Fire-resistant silicone rubber cable material and preparation method thereof

A silicone rubber and cable material technology, applied in the field of refractory materials, can solve the problems of high stability, high environmental protection requirements, low processing efficiency, low light transmittance, etc. of halogen-free cables, achieving good mechanical properties, not easy to fall off, The effect of no three waste emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

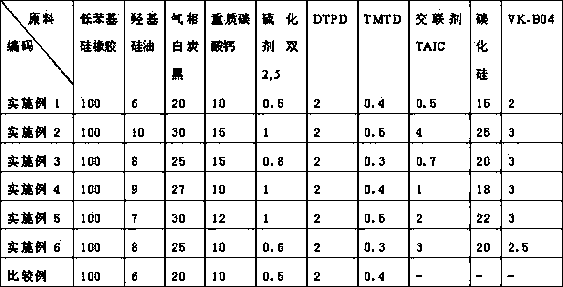

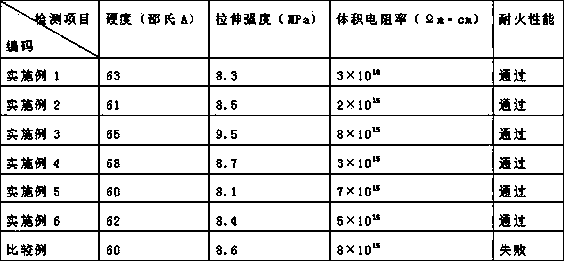

[0030] According to the formula under the item of embodiment 1 in table 1, prepare the raw material of refractory silicone rubber cable material.

[0031] The preparation method of refractory silicone rubber cable material is as follows:

[0032] Add hydroxyl silicone oil, fumed white carbon black, superfine active ground calcium carbonate, anti-aging agent, accelerator, flame retardant and heat stabilizer to low-phenyl silicone rubber, and after 30 minutes of mixing, add it to the open mill Vulcanizing agent and auxiliary vulcanizing agent, and then molded and extruded to make refractory silicone rubber cable material products.

Embodiment 2-6

[0034] Prepare the raw materials of the refractory silicone rubber cable material according to the formulas under the items of Examples 2-6 in Table 1.

[0035] The preparation method of the refractory silicone rubber cable material is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com