Heat exchange tube and smoke heat exchanger

A flue gas heat exchanger and heat exchange tube technology, applied in the field of flue gas heat exchangers and heat exchange tubes, can solve problems such as low heat exchange efficiency, small heat exchange area, and tearing of connection positions, and achieve improved heat exchange Efficiency, the effect of increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

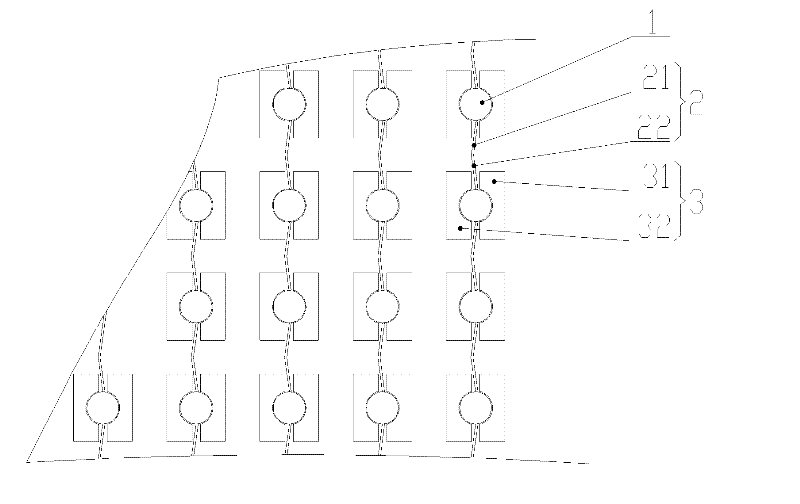

[0039] The core of the present invention is to provide a heat exchange tube whose structural design can effectively increase the heat exchange area of the heat exchange tube without increasing or greatly increasing its occupied space, thereby significantly improving The heat transfer efficiency of the heat exchange tube. In addition, another core of the present invention is to provide a flue gas heat exchanger including the heat exchange tube.

