Automatic hydraulic knife grinder

A knife sharpening machine and automatic technology, applied in the field of sharpening tools, can solve the problems of threatening the personal safety of operators, difficulty in batch processing of knife edges, environmental and noise pollution, etc., and achieve the effect of saving labor, convenient operation and realizing recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

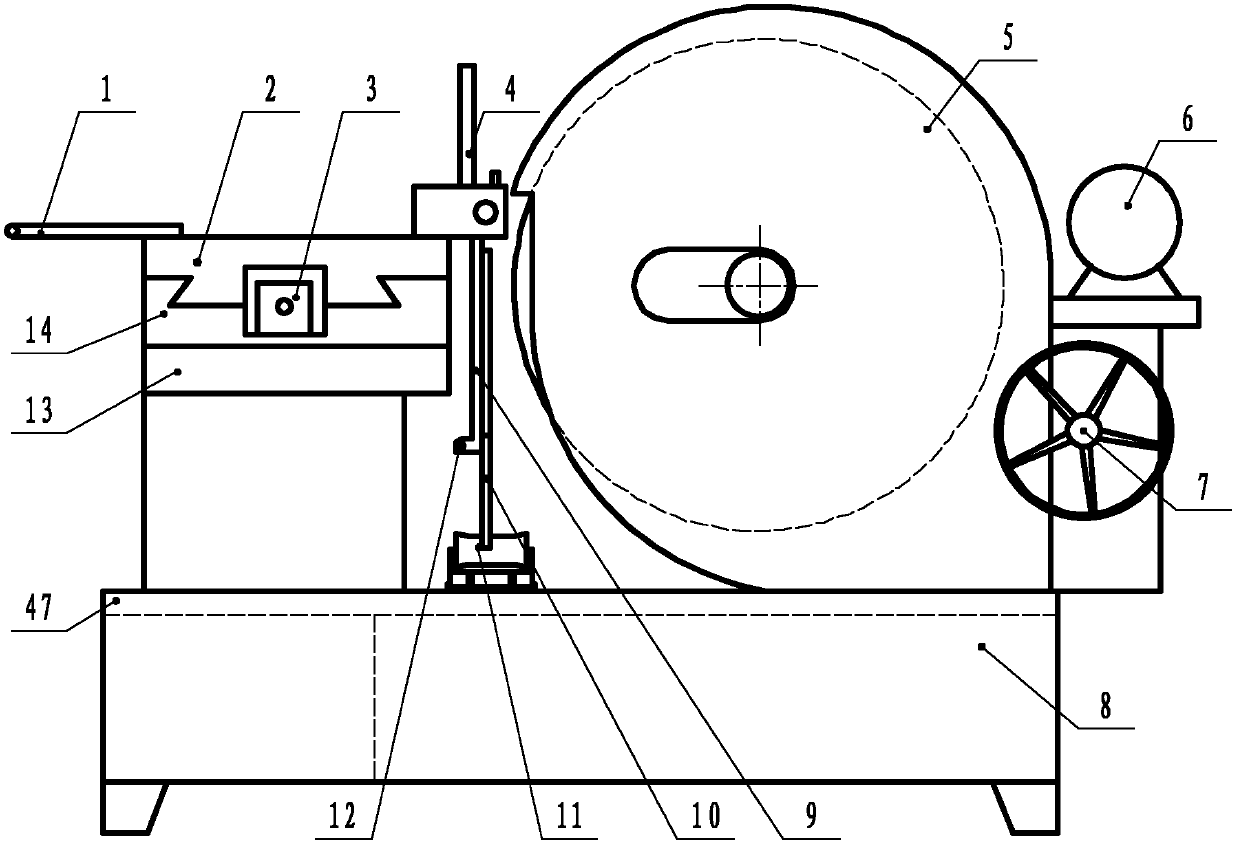

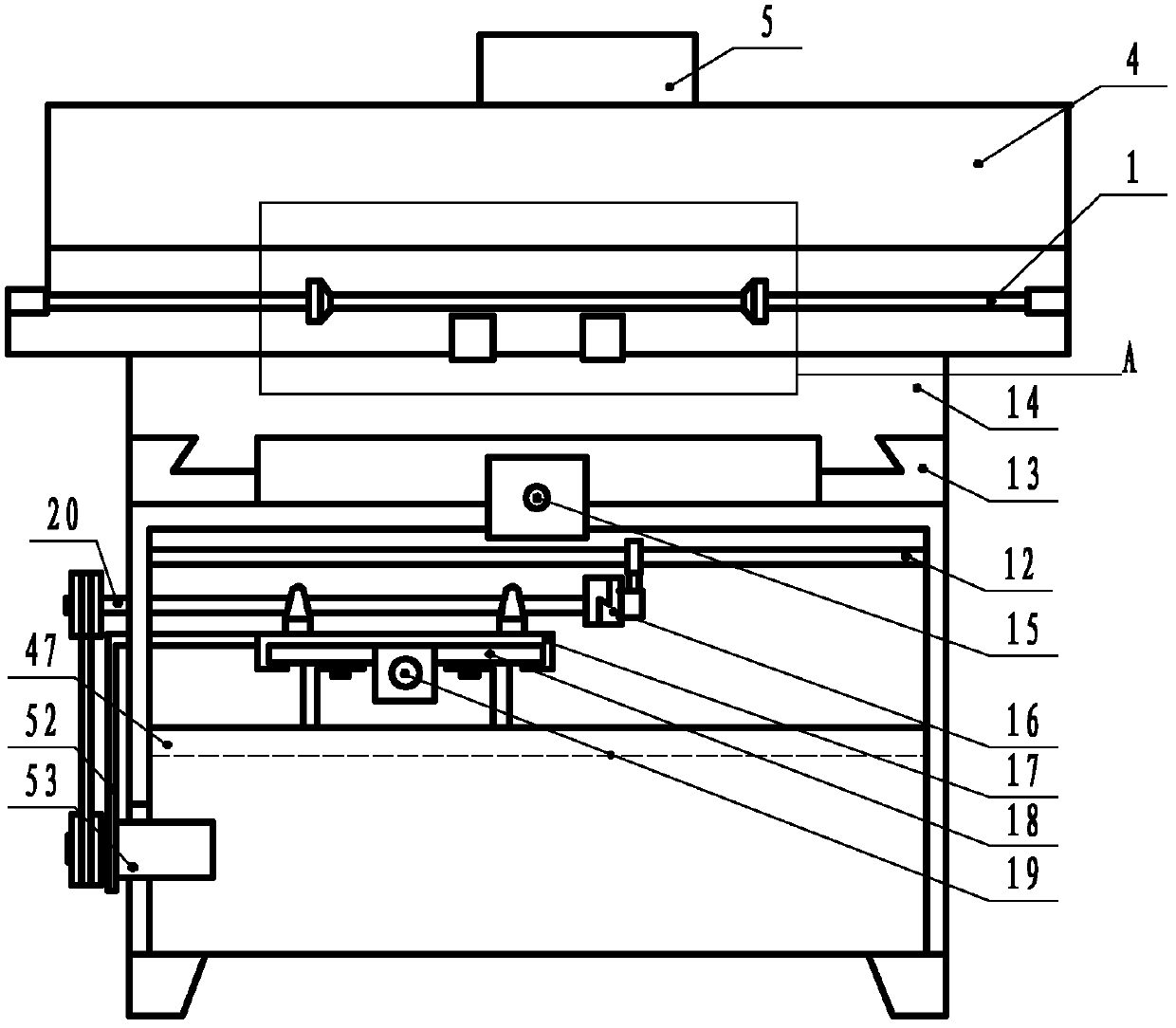

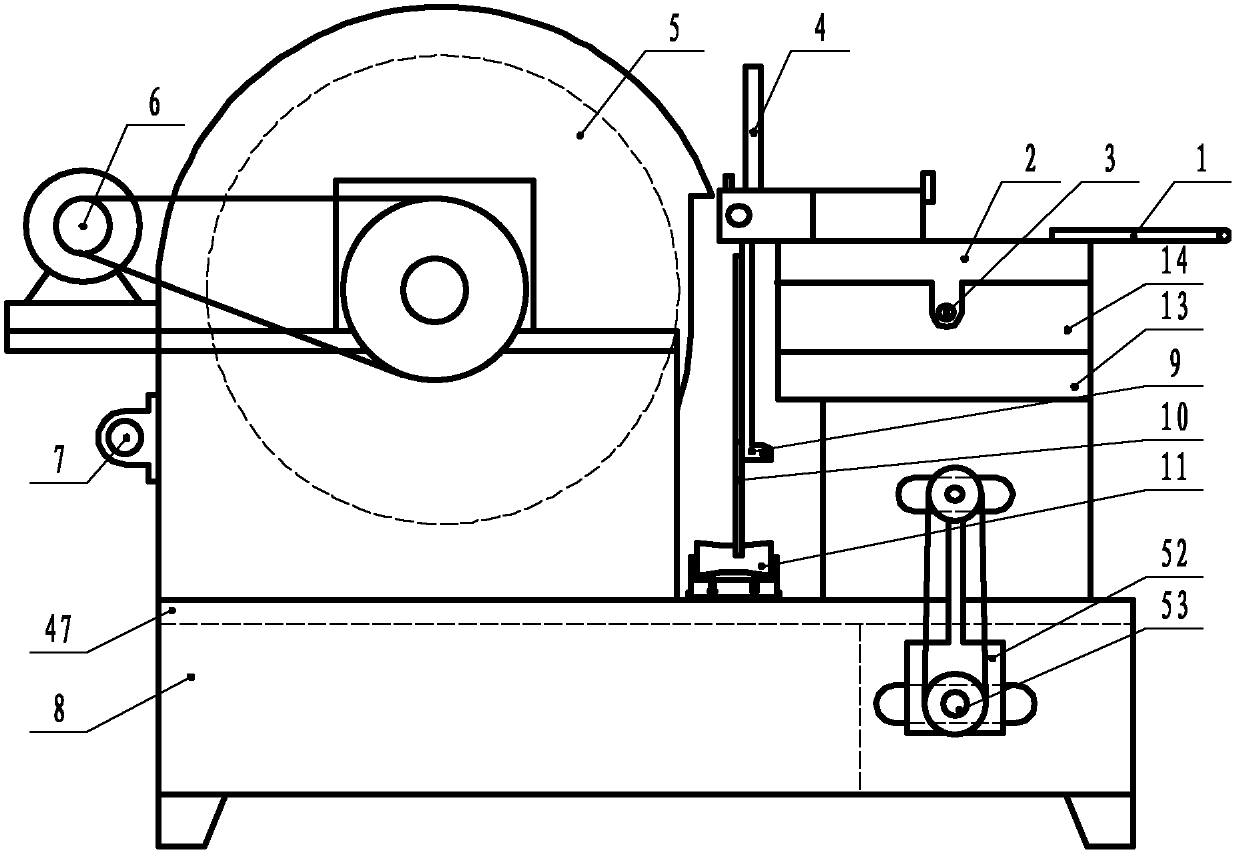

[0043] The present invention will be further described below in conjunction with accompanying drawing:

[0044]A hydraulic automatic knife sharpening machine, comprising a frame, a working device and a grinding mechanism, the working device and the grinding mechanism are fixedly installed on the frame, and the frame is provided with a surrounding water baffle 47; the working device includes a displacement transmission Mechanism, eccentric shaft slide mechanism and fine-tuning device; the displacement transmission mechanism includes an upper slide 2, a middle slide 14 and a lower slide 13, the upper slide 2 is provided with a baffle 4, and the middle slide 14 is provided with a contact A 49 and a contact B 50; the bottom of the upper slide 2 and the middle slide 14 are respectively equipped with a hydraulic cylinder A 3 and a hydraulic cylinder B 15, and one side of the upper slide 2 is provided with a stroke limiter 1, and the stroke switch limiter 1 includes a limiter Ring A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com