Environmental-protection bio-based semi-aromatic PA10T/11 copolymerization material and preparation method thereof

A semi-aromatic, bio-based technology, applied in the field of environmentally friendly bio-based semi-aromatic PA10T/11 copolymer materials and its preparation, can solve the problems of low water absorption, narrow processing window, poor toughness, etc., and achieve low water absorption, polymerization The effect of short cycle time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

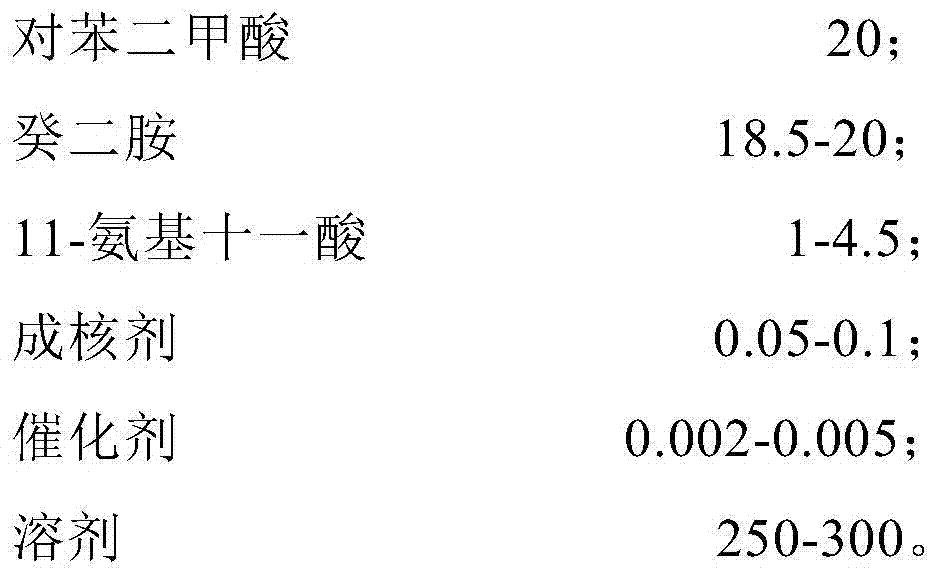

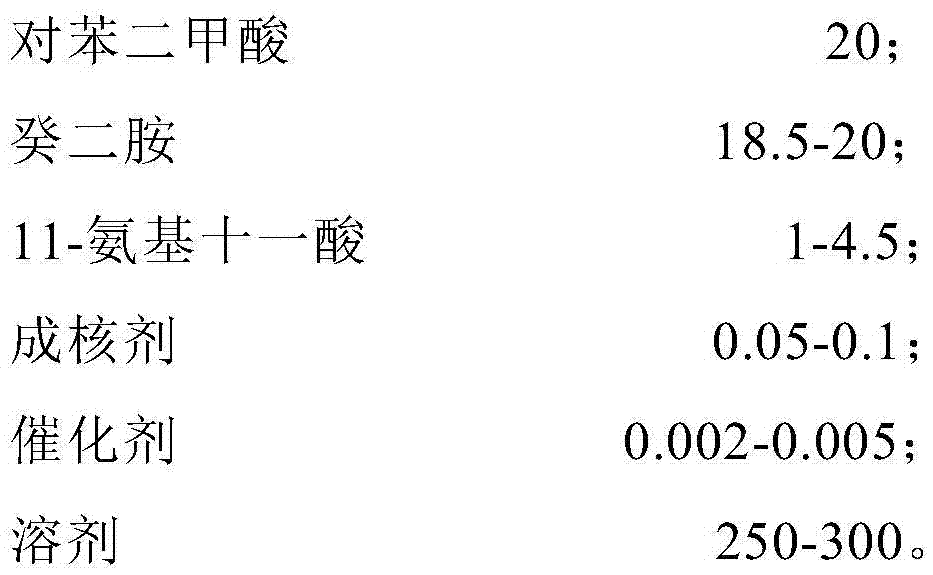

Method used

Image

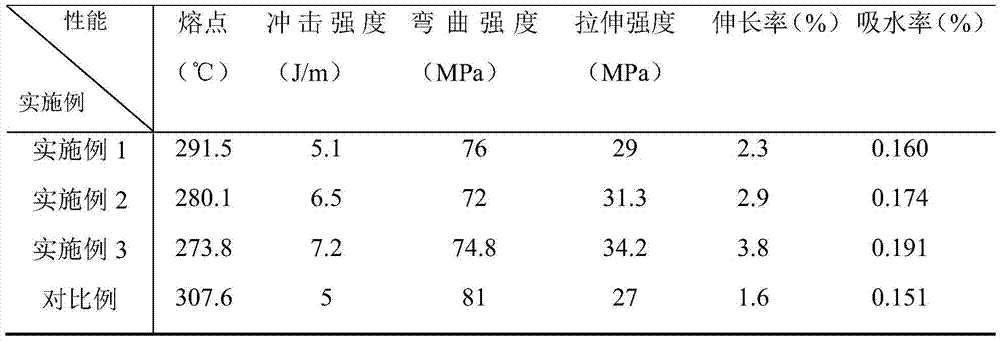

Examples

Embodiment 1

[0037] Take 20 mol of terephthalic acid, 20 mol of decanediamine, 0.05 mol of barium sulfate as a nucleating agent, and 0.002 mol of catalyst sodium hypophosphite and mix them evenly, then add them into a high-pressure polymerization reactor equipped with a high-efficiency stirring device, and weigh Take 250 mol of solvent deionized water in the reaction kettle, seal the high-pressure polymerization reaction kettle, start stirring and raise the temperature to 90°C, and then stir at this temperature for 2 hours to make the two fully salt.

[0038] Open the reactor again, add 1mol of 11-aminoundecanoic acid into it, seal the high-pressure polymerization reactor, use high-purity inert gas to replace the air in the reactor for 3 times, and finally reserve 0.05MPa inert gas as a protective gas .

[0039] Turn on the stirring, control the heating rate, and raise the temperature to 290°C at a constant speed in 2 hours, and when the pressure in the kettle is 3.5MPa, the reaction kettl...

Embodiment 2

