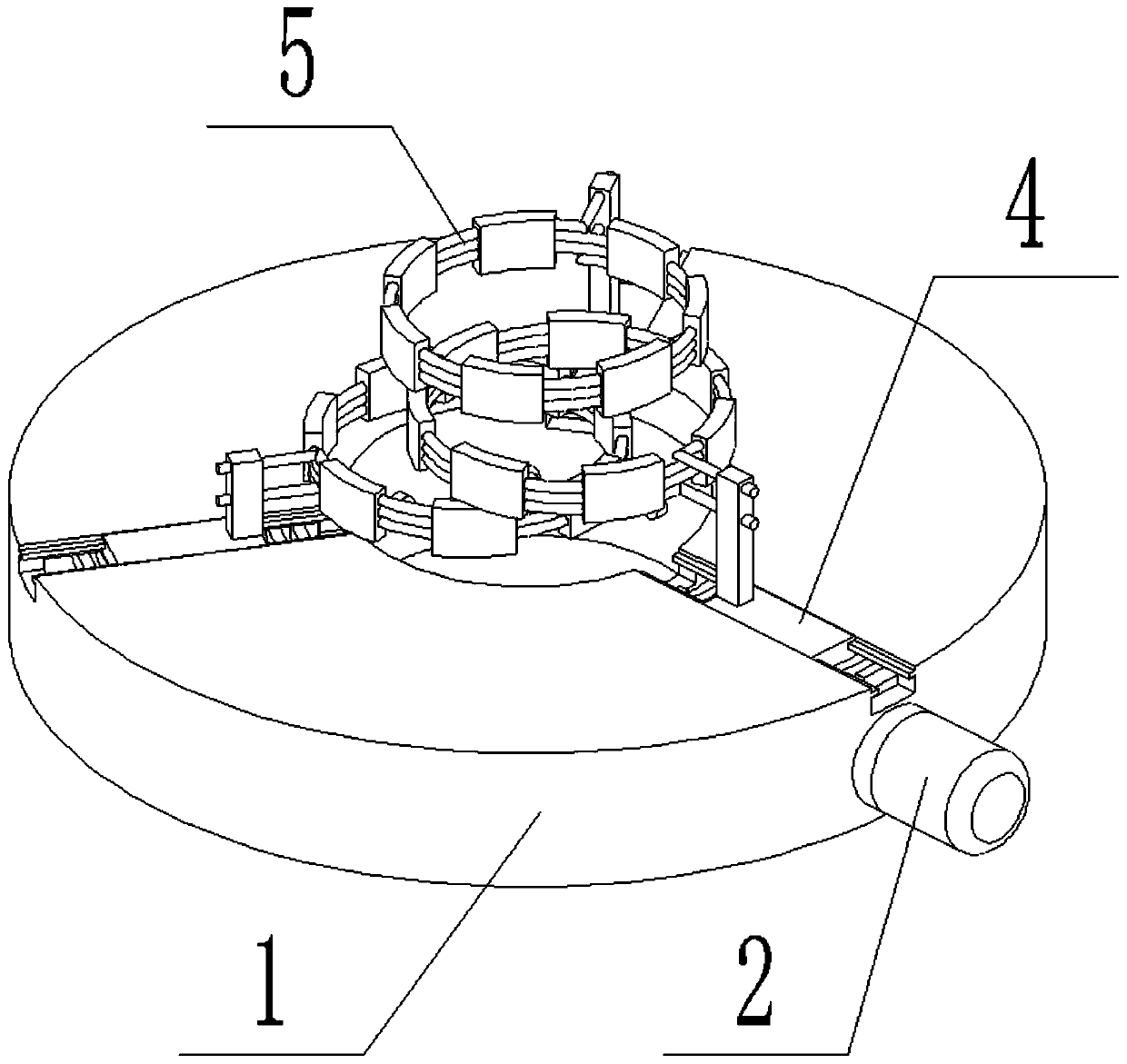

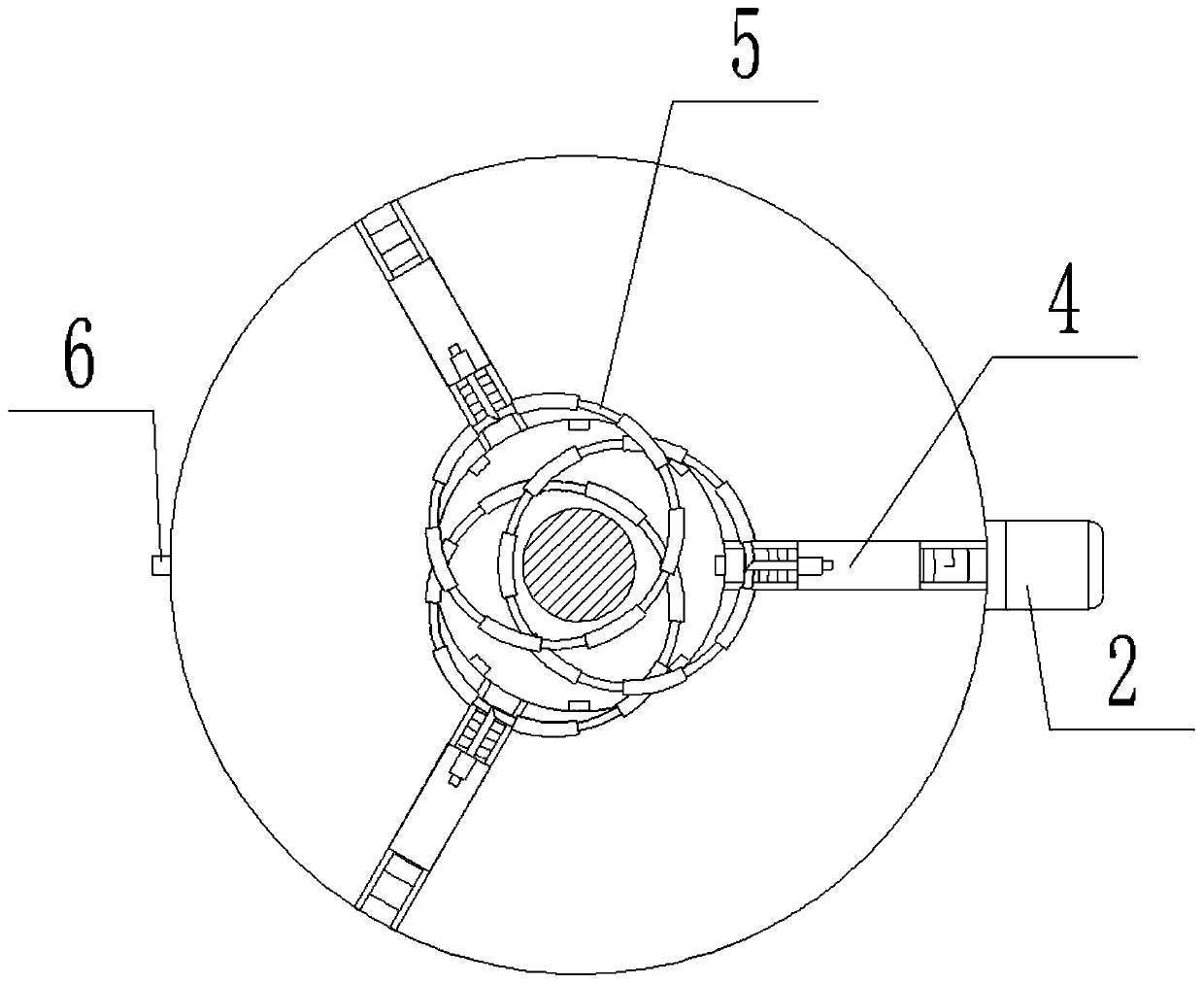

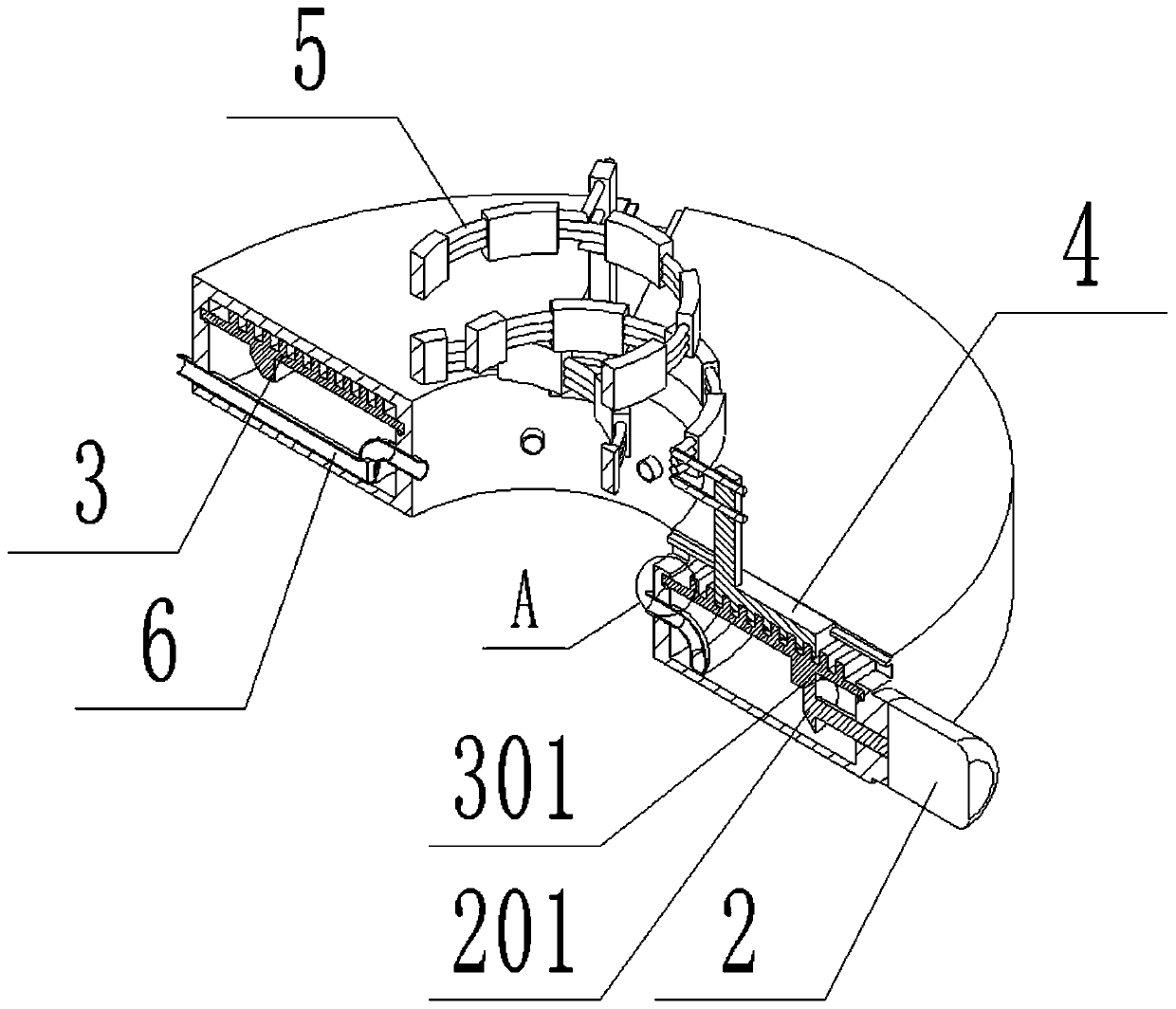

Adjustable quenching and heating device for tempering production line equipment

InactiveCN111270055AChange eccentricityChange diameterFurnace typesIncreasing energy efficiencyProduction lineTempering

The invention provides an adjustable quenching and heating device for tempering production line equipment. The adjustable quenching and heating device comprises a base, a protruding block and a cooling pipe. A threaded plate is axially connected into the base. Three sliding supports are evenly distributed on and sliding connected with the top of the base. A high-frequency heating pipe is fixedly connected with the top of each sliding support. A cooling pipe is fixedly connected with the inner lower side of the base. A motor is fixedly connected with the right end face of the base. By changingthe sizes of the inscribed circles of the three high-frequency heating pipes and performing heating through the high-frequency heating pipes with the similar inscribed circles, the aim of hanging thediameter of quenched parts is realized, the adaptability and production efficiency of the quenching equipment are improved, the quenching work of a step shaft can be completed at a time, the quenchingprocess is reduced, productivity is improved, and production cost is reduced.

