Rotation-ball washing machine and method

A washing machine and ball-rotating technology, which is applied in the field of washing machines, can solve the problem that clothes are not easy to be taken up, and achieve the effects of good washing effect, good water saving effect, and reliable rotating shaft switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation of the rotary ball washing machine under the above-mentioned basic motion mode is as follows:

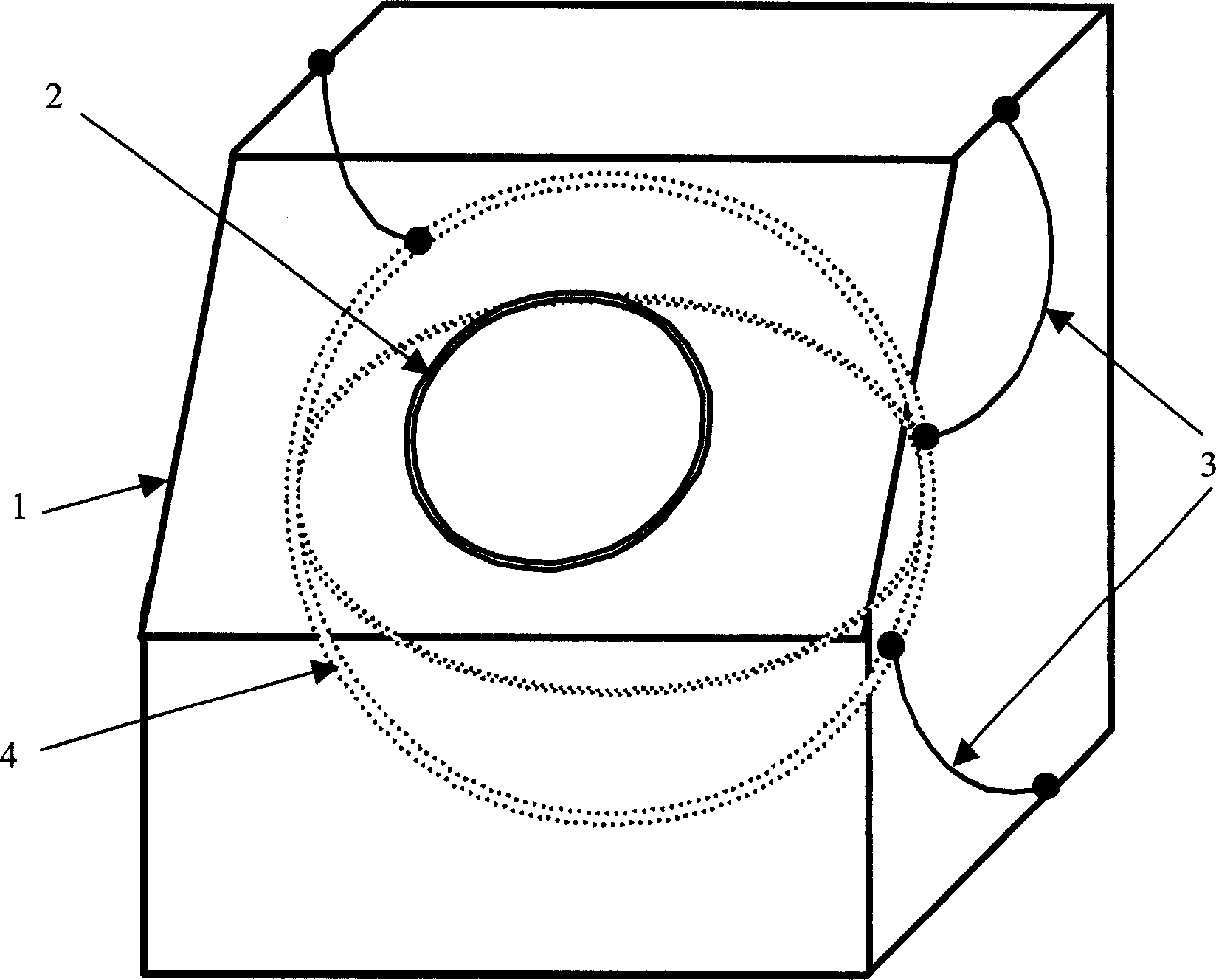

[0034] Such as figure 1As shown, the rotary ball washing machine is composed of a shell 1, an outer machine door 2, a plurality of supports 3, and parts 4 of a rotating sphere.

