Low-resistance buried-gate solar cell and manufacture method thereof

A technology of solar cells and manufacturing methods, which is applied in the manufacture of circuits, electrical components, and final products, can solve problems such as incompleteness, and achieve the effects of increasing the contact area, reducing the front contact resistance, and solving the contact area and electrode shading area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

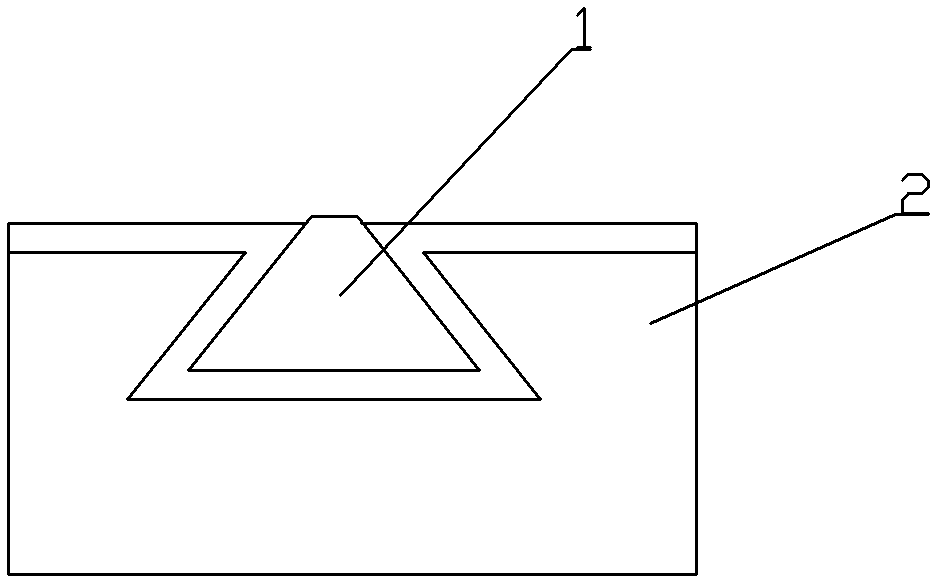

[0016] Such as figure 2 As shown, a low-resistance buried grid solar cell is provided with a front electrode on the light-receiving surface of the battery 2. On the light-receiving surface of the battery 2, a trapezoidal groove 3 with an upper narrow and a lower width is opened at the position where the front electrode needs to be arranged. A trapezoidal buried gate electrode 1 is fabricated inside.

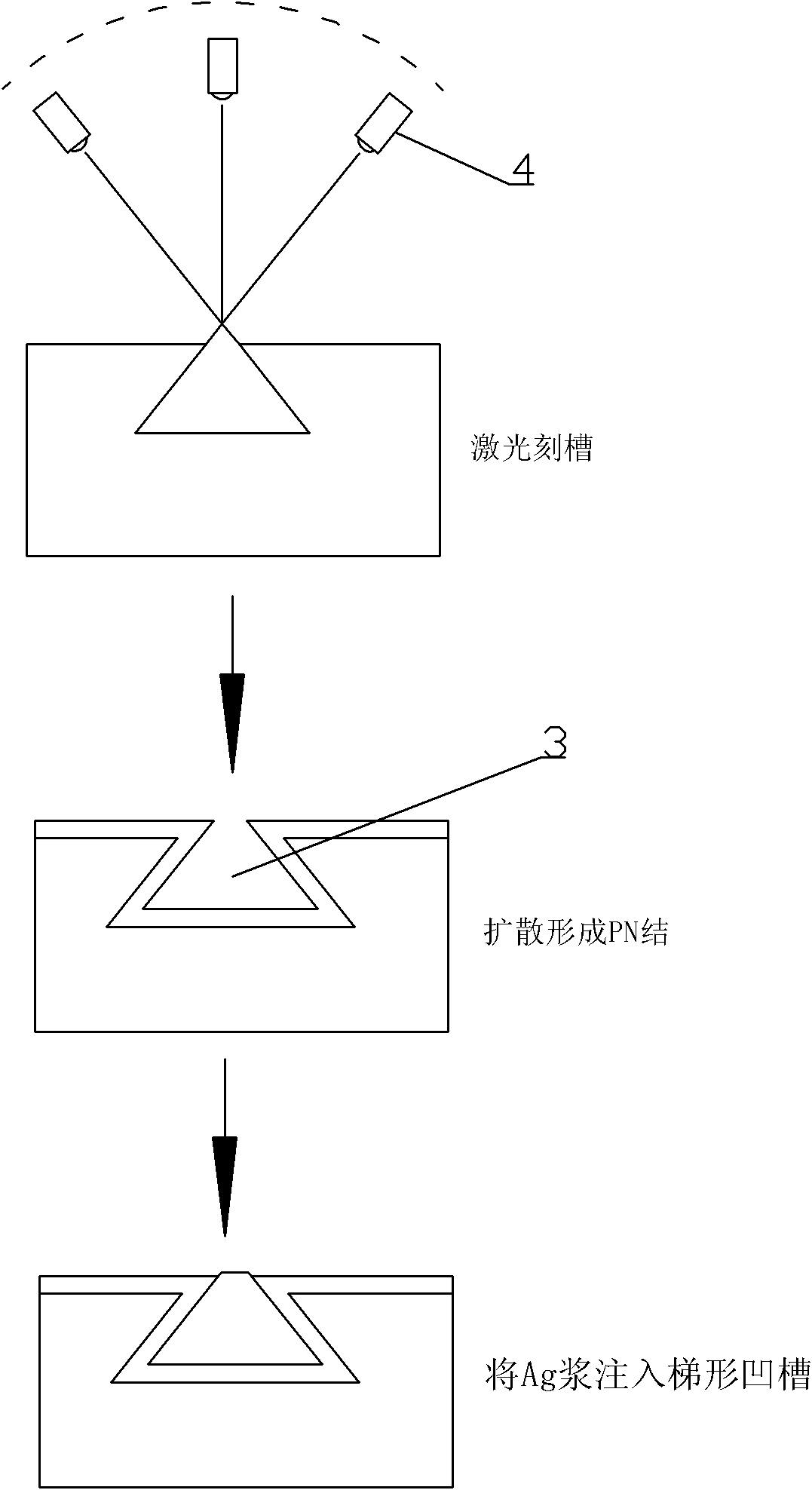

[0017] Such as image 3 As shown, the manufacturing method of the low-resistance buried grid solar cell is as follows: firstly, a trapezoidal groove 3 is made by laser grooving at the position where the trapezoidal buried gate electrode 1 needs to be formed;

[0018] The light-receiving surface forms a PN junction through a diffusion process, and the PN junction also exists in the trapezoidal groove 3;

[0019] Then use screen printing technology to inject the Ag paste into the trapezoidal groove 3;

[0020] Finally, Al paste and Ag-Al paste are printed on the back and sinter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com