Filter element for an extractor hood and extractor hood

A filter element and fume extraction hood technology, applied in the field of fume extraction hoods, can solve the problems of increasing noise, increasing air resistance, etc., and achieve the effects of reducing flow resistance, improving odor elimination, and reducing volume flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

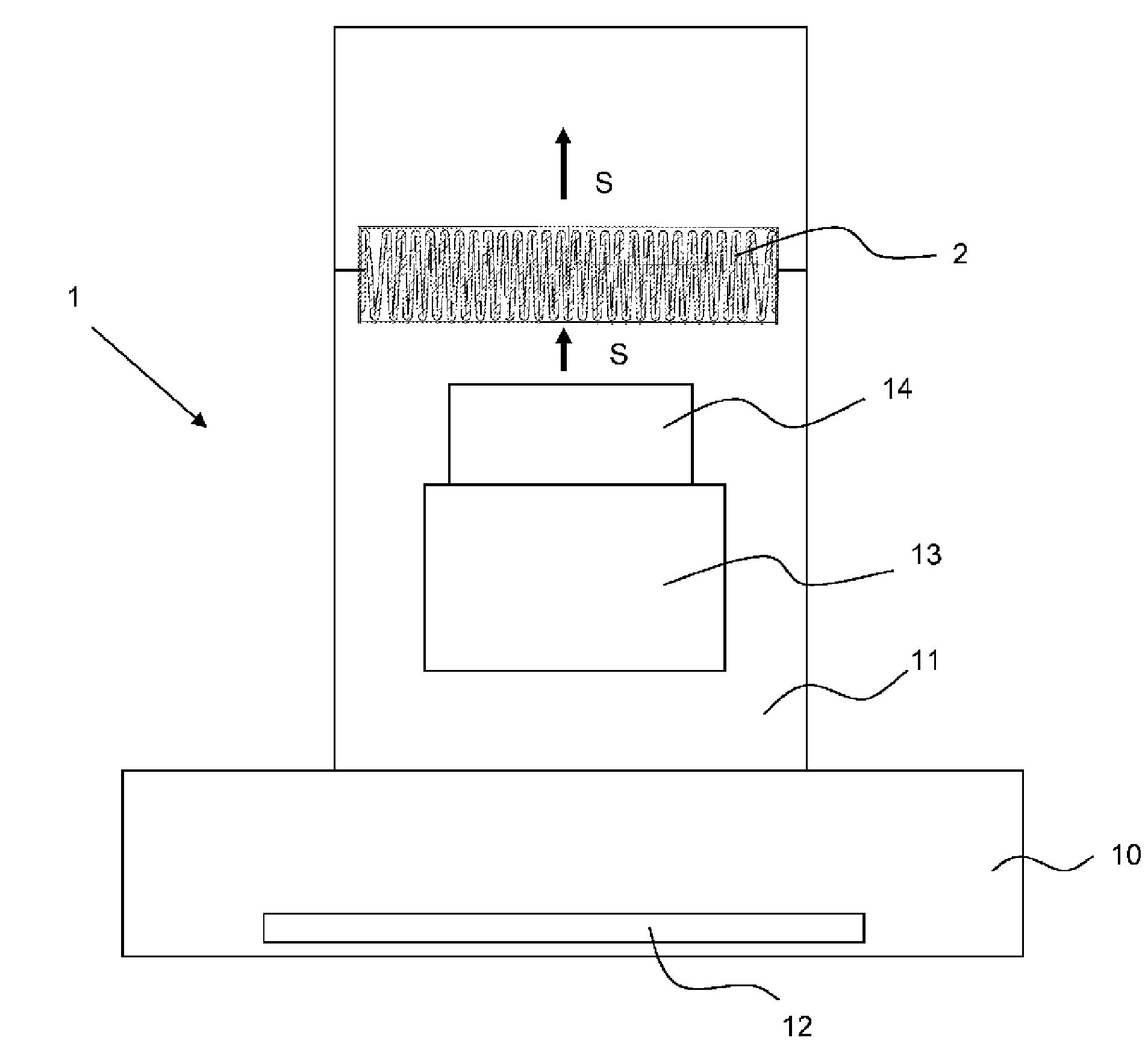

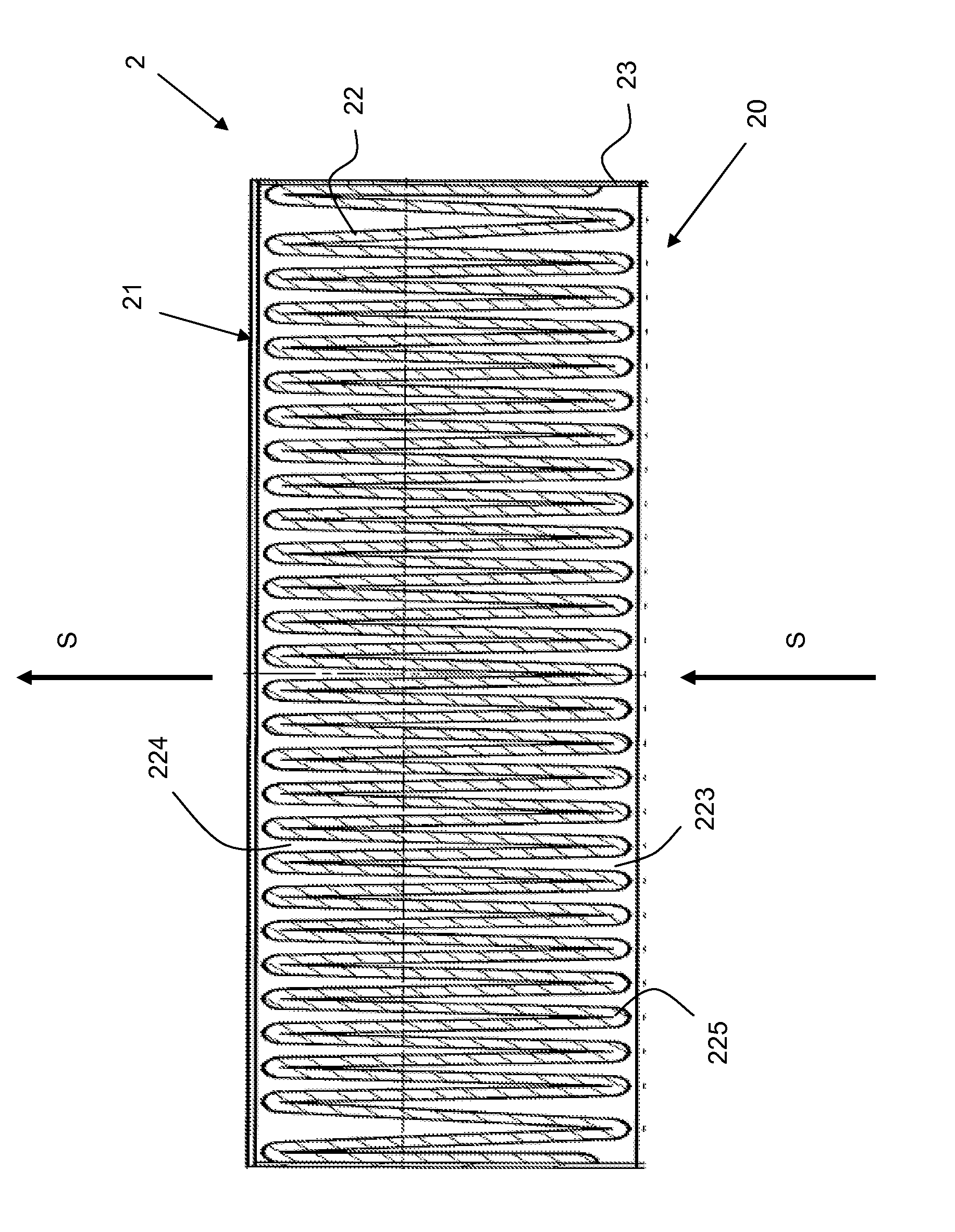

