Apparatus and method for processing, coating or curing a substrate

A technology for coating substrates and equipment, applied in the direction of pretreatment of surfaces, devices for applying liquid to surfaces, coatings, etc., which can solve the problems of uneven power supply of runways, high engineering tolerances, and long-term feasibility affecting uniformity. Achieve the effect of reducing plasma quenching, reducing engineering tolerances, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

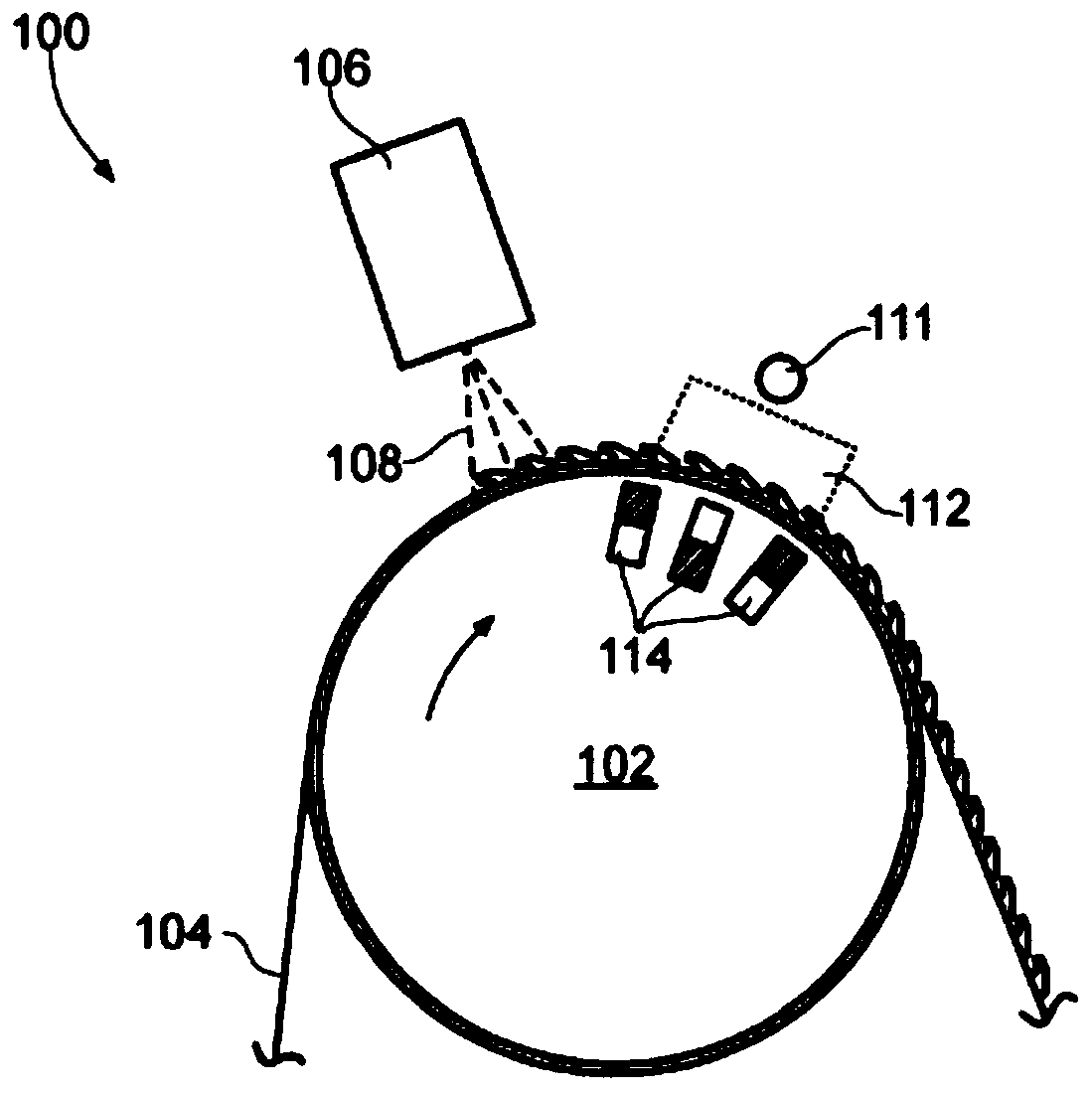

