Orifice plate for controlling solids flow, methods of use thereof and articles comprising the same

A technology of solid particles and orifice plates, applied in the field of orifice plates, can solve problems such as low efficiency of heat exchangers, failure of components, poor heat transfer performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

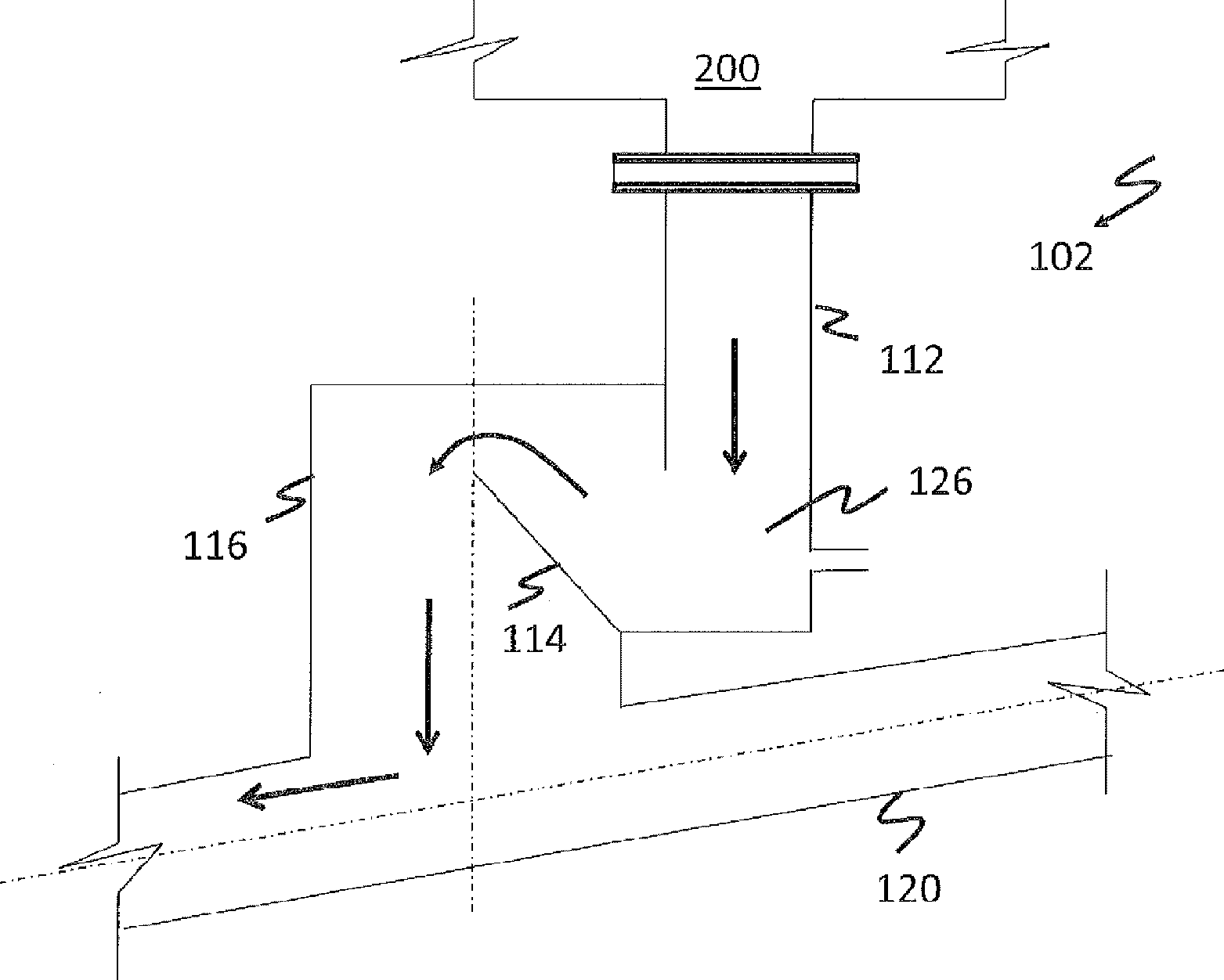

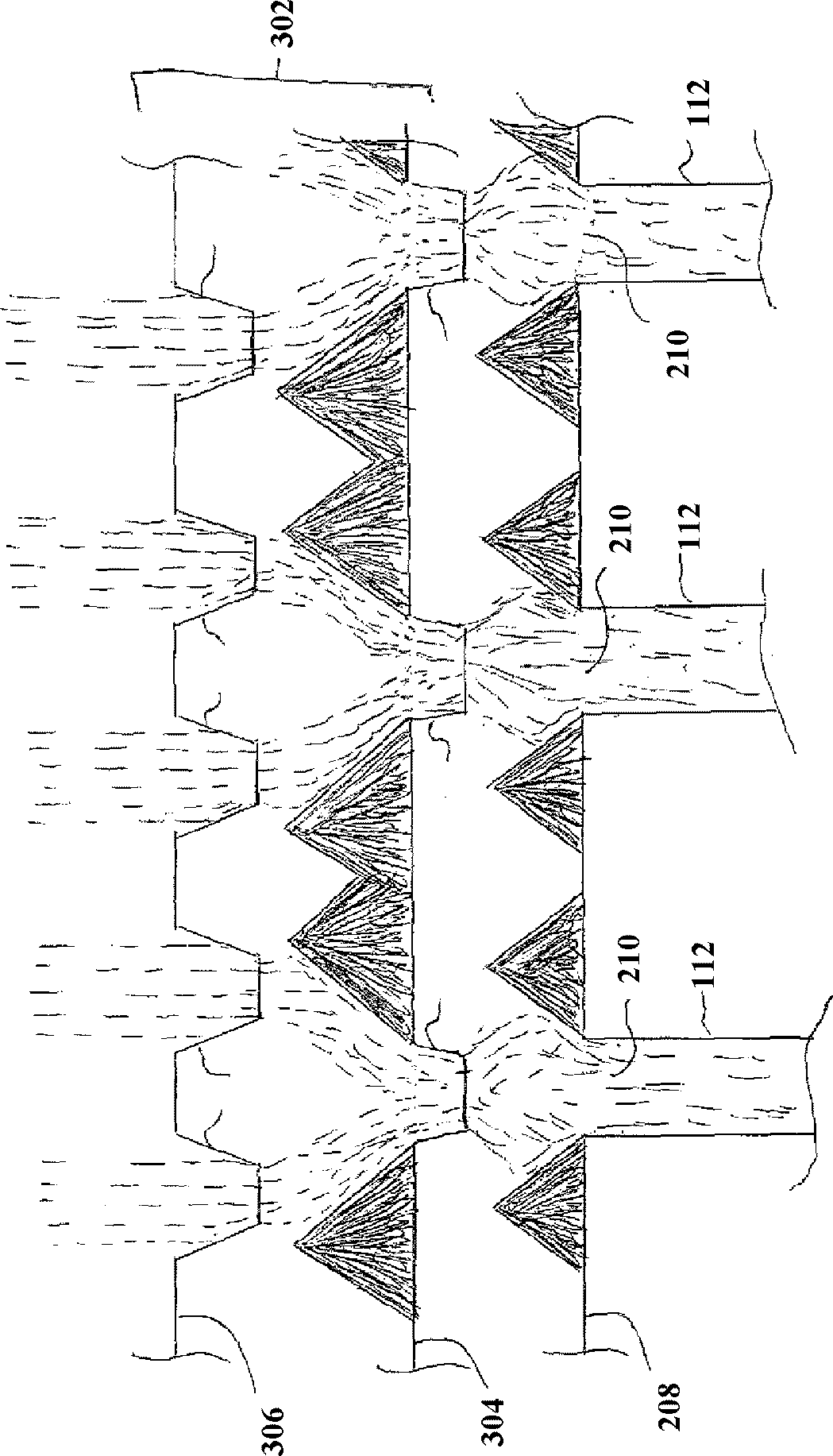

[0052] This example depicts the difference in the size of a moving bed heat exchanger when orifice plates are used, and when no orifice plates are used. The preliminary arrangement of the moving bed heat exchanger indicates that ash flow distribution and control are important to the design. The original moving bed heat exchanger design used a mass flow hopper 70 with a 70 degree angle to ensure a uniform flow of solids in the moving bed heat exchanger. shown above figure 2 , the hopper is mounted above the standpipe 112. This method requires a very tall moving bed heat exchanger, or a moving bed heat exchanger with an excessive number of hoppers and ash control valves at the bottom of the moving bed heat exchanger. Using a continuous plate with orifices reduces the gap height between the moving bed heat exchanger tube bundle and the inlet to the ash control valve by a third.