[0040] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

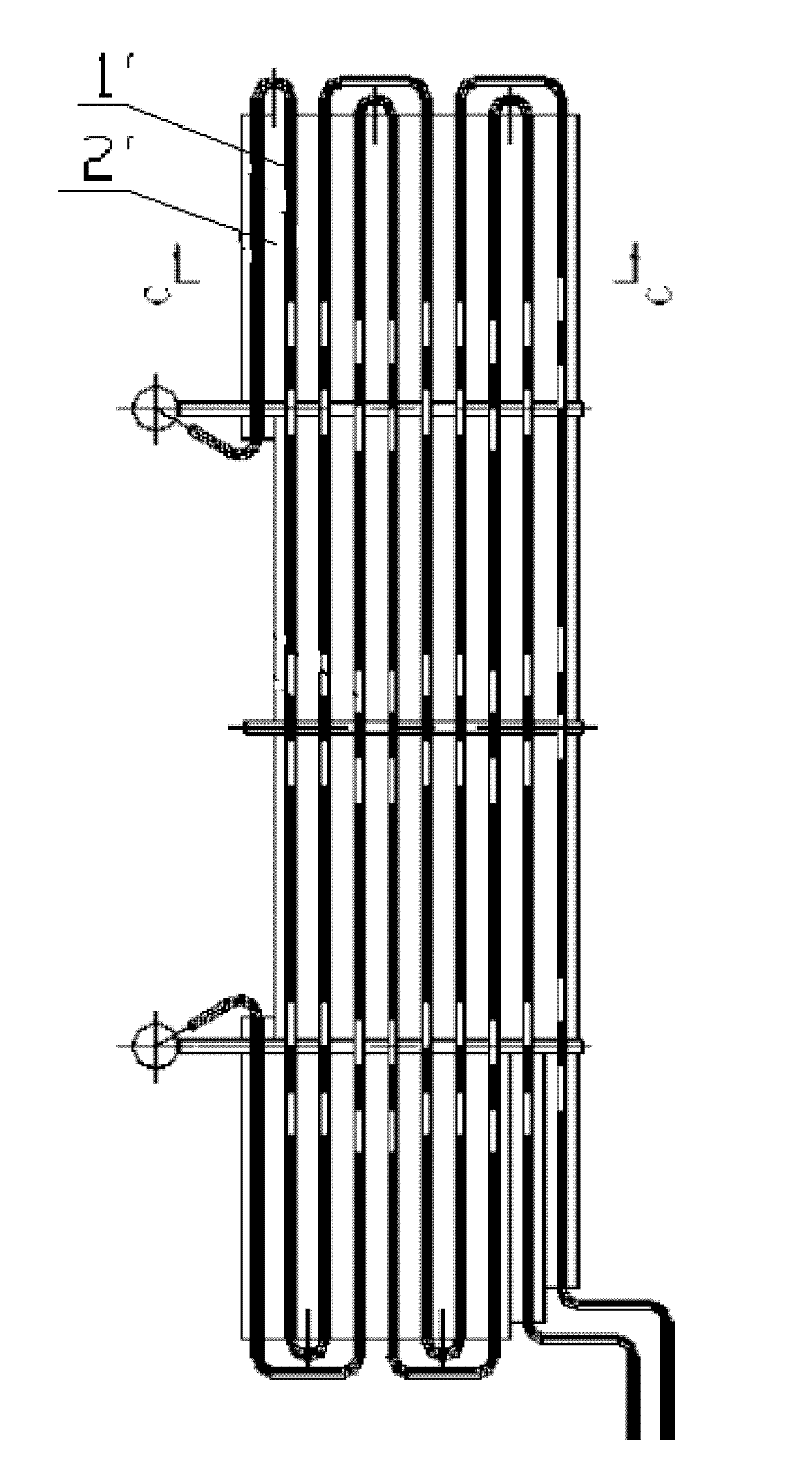

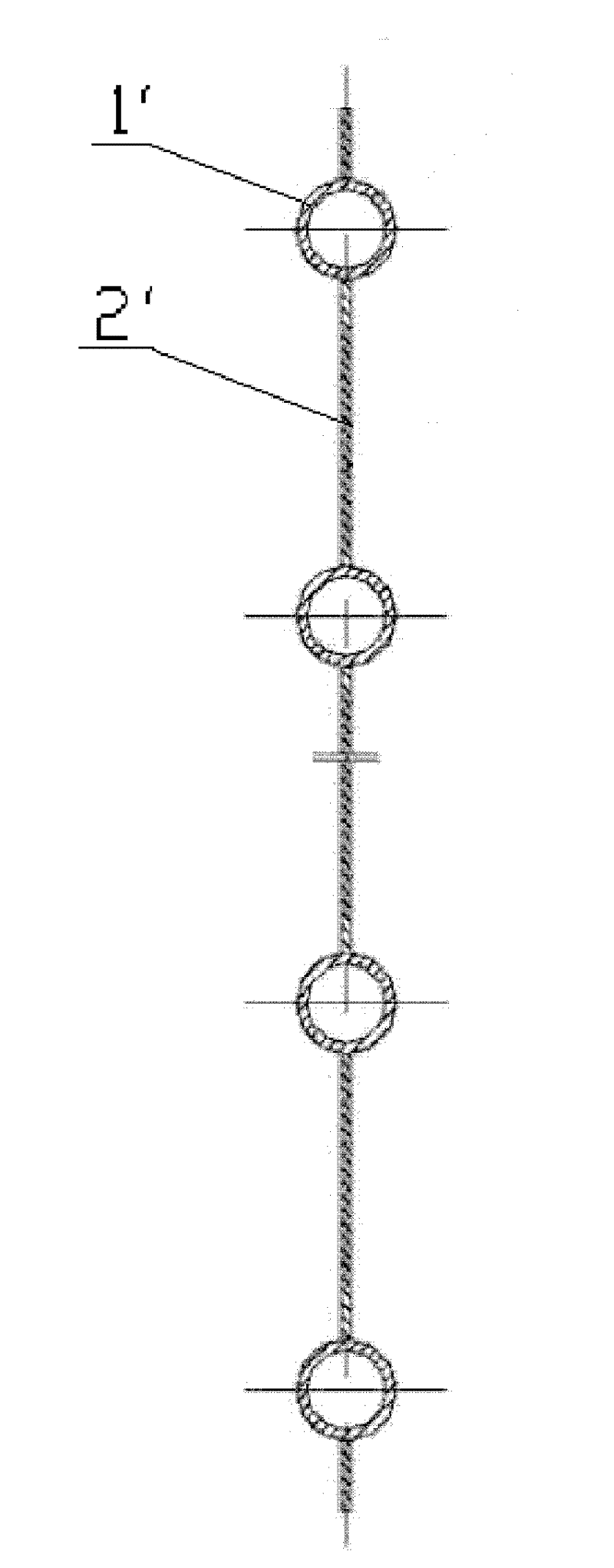

[0041] Please refer to image 3 , Figure 4 , Figure 5 and Figure 6 , image 3 It is a structural schematic diagram of the heat exchange tube in the first embodiment of the present invention; Figure 4 It is a structural schematic diagram of a heat exchange tube section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com