Prefabricated frame bracket-free long column and construction method thereof

A construction method and prefabricated technology, applied in the field of frame columns, can solve the problems of complex structure, low comprehensive cost and high comprehensive cost of prefabricated reinforced concrete frame joints, and achieve reliable construction quality, small steel consumption and high shear bearing capacity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

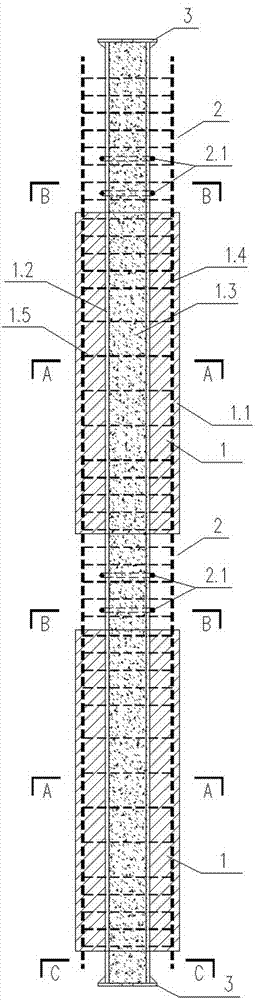

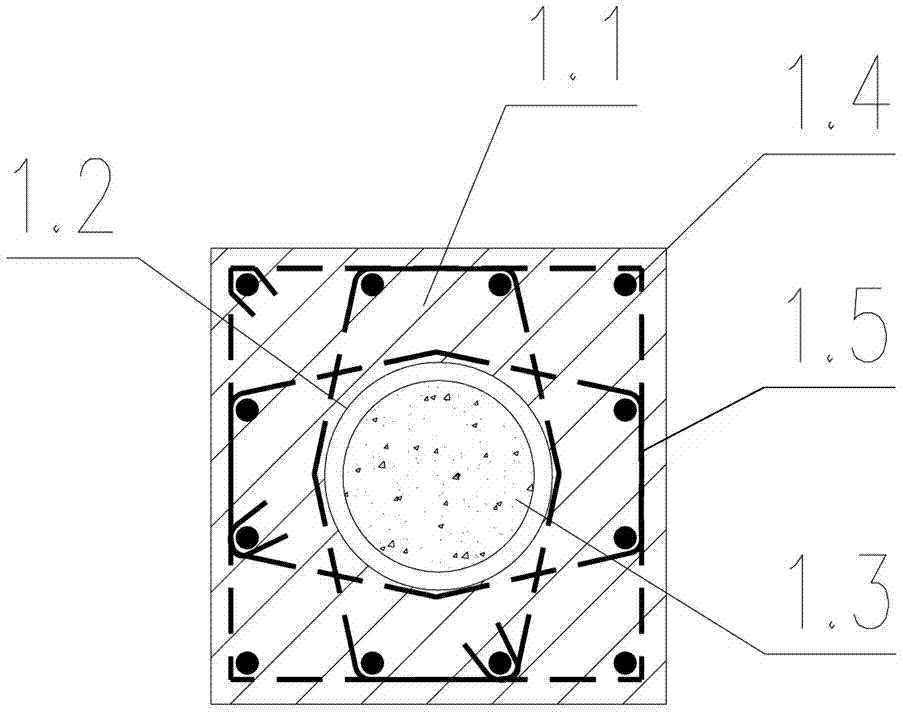

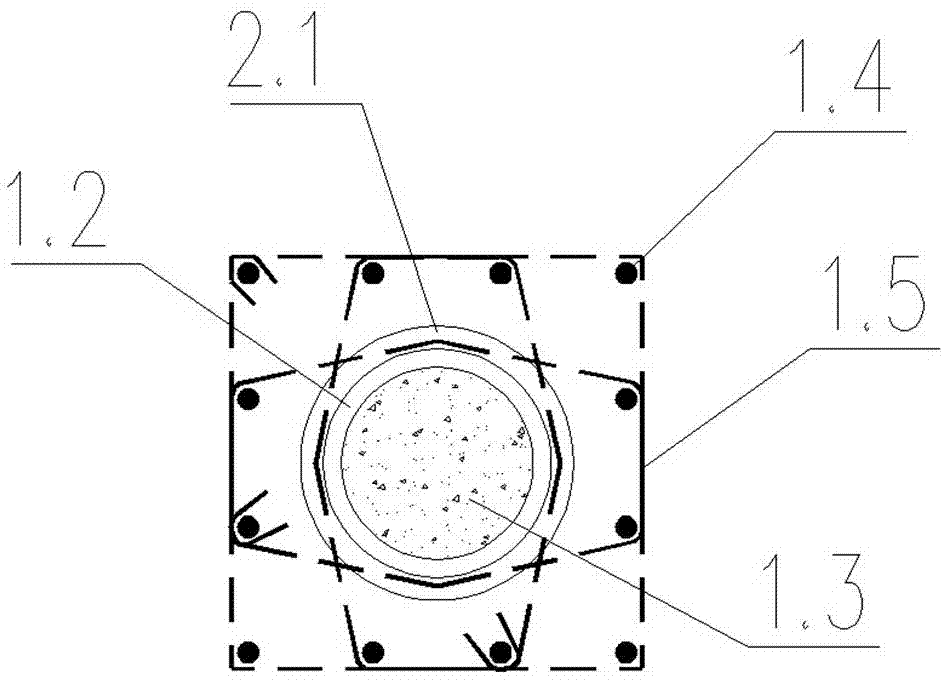

[0047] Embodiment one, see Figure 1-4 As shown, this prefabricated frame has no corbels and long columns, including more than two storey columns 1 and more than two beam-column nodes 2;

[0048] The steel pipes 1.2 at the interstory columns 1 and beam-column joints 2 of the long column, the first pre-cast steel pipe inner concrete 1.3 and the column longitudinal steel bars 1.4 bound outside the steel pipes are integrally penetrated, and the longitudinal steel bars 1.4 are horizontally There are column stirrups 1.5 tied at intervals;

[0049] The long column is pre-cast with steel pipe outer concrete for the second time in the range of each interlayer column 1, and the steel pipe outer concrete is combined with column longitudinal reinforcement 1.4 and column stirrup 1.5 to form steel pipe outer reinforced concrete 1.1, and the interlayer column 1 is made of A laminated column composed of reinforced concrete 1.1 outside the steel pipe, 1.2 steel pipe, and 1.3 inner concrete p...

Embodiment 2

[0098] Embodiment two, see Figure 5 As shown, the cross section of the steel pipe 1.2 is circular, the cross section of the reinforced concrete 1.1 outside the steel pipe is circular, and the rest are the same as in the first embodiment.

Embodiment 3

[0099] Embodiment three, see Image 6 As shown, the cross section of the steel pipe 1.2 is square, the cross section of the reinforced concrete 1.1 outside the steel pipe is square, and the rest are the same as in the first embodiment. Steel pipe 1.2 is rectangular or square, although the restraint effect is reduced, but the rectangular or square cross-section covers a larger area than the circular one, thus containing more high-strength concrete, which is also very effective for improving the bearing capacity of long columns.

[0100] The side length of the steel pipe 1.2 is 150-500 mm.

[0101] Calculation example 4. A steel pipe concrete composite column with side length 500x500, rectangular steel pipe □D300x7, using Q345, C80 concrete inside the pipe, C40 concrete outside the pipe; longitudinal reinforcement 12D20, steel reinforcement HRB400. The square or rectangular steel pipe does not count the effect of increasing the strength of the concrete restraint in the pipe.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com