Heat exchange heat pipe of water heater

A technology for water heaters and heat exchange tubes, applied in the field of heat exchange tubes, can solve the problems of difficult product quality assurance and increased production costs between the heat exchange head and the tube sheet, and solve welding problems, maintain heat exchange efficiency, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

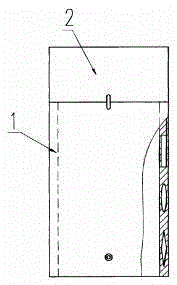

[0009] The present invention will be further explained below in conjunction with the accompanying drawings.

[0010] A water heater heat exchange heat pipe is characterized in that it includes a combustion chamber 1 and a main heat exchanger 2, and the main heat exchanger 2 has heat exchange pipes 3 and heat exchange fins 4. The combustion chamber 1 is surrounded by more than one hollow plate, the hollow plate of the combustion chamber 1 communicates with the heat exchange tube 3, there is water flowing in the hollow plate and the heat exchange tube 3 for heat exchange, and the cross section of the hollow plate can be hollow and circular , prismatic, rectangular and other geometric shapes.

[0011] By adopting the above solution, the present invention has a simple structure, maintains the heat exchange efficiency of the thin-walled heat exchange tube, and simultaneously solves the problem of welding between the heat exchange tube and the tube sheet.

[0012] The above content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com