CMOS image sensor and its manufacture method

A pattern and device technology, applied in CMOS image sensors and their manufacturing, in the field of increasing the capacitance of the floating diffusion area, can solve the problems of easy noise generation and low capacitance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

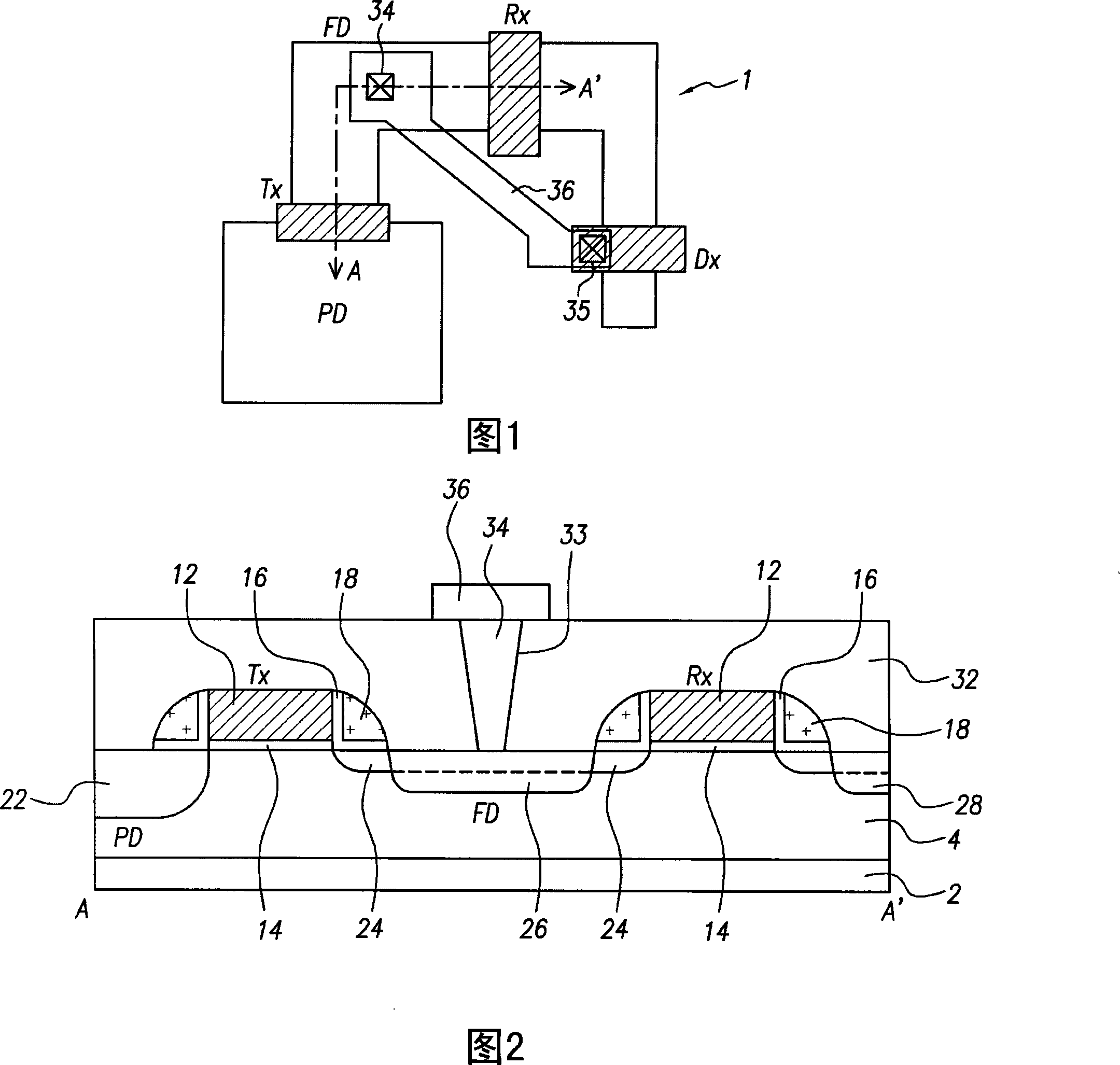

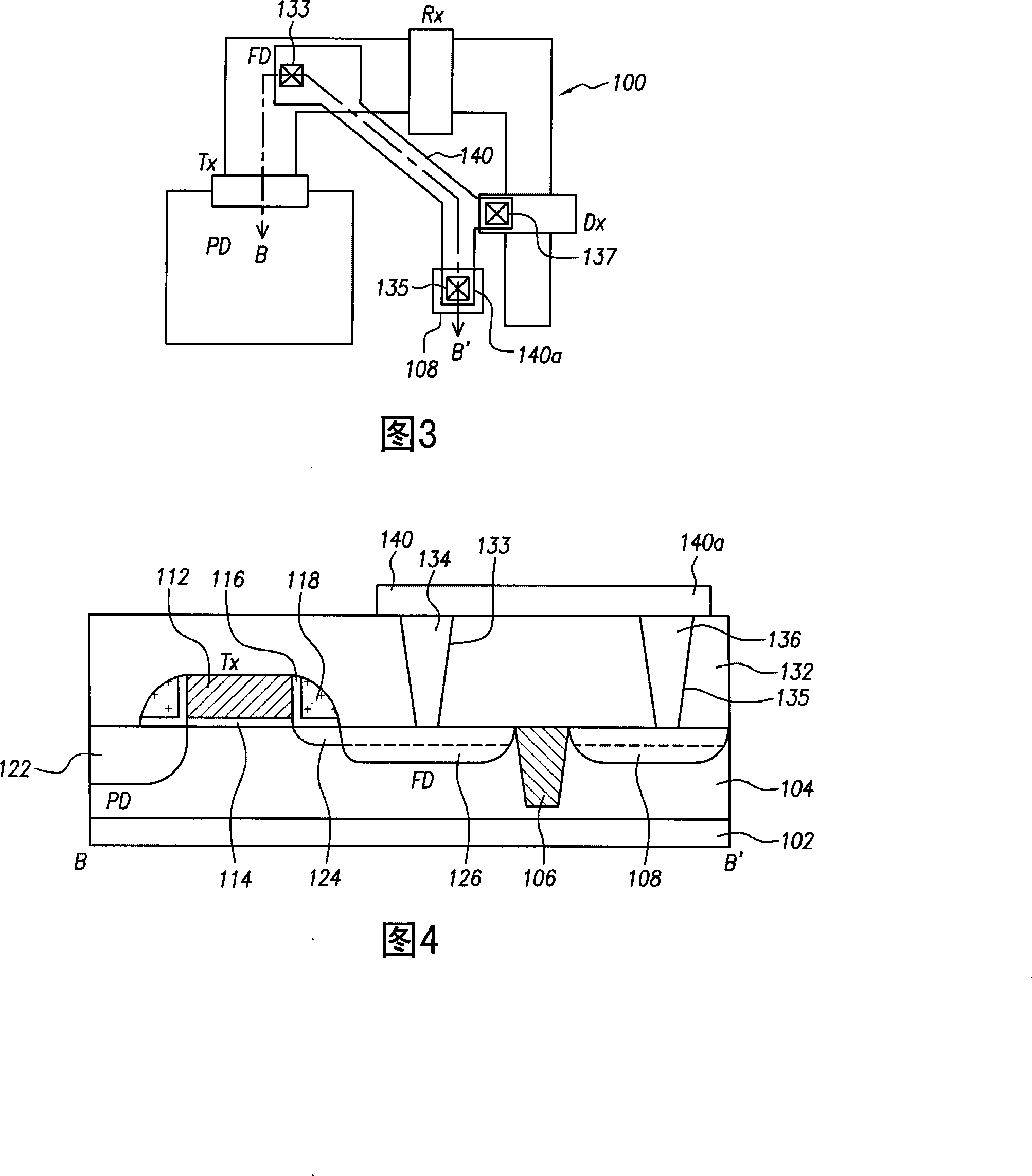

[0038] As shown in the example of FIG. 3, the CMOS image sensor according to the embodiment of the present invention may include a photodiode region PD formed in the widest part of the active region 100. An island-type active region (also referred to as an "island region") 108 may be formed adjacent to the photodiode region PD. The junction capacitance of the active region 108 may be formed to be parallel to the source region 126. The transfer transistor Tx, the reset transistor Rx, and the drive transistor Dx may overlap the active region 100 except for the photodiode region PD. In addition to being adjacent to the photodiode region PD, the island region 108 may also be formed in other positions. In addition, the island area 108 may also include at least one or more island areas 108.

