Linear sorting machine based on local rotation and sorting method thereof

A sorter, linear technology, applied in sorting, conveyors, mechanical conveyors and other directions, can solve the problems of small amount of pieces, unable to apply automatic sorting, etc., to achieve high adaptability, shorten the capital chain and turnover cycle, The effect of reducing equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

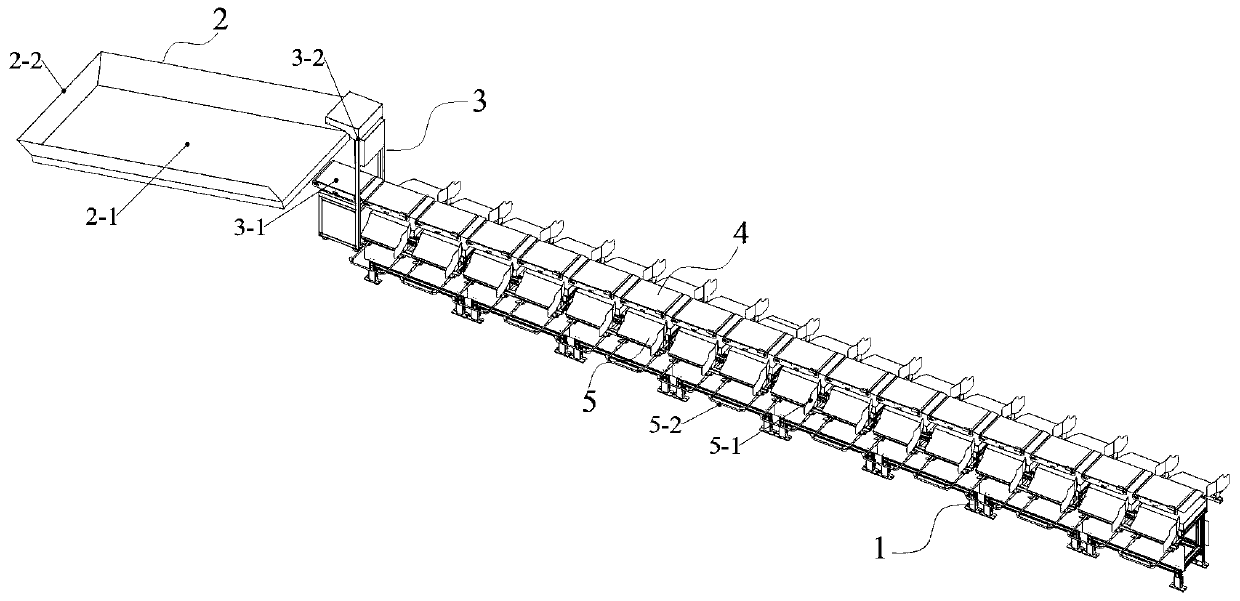

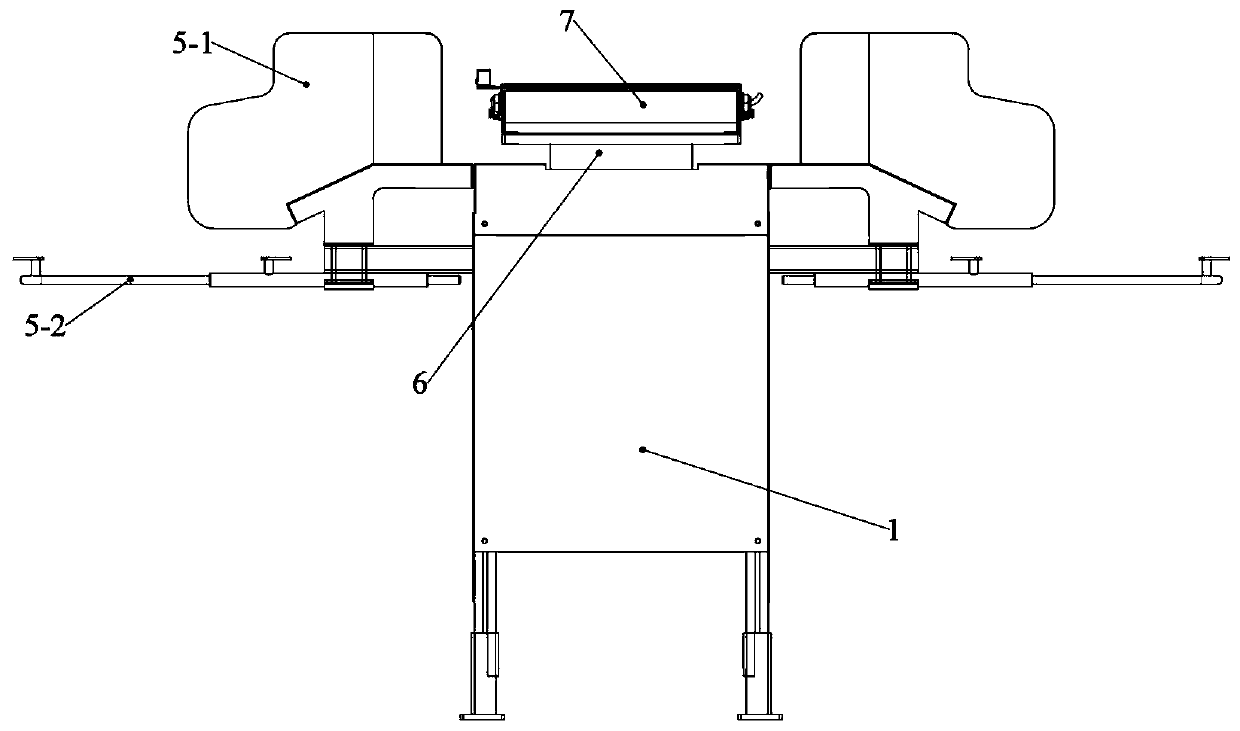

[0037] Such as figure 1 As shown, a linear sorting machine based on partial rotation includes a frame 1, a temporary storage and loading device 2, a weighing and scanning device 3, a conveying and sorting device 4, an unloading table 5 and a controller. The weighing and code scanning device 3 is arranged between the temporary storage and loading device 2 and the conveying and sorting device 4 . The conveying and sorting device 4 is installed on the frame 1, and includes n rotating sorting units arranged end to end in a long strip; n≥2.

