Oxy-combustion steam generator

A steam generator, pure oxygen technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve problems such as increasing cost and complexity, increasing auxiliary power demand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

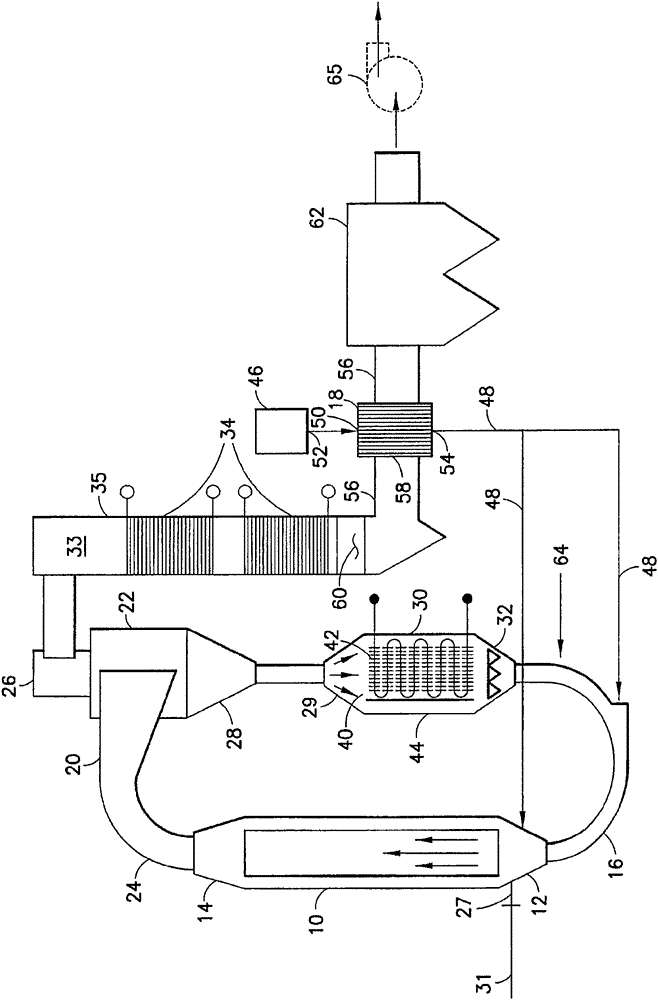

[0012] Such as figure 1 As shown, the transport reactor generally indicated by the numeral 10 operates as a combustor and defines an inlet 12 and an outlet 14 . A solid fuel 64, such as but not limited to coal, is fed to the transport reactor. Substantially all of the transport gas is provided by conduits 16 and 48 when transport reactor 10 is operating at or above a specified system load. The particular system load is defined by the situation when all or substantially all of the transport gas is provided by conduits 16 and 48 at the minimum flow rate for operating the transport reactor 10 . The minimum flow rate is defined by the design and parameters of the transfer reactor and solid fuel, such as the size of the transfer reactor and solid fuel. A portion or substantially all of the transport gas may be heated in an oxygen preheater 18 (explained in the detailed description below) before being supplied to the combustor. The combustion chamber outlet 14 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com