Owner:许仙福

OLED light-emitting device with silver nanolayer, and production method thereof

ActiveUS10566579B2Improve internal quantum efficiencyEnhance speed of spontaneous radiationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringHole transport layer

This disclosure provides an OLED light-emitting device, a production method thereof as well as a display apparatus, and relates to the technical field of OLED display, which can enhance the internal quantum efficiency of a blue OLED light-emitting device. This OLED light-emitting device comprises a substrate, and an anode, a hole transport layer, a blue light-emitting layer and a cathode provided on the substrate; the OLED light-emitting device further comprises an Ag nanolayer located between the anode and the hole transport layer; wherein the blue light-emitting layer is a blue phosphorescent light-emitting layer; the absorption spectrum of the Ag nanolayer overlaps the emission spectrum of the blue phosphorescent light-emitting layer, and the blue phosphorescent light-emitting layer is located within the penetration depth of surface plasma of Ag nanoparticles in the Ag nanolayer. It is used in the production of a blue OLED light-emitting device and a display apparatus comprising the same.

Owner:BOE TECH GRP CO LTD +1

Drill quenching mechanism

InactiveCN107674966AEasy to processImprove work efficiencyFurnace typesHeat treatment furnacesQuenchingBatch production

The invention relates to a quenching mechanism for a drill bit, which comprises a processing box body; a quenching platform installed in the box body; The motor is driven to rotate; a heating unit and a cooling unit are arranged in the processing box and distributed along the quenching platform in turn. The guide plate is provided with a vertically oppositely extending heat-resistance-resistance baffle which is embedded and moves up and down. The advantage of the invention is that: through the mutual cooperation between the quenching platform, the placing plate group, the heating unit, and a cooling unit, the material feeding, material heating and material cooling processes can be simultaneously performed, and the cyclic work can be performed to realize batch production. production.

Owner:南通旭越光电科技有限公司

Method for producing quenched and tempered wear-resistant steel plate NM400 with thickness of 30 mm or less by using online waste heat

The invention relates to a method for producing a wear-resistant steel plate NM400 which is 30 mm in thickness and is quenched and tempered by using on-line waste heat. The on-line waste heat is used for carrying out on-line quenching on a medium-thickness plate production line by using waste heat after rolling and carrying out tempering by using an off-line heat treatment furnace, the tempering temperature is 450-500 DEG C, and the tempering time is 1.8 Tmin (T is the thickness of the steel plate). According to the method, on-line waste heat quenching is used for replacing the process that the steel plate is heated to an austenite area from the room temperature in an off-line heat treatment furnace and then quenched, and the heat treatment cost for producing the quenched and tempered wear-resistant steel plate is greatly reduced. Through the design of chemical components, the martensite structure is obtained by cooling to below 400 DEG C at the cooling rate of 10-15 DEG C / s. The NM400 steel grade comprises the following chemical components in percentage by mass: 0.22 to 0.26 percent of C, 0.4 to 0.6 percent of Si, 1.3 to 1.55 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.007 percent of S, 0.3 to 0.45 percent of Mo, 0.8 to 0.95 percent of Cr, 0.01 to 0.035 percent of Al, 0.001 to 0.005 percent of B, less than or equal to 0.04 percent of Ti and the balance of Fe and inevitable impurities.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