[0042] Take 20mol of terephthalic acid, 19.2mol of decanediamine, 0.075mol of titanium dioxide as a nucleating agent, and 0.003mol of calcium hypophosphite as a catalyst and mix evenly, then add it to a high-pressure polymerization reactor equipped with a high-efficiency stirring device, and weigh Take 300 mol of solvent deionized water in the reaction kettle, seal the high-pressure polymerization reaction kettle, start stirring and raise the temperature to 105°C, and then stir at this temperature for 1.5h to make the two fully salt-formed.

[0043] Open the reactor again, add 3mol of 11-aminoundecanoic acid into it, seal the high-pressure polymerization reactor, use high-purity inert gas to replace the air in the reactor for 4 times, and finally reserve 0.15MPa inert gas as a protective gas .

[0044]Start stirring, control the heating rate, and use 1.75h to raise the temperature to 280°C at a constant speed, and when the pressure in the kettle is 3.0MPa, the reaction kettle ...

Embodiment 3

[0047] Take 20 mol of terephthalic acid, 18.5 mol of decane diamine, 0.1 mol of nucleating agent silicon dioxide, and 0.005 mol of catalyst potassium hypophosphite, mix them evenly, and then add them into a high-pressure polymerization reactor equipped with a high-efficiency stirring device , Weigh 300 mol of solvent deionized water in the reaction kettle, seal the high-pressure polymerization reaction kettle, start stirring and raise the temperature to 120°C, and then stir at this temperature for 1 hour to make the two fully salt.

[0048] Open the reactor again, add 4.5mol of 11-aminoundecanoic acid into it, seal the high-pressure polymerization reactor, use high-purity inert gas to replace the air in the reactor for 5 times, and finally reserve 0.25MPa inert gas as a protection gas.

[0049] Start stirring, control the heating rate, and use 1.5 hours to raise the temperature to 270°C at a constant speed, and when the pressure in the kettle is 2.5MPa, the reaction kettle is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com