Drill quenching mechanism

A technology for drilling and processing boxes, applied in quenching devices, furnaces, heat treatment equipment, etc., can solve the problems of low work efficiency, low cooling efficiency, easy to burn hands, etc., to improve work efficiency, ensure smooth progress, and ensure heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

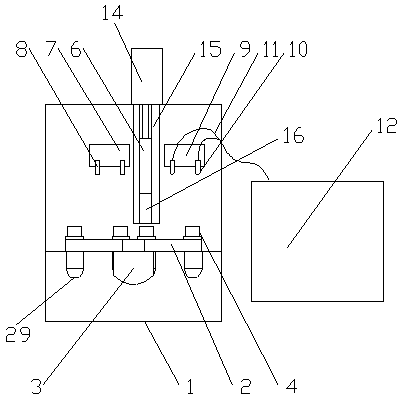

[0020] Such as figure 1 , figure 2 A drill bit quenching mechanism is shown, which is used for quenching the drill bit of an electric tool, including

[0021] A processing box 1, the processing box 1 is a rectangular parallelepiped hollow structure, and one side of the processing box 1 has an opening for feeding and taking materials.

[0022] A quenching platform 2 installed in the box, the quenching platform 2 is a disc-shaped structure, and the quenching platform 2 is driven by a rotating motor 3 to rotate 360°.

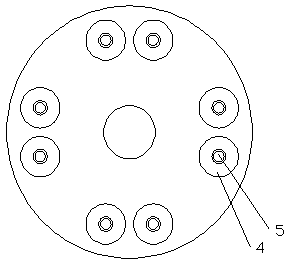

[0023] A material placement unit installed on the upper end surface of the quenching platform 2, such as figure 2 As shown in the schematic diagram, it can be seen that the material placement unit includes several pairs of placement disk groups distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com