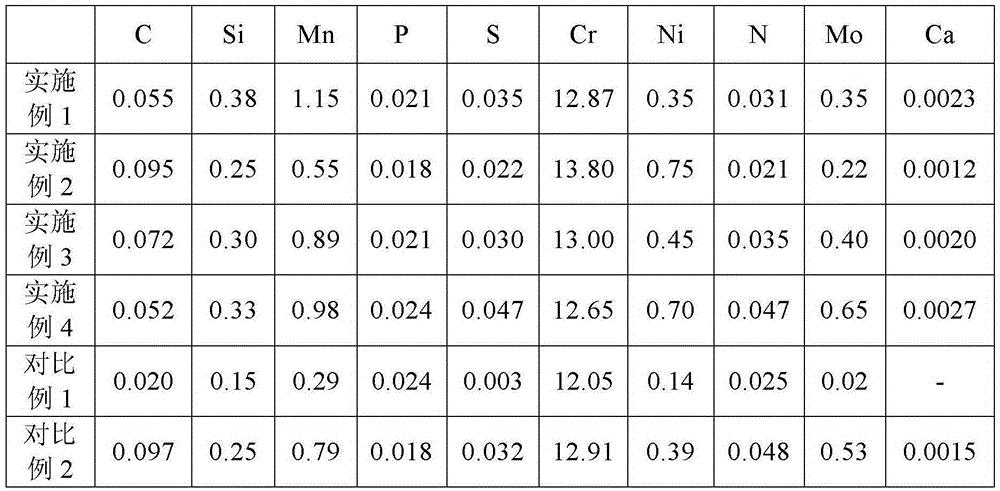

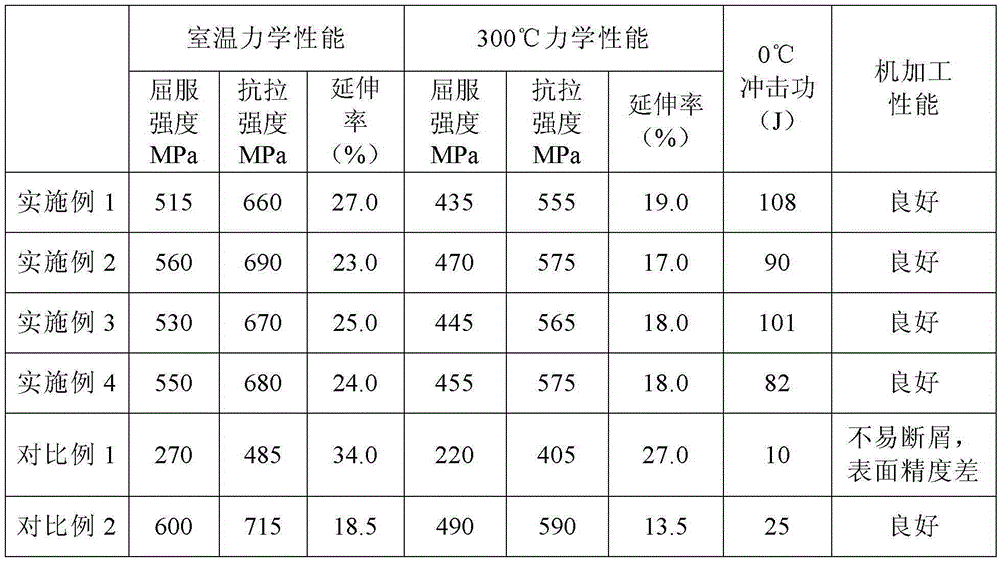

A kind of martensitic stainless steel and its manufacturing method

ActiveCN103710638BImprove room temperature strengthImprove medium temperature strengthMetallurgyMartensitic stainless steel

