Air extraction device and method for removing particles carried by an air flow

A technology of air suction and air flow, applied in the direction of components, separation methods, chemical instruments and methods for pumping devices for elastic fluids, which can solve problems such as high fan ventilation volume, and achieve low current consumption and noise generation The effect of low and good separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

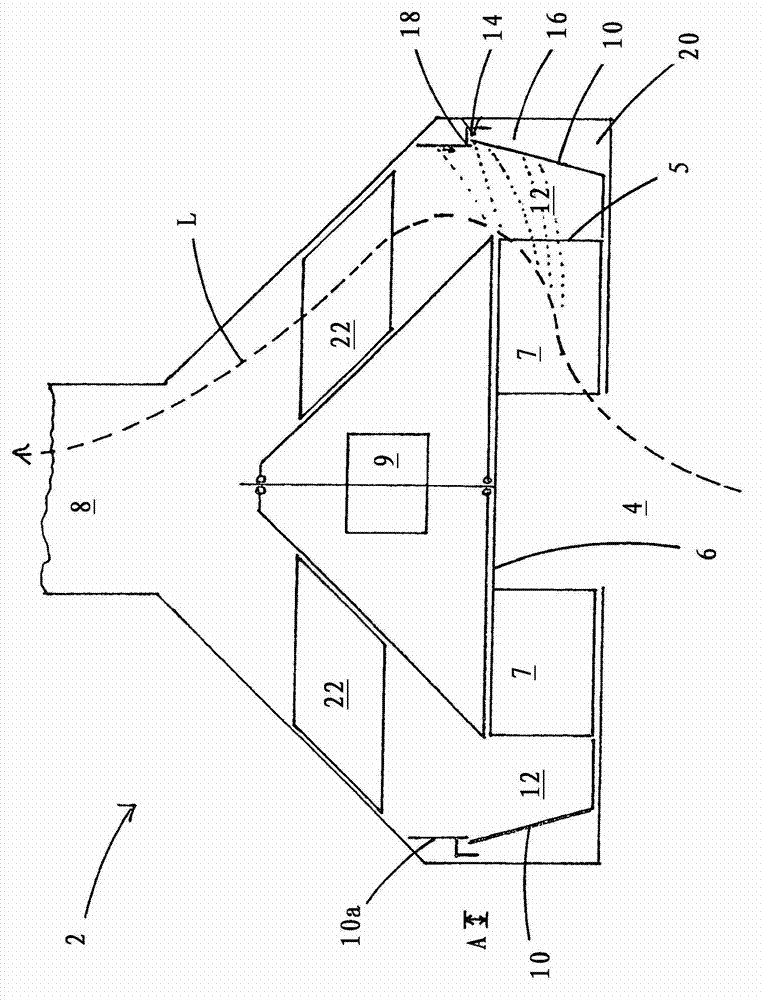

[0027] figure 1 A schematic cross-sectional view of the air suction device 2 is shown, through which an air flow L flows through an air guide channel formed in the air suction device 2 . Starting from the intake opening 4 in a first section, the air guide channel passes through a fan wheel 6 which can be driven by a motor 9 . The fan wheel 6 is provided with some air blades 7 . Through the rotational movement of the fan wheel 6 , the air flow L is accelerated in the radial direction outwards in the gaps between the individual air blades 7 and reaches its highest speed when it exits the fan wheel 6 . The rear edges, viewed in the direction of flow, of adjacent air blades 7 each delimit laterally an outflow opening 5 through which the air flow L exits the fan wheel 6 .

[0028] The throughflow space 12 directly adjoins the outflow opening 5 as part of the second section of the air guiding channel. The throughflow chamber 12 is delimited upstream by the outflow opening 5 and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com