Finned tube heat exchanger

A heat exchanger and finned tube technology, which is applied in the field of finned tube heat exchangers, can solve the problem of unequal heat transfer performance of heat exchangers, and achieve the effect of improving heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

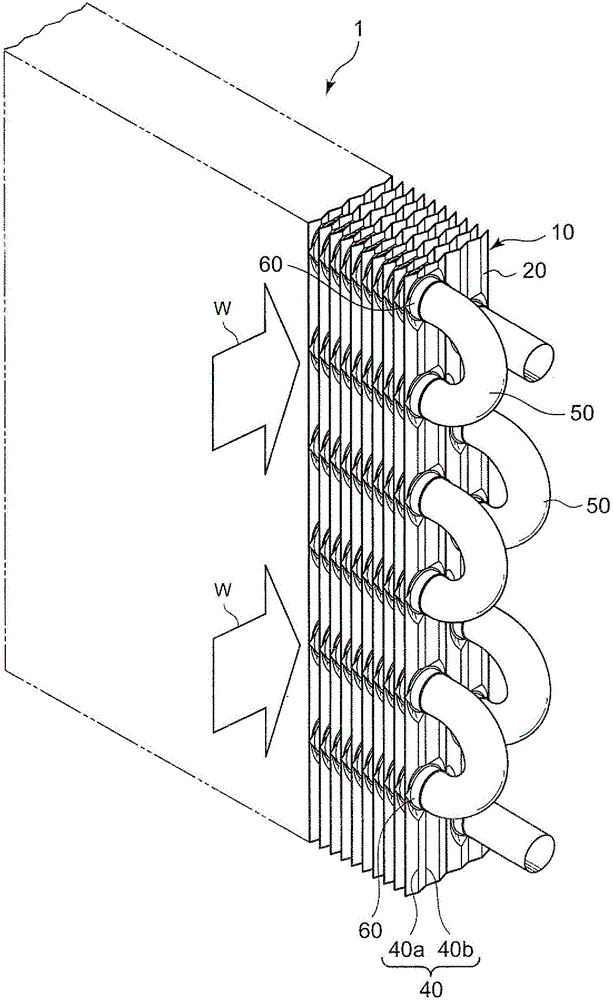

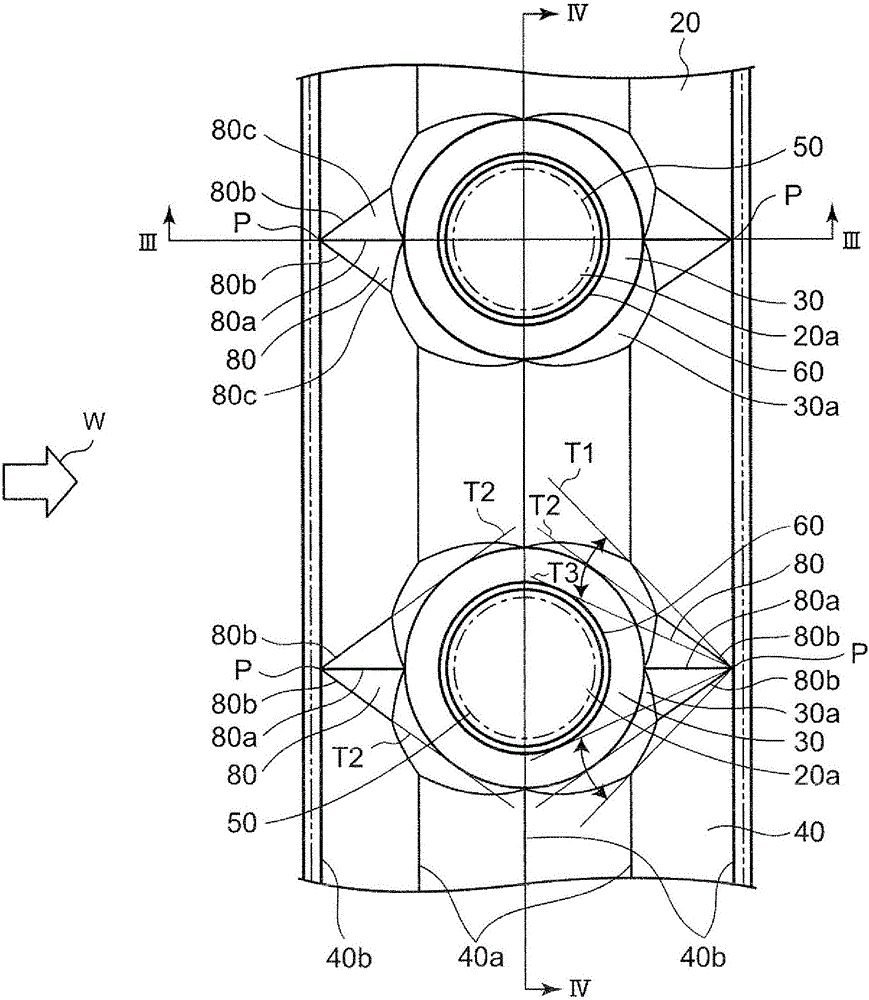

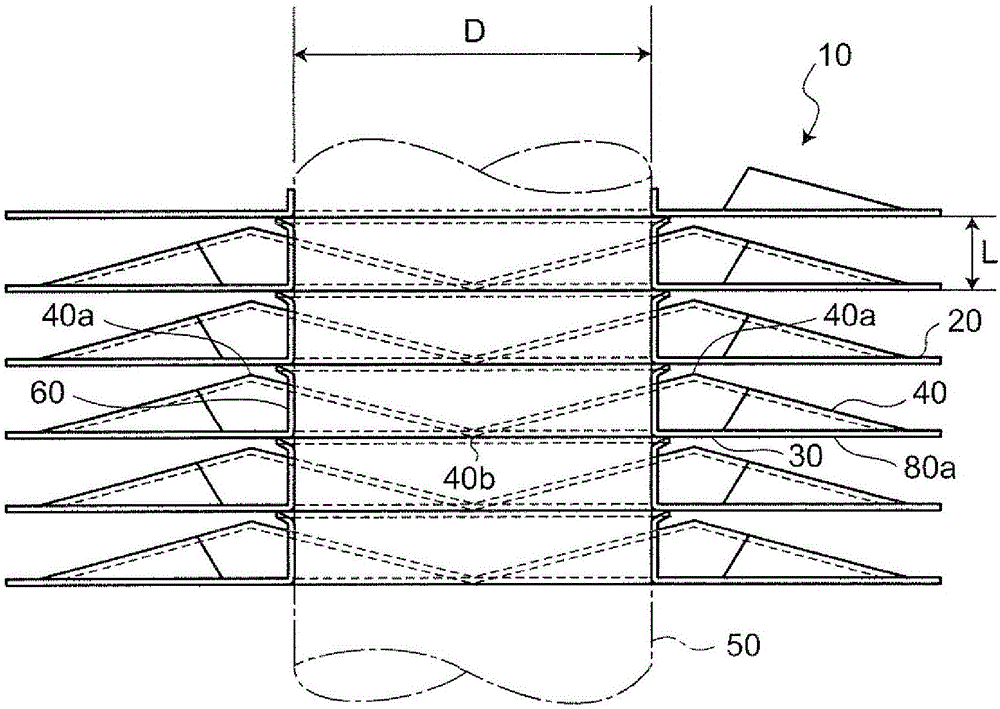

[0058] Next, the fin-tube heat exchanger according to Embodiment 1 of the present invention will be described with reference to the drawings.

[0059] figure 1 It is a perspective view showing the basic mechanism of the fin-tube heat exchanger according to Embodiment 1 of the present invention. figure 2 will be figure 1 A part of the heat transfer fins of the illustrated fin-and-tube heat exchanger is enlarged, and a front view is shown of the laminated surface which is the front surface of the heat transfer fins.

[0060] Such as figure 1 As shown, in the fin-tube heat exchanger 1 , a plurality of heat transfer fins 20 having the same shape are stacked in parallel with a certain interval L (stacked state) to constitute the heat exchange block 10 . In Embodiment 1, the respective heat transfer fins 20 are arranged (stacked) in a row with an interval L of 1.5 mm. The interval L at which each heat transfer fin 20 is arranged can be appropriately changed according to the ...

Embodiment approach 2

[0087] A finned tube heat exchanger according to Embodiment 2 of the present invention will be described with reference to the drawings.