Owner:宝武特种冶金有限公司

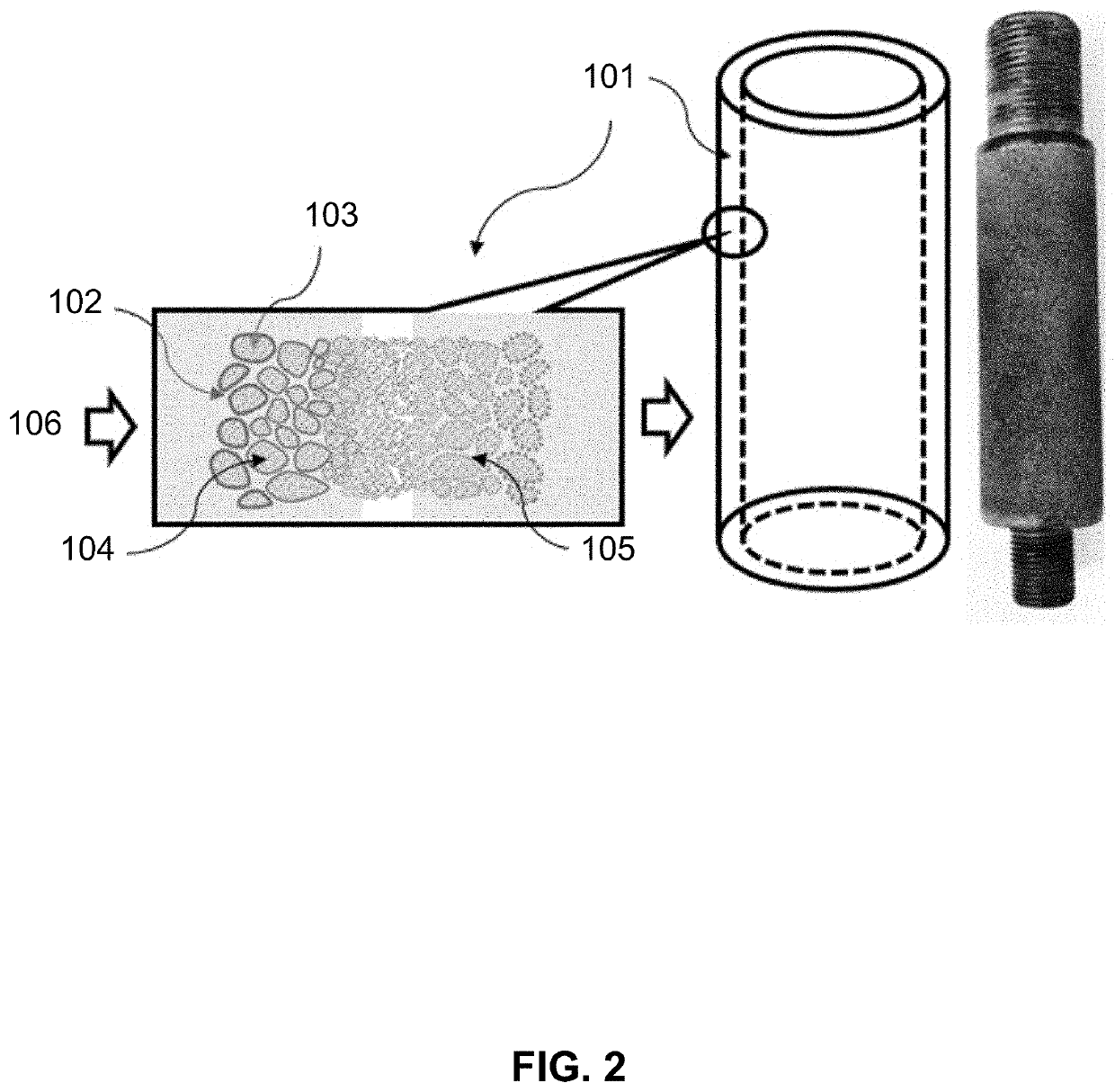

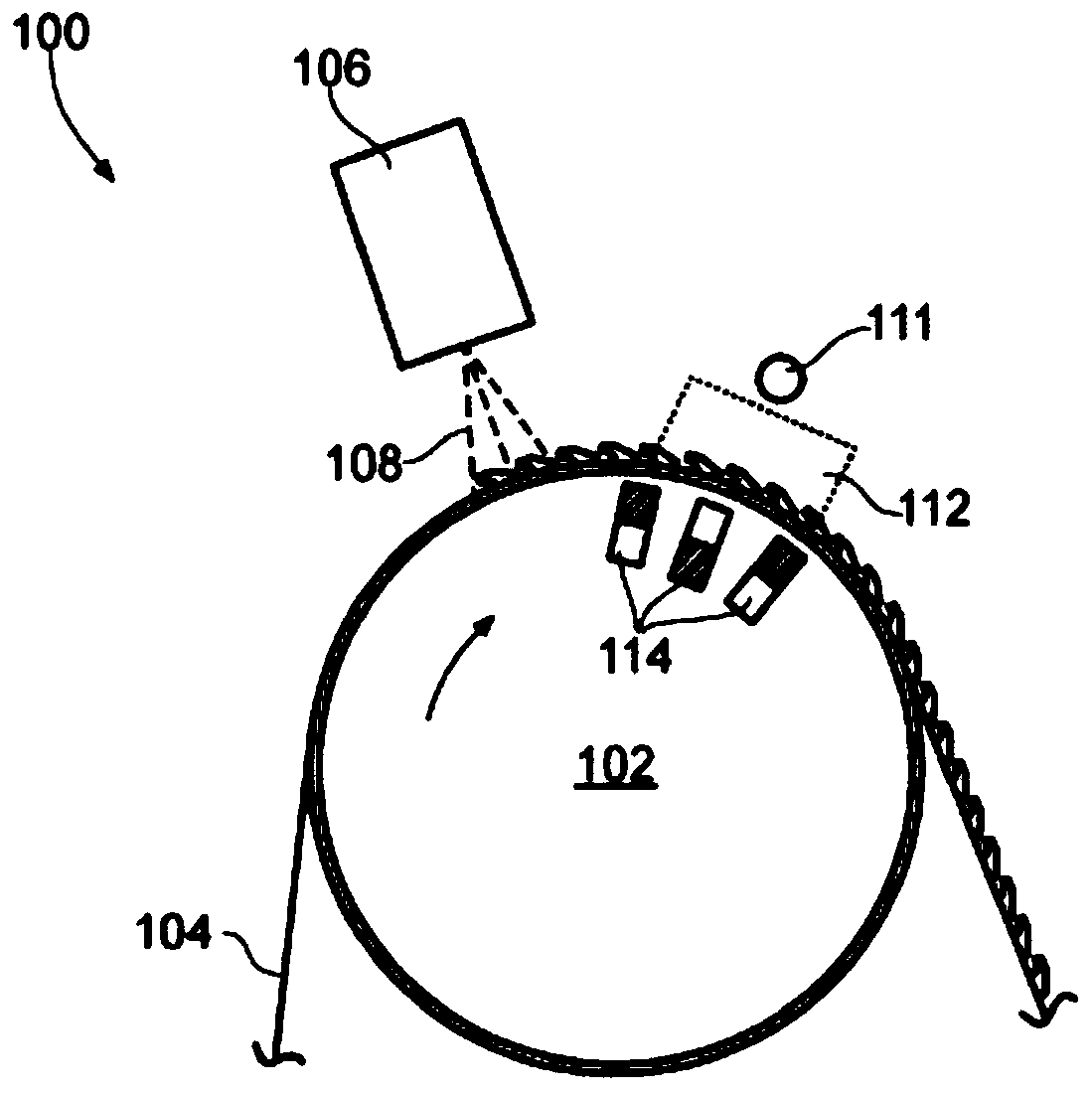

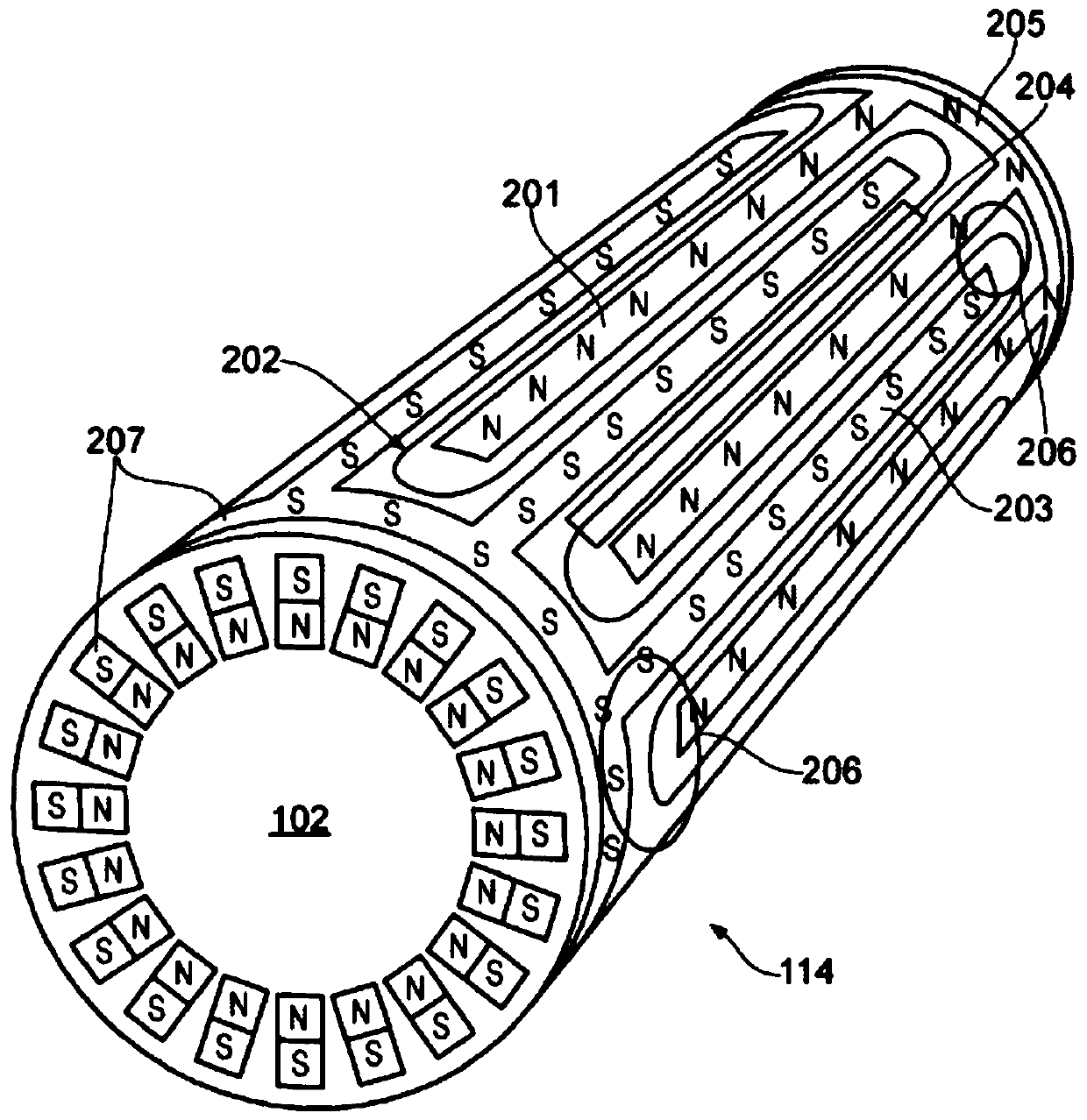

Apparatus and method for processing, coating or curing a substrate

PendingCN111418041AReduce quenching processUniform energy supplyElectric discharge tubesVacuum evaporation coatingPlasma generatorElectrical polarity

An apparatus for processing or curing a substrate, the apparatus comprising: a support (102) arranged to transport a moving flexible substrate (104), a plasma generator (110) arranged to generate plasma (112), a magnet array (114) arranged to spatially define the plasma, wherein the magnet array comprises: a first elongate magnet (404) having a first polarity; a second elongate magnet (406), substantially parallel to the first elongate magnet, having a second polarity, opposite to the first polarity, such that the first and second elongate magnets define a first straight magnetic flux portion(204); a third elongate magnet (408), substantially parallel to the first elongate magnet,having the first polarity, such that the second and third elongate magnets define a second straight magnetic flux portion, connected to the first straight magnetic flux portion by a first curved magnetic flux portion (206); a fourth elongate magnet (410), substantially parallel to the first elongate magnet, having the second polarity, such that the third and fourth elongate magnets define a third straight magnetic flux portion, connected to the second straight magnetic flux portion by a second curved magnetic flux portion.

Owner:CAMVAC

Direct quenching type yield 800mpa grade structural steel plate and production method thereof

Owner:HEBEI IRON AND STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com