Graphene modified oxygen-resistant polyethylene master batch and preparation method and application thereof

A technology of graphene modification and polyethylene, which is applied in the field of pipes, can solve the problems of reduced barrier performance, loss of oxygen barrier ability, reduction of pipe flexibility and impact resistance, etc., and achieves improved dimensional stability, enhanced heat resistance, The effect of enhanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

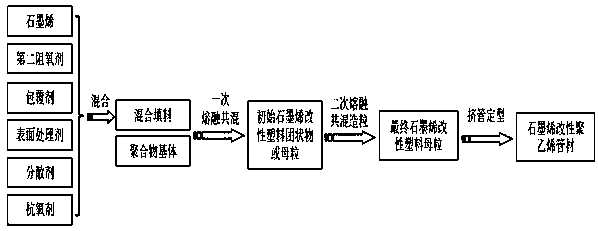

Method used

Image

Examples

Embodiment 1

[0080] The preparation method of the graphene-modified oxygen-barrier polyethylene masterbatch and the application of the graphene-modified oxygen-barrier polyethylene masterbatch as a pipe include the following steps:

[0081] S11. Add 20 parts of graphene prepared by mechanical exfoliation, 5 parts of montmorillonite, 10 parts of SEBS, 0.3 part of silane coupling agent KH550, 5 parts of EBS, and 0.5 part of phosphorus antioxidant into a high-speed mixer, Mix at ℃ for 20min and rotate at 500rpm to obtain a pre-dispersed and coated mixed filler;

[0082] S12. Add the mixed filler obtained in S11 and 59.2 parts of PE-RT resin granules into a rotary internal mixer, and knead at 200° C. for 20 minutes to obtain an initial graphene-modified polyethylene mass;

[0083] S13. The initial graphene-modified polyethylene mass obtained in S12 is granulated through a twin-screw extruder, and the extrusion temperature is 210° C. to obtain the final graphene-modified polyethylene masterbatc...

Embodiment 2

[0086] The preparation method of the graphene-modified oxygen-barrier polyethylene masterbatch and the application of the graphene-modified oxygen-barrier polyethylene masterbatch as a pipe include the following steps:

[0087]S21. 40 parts of graphene prepared by mechanical exfoliation, 10 parts of montmorillonite, 20 parts of SEBS, 1 part of silane coupling agent KH550, 10 parts of EBS, 0.3 part of phosphorus antioxidant are added in the high-speed mixer, and the Mix at ℃ for 20min and rotate at 500rpm to obtain a pre-dispersed and coated mixed filler;

[0088] S22. The mixed filler obtained in S21 and 18.7 parts of PE-RT resin particles were added to an overturning internal mixer, and mixed for 20 minutes at 200° C. to obtain an initial graphene-modified polyethylene mass;

[0089] S23. The initial graphene-modified polyethylene mass obtained in S22 is granulated through a twin-screw extruder at an extrusion temperature of 210° C. to obtain the final graphene-modified polye...

Embodiment 3

[0092] The preparation method of the graphene-modified oxygen-barrier polyethylene masterbatch and the application of the graphene-modified oxygen-barrier polyethylene masterbatch as a pipe include the following steps:

[0093] S31. 10 parts of graphene prepared by mechanical exfoliation, 5 parts of montmorillonite, 5 parts of SEBS, 0.1 part of silane coupling agent KH550, 0.5 part of EBS, 0.1 part of phosphorus antioxidant are added in the high-speed mixer, and the Mix at ℃ for 20min and rotate at 500rpm to obtain a pre-dispersed and coated mixed filler;

[0094] S32. Add the mixed filler obtained in S31 and 79.3 parts of PE-RT resin granules into the rotary internal mixer, and knead at 200° C. for 20 minutes to obtain the initial graphene-modified polyethylene mass;

[0095] S33. Pelletizing the initial graphene-modified polyethylene mass obtained in S32 through a twin-screw extruder at an extrusion temperature of 210° C. to obtain the final graphene-modified polyethylene ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com