Lifting film type evaporator comprehensive test experiment system

A technology of comprehensive testing and experimental system, applied in the field of lifting film evaporation/reboiler testing experimental system, can solve the problems of waste of resources, large investment, large floor space, etc., to achieve improved accuracy and reliability, and a compact system structure , the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

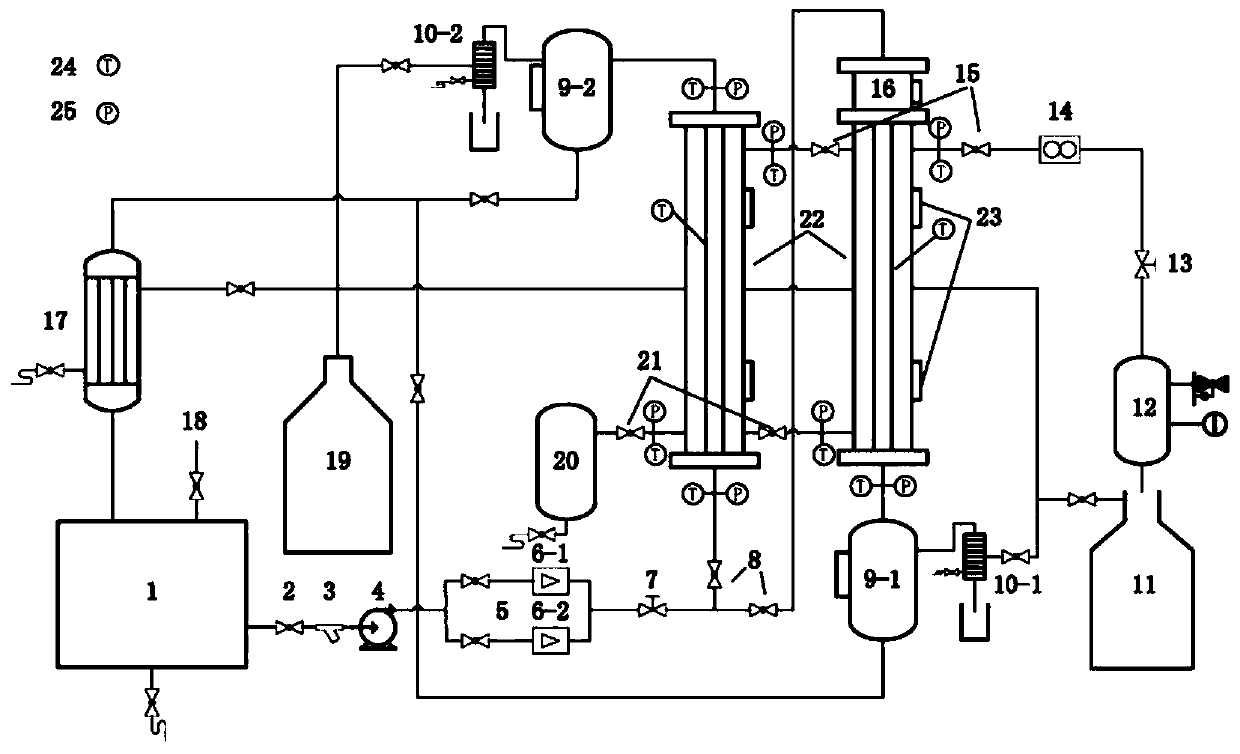

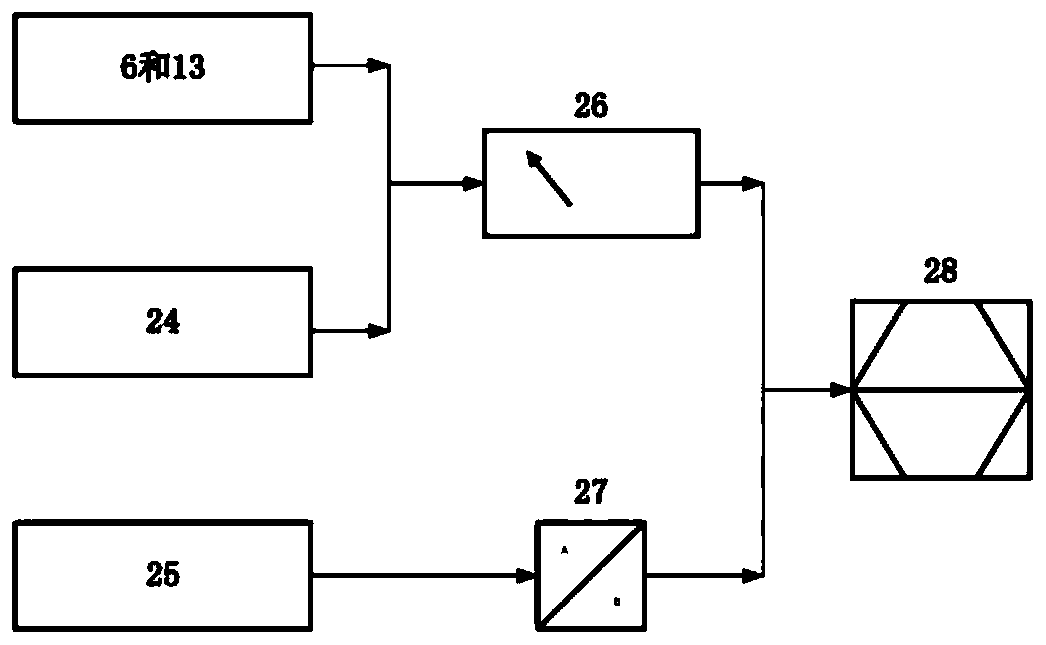

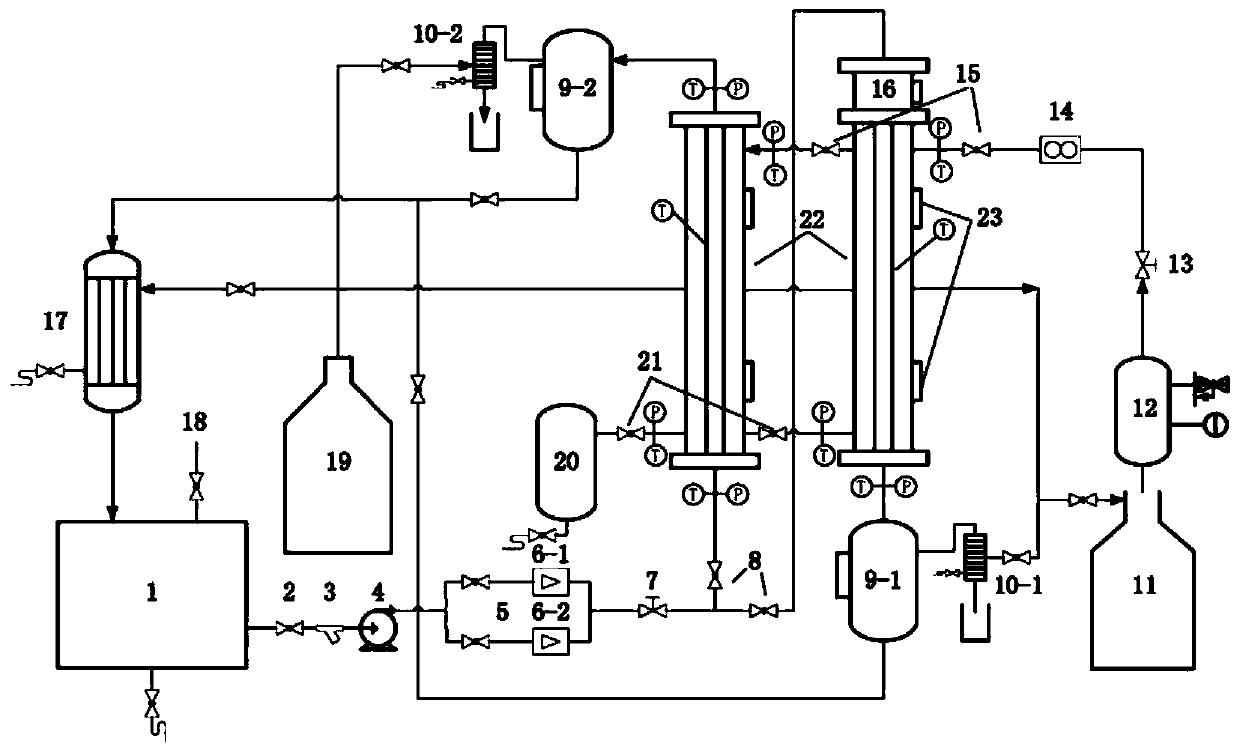

[0033] Lifting film evaporation / reboiler comprehensive test experimental system of the present invention, such as figure 1 As shown, it is composed of a cooling medium pipeline unit, a steam pipeline unit, a test heat exchanger unit and a data measurement and control unit, and each unit is connected through pipelines or corresponding connecting elements.

[0034] The inlet of the centrifugal pump 4 in the cooling medium pipeline unit is connected to the outlet of the heating water tank 1 through the threaded ball valve 2 and the Y-type filter 3, and the outlet of the centrifugal pump 4 is connected to the first parallel pipeline 5, and each pipe of the first parallel pipeline 5 A valve and a turbine flowmeter are installed in each pipeline, and the regulating valve 7 can control the flow rate of the first parallel pipeline, so that the cooling medium flows into the main heat exchanger tube side inlet to be tested through the second parallel pipeline 8, and after heat exchange, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com