Liquid phase heat exchange fluidized bed heat exchanger

A technology of heat exchanger and liquid phase, which is applied in the field of fluidized bed heat exchanger for liquid phase heat exchange, and can solve the problems of decreased heat exchange effect and easy fouling of heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

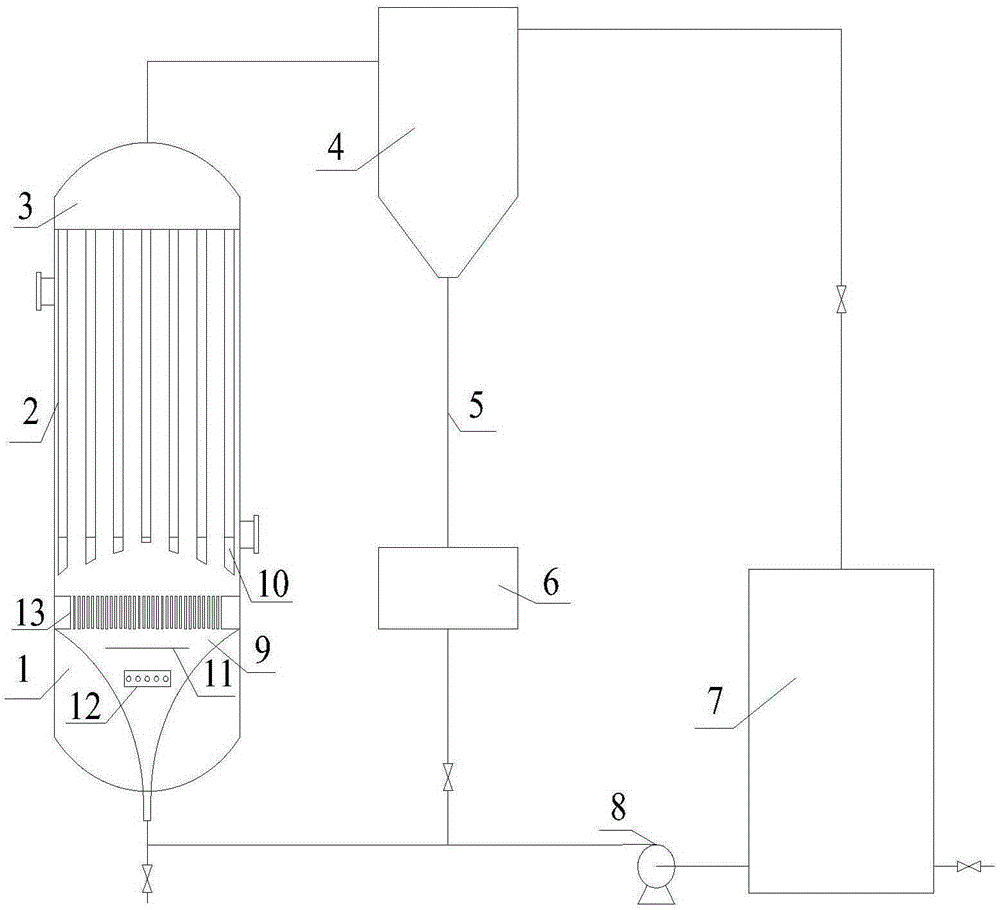

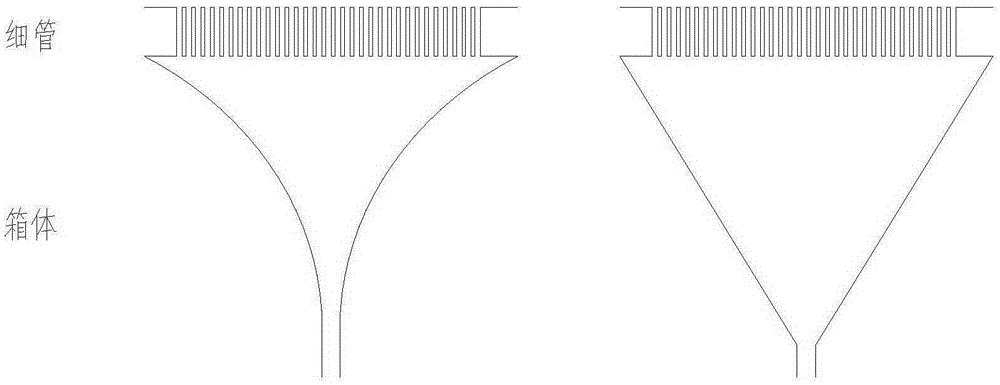

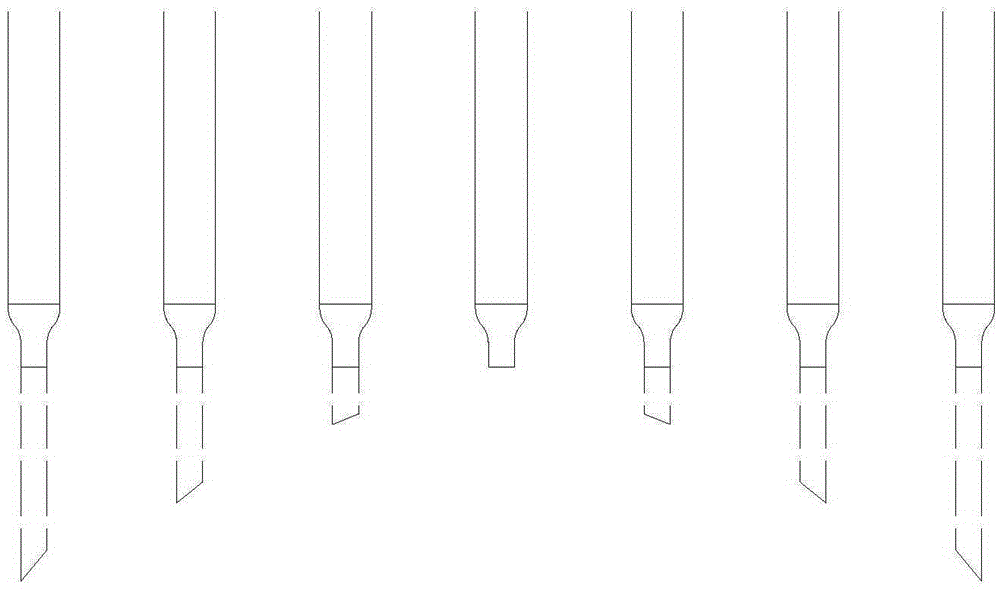

[0028] use figure 1The liquid-phase heat-exchanging fluidized-bed heat exchanger shown is applied to a constant-top heat exchanger of a refinery's atmospheric and decompression device. The liquid-phase heat-exchanging fluidized-bed heat exchanger is equipped with 442 heat exchanger tubes. The length of each tube is 5000mm, the diameter of the tube is Φ22×1.5mm, and the tubes are arranged in an equilateral triangle. The solid particles are glass beads with an average particle diameter of 5 mm, and the average volume solid content of the solid particles in the liquid-phase heat exchange fluidized bed heat exchanger is 3%. The liquid phase is crude oil, and the flow velocity is 1.5m / s. The distribution bin is figure 2 Conical shape shown. Distribution box height 500mm. There are 1768 thin tubes with a diameter of 6mm and a length of 8mm. The diameter of the lower casing is 12mm, and the arrangement is as follows: one in the middle, with a length of 15mm, no bevel and no hol...

Embodiment 2

[0030] The same liquid-phase heat exchange fluidized bed heat exchanger as in Example 1 is applied to the constant top heat exchanger of a refinery's atmospheric and vacuum device. The solid particles are made of glass beads with an average particle diameter of 2mm. The average volume