Novel phthalonitrile resin and preparation method thereof

A technology of phthalonitrile resin and phthalonitrile, which is applied in the field of thermosetting phthalonitrile resin and its preparation, can solve the problems of reducing the heat resistance and mechanical properties of the resin, so as to improve solubility and increase confusion degree, the effect of lowering the melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

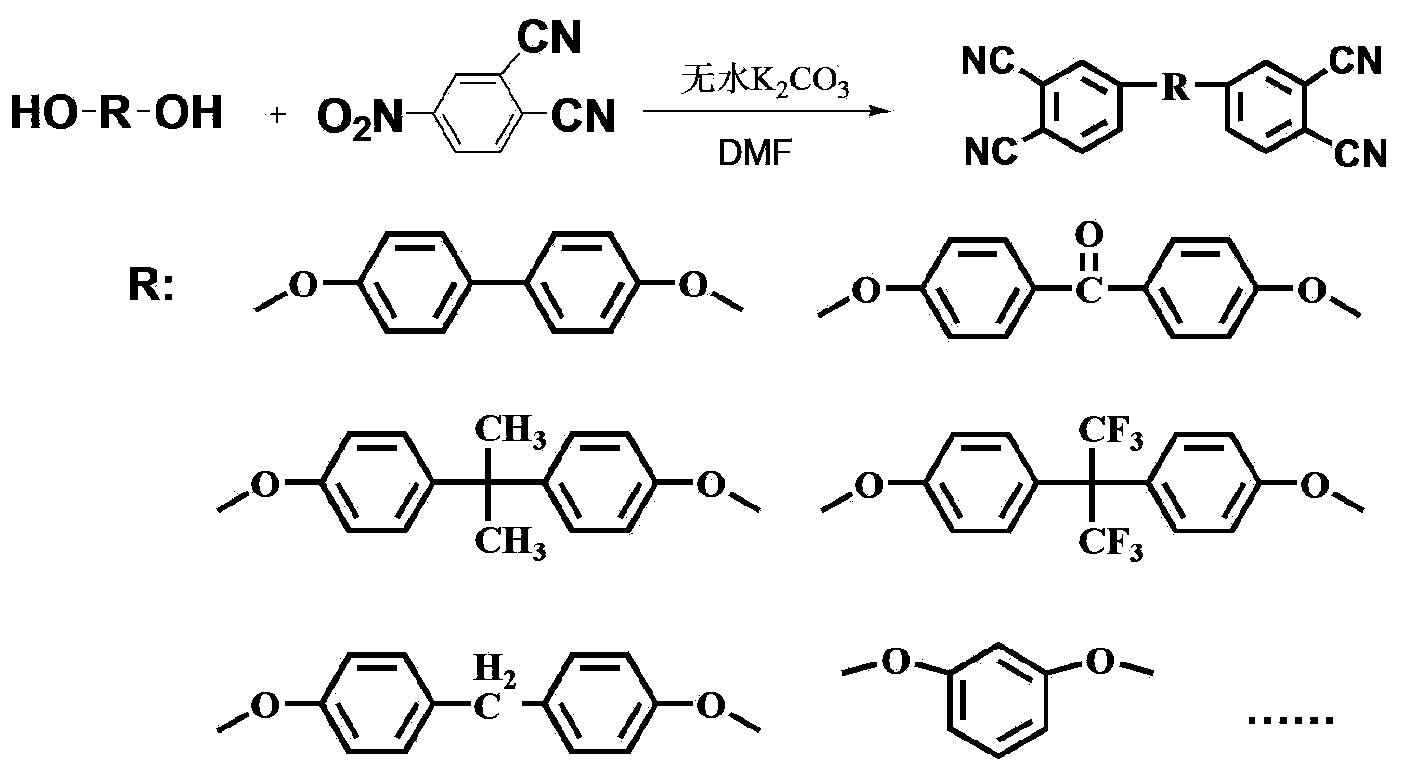

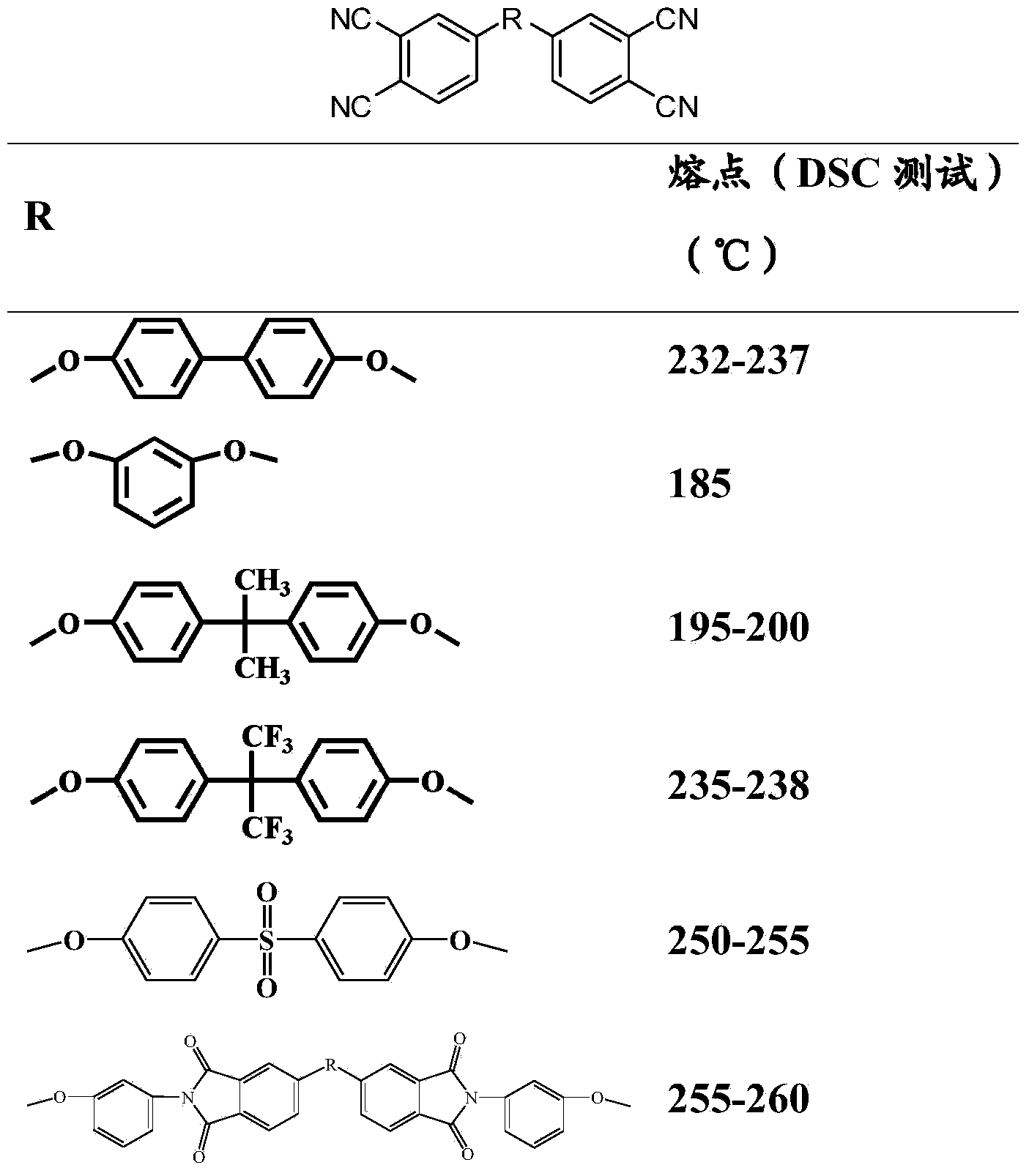

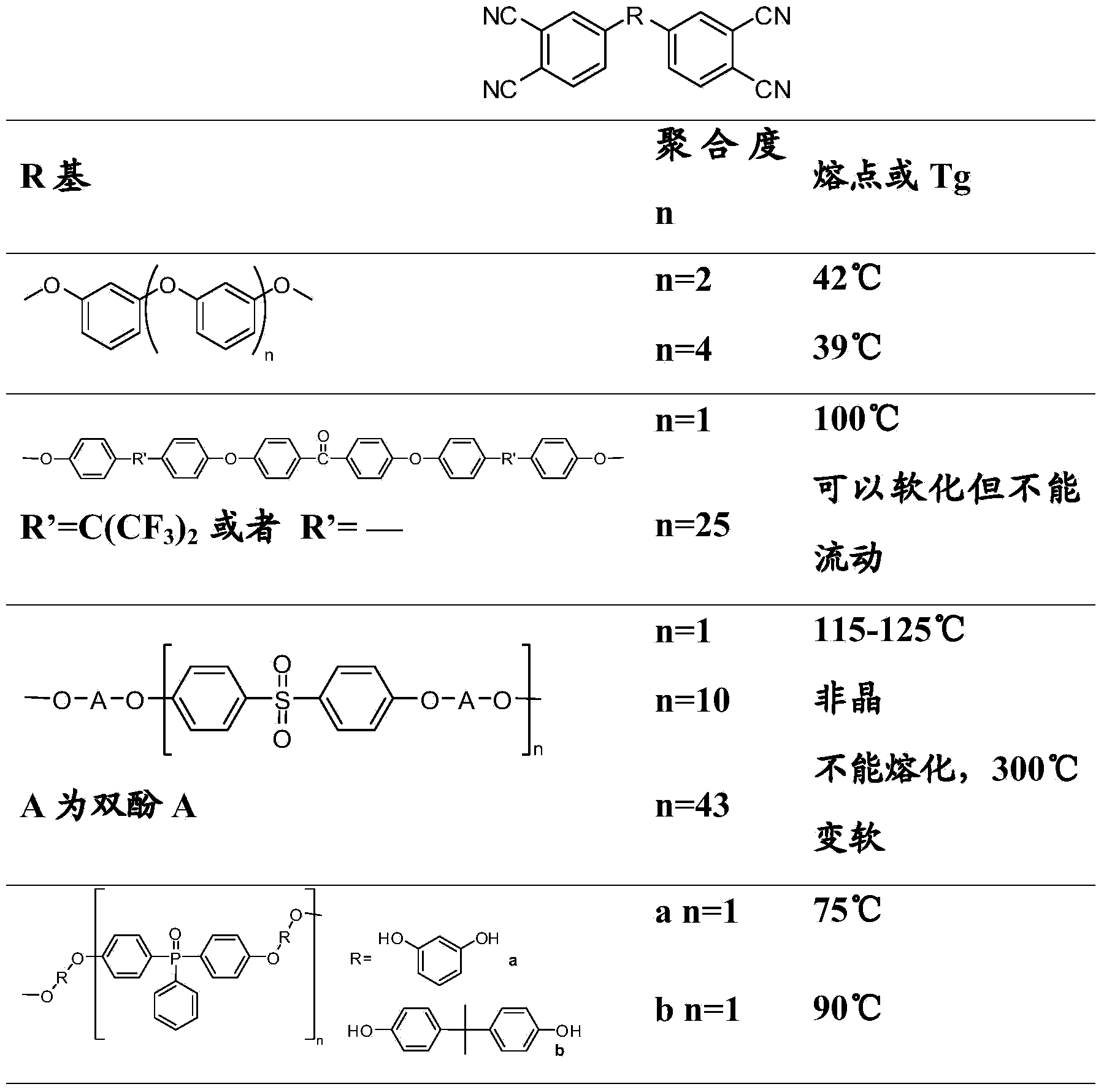

Method used

Image

Examples

Embodiment 1

[0081] Under nitrogen protection at room temperature, 0.2 mol of 4,4'-biphenol was dissolved in 2.34 mol of N,N-dimethylformamide (DMF), and 0.3 mol of anhydrous potassium carbonate was added thereto, and the temperature was raised to 80 °C. 0.15mol of 4-nitrophthalonitrile and 0.25mol of 3-nitrophthalonitrile were dissolved in 4.68mol of DMF, and slowly added dropwise to the above solution. After the dropwise addition, the reaction was kept at 80° C. for 8 hours. After the reaction, the solution system was first lowered to room temperature, and then the solution was slowly precipitated in 5 times distilled