Circulating fluidized bed boiler bottom slag waste heat recovery device

A technology of circulating fluidized bed and recovery device, which is applied to fluidized bed combustion equipment, lighting and heating equipment, and fuel burning in a molten state, etc. It can improve the heat transfer coefficient, reduce the flow resistance and prolong the heat transfer time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

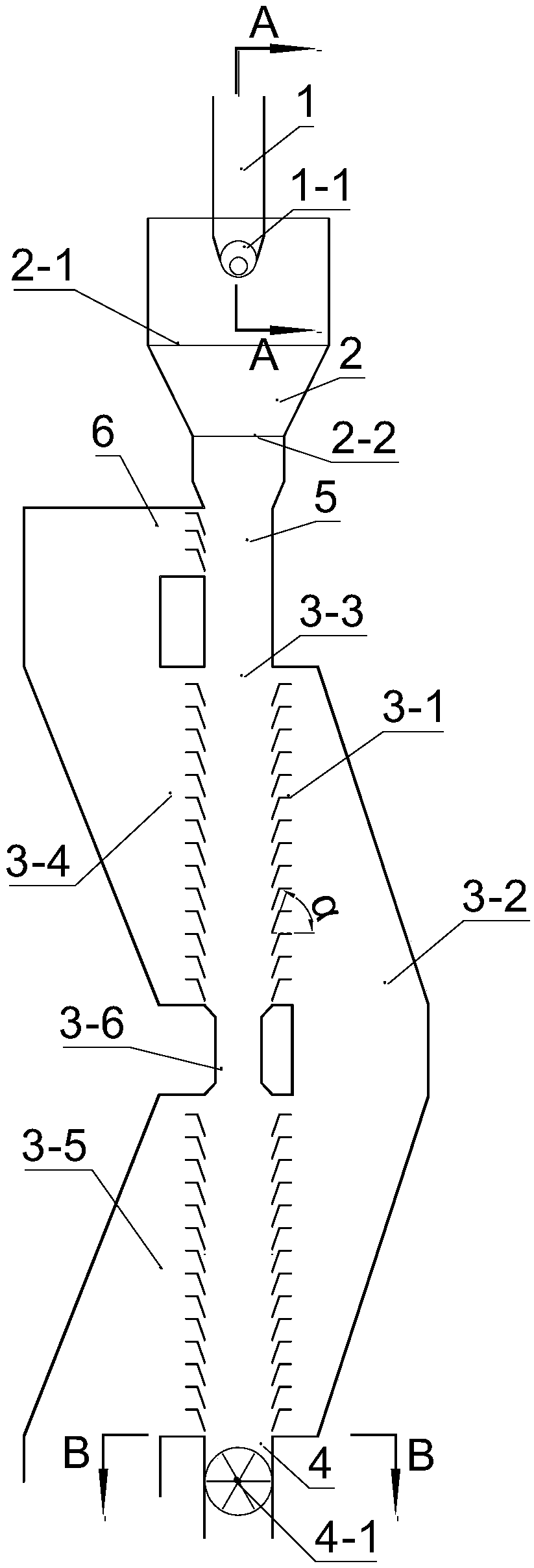

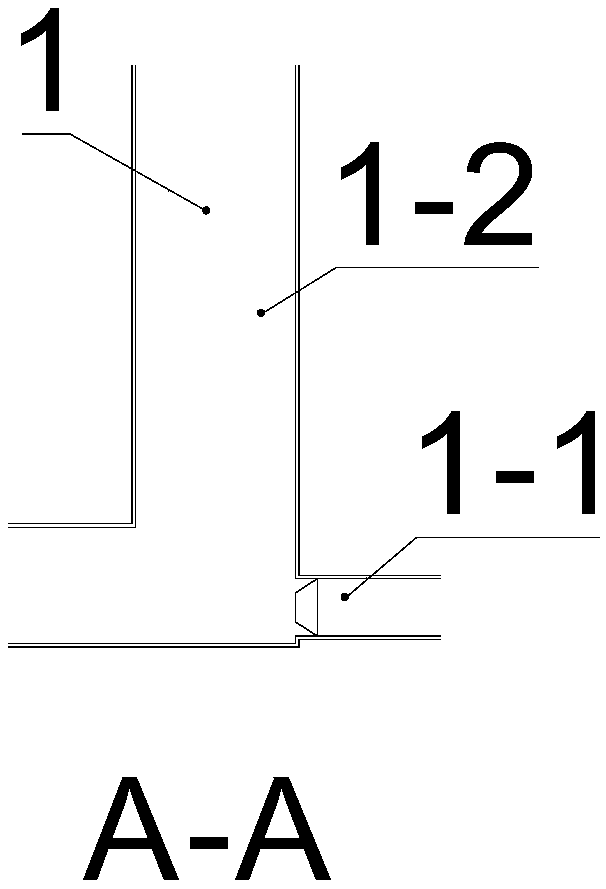

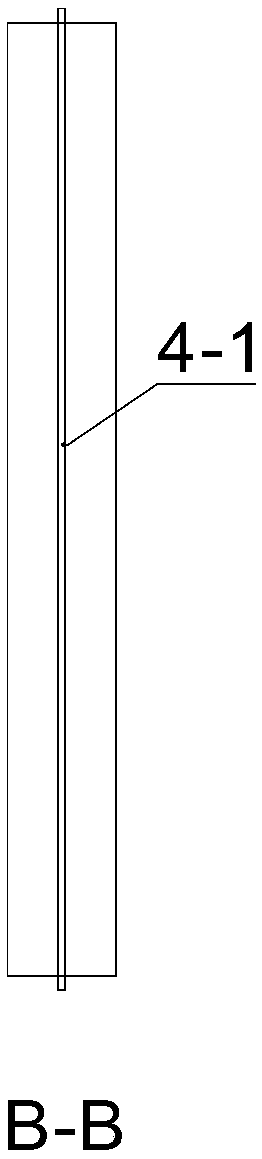

[0017] The structure of a circulating fluidized bed boiler bottom slag waste heat recovery device involved in this embodiment is as follows: Figure 1-Figure 4 As shown, it includes an L-type ash control valve 1, a sorting section pipeline 2, a cross-flow moving bed heat exchanger 3 and a slag discharge device 4, wherein the length of the standpipe section 1-2 of the L-type ash control valve 1 is 2m, and the air flow for introducing The ratio of the length of the tube 1-1 extending into the valve body to the length of the standpipe section 1-2 is 0; the sorting section pipeline 2 is a section of necking pipeline with a large top and a small bottom, and the upper part of the sorting section pipeline 2 is the sorting section inlet 2-1, Its lower part is the sorting section outlet 2-2, the ratio of the cross-sectional area of the sorting section inlet 2-1 to the sorting section outlet 2-2 is 2, and the sorting section outlet 2-2 is 1 time of the cross-sectional area of the bot...

Embodiment 2

[0021] The structure of a circulating fluidized bed boiler bottom slag waste heat recovery device involved in this embodiment is as follows: Figure 5-Figure 6As shown, it includes an L-type ash control valve 1, a sorting section pipeline 2, a cross-flow moving bed heat exchanger 3 and a slag discharge device 4, wherein the length of the standpipe section 1-2 of the L-type ash control valve 1 is 2m, and the air flow for introducing The ratio of the length of the tube 1-1 extending into the valve body to the length of the standpipe section 1-2 is 0; the sorting section pipeline 2 is a section of necking pipeline with a large top and a small bottom, and the upper part of the sorting section pipeline 2 is the sorting section inlet 2-1, Its lower part is the sorting section outlet 2-2, the ratio of the cross-sectional area of the sorting section inlet 2-1 to the sorting section outlet 2-2 is 2, and the sorting section outlet 2-2 is 1 time of the cross-sectional area of the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com