Construction method of crack-resisting cement stabilized crushed stone base course

A cement-stabilized crushed stone and construction method technology, which is applied to cohesive pavement paved on site, climate change adaptation, construction, etc., to achieve the effects of improved crack resistance, guaranteed paving thickness, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the drawings.

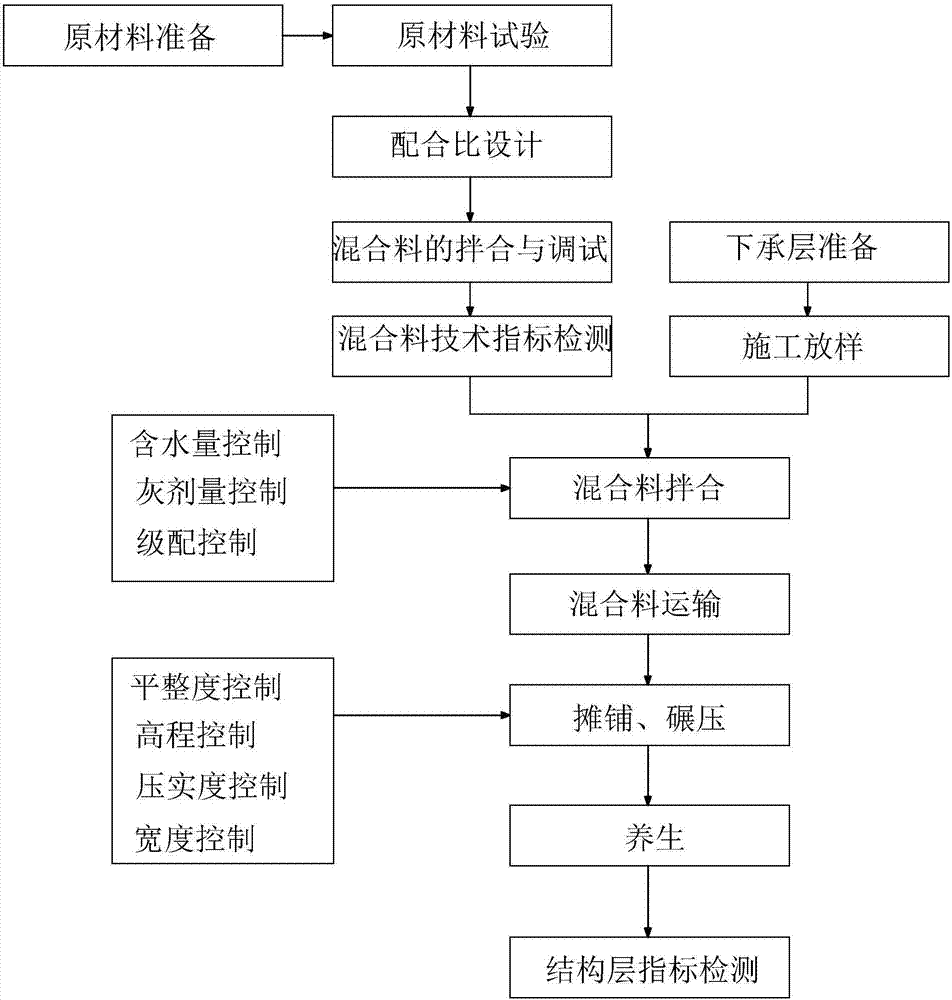

[0045] A construction method of anti-crack cement stabilized crushed stone base course includes the following steps:

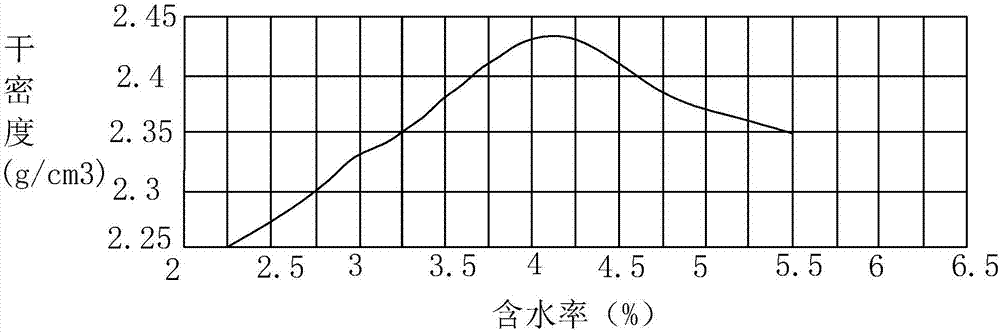

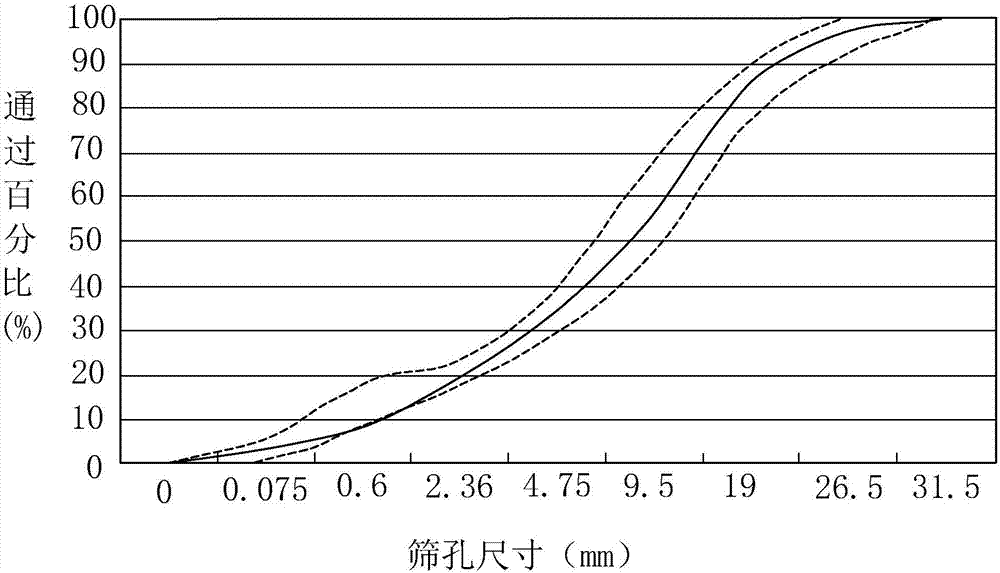

[0046] Step a, raw material configuration: including aggregate, 3% to 5% cement and water, please refer to the attached figure 2 The compaction test of cement stabilized macadam with different cement content by the vibration compaction molding method shows that the unconfined compressive strength specimens with cement content of 3%, 4.0%, and 5% are tested after standard curing The 7d unconfined compressive strength meets the requirements of the design documents. According to the "Technical Specification for Construction of Highway Pavement Base Course" (JTJ034-2000) and the recommended cement content in the design, based on the principle of quality first, the final cement content is determined to be 4.0%. Ordinary Portland cement, slag Portland cement and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com