[0088] Image 6 It is a front view showing the laminated surface of the heat transfer fins 20A in the fin-tube heat exchanger according to the second embodiment. Such as Image 6 As shown, a flat seat portion 30 is formed in a ring shape around a fin collar 60 , and a raised portion (peak) 70 is formed around the seat portion 30 .

[0089] In the heat transfer fin 20A of Embodiment 2, wedge-shaped recesses 80 are formed on both sides of the fin collar 60 , both the windward side and the leeward side, as in the above-mentioned Embodiment 1 . As a result, in the heat transfer fin 20A, a part of the raised portion (peak portion) 70 formed around the seat portion 30 is formed so that the upwind side and the leeward side are notched (there are voids). As a result, in the fin-and-tube heat exchanger according to Embodiment 2, the airflow flowi...

Embodiment approach 3

[0092] Embodiment 3 of the fin-tube heat exchanger of the present invention will be described with reference to the drawings.

[0093] Figure 7 It is a front view showing the laminated surface of the heat transfer fins 20B of the fin-tube heat exchanger according to the third embodiment. Such as Figure 7 As shown, an elliptical seat portion 30 having a flat surface is formed around the fin collar 60 , and a standing portion (peak portion) 70 is formed around the seat portion 30 .

[0094]In the heat transfer fin 20B according to the third embodiment, wedge-shaped recesses 80 are formed on both the windward side and the leeward side of the fin collar 60 as in the above-mentioned first embodiment. As a result, in the heat transfer fin 20B, a part of the raised portion (peak portion) 70 formed around the seat portion 30 is missing on the windward side and the leeward side (there is a void portion). As a result, in the fin-and-tube heat exchanger according to Embodiment 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com