Tungsten telluride-tungsten boride heterojunction electrocatalyst and preparation method and application thereof

An electrocatalyst, tungsten boride technology, applied in the field of electrocatalytic materials, can solve the problems of limited commercial application, low stability, low reserves, etc., and achieve the effects of optimizing local electronic structure, highly stable hydrogen evolution performance, and low preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

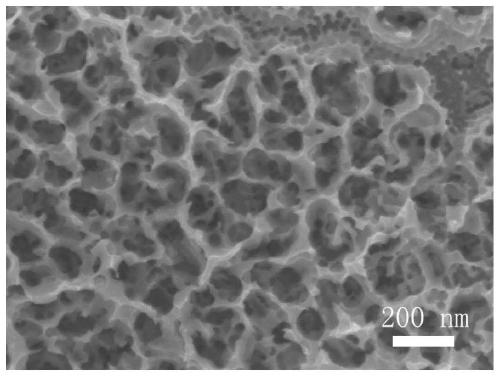

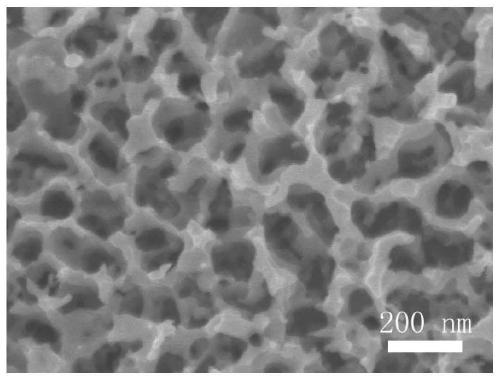

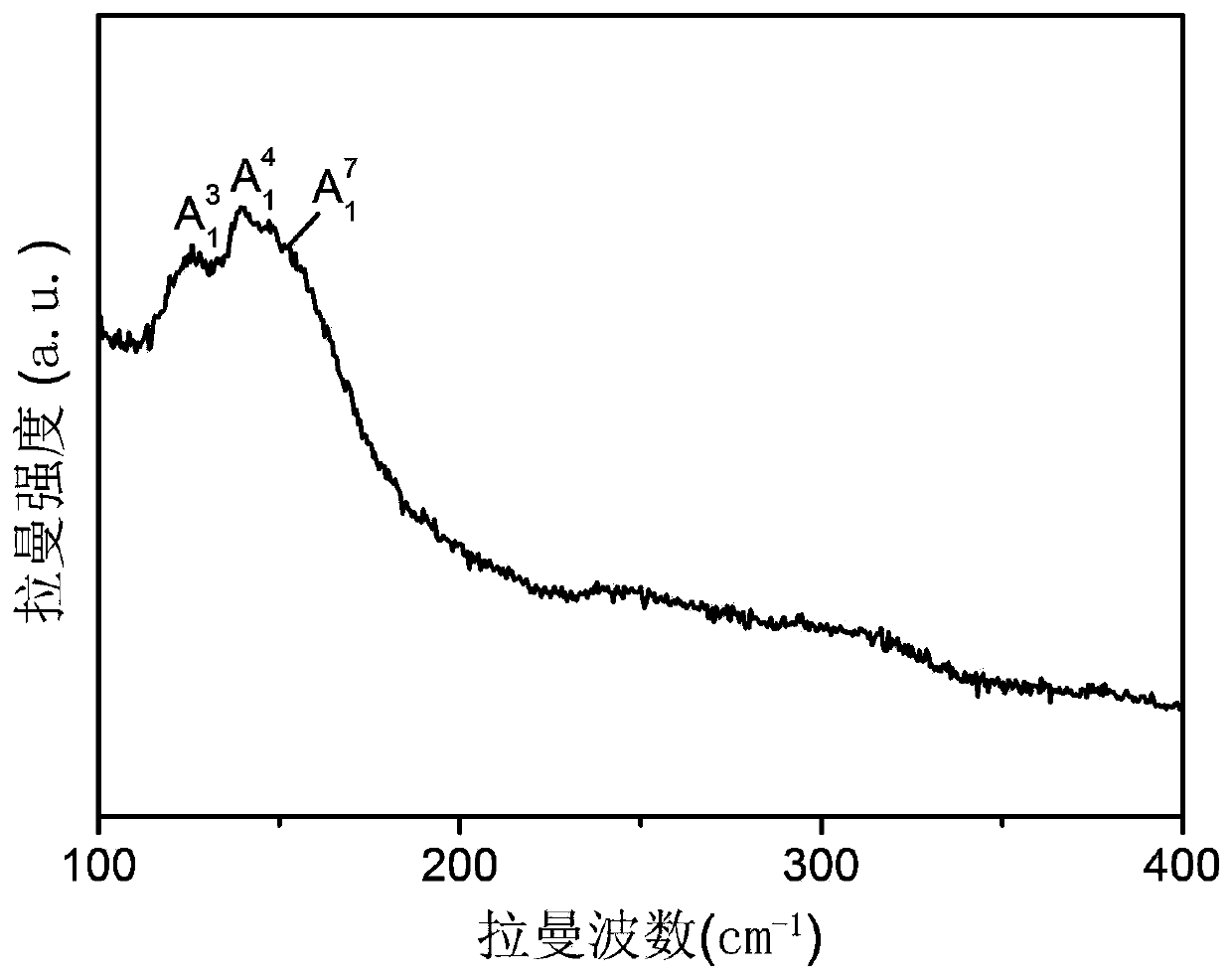

[0041]A tungsten telluride-tungsten boride heterojunction electrocatalyst in this embodiment, the catalyst uses anodized tungsten foil as a template and a tungsten source, respectively uses tellurium powder as a tellurium source, boron-oxygen mixture powder As a solid boron source, a two-phase heterojunction nanoporous film of tungsten telluride and tungsten boride is prepared by two-step chemical vapor deposition successively. The nanoporous film has the characteristics of loose and porous materials. The boron-oxygen mixture powder is a mixture powder composed of amorphous boron powder and diboron trioxide powder according to a material ratio of 1:1.

[0042] The preparation method of the tungsten telluride-tungsten boride heterojunction electrocatalyst is as follows:

[0043] (1) The metal tungsten foil with a surface area of 1 square centimeter was ultrasonically cleaned with acetone, absolute ethanol and deionized water for 30 minutes to remove surface organic matter and...

Embodiment 2

