A kind of martensitic stainless steel and its manufacturing method

A martensitic stainless steel and a manufacturing method technology, applied in the field of martensitic stainless steel and its manufacturing, can solve the problems of difficult to guarantee machinability and high cost, and achieve improved free cutting and machinability, good toughness, and high room temperature strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

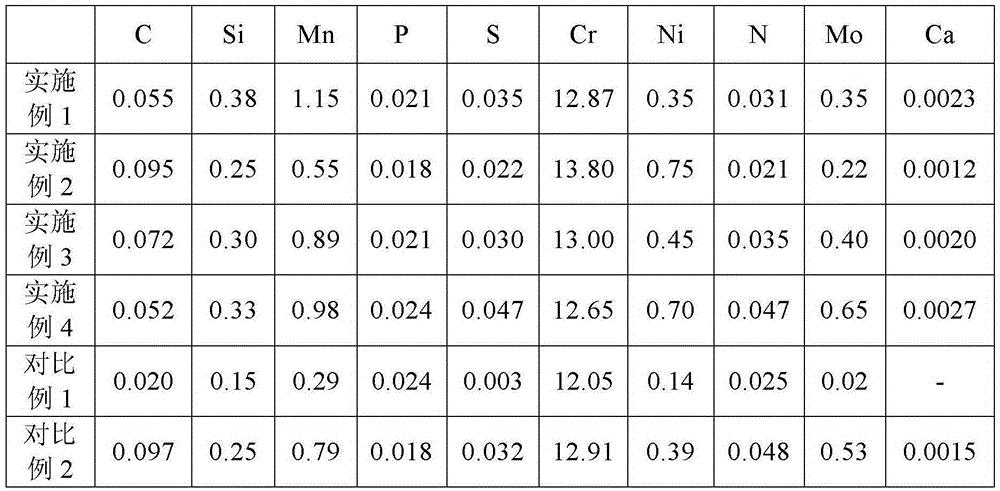

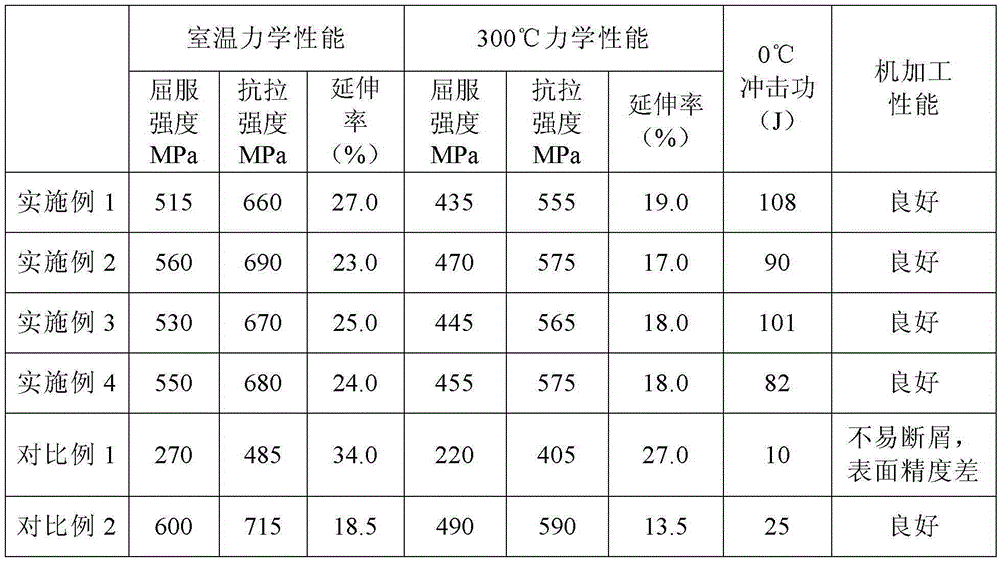

Embodiment 1

[0046] Using electric furnace + AOD + LF melting, casting into 200mm continuous casting slab, heating temperature 1120 ℃, furnace time 220min, final rolling temperature controlled at 990 ℃, hot rolled plate thickness 30mm, rapid cooling to 200 ℃ at a speed of 0.8 ℃ / s Then, air-cool to room temperature, perform high-temperature tempering heat treatment at 720°C for 180 minutes, and obtain martensitic stainless steel plates after pickling. The sheet has excellent strength at room temperature and medium temperature and good toughness, and its good machinability is ensured by controlling the content of calcium and sulfur. All properties are listed in Table 2.

Embodiment 2

[0048] Using electric furnace + AOD + LF melting, casting into 150mm continuous casting slab, heating temperature 1150℃, time in furnace 160min, final rolling temperature controlled at 1010℃, hot rolled plate thickness 20mm, rapid cooling to 200℃ at a speed of 1.0℃ / s Then, air-cool to room temperature, perform high-temperature tempering heat treatment at 740°C for 140 minutes, and obtain a martensitic stainless steel plate after pickling. The sheet has excellent strength at room temperature and medium temperature and good toughness, and its good machinability is ensured by controlling the content of calcium and sulfur. All properties are listed in Table 2.

Embodiment 3

[0050] Using electric furnace + AOD + LF melting, mold casting 365mm slab, heating temperature 1100°C, time in furnace 420min, final rolling temperature controlled at 970°C, hot rolled plate thickness 40mm, rapid cooling to below 200°C at a speed of 0.6°C / s , and then air-cooled to room temperature, high-temperature tempering heat treatment at 710°C for 240 minutes, and pickling to obtain a martensitic stainless steel plate. The sheet has excellent strength at room temperature and medium temperature and good toughness, and its good machinability is ensured by controlling the content of calcium and sulfur. All properties are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com