Bent windowpane

A glass sheet and bending technology, used in windshields, glass molding, glass manufacturing equipment, etc., can solve the problems of restricting the geometric shape of glass, the bending process cannot be combined arbitrarily, and it is difficult to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

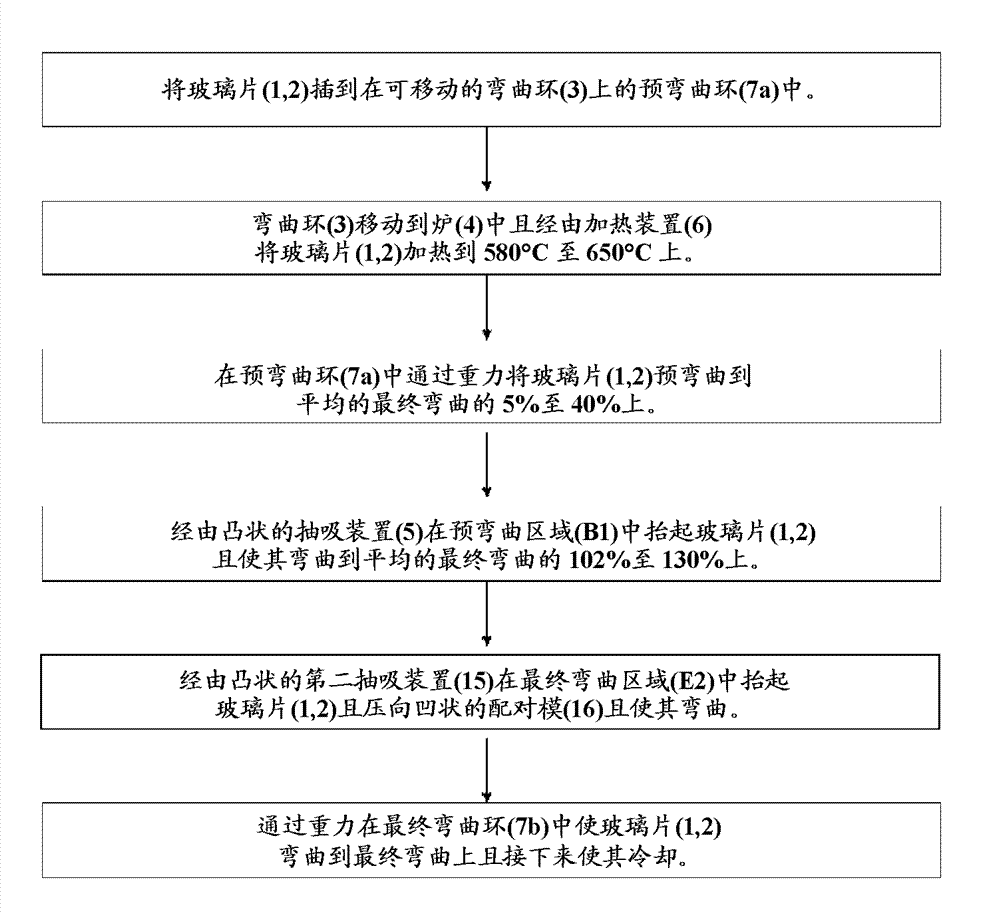

Method used

Image

Examples

Embodiment Construction

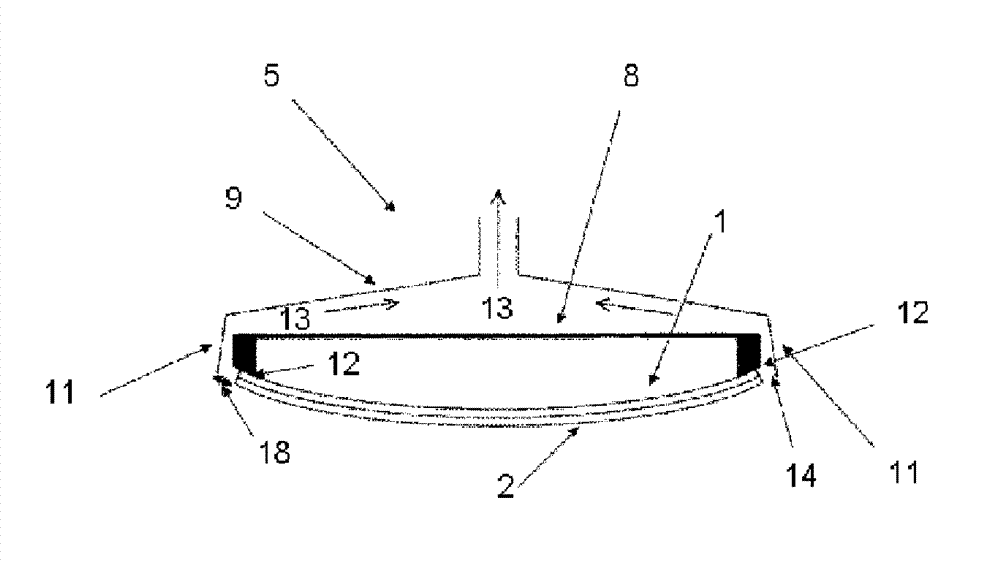

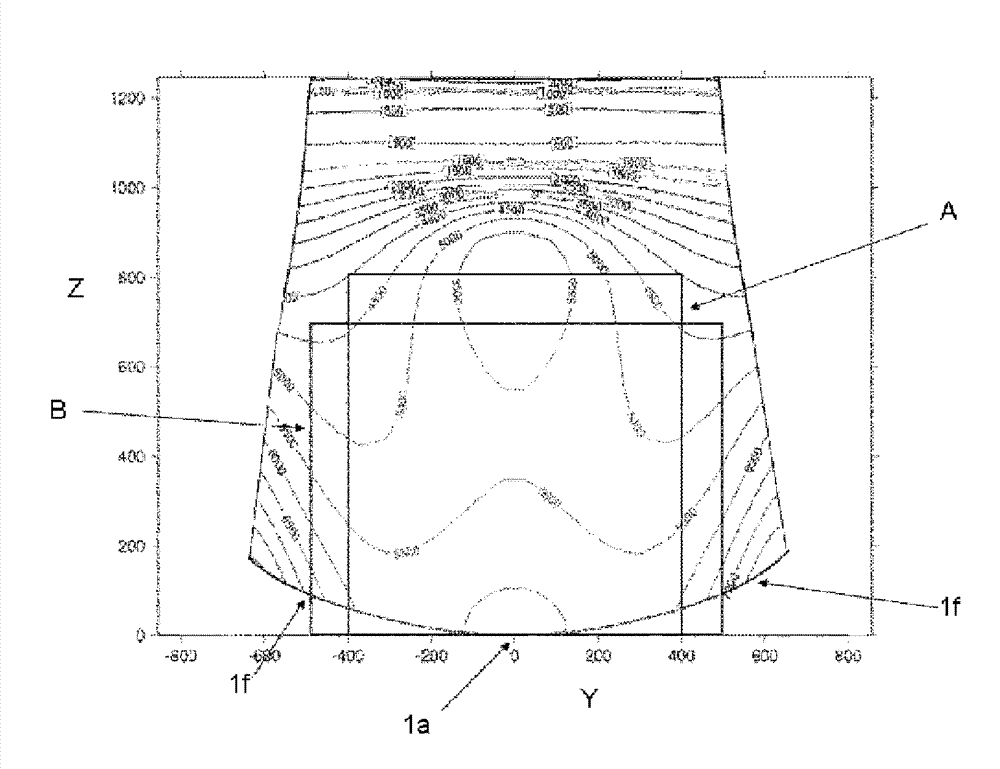

[0046] figure 1 A cross-section of a furnace according to the invention for producing glass sheets according to the invention is shown. The furnace comprises a heating device (6) and a corresponding bending ring support (3) with a pre-bending ring (7a) movable inside and outside the furnace via a transport device (10). In the preheating zone (A) the glass sheets (1, 2) are heated to the softening temperature of the respective glass. Adjacent to the preheating zone (A), a vertically height-adjustable, preferably convexly curved, first suction device ( 5 ) is coupled in the prebending zone (B). The suction device (5) makes it possible to pick up the glass sheets (1,2) from the bending ring (3), pre-bend the glass sheets (1,2) and place the pre-bent glass sheets (1,2) on the final bending It becomes possible on the ring (7b). The pre-bending ring ( 7 a ) and the final bending ring ( 7 b ) can be adjusted from the pre-bending ring ( 7 a ) into the final bending ring ( 7 b ), e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com