A four-point-to-central motion parallel mechanism palm manipulator capable of hooking and pinching

A manipulator and parallel technology, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of large offset, large eccentric force distance of manipulators, low efficiency of clamping process, etc., and achieve good dimensional adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

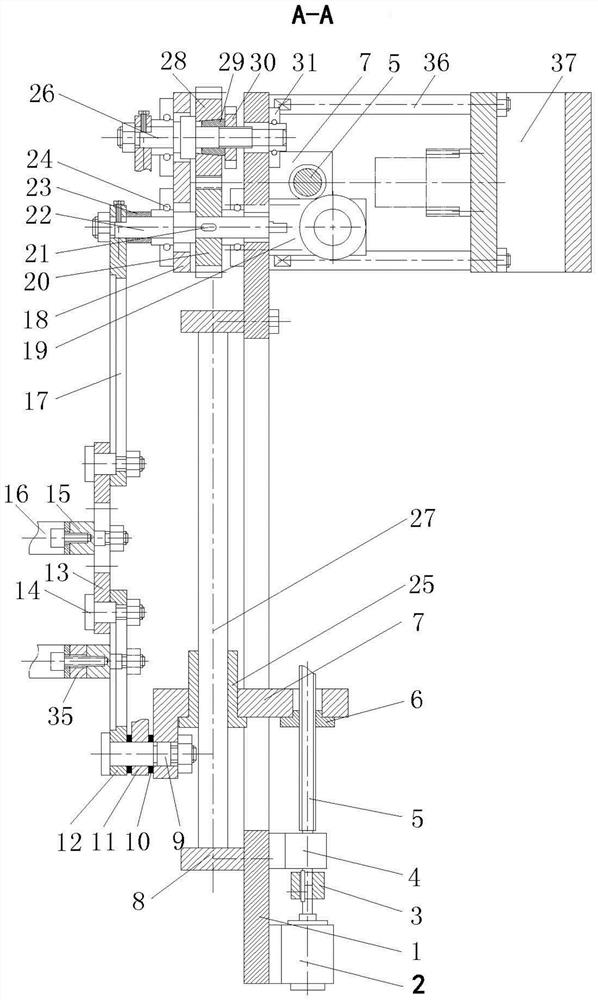

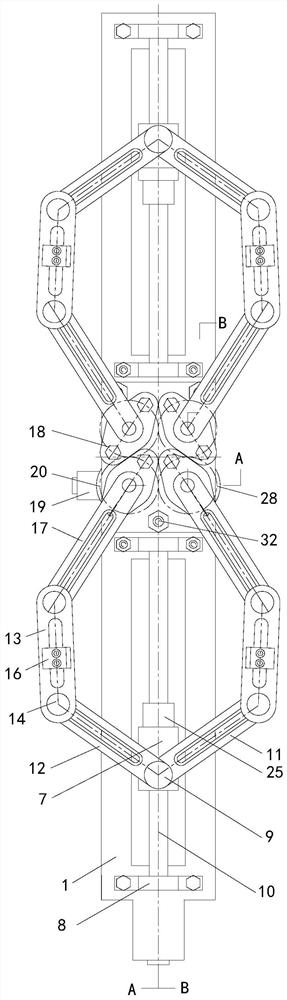

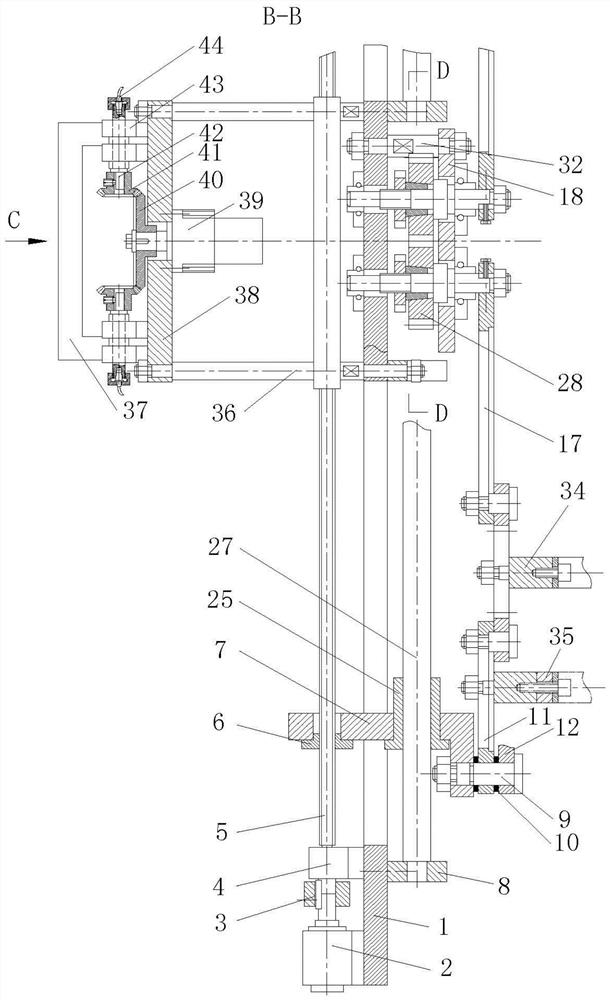

[0069] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0070] as attached Figure 1-5 As shown, the present invention can hook and pinch the four-point center movement parallel mechanism palm manipulator, including base plate 1, motor 2, shaft coupling 3, large parallel belt seat bearing 4, positive and negative thread screw 5, positive thread screw Lever nut 6, right-angle plate slider 7, guide rail seat 8, hinge shaft 9, wear-resistant washer 10, driven rocker 11, active rocker 12, connecting rod 13, pin shaft 14, short finger seat 15, finger parts 16 , slotted crank 17, gear cover 18, stepper motor with worm gear reducer 19, driving gear 20, flat key 21, drive shaft 22, long sleeve 23, bearing with seat 24, linear slide 25, driven shaft 26. Linear guide rail 27, tapered hole gear 28, tapered sleeve 29, oblate nut 30, small belt seat bearing 31, short guide stud 32, reverse thread screw nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com