[0053] Therefore, an orifice plate system with 2 plates is formed to reduce the height requiremen...

example 2

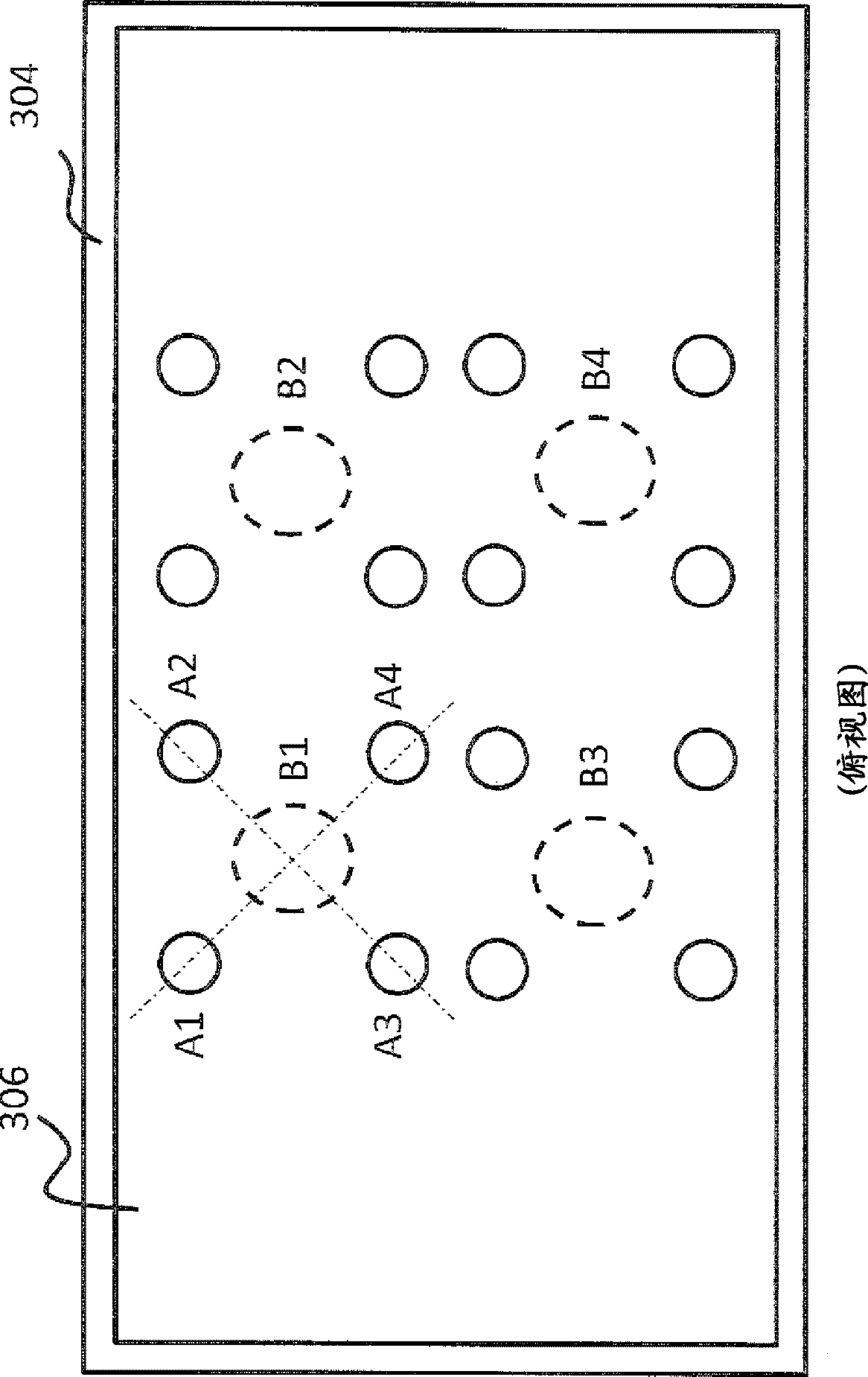

[0055] This example depicts the difference in performance between a moving bed heat exchanger without orifice plates and with orifice plates. Such as figure 1 With 4 ash control valves like the one depicted in , installed in the flat bottom area below the moving bed heat exchanger, it is expected that the ash itself will be evenly distributed over the inlet of the ash control valves at a certain angle of internal friction of solid particles representing 70 degrees. height.

[0056] The 70 degree friction angle exists for a short distance above the inlet of the ash control valve, and then the solids plume extends upward to the top, as Figure 7 as shown in the photo. There is a dead volume of ash between the plumes, which can be Figure 7 as seen in the gray areas of the . A run of the slice model without the orifice distribution plate shows that the ash flow plume extends from the top of the ash column down to the ash control valve with less spread of the plume. This ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com