Adjustable quenching and heating device for tempering production line equipment

A production line equipment and heating device technology, applied in the direction of quenching device, heat treatment equipment, heat treatment furnace, etc., can solve the problems that the diameter cannot be changed, affects production efficiency, and poor adaptability, so as to improve adaptability, production efficiency, and increase productivity , Reduce the effect of quenching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

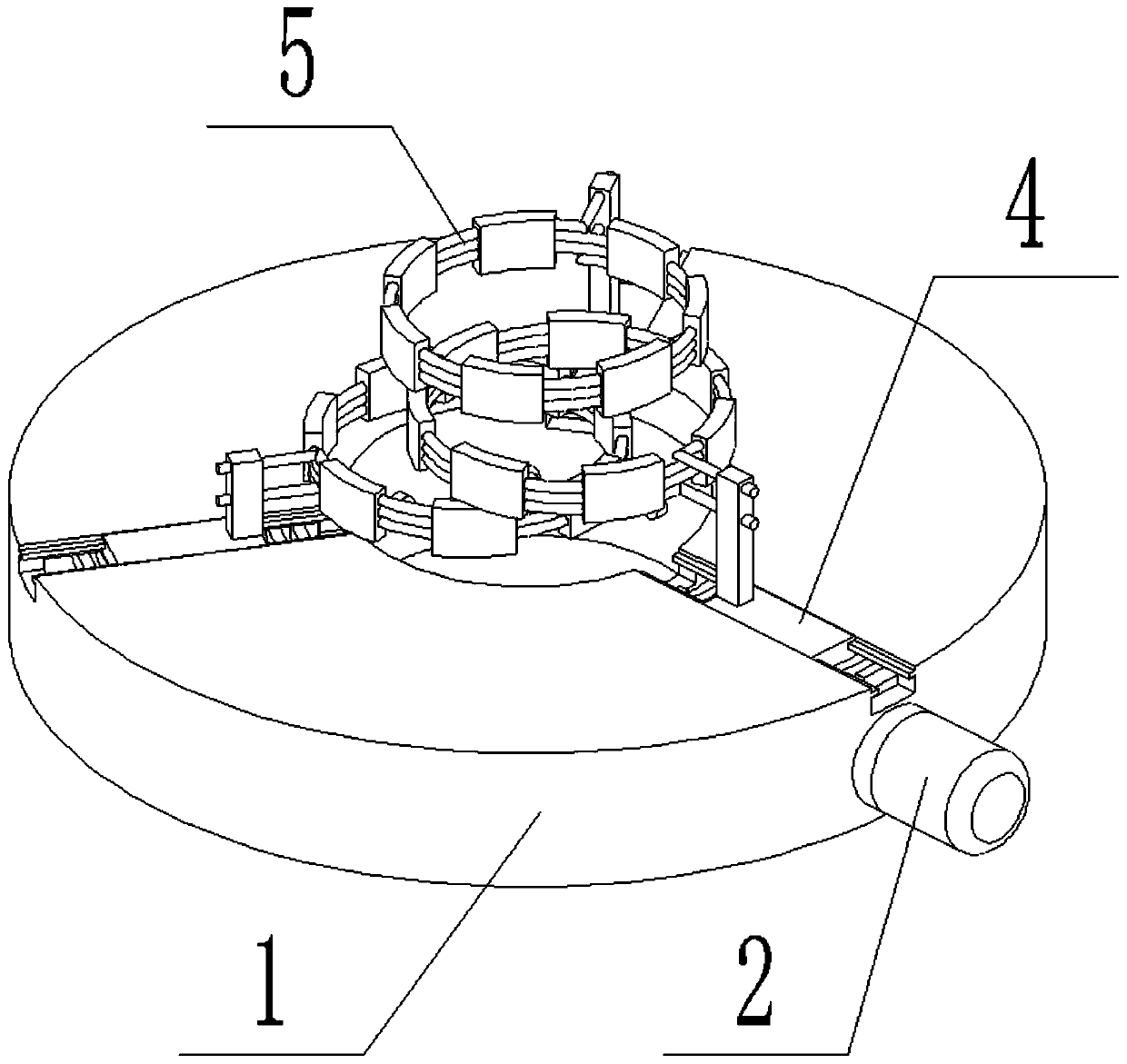