solid content in the heat fluidized bed heat exchanger is 8%. The liquid phase is crude oil, and the flow velocity is 4m / s. The distribution bin is figure 2 Trumpet shown. Distribution box height 1500mm. There are 1768 thin tubes with a diameter of 6mm and a length of 15mm. The diameter of the casing along the lower edge is 7.5mm, and the arrangement is as follows: one in the middle, length 20mm, no groove, no opening; 183 casings in the middle 7 layers, length 30mm, groove 30 degrees, one hole, aperture 3mm, a total of 258 pieces in the outer 4 layers, the length is 50mm, the bevel is 15 degrees, and two holes are opened with a diameter of 2.5mm. The distribution plate is Figure 4 As sho...

Embodiment 3

[0032] The same liquid-phase heat exchange fluidized bed heat exchanger as in Example 1 is applied to a constant top heat exchanger of a refinery atmospheric and decompression device, and the solid particles are alumina beads with an average particle diameter of 5 mm. The average volume solid content in the phase-exchange fluidized bed heat exchanger is 3%. The liquid phase is crude oil, and the flow velocity is 1.5m / s. The distribution bin is figure 2 Conical shape shown. Distribution box height 500mm. There are 1326 thin tubes distributed, with a diameter of 6mm and a length of 8mm. The diameter of the casing along the lower edge is 12mm, and the arrangement is as follows: one in the middle, length 15mm, no groove, no opening; 183 casings in the middle 7 layers, length 20mm, groove 60 degrees, and a hole with a diameter of 6mm , a total of 258 pieces in the outer 4 layers, the length is 30mm, the bevel is 30 degrees, and a hole is opened with a diameter of 6mm. The dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com