[0048] A tungsten telluride-tungsten boride heterojunction electrocatalyst in this embodiment, the catalyst uses anodized tungsten foil as a template and a tungsten source, respectively uses tellurium powder as a tellurium source, boron-oxygen mixture powder As a solid boron source, a two-phase heterojunction nanoporous film of tungsten telluride and tungsten boride is prepared by two-step chemical vapor deposition successively. The nanoporous film has the characteristics of loose and porous materials. The boron-oxygen mixture powder is a mixture powder composed of amorphous boron powder and diboron trioxide powder according to a material ratio of 1:1.

[0049] The preparation method of the tungsten telluride-tungsten boride heterojunction electrocatalyst is as follows:

[0050] (1) The metal tungsten foil with a surface area of 1 square centimeter was ultrasonically cleaned with acetone, absolute ethanol and deionized water for 45 minutes to remove surface organic matter an...

Embodiment 3

[0055] A tungsten telluride-tungsten boride heterojunction electrocatalyst in this embodiment, the catalyst uses anodized tungsten foil as a template and a tungsten source, respectively uses tellurium powder as a tellurium source, boron-oxygen mixture powder As a solid boron source, a two-phase heterojunction nanoporous film of tungsten telluride and tungsten boride is prepared by two-step chemical vapor deposition successively. The nanoporous film has the characteristics of loose and porous materials. The boron-oxygen mixture powder is a mixture powder composed of amorphous boron powder and diboron trioxide powder according to a material ratio of 1:1.

[0056] The preparation method of the tungsten telluride-tungsten boride heterojunction electrocatalyst is as follows:

[0057] (1) The metal tungsten foil with a surface area of 1 square centimeter was ultrasonically cleaned with acetone, absolute ethanol and deionized water for 30 minutes to remove surface organic matter an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com