Grain refinement type cast magnesium alloy and preparation method thereof

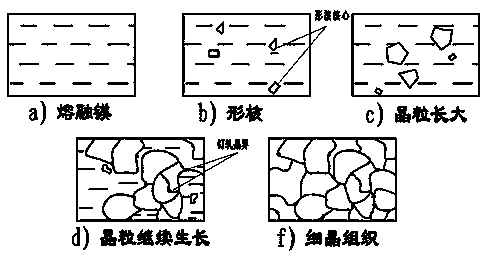

A technology for casting magnesium alloys and grain refinement, applied in the field of metal material casting, can solve problems such as low absolute strength, and achieve the effects of improving mechanical properties, improving resistance, and increasing the number of crystal nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A grain-refined cast magnesium alloy, the components and mass percentages are: ZrC: 0.2%, HfC: 0.2%, Al: 5%, Mn: 1%, Zn 0.8%, Ca: 1%, Yl. 5%, Sr 0.5%, the balance Mg and impurities;

[0035] The preparation method is as follows:

[0036] (1) Ingredients: The mass percentages of raw materials and various substances are: ZrC: 0.2%, HfC: 0.2%, Al: 5%, Mn: 1%, Zn 0.8%, Ca: 1%, Y 1.5%, Sr 0.5%, the balance Mg and impurities;

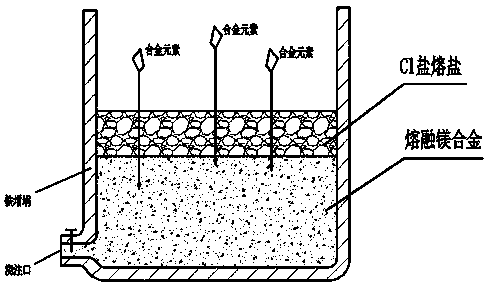

[0037] (2) Smelting: Use an iron crucible to smelt in an ordinary resistance furnace. First, metal Mg is smelted. Measured and preheated pure metal Al, metal Mn, metal Ca, metal Y and metal Sr, control the melting temperature of 720°C to 770°C, and use Cl salt molten salt as the melting protective layer to obtain liquid metal;

[0038] (3) Casting: quickly cool the molten metal to 710°C to 750°C for pouring, and ensure that the casting is completed within 45 minutes;

[0039] (4) Heat treatment: solid solution the product obtained in step (3) at 38...

Embodiment 2

[0042] A grain-refined cast magnesium alloy, the components and mass percentages are: ZrC: 0.8%, HfC: 0.8%, Al: 6%, Mn: 2%, Zn 1%, Ca: 3%, Y 2 %, Sr 0.58%, the balance Mg and impurities;

[0043] The preparation method is as follows:

[0044] (1) Ingredients: The mass percentages of raw materials and various substances are ZrC: 0.8%, HfC: 0.8%, Al: 6%, Mn: 2%, Zn 1%, Ca: 3%, Y 2%, Sr 0.58% , the balance Mg and impurities;

[0045] (2) Smelting: Use an iron crucible to smelt in an ordinary resistance furnace. First, metal Mg is smelted. Measured and preheated pure metal Al, metal Mn, metal Ca, metal Y and metal Sr, control the melting temperature of 720°C to 770°C, and use Cl salt molten salt as the melting protective layer to obtain liquid metal;

[0046] (3) Casting: quickly cool the molten metal to 710°C to 750°C for pouring, and ensure that the casting is completed within 45 minutes;

[0047] (4) Heat treatment: solid solution the product obtained in step (3) at 380°C-4...

Embodiment 3

[0050] A grain-refined cast magnesium alloy, the components and mass percentages are: ZrC: 1.2%, HfC: 1.2%, Al: 8%, Mn: 2%, Zn 1.2%, Ca: 3%, Y3% , Sr 1%, the balance Mg and impurities;

[0051] The preparation method is as follows:

[0052] (1) Ingredients: The mass percentages of raw materials and various substances are ZrC: 1.2%, HfC: 1.2%, Al: 8%, Mn: 2%, Zn 1.2%, Ca: 3%, Y3%, Sr 1%, The balance of Mg and impurities;

[0053] (2) Smelting: Use an iron crucible to smelt in an ordinary resistance furnace. First, metal Mg is smelted. Measured and preheated pure metal Al, metal Mn, metal Ca, metal Y and metal Sr, control the melting temperature of 720°C to 770°C, and use Cl salt molten salt as the melting protective layer to obtain liquid metal;

[0054] (3) Casting: quickly cool the molten metal to 710°C to 750°C for pouring, and ensure that the casting is completed within 45 minutes;

[0055] (4) Heat treatment: solid solution the product obtained in step (3) at 380°C-420...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com