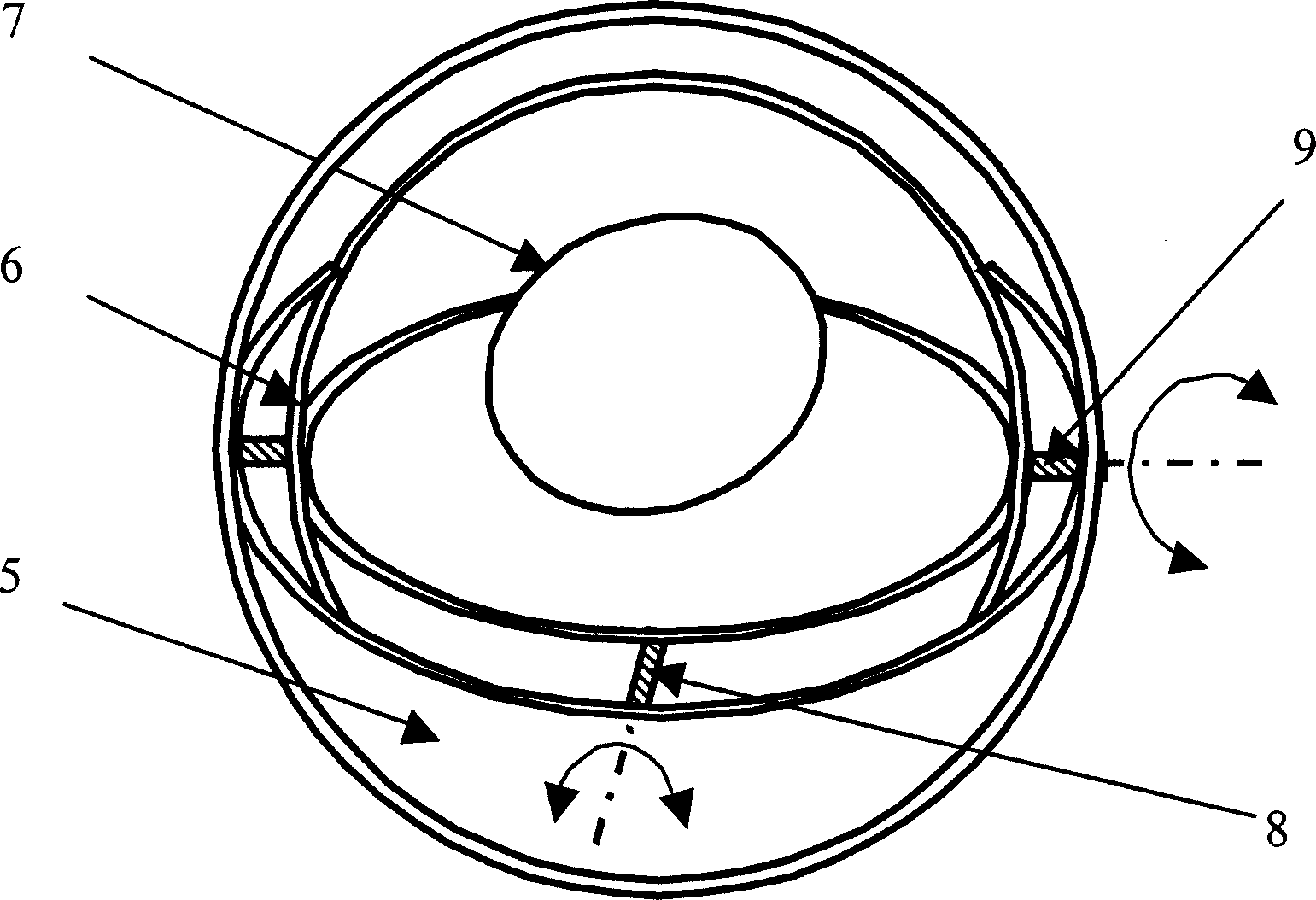

[0035] Such as figure 2 As shown, the internal three-dimensional mechanism of the rotary ball washing machine is composed of an outer sphere 5, an inner sphere 6, an inner door 7, a first rotating shaft system 8 and a second rotating shaft system 9 in the basic motion mode.

[0036] Cylinder (drum type)

[0037] Table 1 Comparison of volume and water storage of drum type and brick ball washing machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com