Online test system of high temperature calcined coke heat exchanger

A test system and heat exchanger technology, applied in the field of online test system for high-temperature calcined coke heat exchangers, can solve the problems of no special heat exchanger for calcined coke, lack of design basis for special heat exchangers for calcined coke, etc., and achieve Facilitate the effect of the heat transfer mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

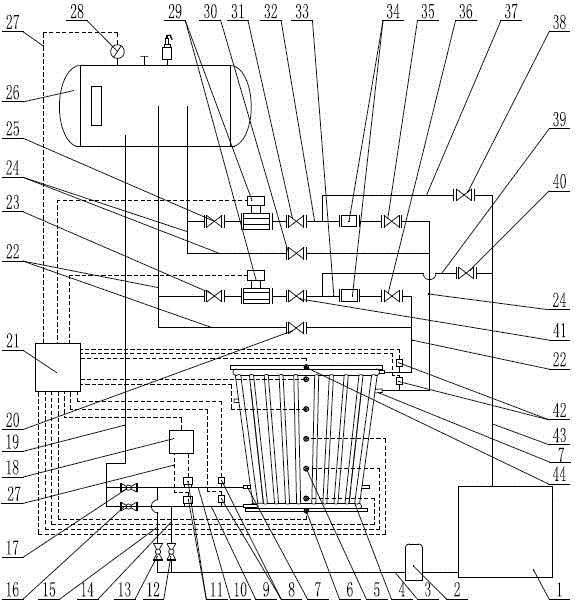

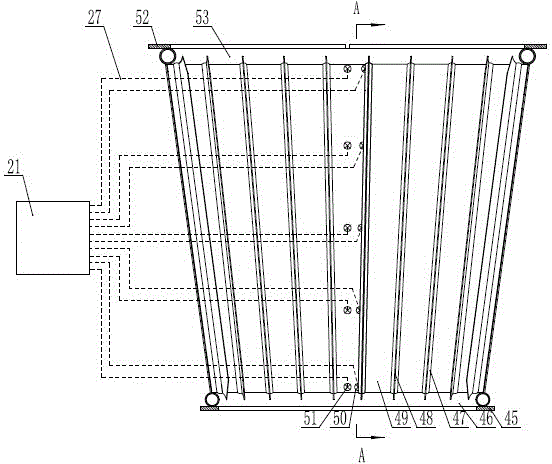

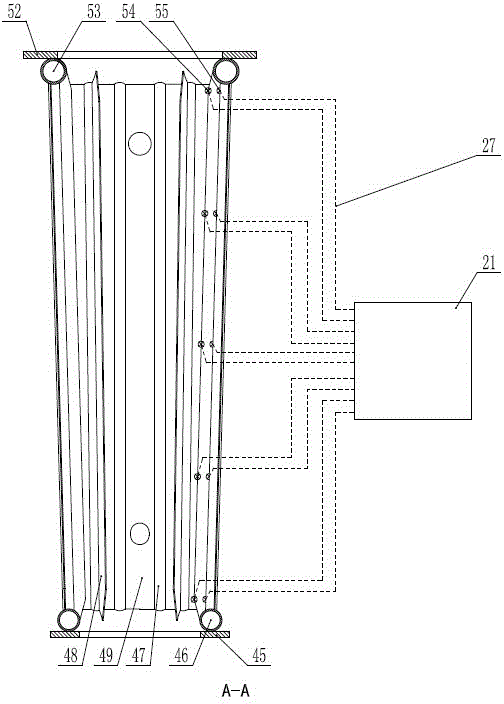

[0020] Figure 1~5 It is the best embodiment of the high-temperature calcined coke heat exchanger online test system, and the following is combined with the attached Figure 1~5 The on-line test system for the high-temperature calcined coke heat exchanger is further explained.

[0021] Refer to attached figure 1 : This high-temperature calcined coke heat exchanger on-line test system includes a steam collecting drum 26 with a pressure gauge 28, a descending pipeline, a heat exchanger composed of an outer heat exchanger 4 and an inner heat exchanger 7, and an ascending pipeline . Wherein, one end of the descending main pipe 19 of the descending pipeline communicates with the steam collecting drum 26, and the other end communicates with the outer heat exchanger water inlet pipe 9 and the inner heat exchanger water inlet pipe 10 respectively; the outer heat exchanger water inlet pipe 9 is connected with the outer heat exchanger 4 is communicated with and provided with a third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com