Alkali-activated cementitious material for 3D printing

A gelling material and 3D printing technology, which is applied in the direction of additive processing, etc., can solve the problems of too fast setting time and poor fluidity of alkali-induced gelling materials, and achieve the requirements of alleviating shrinkage cracking, short setting time, and ensuring work performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

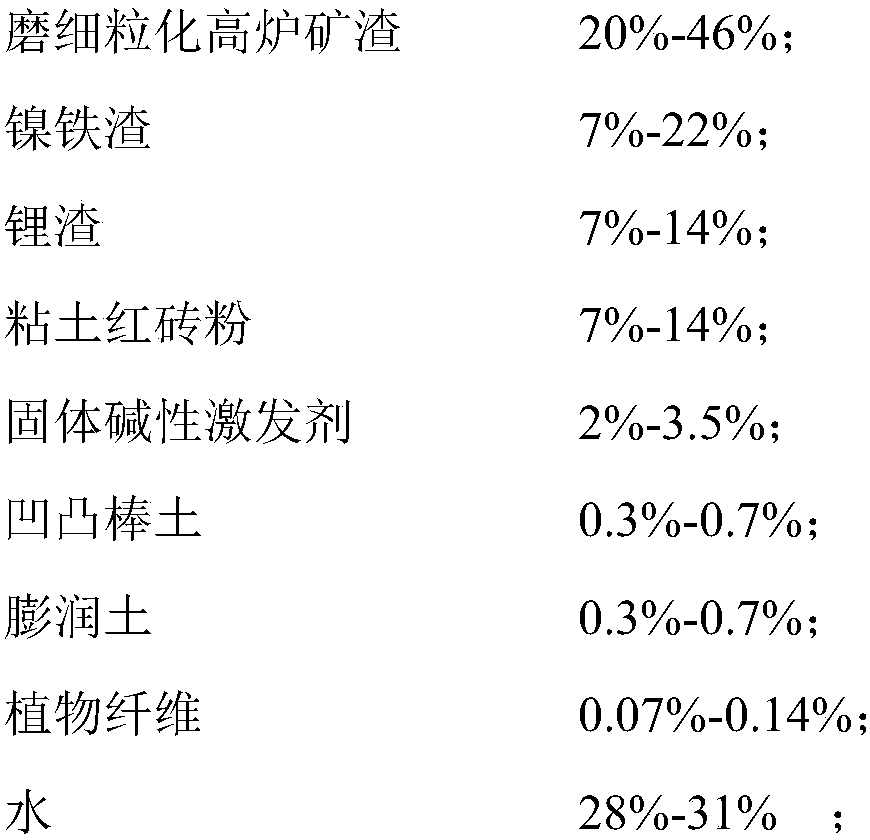

Method used

Image

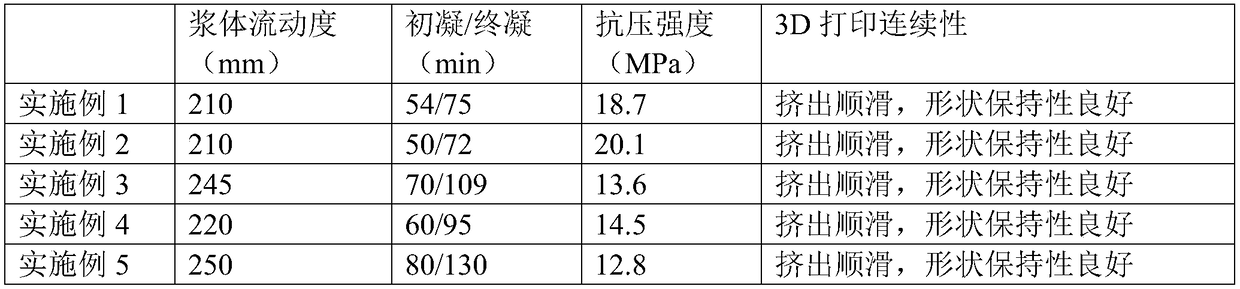

Examples

Embodiment 1

[0024] A new type of alkali-activated gelling material for 3D printing, the mass percentage of each component of the raw material is 46% of ground fine-grained blast furnace slag, and the specific surface area is 450m 2 / kg; ferronickel slag 7%, specific surface area 345m 2 / kg; lithium slag 7%, specific surface area 530m 2 / kg; red brick powder 7%, specific surface area 650m 2 / kg; attapulgite 0.45%, fineness 430 mesh; sodium bentonite 0.45%, fineness 320 mesh; sisal fiber 0.1%, diameter 0.12mm, length 8mm; the addition of the alkali activator lithium hydroxide It is 2%, and the addition of described water is 30%.

[0025] Take by weight percentage respectively 46% grinding fine grained blast furnace slag, 7% ferronickel slag, 7% lithium slag and 7% red brick powder, ferronickel slag, lithium slag and 7% red brick powder in this embodiment The red brick powder has not been treated by microwave heating activity excitation, and at the same time, 0.45% attapulgite and 0.45% s...

Embodiment 2

[0027] A new type of alkali-activated gelling material for 3D printing, the mass percentage of each component of the raw material is 46% of ground fine-grained blast furnace slag, and the specific surface area is 450m 2 / kg; nickel-iron slag 7%, specific surface area 345m2 / kg; lithium slag 7%, specific surface area 530m 2 / kg; red brick powder 7%, specific surface area 650m2 / kg; attapulgite 0.45%, fineness 430 mesh; sodium bentonite 0.45%, fineness 320 mesh; sisal fiber 0.1%, diameter 0.12mm, length 8mm; The added amount of the alkali activator lithium hydroxide is 2%, and the added amount of the water is 30%.

[0028] Take by weight percentage respectively 46% grinding fine grained blast furnace slag, 7% ferronickel slag, 7% lithium slag and 7% red brick powder, ferronickel slag, lithium slag and 7% red brick powder in this embodiment The red brick powder has been activated by microwave heating, and at the same time, 0.45% of attapulgite and 0.45% of sodium bentonite are add...

Embodiment 3

[0030] A new type of alkali-activated gelling material for 3D printing, the mass percentage of each component of the raw material is 31% of ground fine-grained blast furnace slag, and the specific surface area is 550m 2 / kg; ferronickel slag 22%, specific surface area 600m 2 / kg; lithium slag 7%, specific surface area 550m2 / kg; red brick powder 7%, specific surface area 700m 2 / kg; attapulgite 0.7%, fineness 450 mesh; sodium bentonite 0.7%, fineness 330 mesh; coconut shell fiber 0.1%, diameter 0.16mm, length 10mm; the addition of the alkali activator lithium hydroxide It is 3.5%, and the addition of described water is 28%.

[0031] Take by weight percentage respectively 31% grinding fine grained blast furnace slag, 22% ferronickel slag, 7% lithium slag and 7% red brick powder, ferronickel slag, lithium slag and The red brick powder has been activated by microwave heating. The microwave heating temperature is 500°C, the power is 800W, and the time is 60 minutes; at the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com