Mobile floor cleaning device having noise insulation

A ground cleaning and equipment technology, applied in cleaning equipment, manual floor scrubbing machinery, cleaning machinery, etc., can solve problems such as noise, achieve the effects of reducing noise, reducing flow resistance, and generating less noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

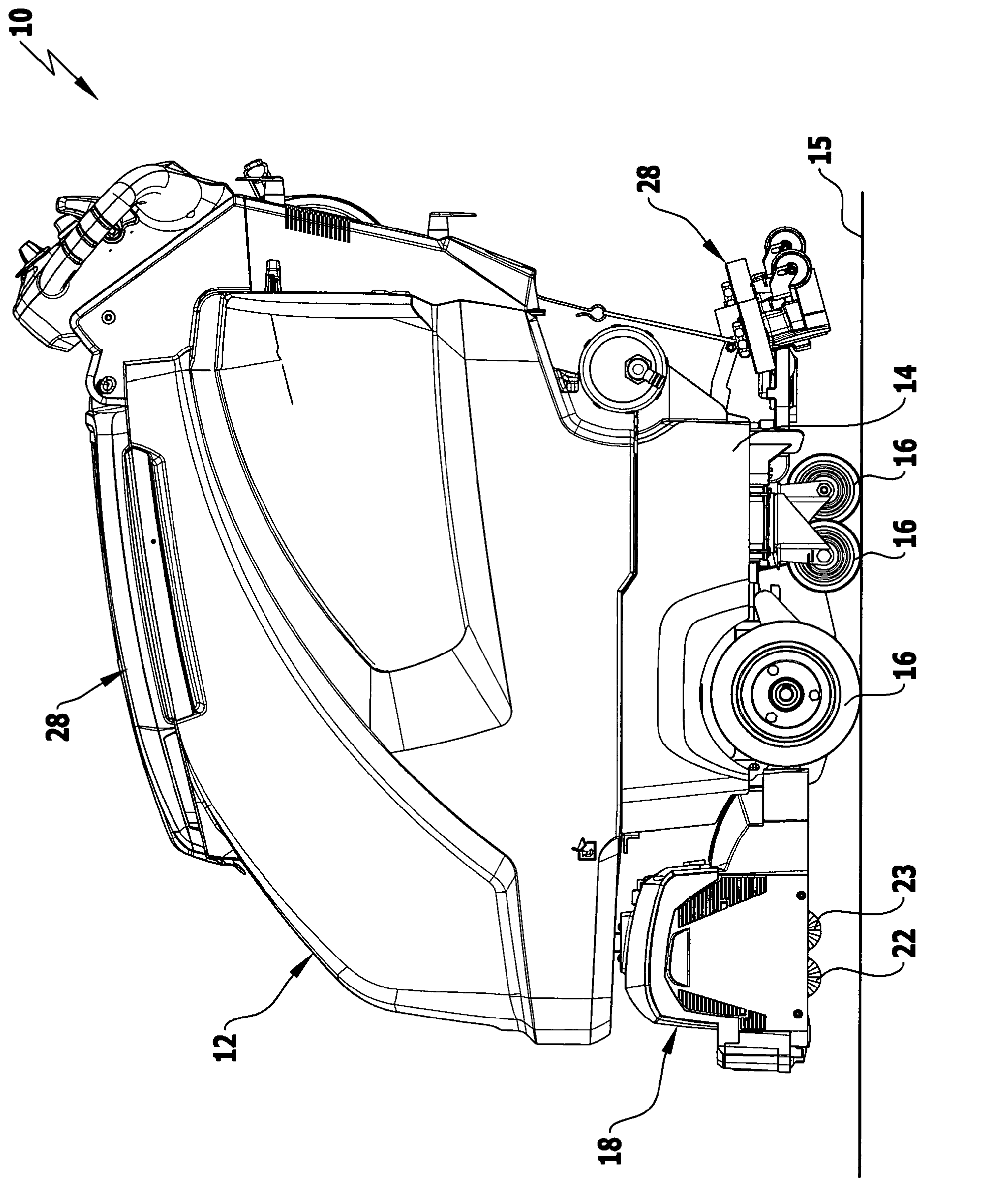

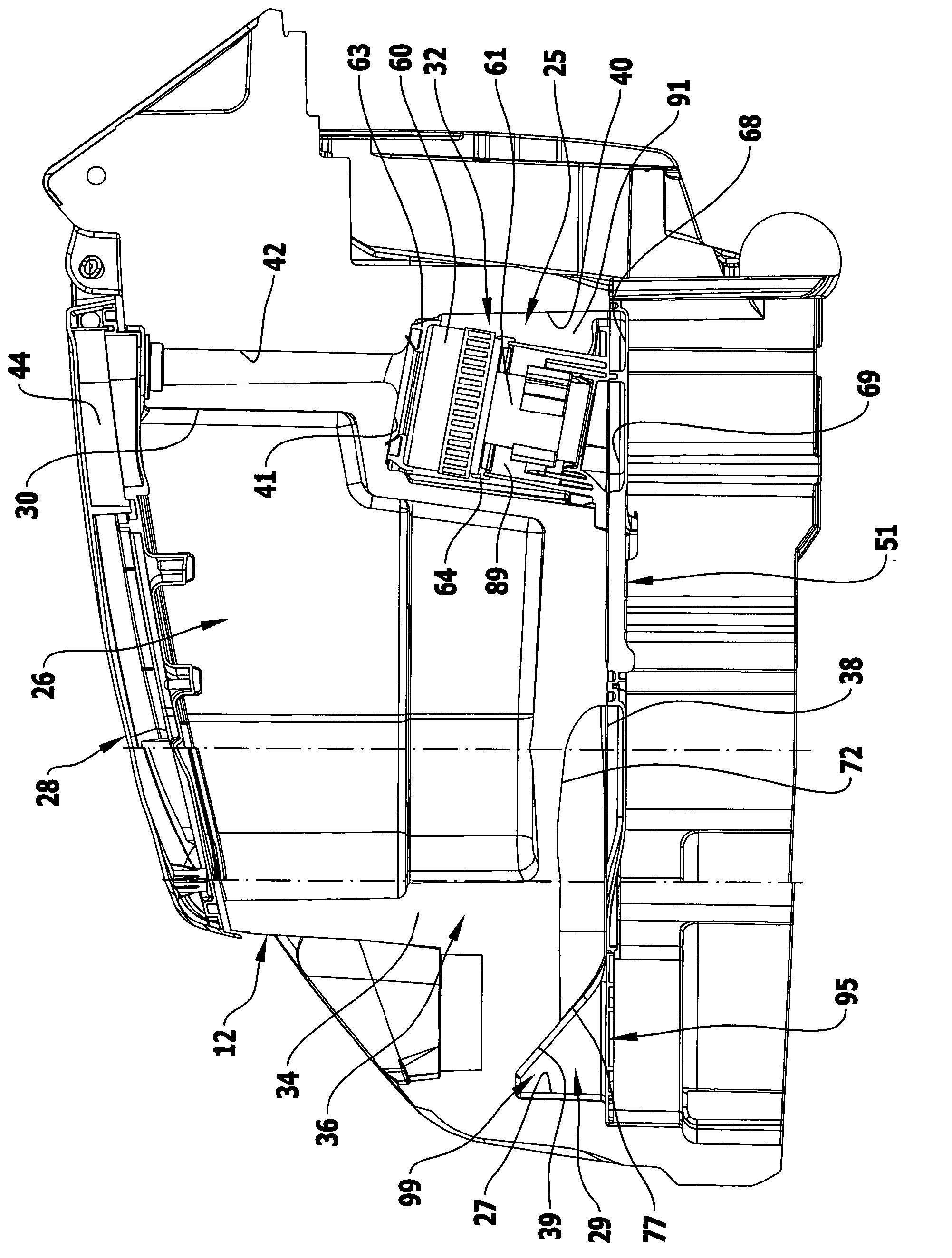

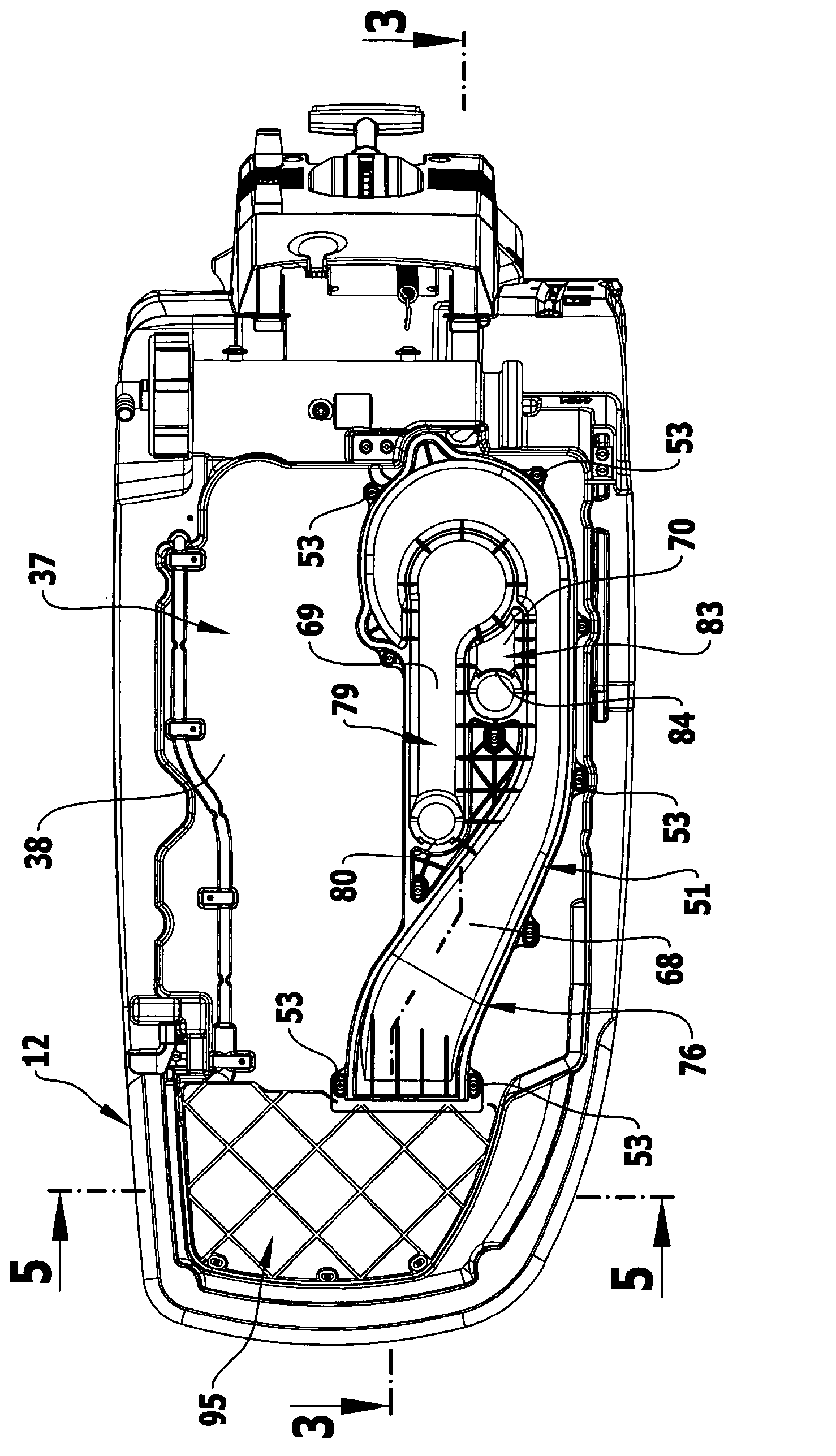

[0038] The figure shows schematically a floor-cleaning device according to the invention in the form of a floor scrubber 10 with which a floor 15 can be cleaned. The scrubber 10 has a one-piece hollow body 12 made of plastic material and placed on a travel mechanism 14 . The running wheels 16 are rotatably mounted on the running gear, so that the scrubber 10 can be moved along the floor 15 . Below the hollow body 12 a brush head 18 is held in front of the carriage 14 and behind the carriage 14 a suction rod 20 is arranged. The brush head 18 has cleaning tools in the form of two rotatably mounted first brush rollers 22 and second brush rollers 23 on its underside and can be removed from it. figure 1 From the raised position shown, the lowering to the floor 15 is started to clean the floor 15 .

[0039] The suction rod 20 generally comprises a suction lip which is not shown in the drawings for a clear overview and can be obtained from it. figure 1 The raised position shown is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com