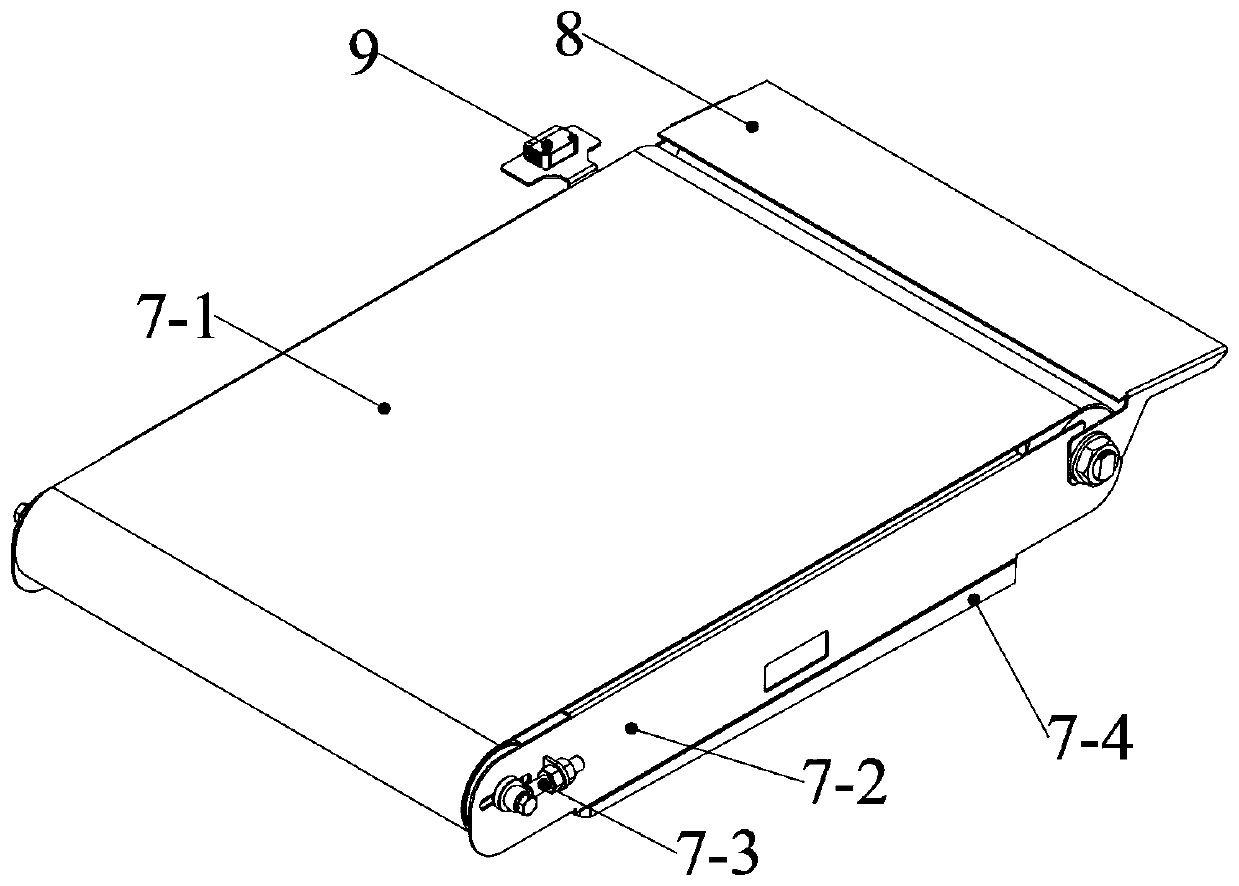

[0038] Such as figure 1 , 2 , 3 and 4, the rotary sorting unit includes a steering power element 6, a sorting conveyor 7, a guide plate 8 and a photoelectric sensor 9. The sorting conveyor 7 is installed on the top of the frame 1 for conveying and unloading of goods. The sorting conveyor 7 includes a conveyor belt 7-1, a roller and a conveyor frame 7-2. Two rollers are respectively installed on the two ends of the conveying support 7-2, a...

Embodiment 2

[0060] Such as Figure 5 As shown, a linear sorter based on partial rotation, the difference between this embodiment and embodiment 1 is:

[0061] (1) Between the length L and width W of the sorting conveyor and the distance B between two adjacent sorting conveyors 7, there is no need to satisfy the inequality

[0062] (2) The guide plate 8 is not provided in the rotary sorting unit; the bottom of the conveying support 7-2 does not need to be provided with a bottom plate with an inclined top surface; the conveying surface of the sorting conveyor 7 can be a horizontal plane or an inclined plane.

[0063] (3) The n rotating sorting units are arranged in a ladder shape from the head end to the end of the rack. The input end of the preceding rotary sorting unit is located above the output end of the subsequent rotary sorting unit. Since two adjacent rotary sorting units are staggered in height, the rotary sorting units will not interfere with each other during rotation around ...

Embodiment 3

[0065] A linear sorter based on partial rotation. The difference between this embodiment and Embodiment 1 is that: a guide plate 8 is set in the rotary sorting unit; the guide plate 8 is installed at the output end of the sorting conveyor 7; the guide plate 8 The inner edge of the guide plate is close to and lower than the output end of the corresponding sorting conveyor 7 conveying surface, and the outer edge is close to the conveying surface of the next rotary sorting unit; the angle between the guide plate 8 and the horizontal plane is 10° to 45°

[0066] In this embodiment, the goods transition between the two rotary sorting units through the guide plate 8 with a relatively large inclination; the goods can slide down smoothly along the guide plate 8 . Compared with embodiment 1, this embodiment can avoid the jamming of goods between the two rotating sorting units to the greatest extent; compared with embodiment 2, this embodiment can avoid damage to goods when they fall at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com