Dry granulation and cinder discharge type Y-type entrained flow bed gasifier

A technology of dry granulation and gasification furnace, which is applied in the field of coal chemical industry, and can solve the problems of poor gas circulation cooling effect, weak centrifugal effect, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

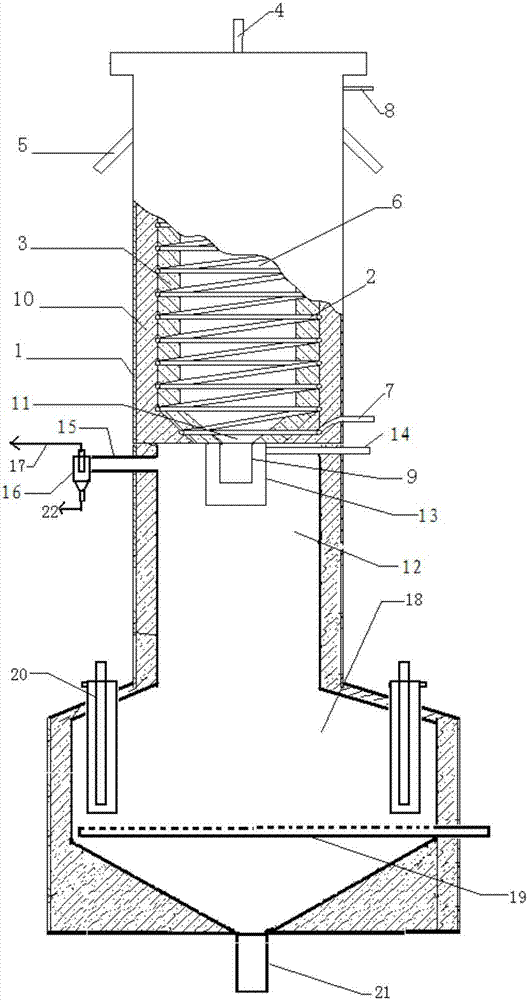

[0021] Below in conjunction with accompanying drawing, the present invention is described in detail: figure 1 As shown, the Y-type entrained entrained gasifier of the dry granulation and slag discharge of the present invention consists of a gasifier shell (1), a cooling jacket (2), a refractory material layer (3), and a top nozzle (4) , side nozzle (5), reaction chamber (6), coolant inlet (7), coolant outlet (8), gasification product outlet (9), insulation material layer (10), segmented conical head (11 ), cooling chamber (12), swirl cooling jacket (13), chilled water nozzle (14), crude gas outlet (15), gas-solid separator (16), gas outlet (17), fluidized bed heat exchanger (18), steam distributor (19), thermowell (20), slag discharge port (21), ash discharge port (22), etc.; gasifier is divided into gasification chamber (6) and quenching chamber (12), the middle is separated by a segmented conical head (11); the shell of the gasification chamber (6) is successively composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com