Tungsten powder, positive electrode body for capacitors, and electrolytic capacitor

An anode body and capacitor technology, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of insufficient leakage current, large leakage current, and no use of tungsten, and achieve good LC characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Reduce tungstic acid at 980°C in a hydrogen flow to obtain an average particle size of 0.5 μm and a specific surface area of 0.3 m 2 / g primary powder of tungsten. Mix 4.8% by mass of commercially available silicon powder (average particle size: 1 μm) prepared separately with this powder, put it into a container made of tungsten, and place it in a vacuum high-temperature furnace with a molybdenum electrode at 3×10 -4 It was left to stand at 1320° C. for 20 minutes under Pa, then cooled until it became room temperature, and returned to normal pressure. Thereafter, it was crushed with a hammer mill, and coarse particles were removed through a sieve with a mesh size of 320 μm to obtain tungsten granulated powder. The obtained granulated powder has an average particle size of 120 μm and a specific surface area of 0.2 m 2 / g.

[0071] Elemental analysis of the obtained granulated powder revealed that silicon was 4.8% by mass, oxygen was 0.95% by mass, and other impuri...

Embodiment 2~5 and comparative example 1~2

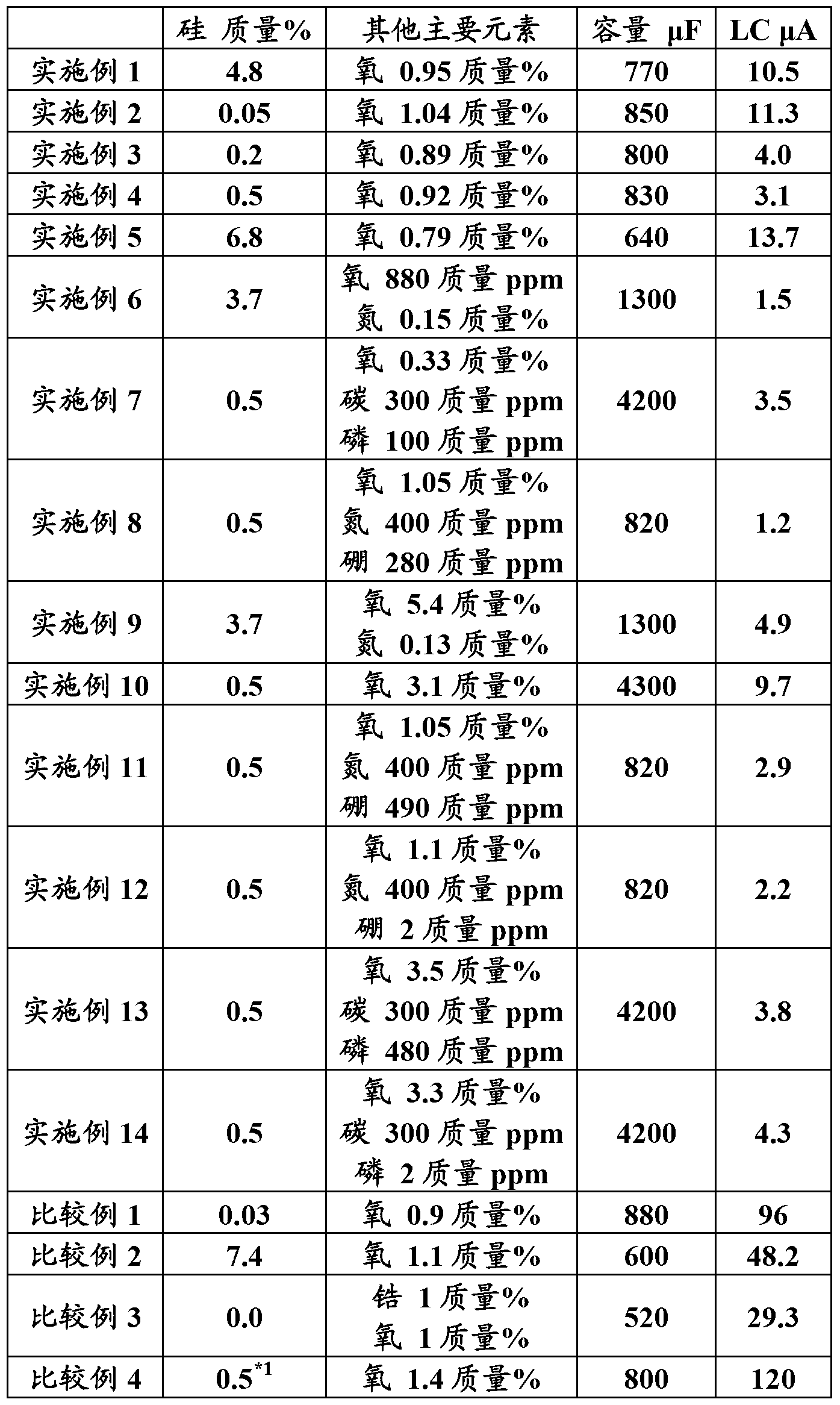

[0074] In Example 1, except having changed the compounding quantity of silicon, it carried out similarly to Example 1, and obtained the tungsten granulated powder. The average particle diameter and specific surface area of each example are the same as Example 1. The granulated powder obtained in each example had the contents of silicon and oxygen as shown in Table 1, and the other impurity elements were all 350 mass ppm or less.

Embodiment 6

[0076] Commercially available tungsten trioxide powder, pulverized pieces (tungsten silicide balls with a diameter of 1 mm) and water, which are 25 times the mass of the tungsten trioxide powder, are put into the Mitsui Mining Co. (Attritor), crushed at 700°C for 5 hours under hydrogen flow.

[0077] After removing the crushed pieces, the water was evaporated to obtain an average particle size of 0.3 μm and a specific surface area of 2.3 m 2 / g primary powder of tungsten. Next, add 3.7% by mass of commercially available silicon powder (average particle size is 1 μm) and mix well, put it into a high-temperature furnace under reduced pressure, and heat it at 7×10 -4 Under Pa, it was left at 1360° C. for 20 minutes. In the middle of the temperature drop to 1000° C., nitrogen gas was added to the furnace so that the temperature was 10 KPa, and it was maintained for 10 minutes. Finally, at room temperature and normal pressure, a mixed gas of 5% by volume of oxygen and 95% by v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com