water to obtain a brownish-yellow precipitate. The precipitate was repeatedly washed with distilled water until the filtrate was clear and the pH value was neutral, and dried in a vacuum oven at 60°C for 8 hours, a brown-yellow powder product was obtained, the product structure was shown in the following formula, and the yield was 85%.

[0082] The softening point of the re...

Embodiment 2

[0086] Under the protection of nitrogen at room temperature, 0.2mol bisphenol A and 0.1mol4,4'-difluorobenzophenone were dissolved in 7.2mol N-methylpyrrolidone (NMP), and 0.4mol anhydrous potassium carbonate was added to it, and the temperature was raised to 100 ℃, stirred and reacted for 1 hour, then filled the water separator with toluene, added 20 ml of toluene to the reaction system, heated to 170-175 ℃ and refluxed for 14 hours, and removed the water generated by the reaction. The reaction solution was cooled to 60°C, 0.05mol of 4-nitrophthalonitrile and 0.05mol of 3-nitrophthalonitrile were dissolved in 2.34mol of NMP, and slowly added dropwise to the above solution. The reaction was kept at 60°C for 6 hours. After the reaction is completed, the solution system is first lowered to room temperature, and then the solution is slowly precipitated in a 5-fold dilute hydrochloric acid distilled aqueous solution to obtain a brown precipitate, and the precipitate is repeatedly ...

Embodiment 3

[0089] Under the protection of argon at room temperature, 0.3mol of hydroquinone and 0.2mol of isophthalic dibromide were dissolved in 10.8mol of N,N-dimethylformamide (DMF), and 0.0064mol of 1,10-o-dinitrogen was added to it. Miscellaneous phenanthrene, 0.0035mol cuprous iodide and 0.7mol anhydrous potassium carbonate, then fill the water separator with toluene, add 20ml toluene to the reaction system, heat up to 140-145°C for reflux reaction for 16 hours, no more water generate. The reaction solution was cooled to 80°C, 0.025mol of 4-nitrophthalonitrile and 0.075mol of 3-nitrophthalonitrile were dissolved in 2.34mol of DMF, and slowly added dropwise to the above solution. The reaction was kept at 80°C for 8 hours. After the reaction is completed, the solution system is first lowered to room temperature, and then the solution is slowly precipitated in a 6-fold dilute hydrochloric acid ice-water solution to obtain a brown precipitate, which is repeatedly washed with ice-water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com