Fluidized bed gasifier and its application

A technology of fluidized bed gasification furnace and gasification agent, which is applied in the direction of gasification process, gasification device details, granular/powdered fuel gasification, etc., and can solve the problem of high carbon dioxide and methane content in residual carbon Operational or production efficiency impact, syngas yield and quality impact, etc., to achieve the effect of high carbon conversion rate, wide adaptability of coal types, and increased temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

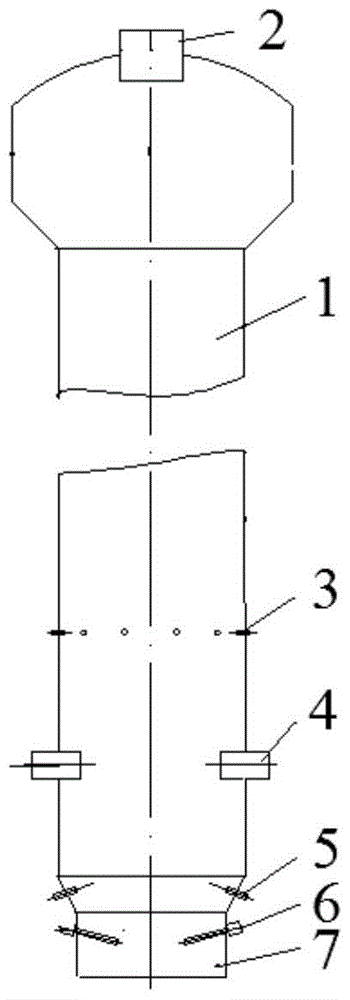

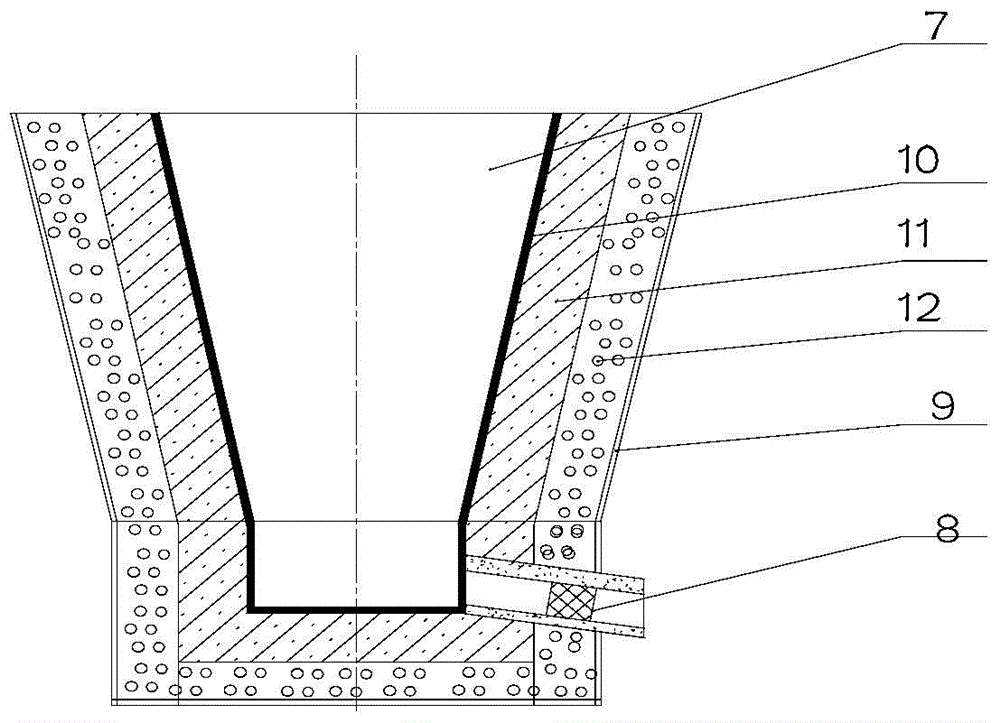

[0036] The fluidized bed gasifier of this embodiment is used for gasification of pulverized coal.

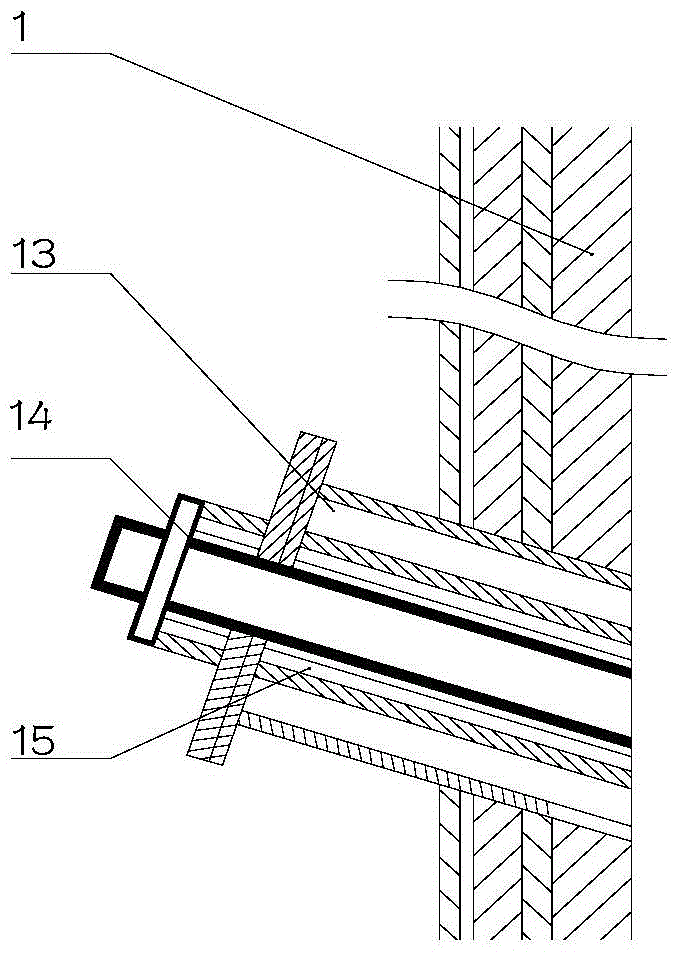

[0037] The synthesis gas outlet 2 is connected to the output pipeline, the primary gasification agent nozzle 5 is connected to the mixer providing the gasification agent through the pipeline, the secondary gasification agent nozzle 3 is connected to the mixer providing the gasification agent through the pipeline, and the material input The pipe 4 is connected with the coal feeder of the coal supply system, and the plasma torch 14 is installed and fixed in the auxiliary gasification agent input pipe 13, and connected with the power supply, water supply and gas supply systems of the plasma torch. The oxygen-enriched steam / steam is output from the mixer providing the gasification agent, and connected to the annular channel 15 through a pipeline. The pulverized coal enters the furnace from the material input pipe 4, and under the action of the high-speed gasification agent sprayed f...

Embodiment 2

[0039] The fluidized bed gasification furnace of this embodiment is used for gasification of garbage mixture.

[0040] The garbage mixture enters the gasifier through the material input pipe for gasification to generate synthesis gas. All the other technical features are the same as in Embodiment 1.

Embodiment 3

[0042] The fluidized bed gasifier in this embodiment is used to gasify pulverized coal with low ash content, high calorific value and high activity.

[0043] The auxiliary gasification agent input by the auxiliary gasification agent input pipe is pure oxygen-steam gasification agent. All the other technical features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com