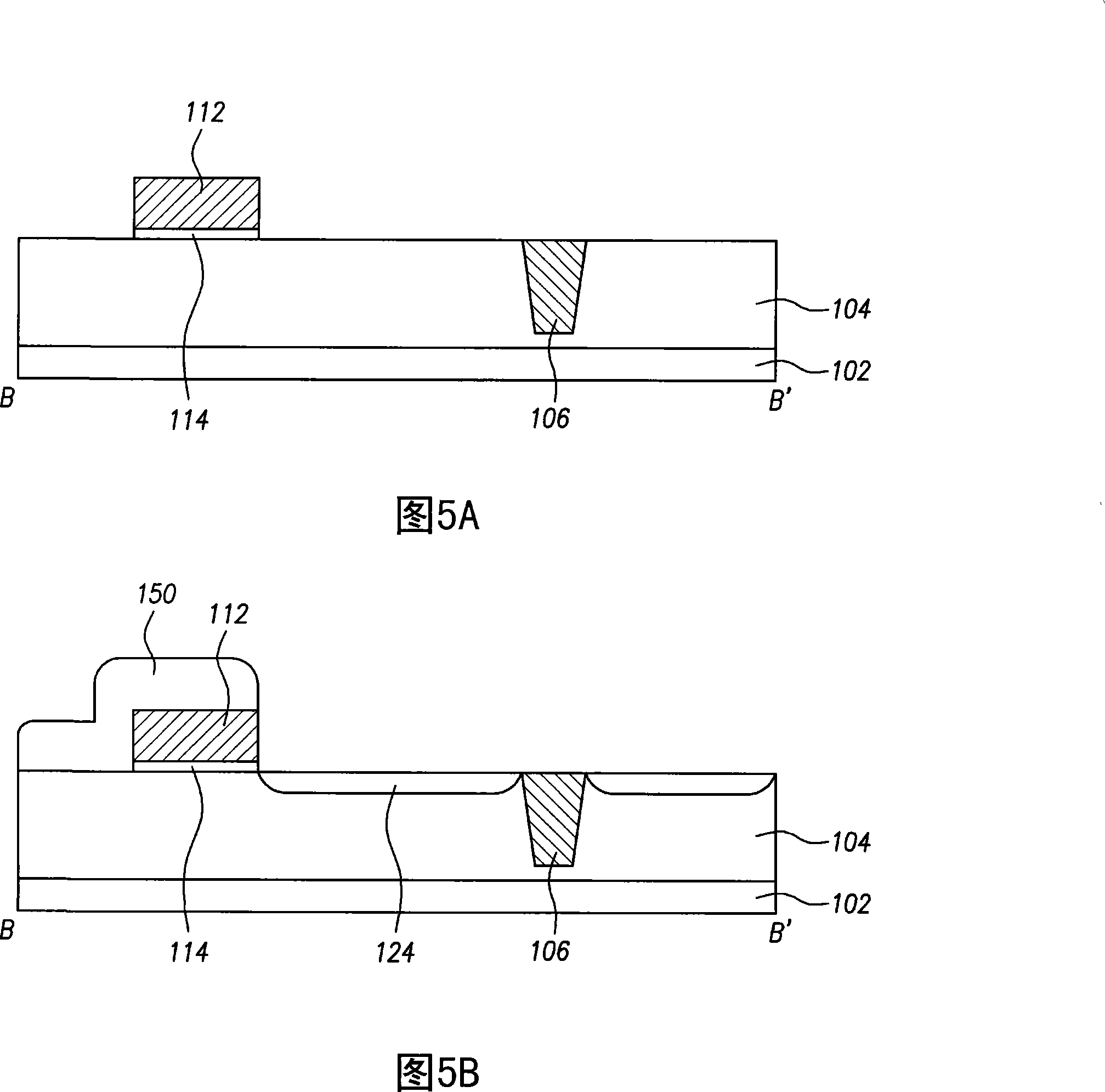

[0039] As shown in the example of FIG. 4, the CMOS image sensor according to the embodiment of the present invention may further include a p++ type semiconductor substrate 102, a p epitaxial layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com