Biodegradable film based on irradiation modification and preparing method thereof

A technology for degrading films and film products, which is applied in the field of radiation-modified biodegradable films and their preparation, can solve the problems of long-term performance, weak anti-aging ability, and easy-to-crack performance, so as to relieve environmental pressure, Increased melt viscosity and reduced cracking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

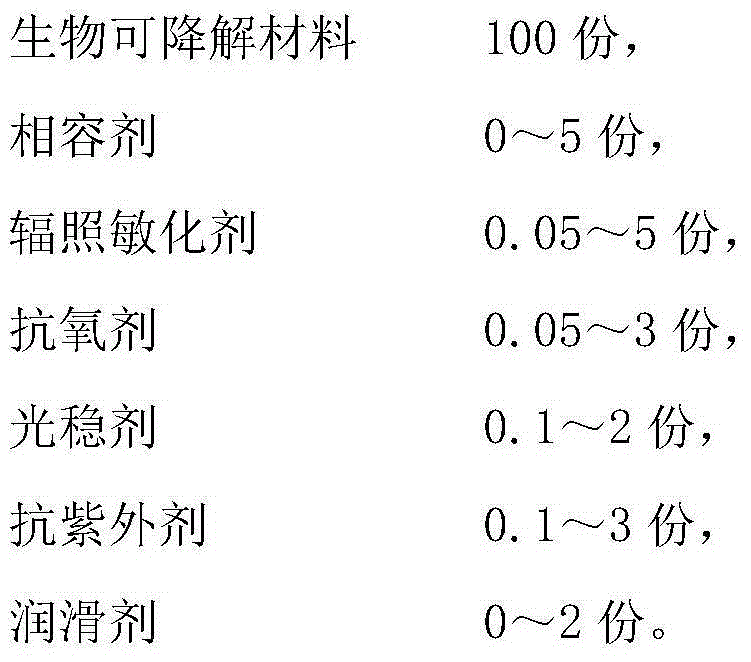

Method used

Image

Examples

Embodiment 1

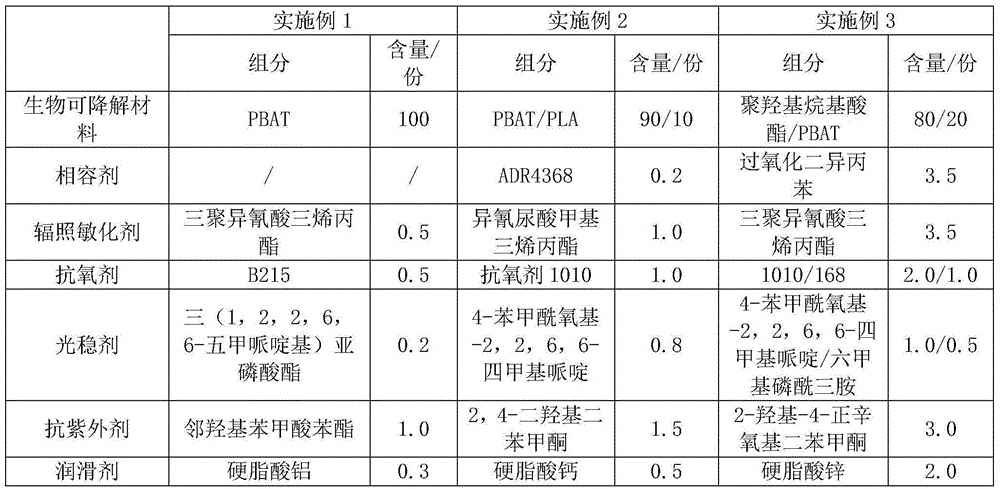

[0041] Embodiment 1 provides a biodegradable film based on irradiation modification and a preparation method thereof, the components and contents of the biodegradable film are shown in Table 1 below; the preparation method specifically includes:

[0042] Raw material pretreatment: take the biodegradable material that has been vacuum-dried at 30°C for 10 hours, mix it according to the ratio of Example 1 in Table 1, stir at 600r / min at room temperature, and stir at high speed for 3 minutes;

[0043] Extrusion granulation: twin-screw extruder melt blending, extrusion granulation, extrusion temperature is 100-135 °C, die temperature of screw extruder is 120-200 °C, screw length-to-diameter ratio is 40:1 , speed 250r / min;

[0044] Processing and molding: vacuum drying at 30°C for 12 hours, blow molding at 110-130°C;

[0045] Irradiation treatment: The film was irradiated with 220kGy electron beams to prepare a biodegradable film (sample number 1).

Embodiment 2

[0047] This embodiment provides a biodegradable film based on irradiation modification and its preparation method. The components and contents of the biodegradable film are shown in Table 1 below; the preparation method specifically includes:

[0048] Raw material pretreatment: Take the biodegradable material that has been vacuum-dried at 80°C for 2 hours, mix it according to the ratio of Example 2 in Table 1, and stir at 800r / min at a high speed for 3 minutes at room temperature;

[0049] Extrusion granulation: twin-screw extruder melt blending, extrusion granulation, extrusion temperature is 110-180 °C, die temperature of screw extruder is 120-200 °C, screw length-to-diameter ratio is 40:1 , speed 150r / min;

[0050] Processing and molding: vacuum drying at 80°C for 4 hours, blow molding at 135-170°C;

[0051] Irradiation treatment: The film was irradiated with 160kGy electron beams to prepare a biodegradable film (sample number 2).

Embodiment 3

[0053] This embodiment provides a biodegradable film based on irradiation modification and its preparation method; the components and contents of the biodegradable film are shown in Table 1 below; the preparation method specifically includes:

[0054] Raw material pretreatment: take the biodegradable material that has been vacuum-dried at 60°C for 6 hours, mix it according to the ratio of Example 3 in Table 1, and stir at a high speed of 1000r / min for 3 minutes at room temperature;

[0055] Extrusion granulation: twin-screw extruder melt blending, extrusion granulation, extrusion temperature is 110-190 ℃, die temperature of screw extruder is 120-200 ℃, screw length-to-diameter ratio is 40:1 , speed 150r / min;

[0056] Processing and molding: vacuum drying at 80°C for 10 hours, blowing and casting at 160-190°C to form a film;

[0057] Irradiation treatment: The film was irradiated with 60kGy electron beams to prepare a biodegradable film (sample number 3).

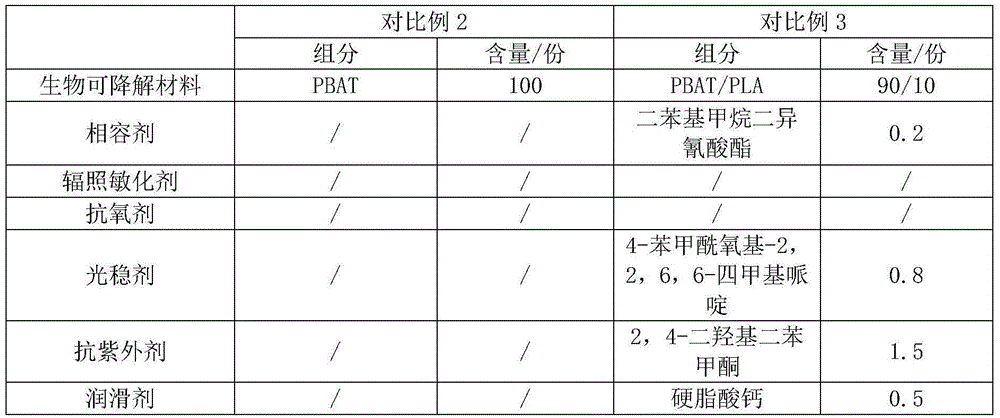

[0058] Table 1

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com