Viscous fluid and solvent mixing device and viscous fluid and solvent mixing method

A viscous fluid and mixing device technology, applied in mixing methods, fluid mixers, mixers, etc., can solve problems such as waste of energy consumption, complex structure of solution mixing devices, etc., and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

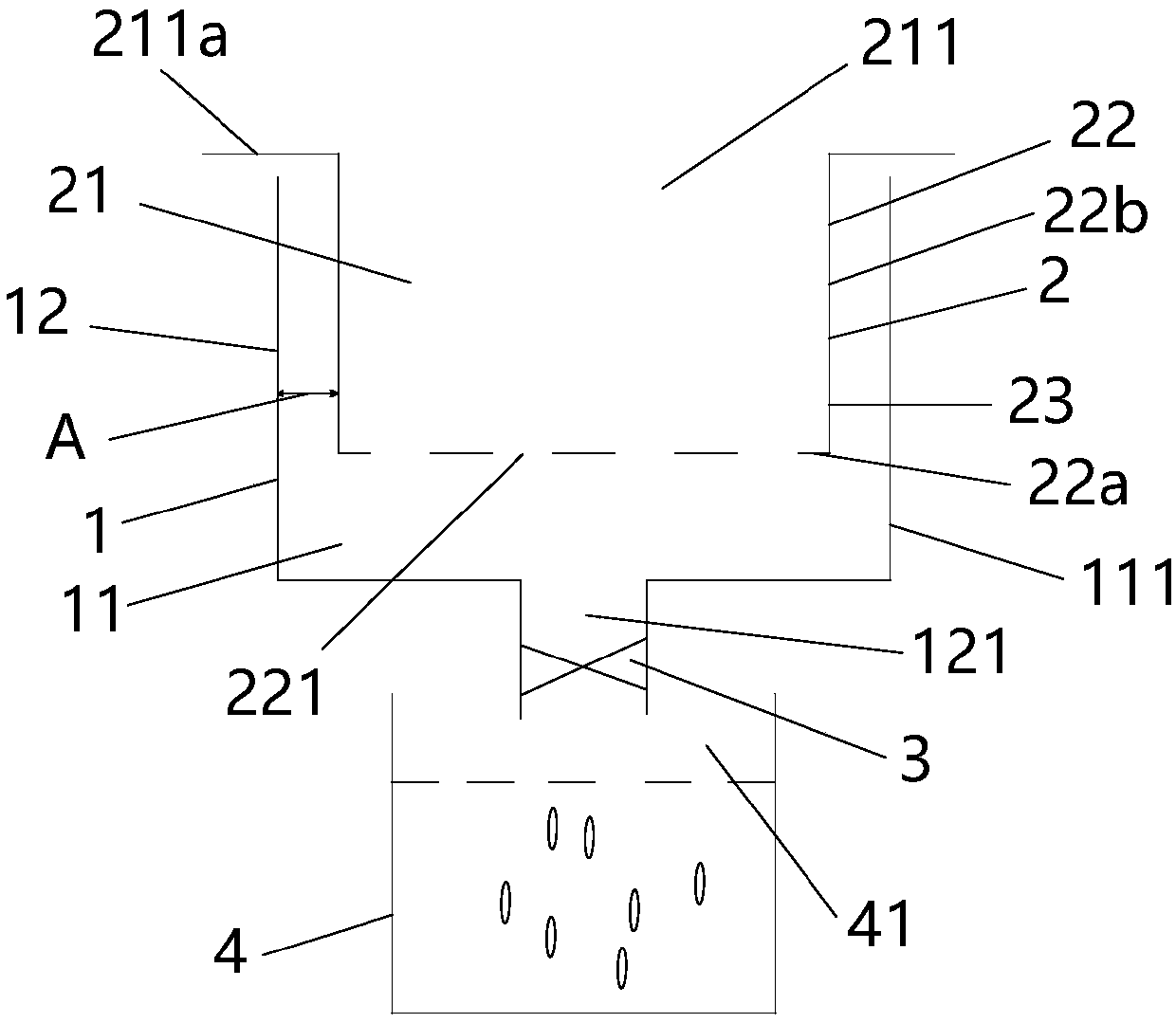

[0029] Such as figure 1 As shown, the figure schematically shows that the mixing device includes a holding container 1 and an inner filter container 2 .

[0030] In the embodiment of the present application, an accommodating cavity 11 is configured inside the container 1, and the accommodating cavity 11 is used to contain viscous fluid and solvent. The connected liquid outlet 121. That is to say, the arrangement of the liquid outlet 121 can facilitate discharging the mixed solution of the viscous fluid and the solvent into the receiving container 4 as described below.

[0031] The inner layer filter container 2 is arranged in the accommodation cavity 11, and a filter cavity 21 is constructed inside the inner layer filter container 2, wherein, a body 22 of the inner layer filter container 2 is configured to communicate with the filter cavity 21. The solution mixing through hole 221, the viscous fluid and the solvent enter the filter cavity 21 and penetrate into the containing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com