Direct quenching type yield 800mpa grade structural steel plate and production method thereof

A technology of structural steel plate and production method, applied in the field of metallurgy, can solve problems such as unfavorable weldability, high alloy content, long process flow, etc., and achieve the effects of good weldability, comprehensive performance assurance, and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

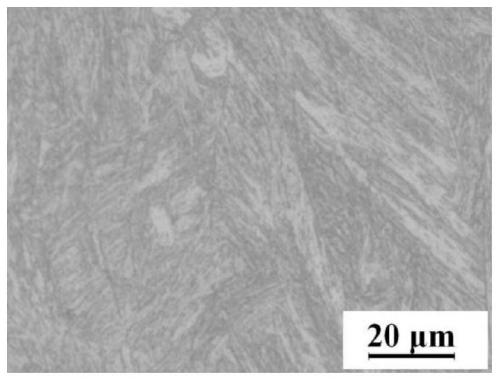

Embodiment 1

[0046] In this embodiment, the thickness of the directly quenched structural steel plate with a yield of 800 MPa is 45 mm, and its chemical composition and mass percentage are shown in Table 1.

[0047] The production method of direct quenching type yield 800MPa structural steel plate in this embodiment includes smelting, continuous casting, heating, rolling, online direct quenching, tempering and air cooling, and the specific process steps are as follows:

[0048] (1) Smelting process: see Table 1 for the chemical composition and mass percentage of molten steel produced during smelting;

[0049] (2) Continuous casting process: the thickness of continuous casting slab is 330mm;

[0050] (3) Heating process: the maximum heating temperature of the billet is 1240°C, the soaking temperature is 1220°C, the total heating time is 11min / cm, and the soaking section is in the furnace for 40min;

[0051] (4) Rolling process: Rolling is carried out using a two-stage controlled rolling pr...

Embodiment 2

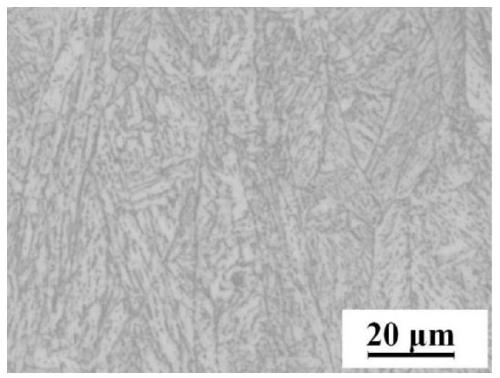

[0056] In this embodiment, the thickness of the directly quenched structural steel plate with a yield of 800 MPa is 36 mm, and its chemical composition and mass percentage are shown in Table 1.

[0057] The production method of direct quenching type yield 800MPa structural steel plate in this embodiment includes smelting, continuous casting, heating, rolling, online direct quenching, tempering and air cooling, and the specific process steps are as follows:

[0058] (1) Smelting process: see Table 1 for the chemical composition and mass percentage of molten steel produced during smelting;

[0059] (2) Continuous casting process: the thickness of continuous casting slab is 300mm;

[0060] (3) Heating process: the maximum heating temperature of the billet is 1240°C, the soaking temperature is 1210°C, the total heating time is 10min / cm, and the soaking section is in the furnace for 40min;

[0061] (4) Rolling process: Rolling is carried out using a two-stage controlled rolling pr...

Embodiment 3

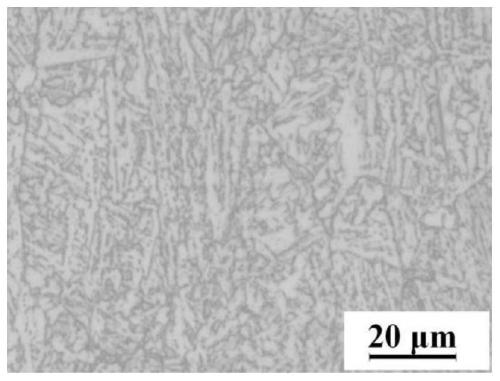

[0066] In this embodiment, the thickness of the directly quenched structural steel plate with a yield of 800 MPa is 30 mm, and its chemical composition and mass percentage are shown in Table 1.

[0067] The production method of direct quenching type yield 800MPa structural steel plate in this embodiment includes smelting, continuous casting, heating, rolling, online direct quenching, tempering and air cooling, and the specific process steps are as follows:

[0068] (1) Smelting process: see Table 1 for the chemical composition and mass percentage of molten steel produced during smelting;

[0069] (2) Continuous casting process: continuous casting slab thickness 200mm;

[0070] (3) Heating process: the maximum heating temperature of the billet is 1230°C, the soaking temperature is 1200°C, the total heating time is 9min / cm, and the soaking section is in the furnace for 40min;

[0071] (4) Rolling process: Rolling is carried out using a two-stage controlled rolling process in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com