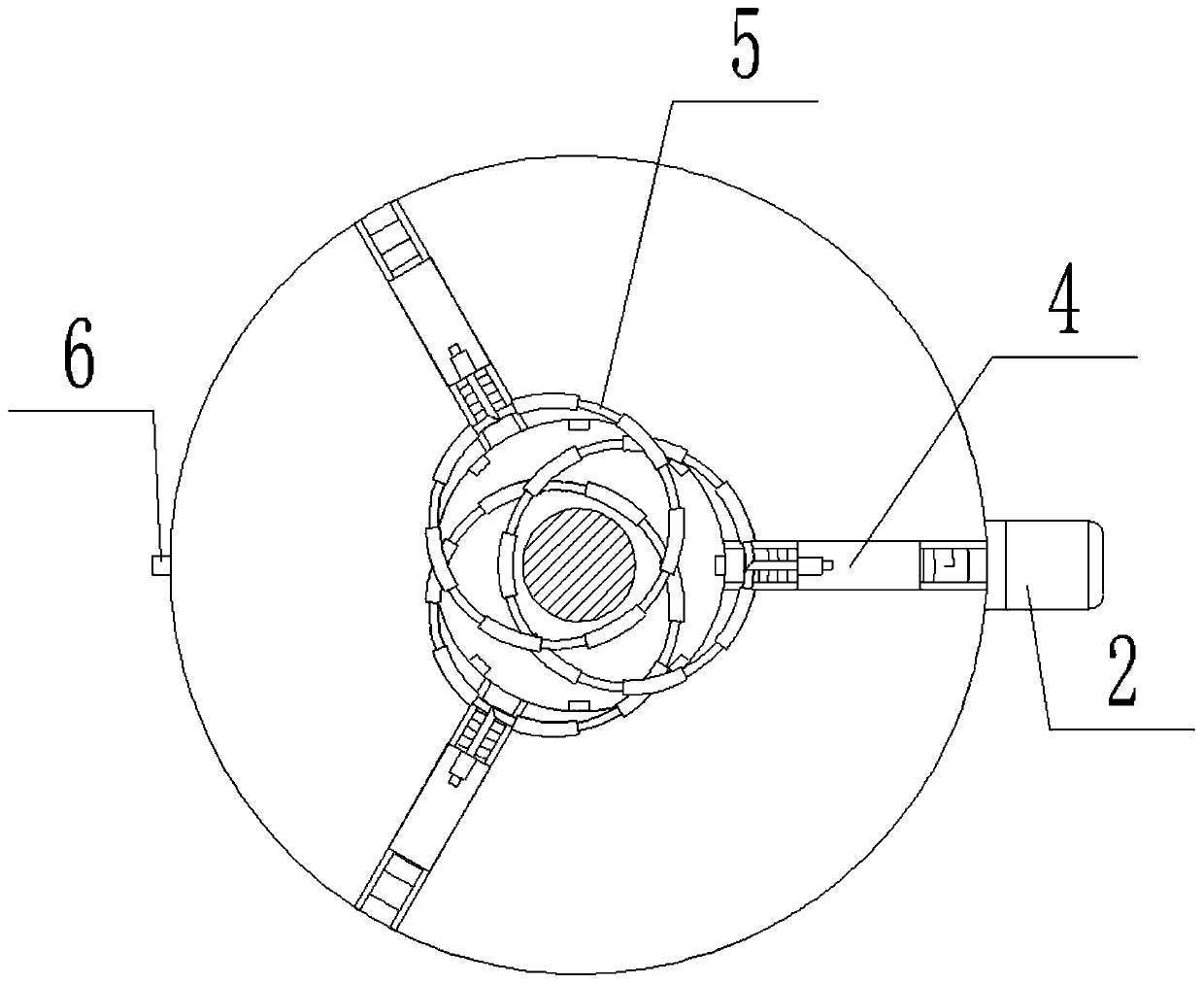

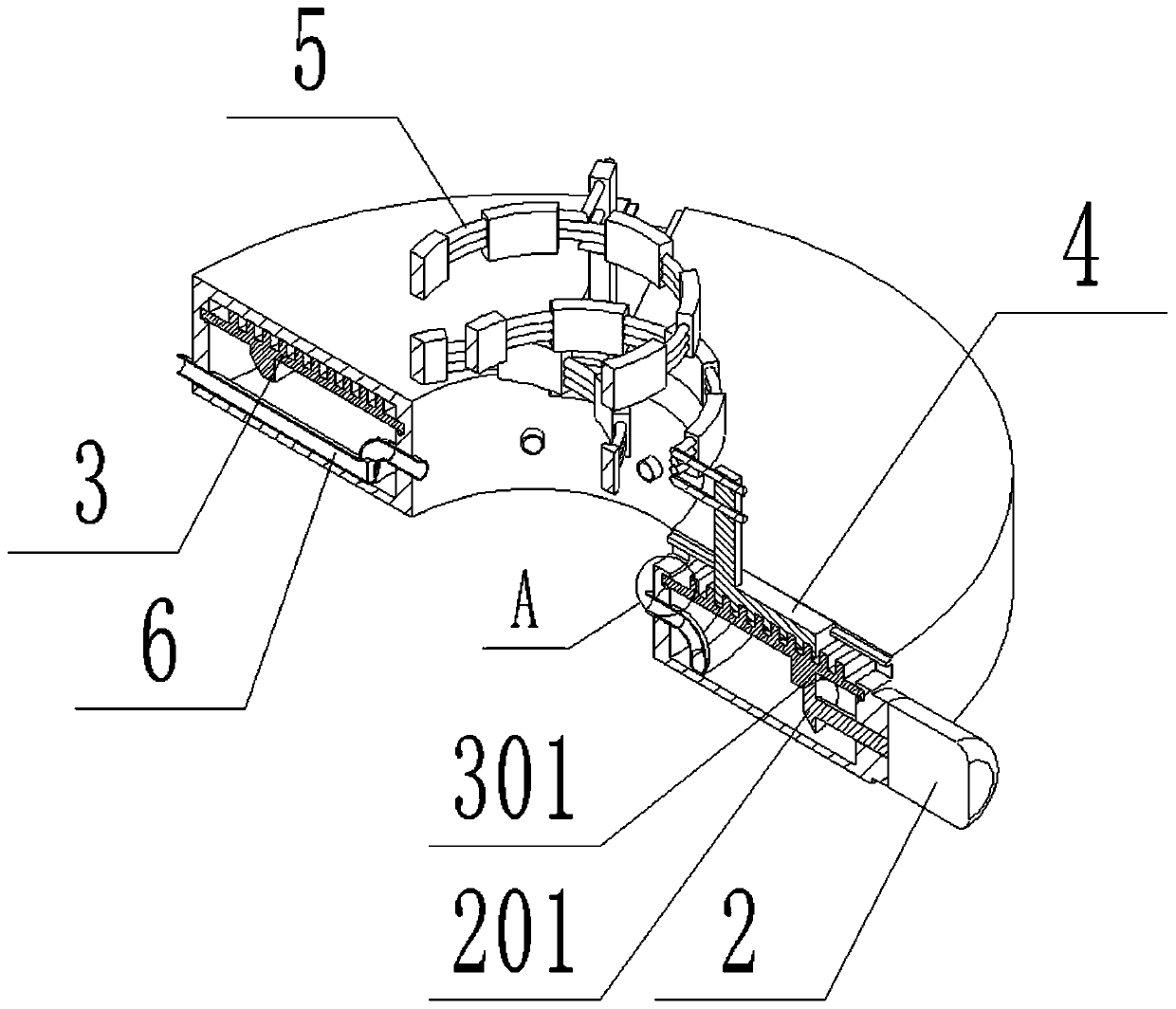

[0032] as attached figure 1 To attach Figure 8 Shown:

[0033] The present invention provides an adjustable quenching heating device for quenching and tempering production line equipment, including: base 1, bump 101, ring groove 102, motor 2, driving bevel gear 201, threaded disc 3, driven bevel gear 301, end thread 302, sliding bracket 4, thread teeth 401, chute 402, high-frequency heating tube 5, magnetic block 501 and cooling tube 6; a group of threaded disks 3 are axially connected to the inside of the base 1; the top of the base 1 is evenly arranged to slide Three sets of sliding brackets 4 are connected; a set of high-frequency heating tubes 5 is fixedly connected to the top of the sliding bracket 4; a set of cooling tubes 6 is fixedly connected to the bottom of the base 1; a set of motors 2 is fixedly connected to the right end of the base 1.

[0034] The base 1 is provided with a group of ring-shaped ring grooves 102. The ring grooves 102 are axially connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com