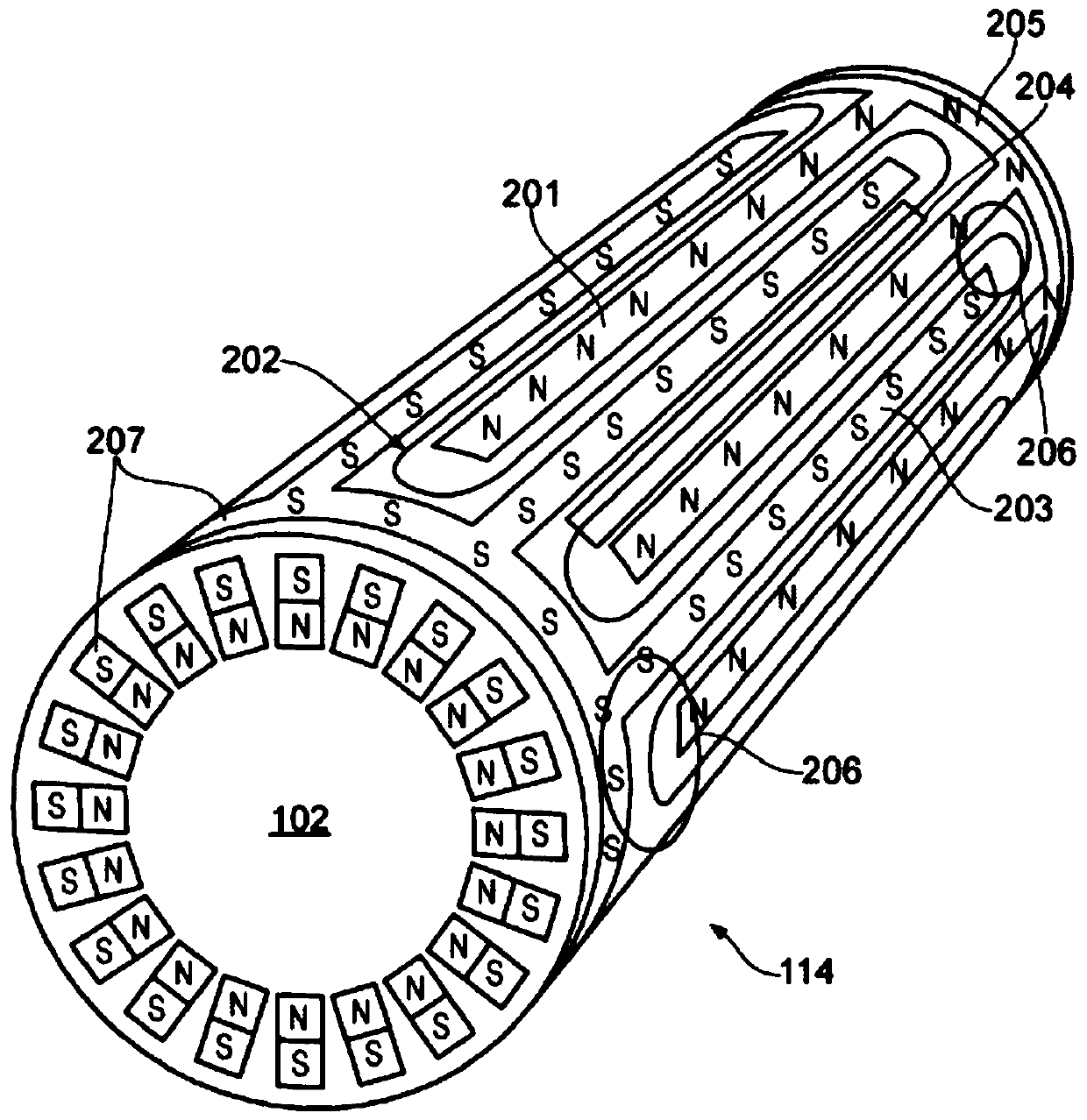

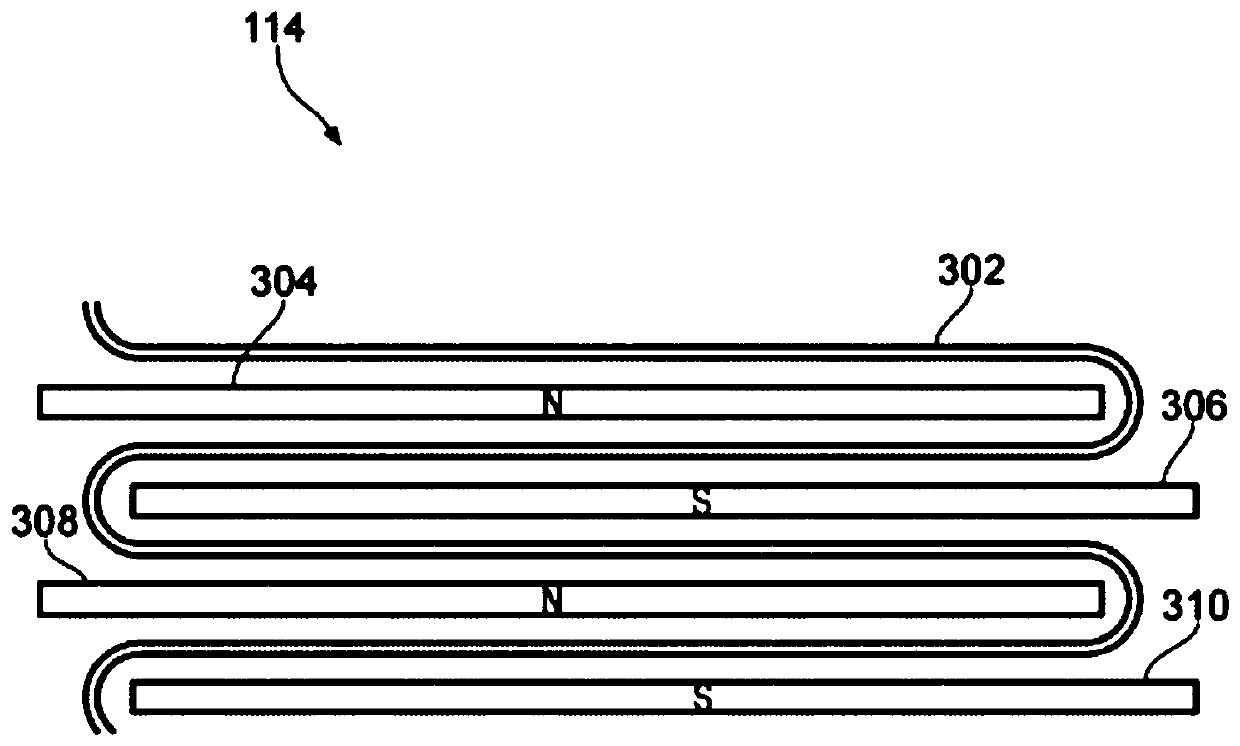

[0053] figure 1 Apparatus 100 for treating, coating or curing a substrate is shown. The apparatus 100 includes a rotating drum 102 for conveying a moving web (web) substrate 104 over the surface of the drum 102 . Adjacent the drum 102 is provided a precursor inlet 106 arranged to apply a precursor 108 to the substrate 104 as the substrate 104 passes under the precursor inlet 106 . Inside the drum 102 there is an array of magnets 114 . The plasma region 112 can be generated by charging the drum relative to the counter electrode 111 using a suitable power source (not shown). Magnet array 114 is fixed such that when drum 102 rotates, magnet array 114 does not rotate with drum 102 but allows the circumferential surface of drum 102 and the film substrate 104 being conveyed to pass thereover. The counter electrode 111 may be of any shape, and may carry an electric charge opposite to the drum, or be grounded. Additionally, electrode 111 may be part of the vacuum chamber or device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com