Method for producing quenched and tempered wear-resistant steel plate NM400 with thickness of 30 mm or less by using online waste heat

A wear-resistant steel plate, quenching and tempering technology, applied in the field of wear-resistant steel production, can solve the problems of energy saving and emission reduction in the iron and steel industry, poor impact deformation resistance of wear-resistant steel, high energy consumption, etc., to shorten the delivery cycle and reduce quenching. process, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

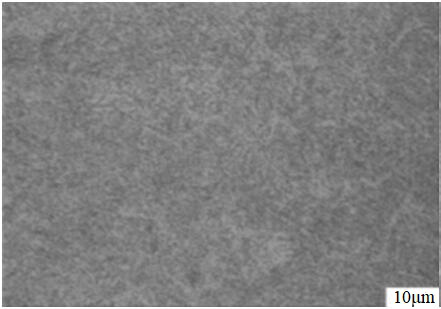

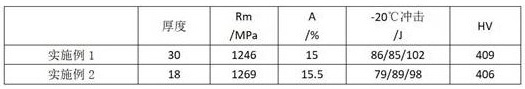

[0025] The chemical composition of a quenched and tempered wear-resistant steel plate NM400 with a thickness of 30mm is calculated by mass percentage: C: 0.23%, Si: 0.55%, Mn: 1.42%, P: 0.01%, S: 0.004%, Mo: 0.4%, Cr: 0.88%, Al: 0.024%, B: 0.0024%, Ti: 0.017%, and the balance is Fe and unavoidable impurities. Such as figure 1 As shown, the metallographic structure of the steel plate is tempered martensite, the grain distribution is uniform, and no mixed crystals and segregation appear.

[0026] The production method of the quenched and tempered wear-resistant steel plate NM400 with a thickness of 30 mm above is as follows:

[0027] (1) In the converter smelting process, the high-quality molten iron is desulfurized by the KR method, and medium-carbon ferromanganese is added during the converter smelting process. The control endpoint P≤0.015%, Als (acid-soluble aluminum): 0.04%; the slag-stopping cone is used , Slag stopper for double slag stop tapping, slag thickness: 40mm, a...

Embodiment 2

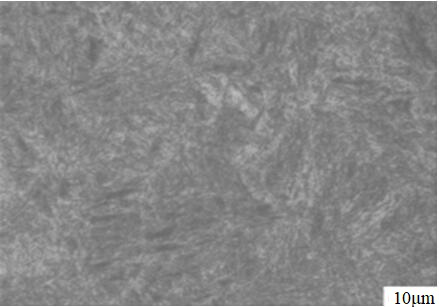

[0038] Such as figure 2 As shown, the chemical composition of a quenched and tempered wear-resistant steel plate NM400 with a thickness of 18mm is calculated by mass percentage: C: 0.23%, Si: 0.54%, Mn: 1.43%, P: 0.012%, S: 0.003%, Mo: 0.41%, Cr: 0.86%, Al: 0.025%, B: 0.0021%, Ti: 0.016%, and the balance is Fe and unavoidable impurities. Such as figure 2 As shown, the metallographic structure of the steel plate is tempered martensite, the grain distribution is uniform, and no mixed crystals and segregation appear.

[0039] The production method of the quenched and tempered wear-resistant steel plate NM400 with a thickness of 18 mm above is as follows:

[0040] (1) In the converter smelting process, the high-quality molten iron that enters the furnace is desulfurized by the KR method. During the converter smelting process, medium-carbon ferromanganese is added, and the control end point is P≤0.015%, Als (acid-soluble aluminum): 0.03%; slag blocking cone is used , Slag stop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com