Radial impeller and fan assembly

A radial flow and impeller technology, applied in radial flow pumps, pump components, mechanical equipment, etc., to increase efficiency and promote noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] In the different figures of the drawings, identical parts or functionally identical parts are indicated by the same reference numerals and symbols. However, if specific features described and / or which can be deduced from the drawing or configuration of a radial impeller or fan unit according to the invention are mentioned only in relation to an embodiment, then the embodiment is according to the invention and not dependent on this embodiment. , these features are notable as individual features or also in combination with other features of the embodiment and may be claimed to belong to the present invention.

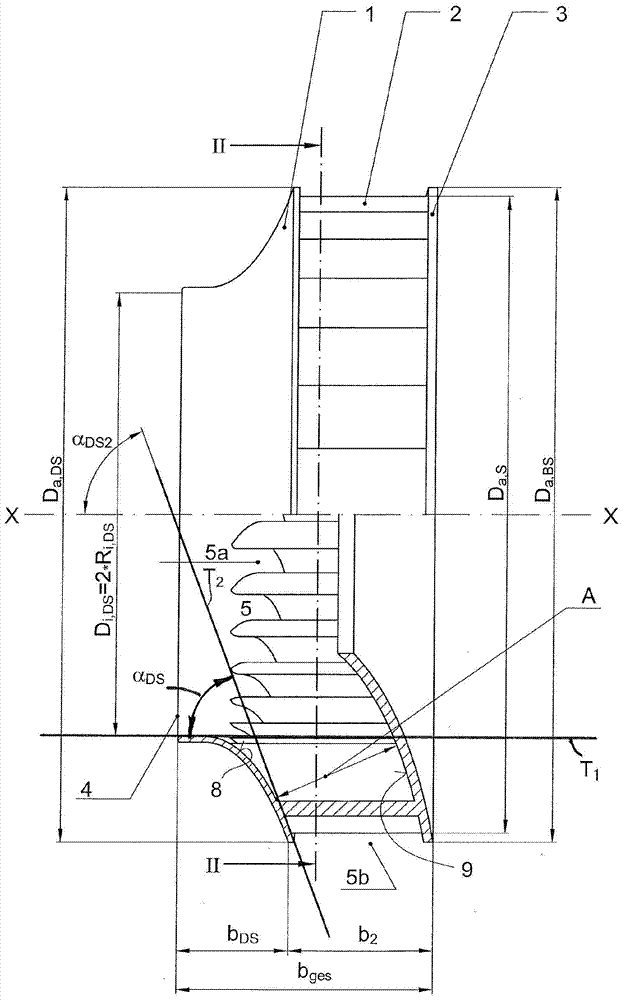

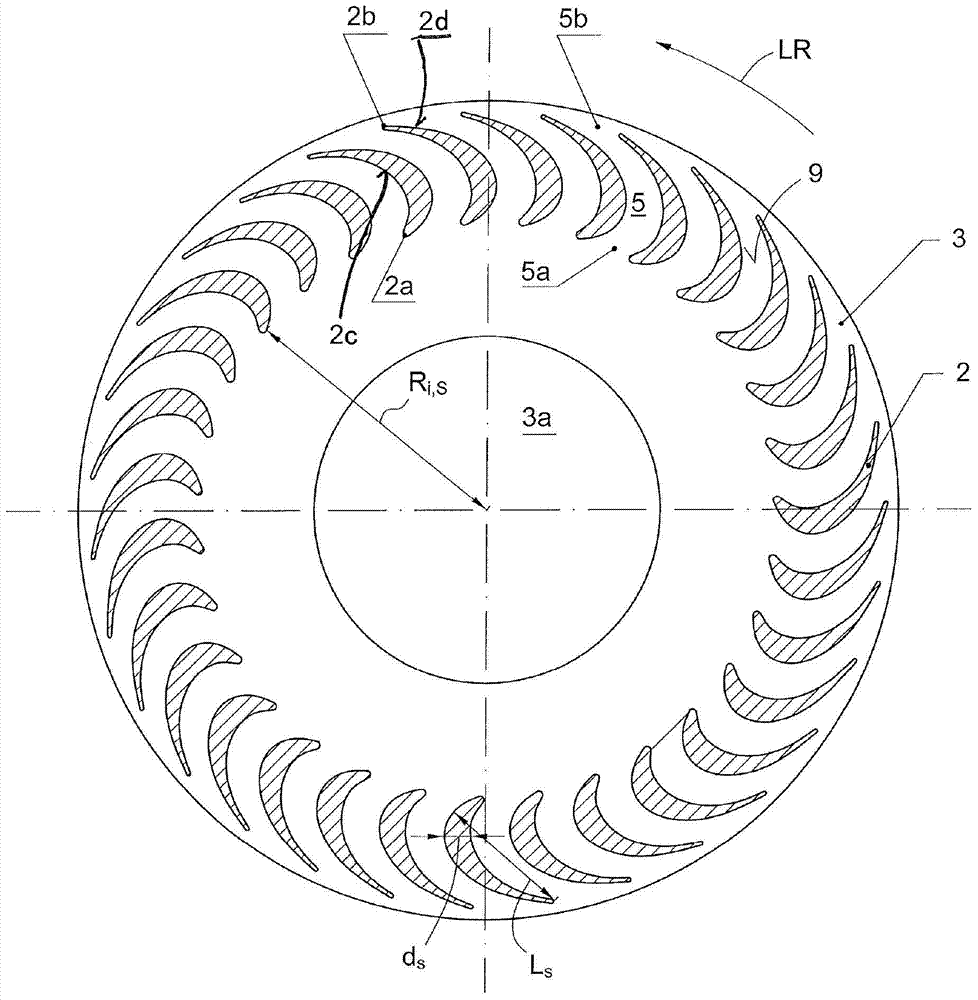

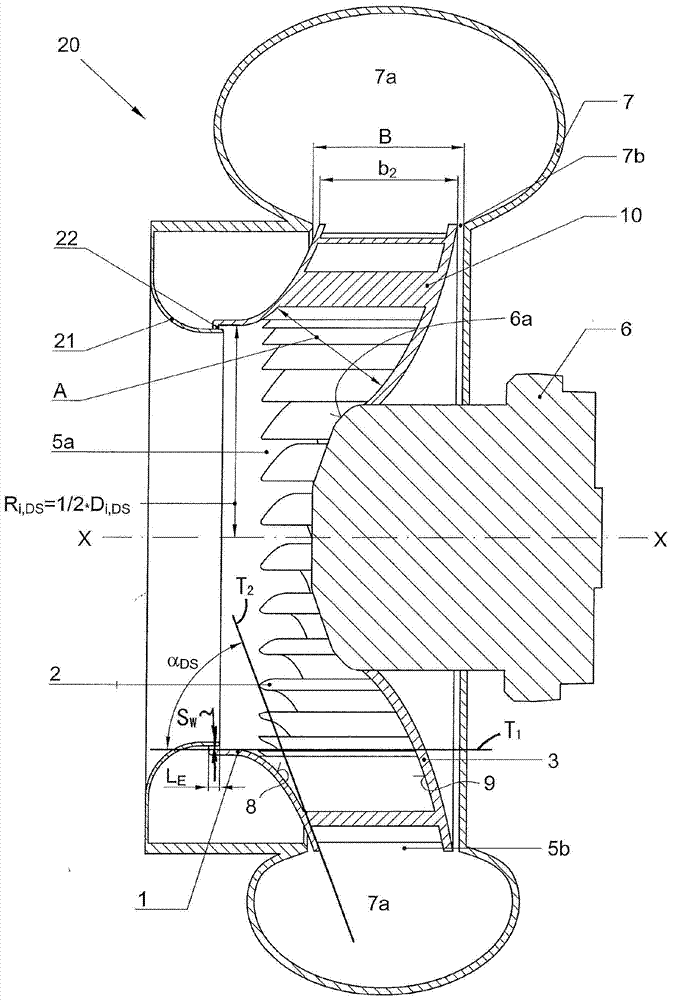

[0108] as first available from figure 1 and figure 2 As seen in , a radial impeller 10 according to the invention has a top disc 1 , a plurality of forward-curved profiled blades 2 and a bottom disc 3 . The top disc 1 forms a suction hole and thus has a circular suction opening 4 for the axial air inlet, the suction opening 4 having an inner diameter D i,DS . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com