Coal coke Y-shaped entrained-flow bed cleaning high-efficiency gasifying technology

An entrained-flow bed and coal-coke technology, which is applied in the coal chemical industry, can solve the problems of the difficulty of hanging slag on the water-cooled wall, the unfavorable structure of the cooling spiral pipe, and the large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

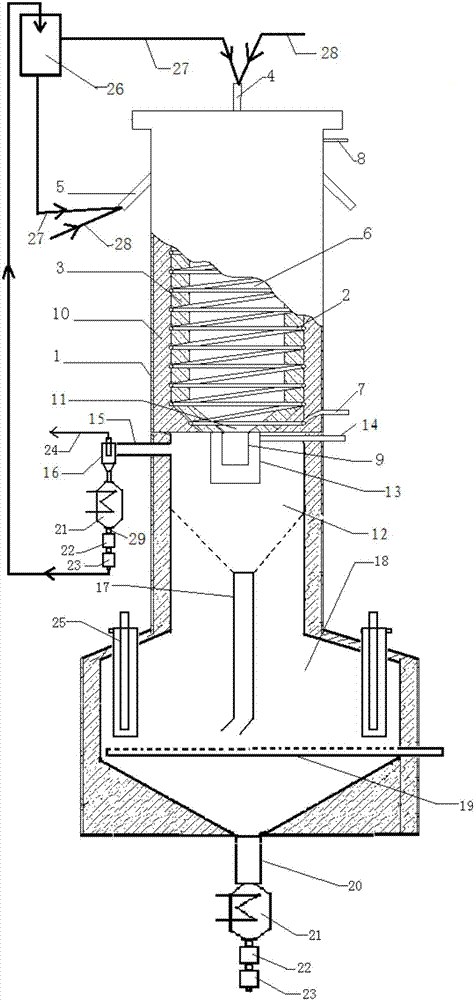

[0024] Below in conjunction with accompanying drawing, the present invention is described in detail: figure 1As shown, the coal char Y-type entrained entrained bed clean and efficient gasification process described in the present invention is that the gasification agent and water vapor from the coal water slurry from the raw material tank or the pulverized coal and the oxygen station pass through the top of the Y-type gasifier. Nozzles (4) and radially inclined side nozzles (5) are sprayed into the gasification chamber (6) for combustion and gasification at a temperature of 1300-2000°C; top nozzles (4) and side nozzles (5) generate multiple jets The hearth center of the gasification chamber (6) collides with each other to form a Y-shaped rotating impact area, ignites each other, stirs and mixes with turbulent flow, and forms a high-temperature reaction area. The residence time of slag in the high-temperature reaction zone is extended by more than 10 times, the cooling jacket (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com