Novel heat exchanger

A heat exchanger, a new type of technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems affecting the heat exchange efficiency, transfer to the inner tube, etc., to achieve good heat exchange capacity and novel appearance , Improve the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

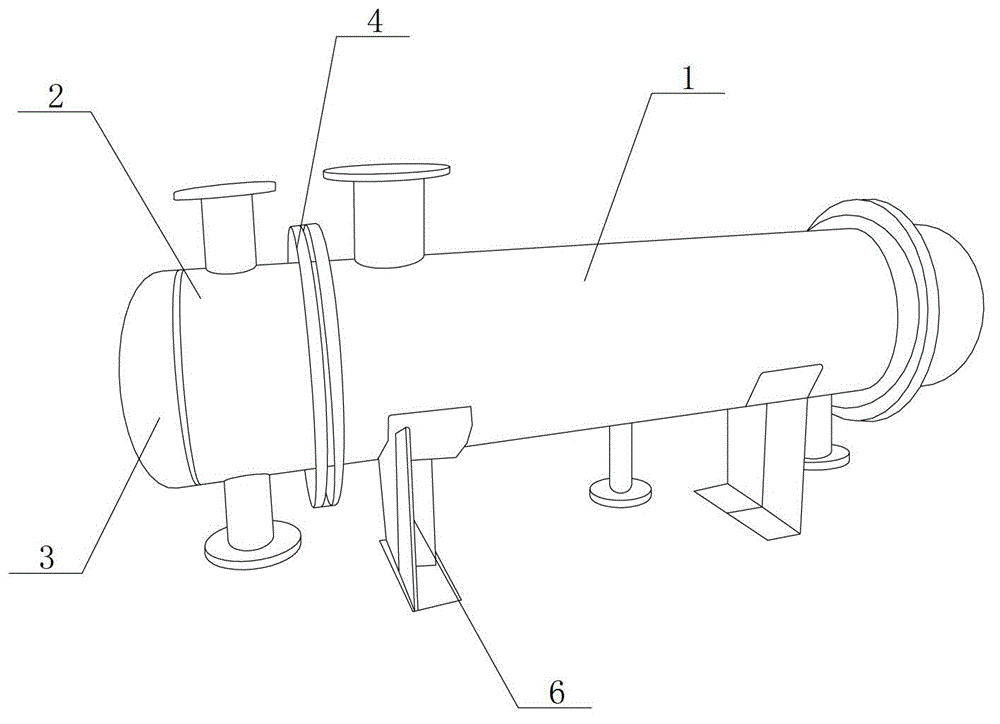

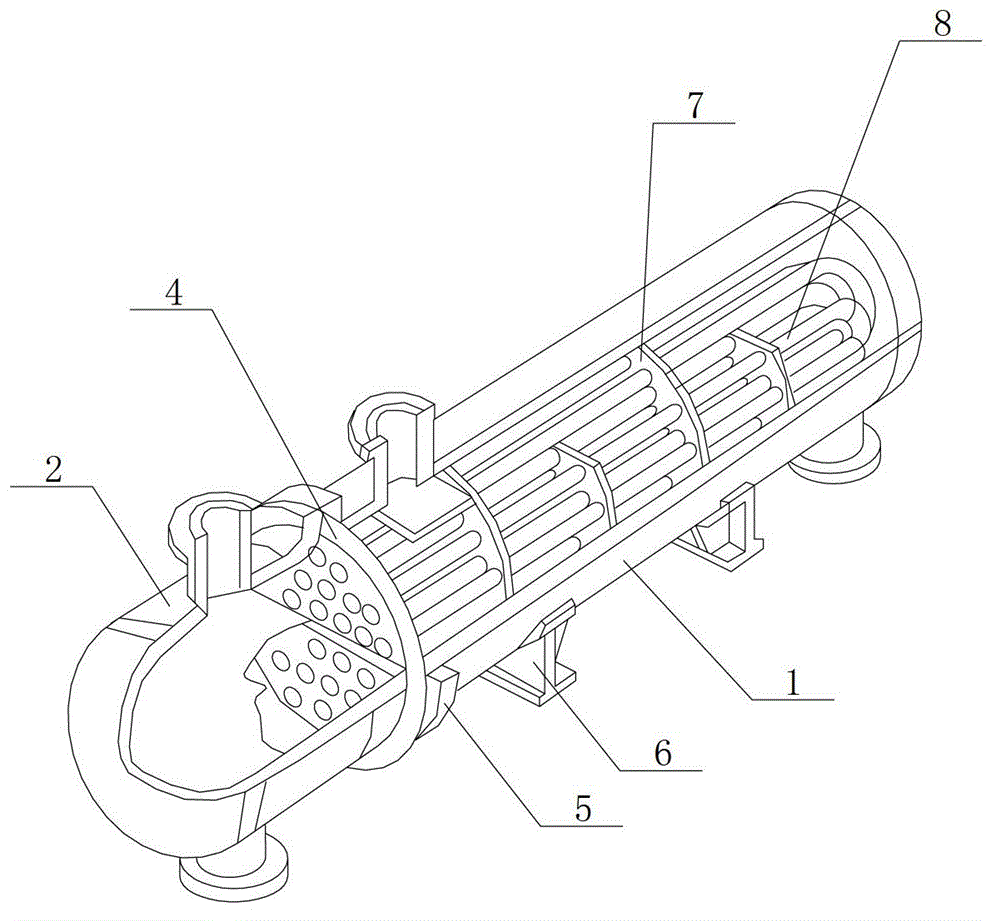

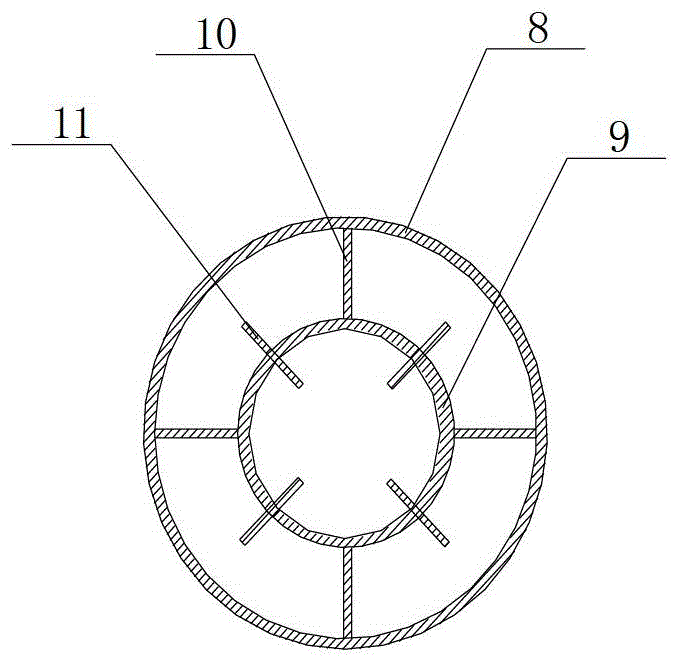

[0011] Reference Figure 1-Figure 3 , This specific embodiment adopts the following technical solutions: it is composed of shell 1, tube box 2, tube box cover 3, tube plate 4, flange 5, support 6, baffle 7, outer tube 8, inner tube 9 , Support body 10, heat exchange fins 11; one end of the shell 1 is provided with a tube box 2, one side of the tube box 2 is provided with a tube box cover 3, the other side of the tube box 2 is provided with a tube plate 4, tube plate A flange 5 is provided on one side of 4, a plurality of supports 6 are uniformly provided on the bottom of the housing 1, a baffle 7 and an outer tube 8 are provided inside the other end of the housing 1, and an inner tube is provided in the outer tube 8 9, and the annular space formed between the outer tube 8 and the inner tube 9 is axially provided with a support body 10, and a plurality of heat exchange fins 11 are uniformly provided on the tube wall of the inner tube 9 in the axial direction.

[0012] The casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com