[0035] exist figure 1 A schematic perspective view of an embodiment of a filter element 2 according to the invention is shown in . The filter element 2 consists of a frame 23 and a filter 22 accommodated in the frame 23 . In the illustration shown, the frame 23 is open downwards and upwards, that is to say it consists only of the sides 231 to 234 . The odor filter 22 is accommodated in the frame 23 such that it does not extend beyond the height of the frame 23 . In the embodiment shown, the lower side of the frame 23 defines the flow-facing side 20 of the filter element 2 and the upper side defines the outlet side 21 . The main flow direction of the air is indicated by arrow S in the figure.

[0036] In the embodiment shown, frame 23 defines a rectangular interior. An odor filter 22 is arranged in the interior of the frame 23 .

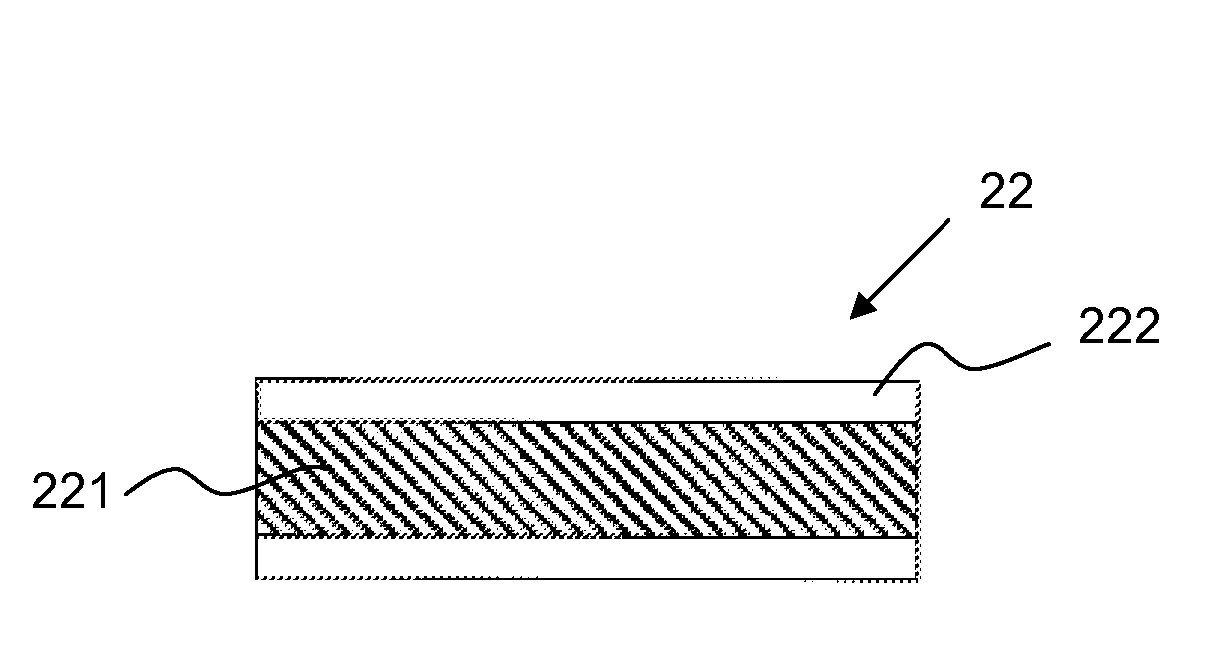

[0037] The odor filter 22 has a planar basic shape. exist image 3 A possible configuration of an odor filter is shown in . The odor filter 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com