High-temperature forged martensitic stainless steel heat treatment method

A technology of martensitic stainless steel and heat treatment method, which is applied in the field of high temperature forging martensitic stainless steel heat treatment, can solve the problem of difficulty in obtaining the 440-type molten filler metal, reduce the number of quenching and tempering, save energy, avoid effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

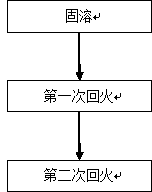

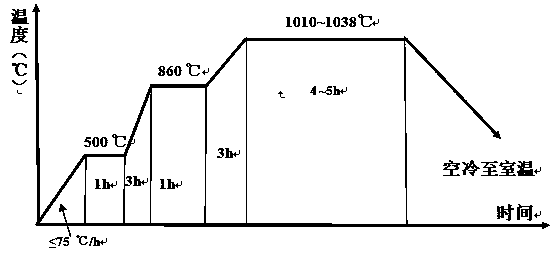

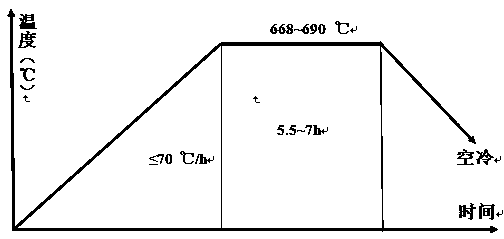

[0020] Embodiment 1: as attached figure 2 As shown, after the forging is put into the furnace, the furnace temperature is raised, and the heating rate is less than or equal to 75°C / hour; when the furnace temperature rises to 500°C, the forging is kept for 1 hour; When the temperature rises to 860°C, keep the forgings warm for 1 hour, and continue heating the furnace at a heating rate of 35°C / hour. When heated to 1010-1038°C, keep the forgings for 4-5 hours after soaking; hang the forgings out of the furnace and air-cool to room temperature; if attached image 3 As shown, the first tempering: when the forging is put into the furnace, the furnace temperature is raised at a rate of less than or equal to 70°C / hour; when the furnace temperature is raised to 691-718°C, the forging is kept warm for 5.5-7 hours; the forging is lifted out of the heat treatment furnace Air cool to room temperature; if attached Figure 4 As shown, the second tempering: when the forging is put into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com