Housing element with integrated heat exchanger

A technology of heat exchange elements and heat exchangers, applied in the direction of indirect heat exchangers, heat exchanger types, engine components, etc., can solve problems such as undesired economic or design reasons, shortened oil life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

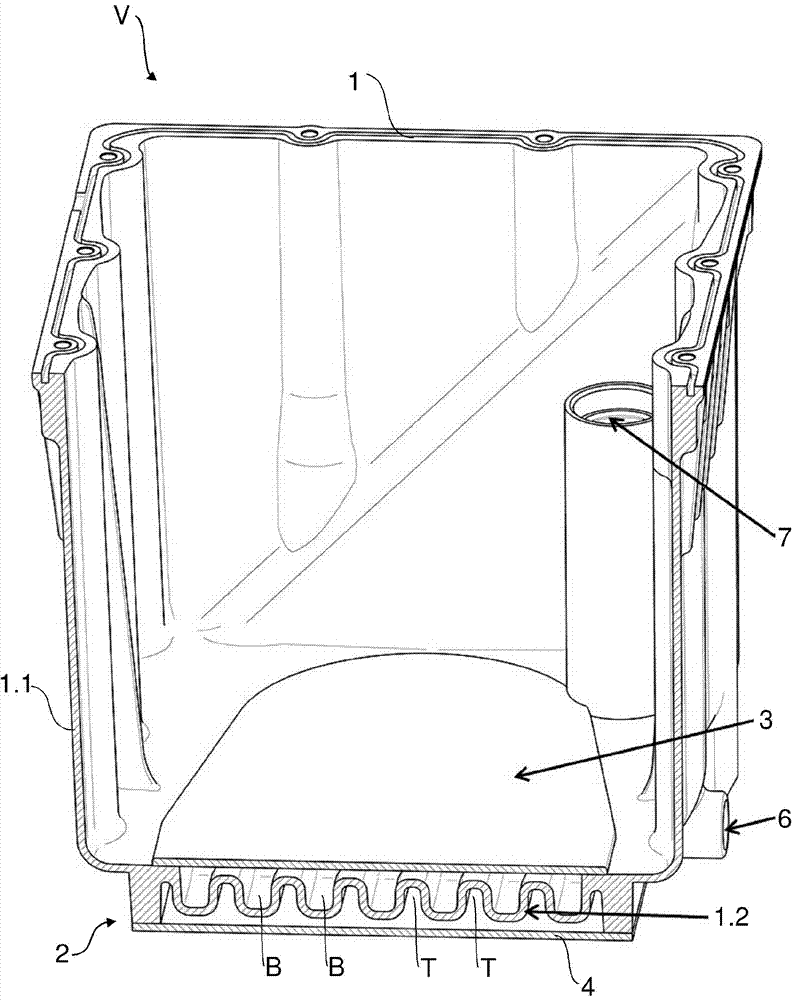

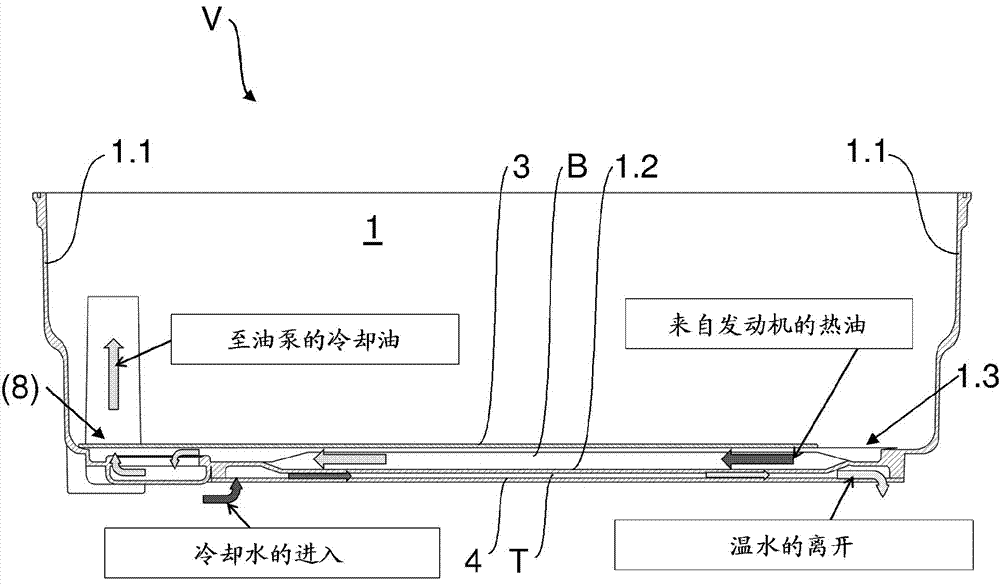

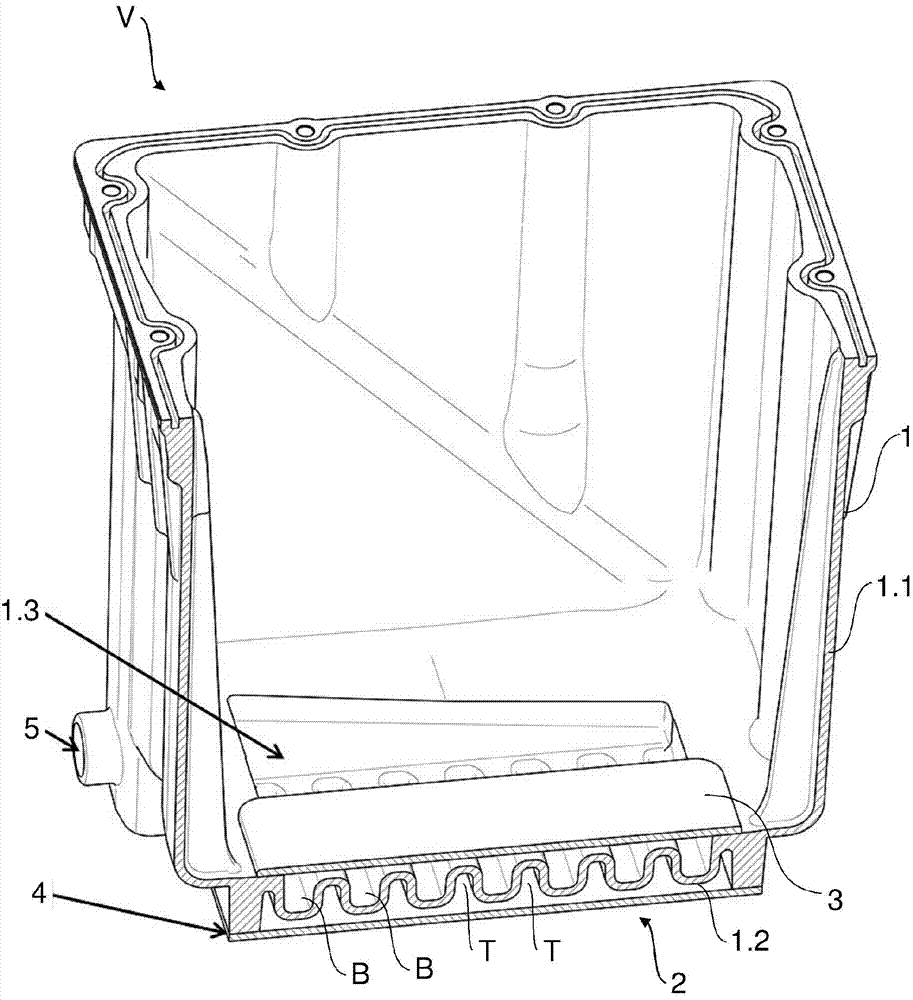

[0043] figure 1 A perspective cross-sectional view of device V (ie oil sump) for an engine (not shown), piston machine (not shown) and / or transmission arrangement (not shown) is shown.

[0044] The oil sump comprises a housing element 1 for forming a side wall structure 1.1 and for containing an operating fluid, in particular oil, and a heat exchanger 2 . The heat exchanger 2 can be supplied with a temperature control fluid, eg water, and comprises a heat exchange element 1.2, by means of which heat exchange between oil and water can be achieved.

[0045] The heat exchange element 1.2 comprises a plurality of throughflow conduits B, through which oil flows during operation, and a plurality of throughflow conduits T, through which water flows during operation. Oil may be drawn in by the engine or the oil pump, for example during operation.

[0046] The heat exchange element 1.2 forms a (bottom) part of the housing element 1, with the result that the heat exchange element 1.2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com